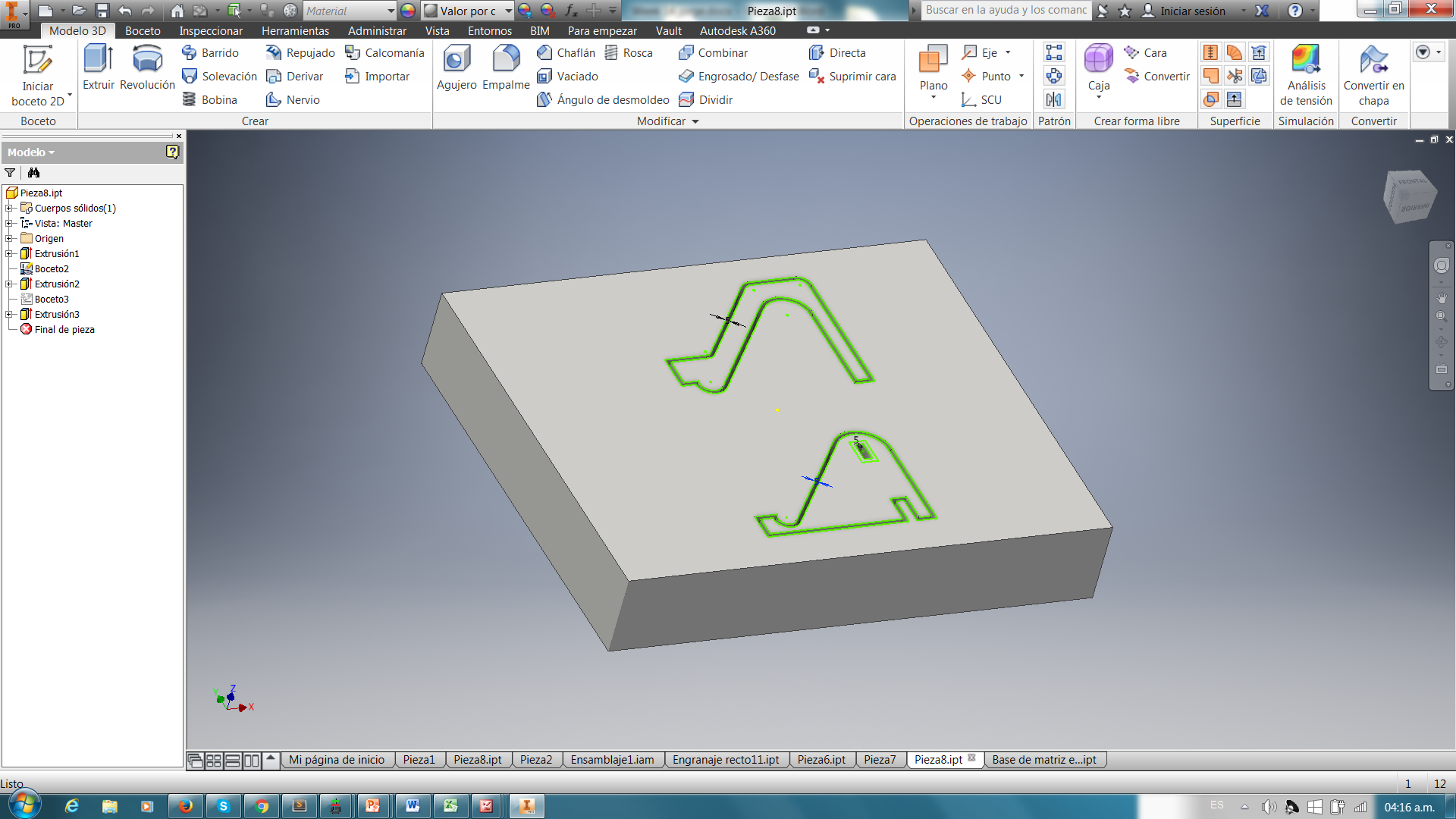

Design and make 3D mold, and produce a fiber composite part in it.

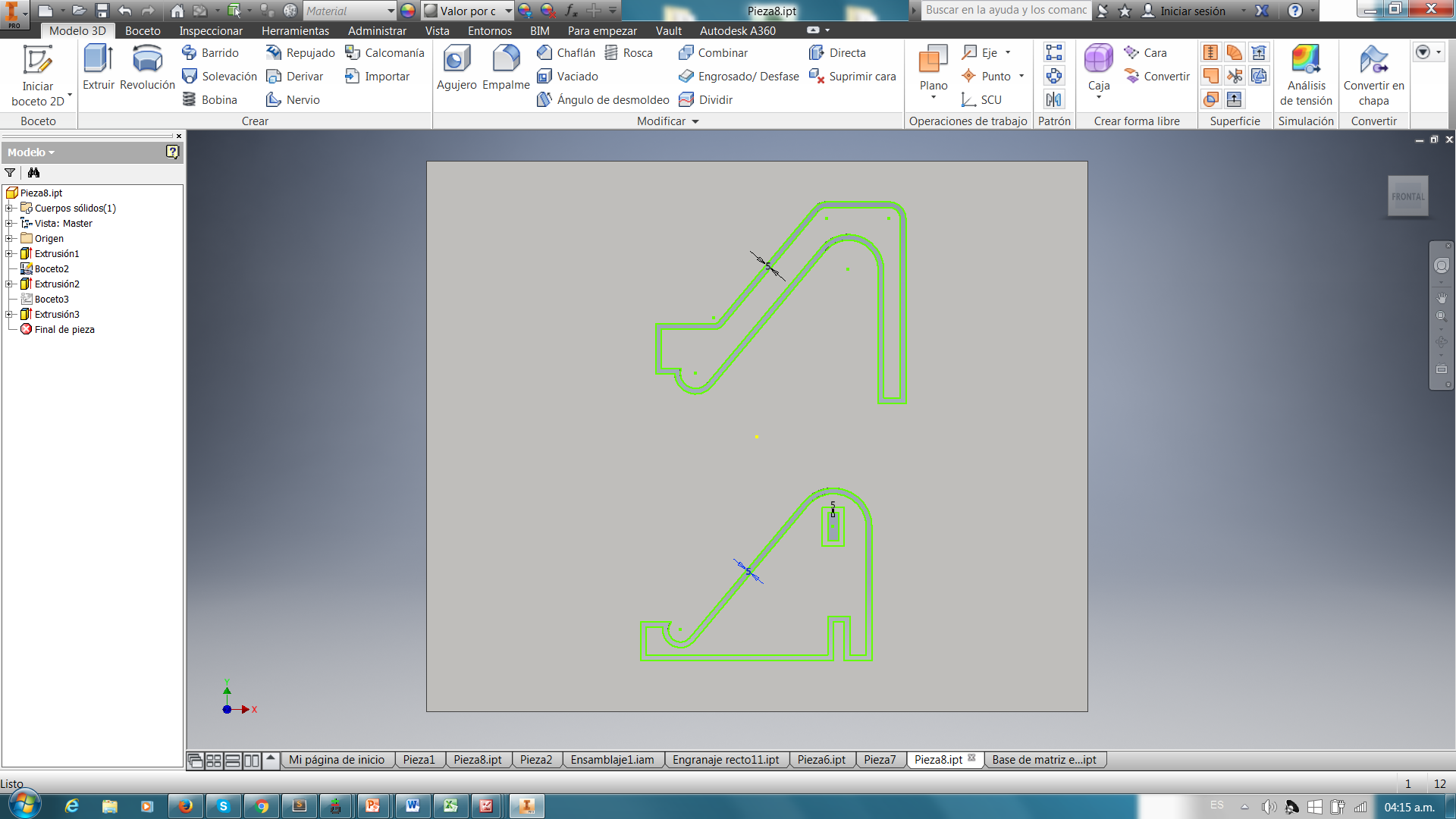

It occurred to me to apply this task on supports to keep my phone during my activities performed. To do this I started my design using inventor

I used the 1206 resin and its respective catalyst. I mix in the volume ratio (5: 1).

The pieces just emerging from the laser cutter

The proportions of the catalysts must be accurate, but the risk of running out with errors.

We cut some yute for thiss activity

Then presses are used to ensure good adhesion

Finally I could get my support for my phone using the components of this activity Composites. One thing to mention is the problem I had trying to choose the material. We had a lot of kind of cloths to choose, and we chose yute because of its properties: the porosity was one of the best reasons to use it. It let the resin spread very easily and gave me the support i needed.