Week 17

Applications and Implications.

ASSIGNMENT:

1.) Propose a final project that integrates the range of units covered, answering:

ASSIGNMENT:

1.) Propose a final project that integrates the range of units covered, answering:

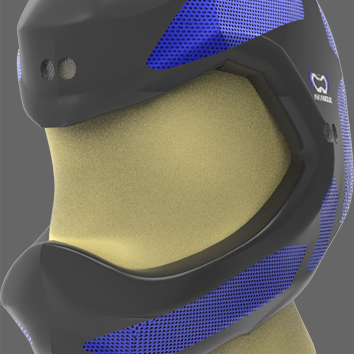

My final project will be a concept helmet for urban use with the ability to self reinforced in necessary situations such as falls or minor accidents.

The idea was born from the keys generated in human skin by subjecting certain body parts to continuous frictions, the human body knows where and when the skin needs to be reinforced. The thickening of the skin is a protective response of the body; to prevent painful blisters appear.

For more details you can read the concept of my idea here:

I searched a lot about products or projects similar to mine. There are a variety of urban helmet on the market, but I only found one with similar characteristics to my proposal:

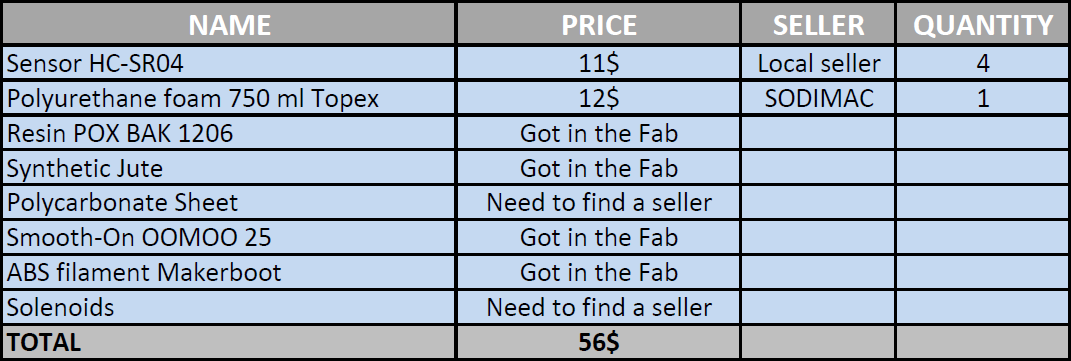

It is not the final cost, I still need to buy and find out the price of some parts.

There are 3 weeks left for my final presentations, 15nd june.

- Week 1: Testing mechanism for the helmet reinforcement.

- Week 2: Fix the 3D design and make the molding and casting of the helmet.

- Week 3: build the helmet, make some test and solve final issues and make the documentation.

For the project to succeed it needs to show at less the functionality of concept helmet having the capacity to reinforced themself.

I'm currently taking this course in FAB LAB TECSUP, in Lima-Perú, through CIDI FADA UNA with the support of CONACYT and PARQUE TECNOLOGICO ITAIPU FOUNDATION

©DESIGNED AND BUILD BY FABIO IBARRA - FAB ACADEMY 2016

EMAIL: fabioibarrab@gmail.com