Week 7

Make something big.

Computer-Controlled Machining week I had a bookshelf, about half-length adult height and width. This bookshelf contains several pieces of desk plate, and two vertical hook can decorate the walls in our wood plank. Books can be placed, decorations, computers and other various items. We add a blank wall functionality. And can be removed or moved to an appropriate location.

本周Computer-Controlled Machining我做了一個書架,約有成年人的半身高度與寬度。此書架含有數片桌板,以及兩片可垂直勾在我們牆上裝飾木條的木板。可放置書籍、裝飾品、電腦等多樣物品。增添我們空白牆面的功能性。且可拆下或移動到適當地點。

Use Inkscape software were bookshelf structure and latch design, and in the mortise part needs chamfered design, chamfer size must be greater than the diameter of the chisel, so latch portion only way for carving, and finally the Good Design the drawing dump into * .dxf format.

利用Inkscape軟體進行書架結構及卡榫設計,而在榫接的部份需要有倒角設計,倒角的大小必須大於雕刻刀的直徑,這樣卡榫的部分才有辦法進行雕刻,最後將設計好的圖檔轉存成*.dxf格式。

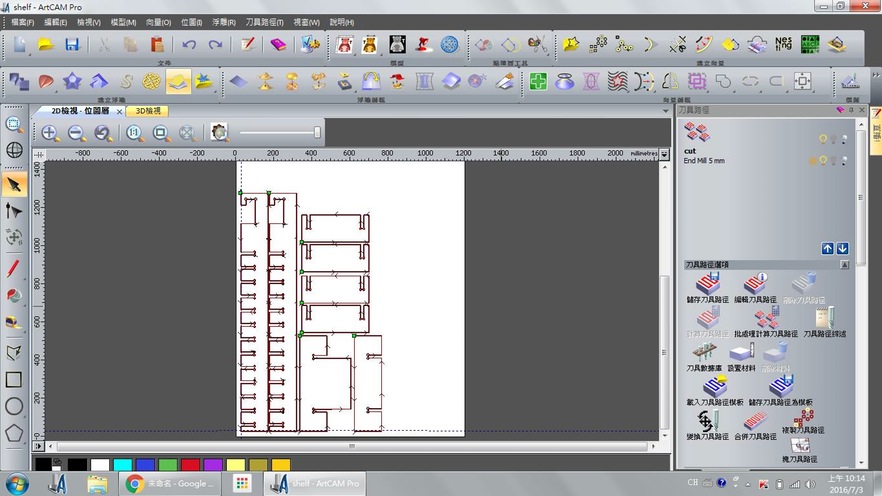

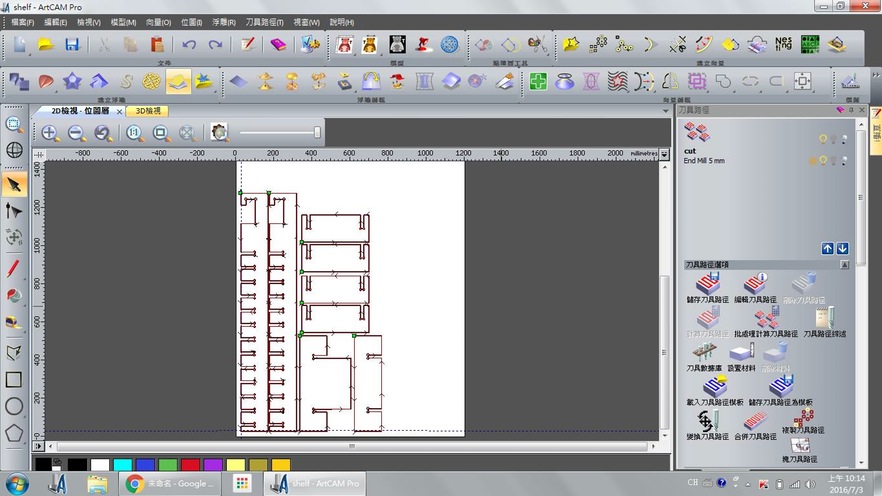

First preceding drawing import ArkCAM. This change only professional drawing pass G-code of the software.

It must first set the parameters cutter, knife diameter, blade diameter, blade length, etc., material thickness, and then calculates the simulation. Chisel speed, feed rate can make adjustments on the machine table. Also mortise part shall be left chamfered inside without software processing.

使將前述圖檔匯入ArkCAM。此唯一專業圖檔傳換G-code之軟體。

需先設定銑刀參數,如刀徑、刃徑、刃長等、材料厚度,再進行運算模擬。雕刻刀轉速、進給率可於機台上再做調整。另外榫接部分須留有倒角,無須軟體內處理。

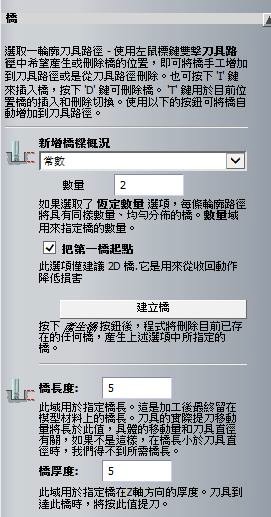

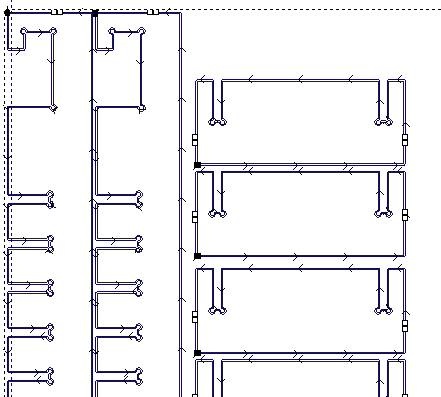

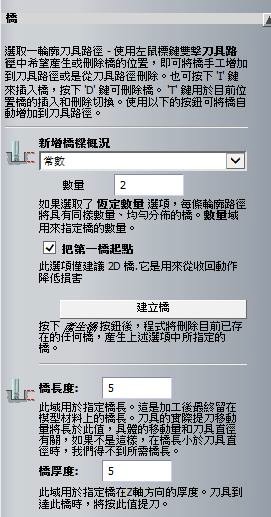

It aims to cut piece should be cut, but avoid cutting the last lap no fixed object moves may damage the object or machine, need to do a "bridge" to carry out large objects and woodblock connection. Without too large, after the completion of the cutting, then manually cut.

切割目的是整塊都要能被切下,但為避免最末一圈物件進行切割時沒有固定而移動,將可能損壞物件或機器,需要做"橋"來進行物件與大木版的連接。無需過大,只需要能抗刀鋸切割時所造成的拉扯。完成切削後,再手動切下此部分。

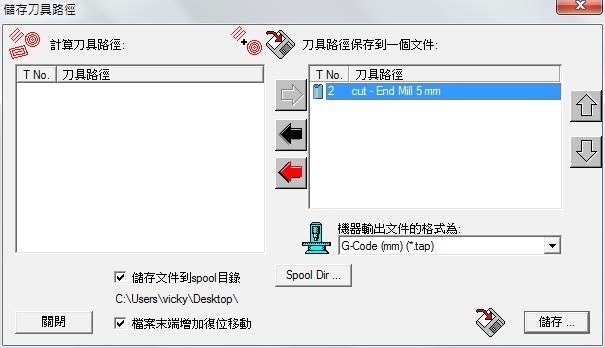

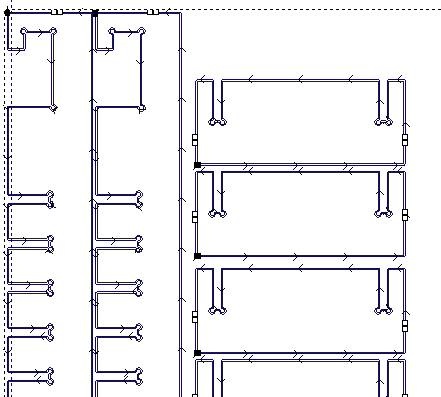

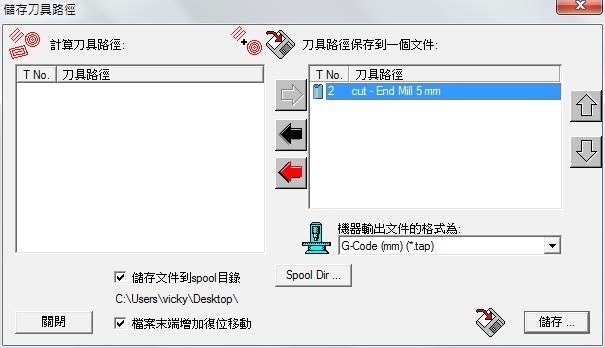

Finally, the simulation file storage machine that can read files. Converted into common of the G-code files. And stored to USB flash drive.

最後,將模擬的檔案儲存機器所能讀取的檔案。我轉換成常見之G-code檔案。並存放至USB隨身碟。

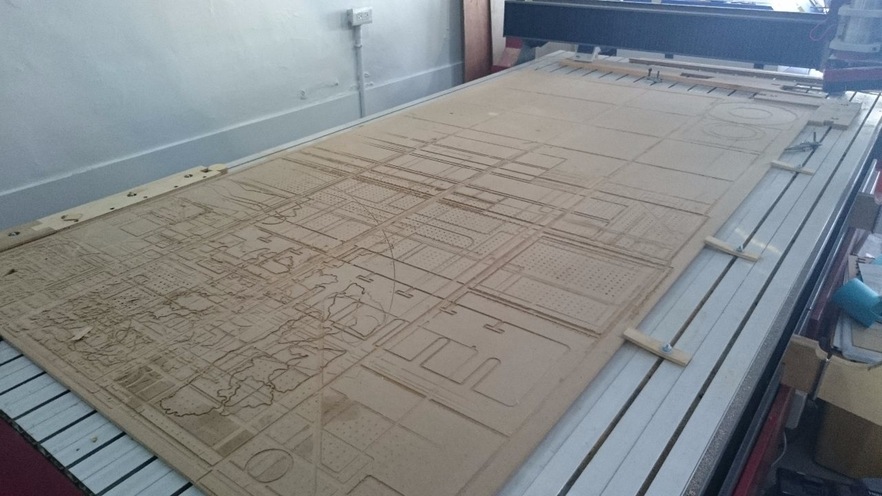

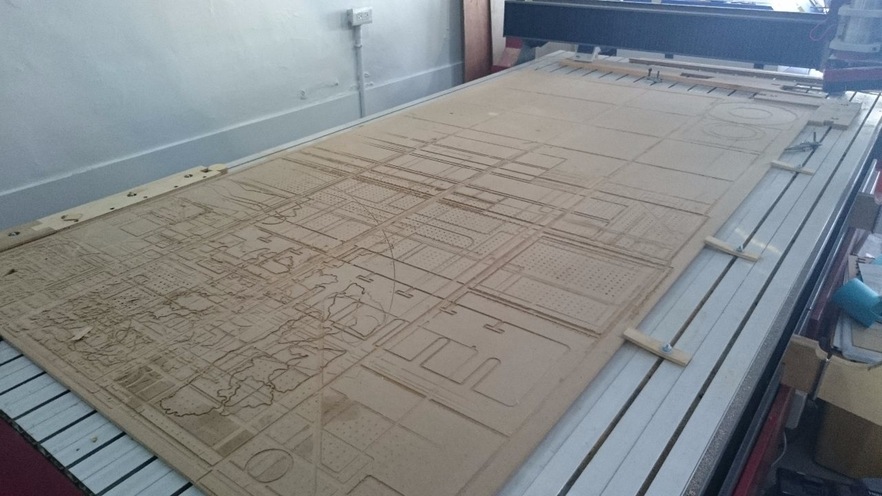

CNC using 3axle Technology co. professional woodworking engraving machine. You can cut large pieces of carved wood, I use the 240 * 120 * 17.8 (cm) thick plywood (Plywood), put the cutting platform after the corners and aligned using a jig fixed. On the cutting platform has been the first place there is a MDF as a buffer layer.

使用的CNC是3axle Technology co. 的專業木工雕刻機(professional woodworking engraving machine)可以切割雕刻大塊木板,我選用的是240*120*17.8(cm)厚度的夾板(Plywood),放上切割平台並對齊邊角後使用夾具固定。切割平台上已經先放有一片MDF作為緩衝層。

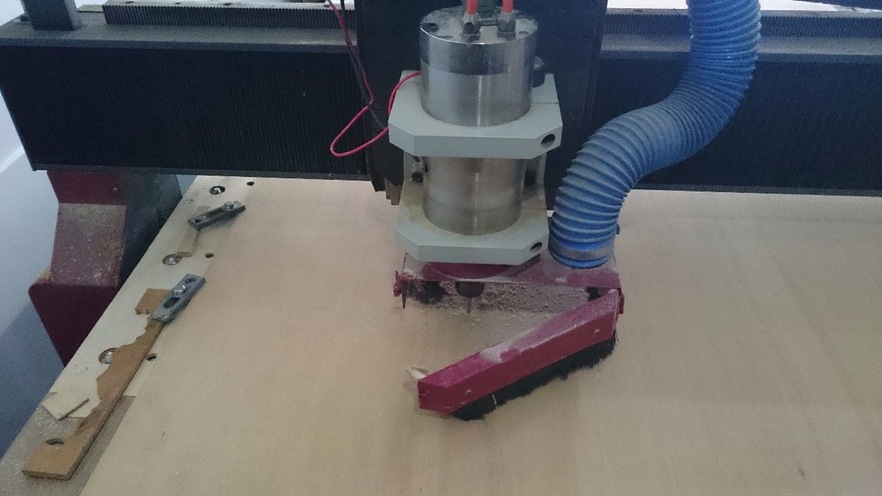

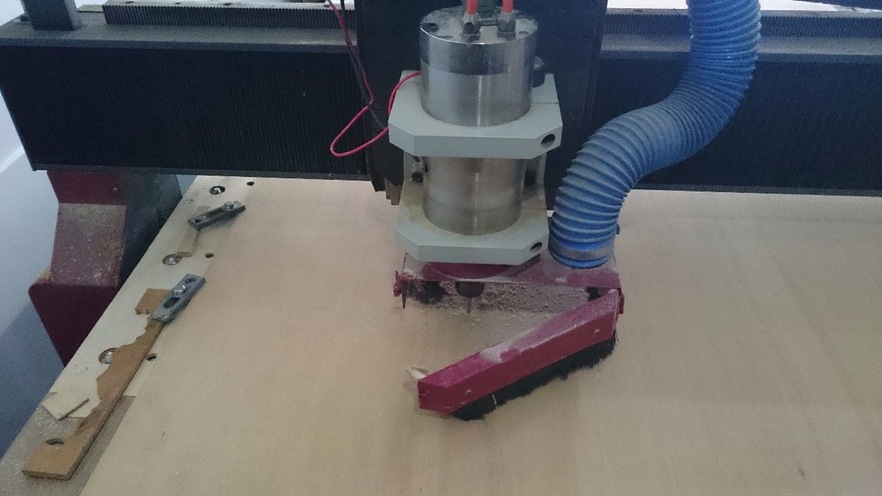

The tool used for end mill of 5mm.

所使用的刀具為5mm的端銑刀。

Switches and speed setting, attention began to use safety equipment such as safety glasses.

開關及轉速設定,開始後注意使用安全防護設備,如安全眼鏡。

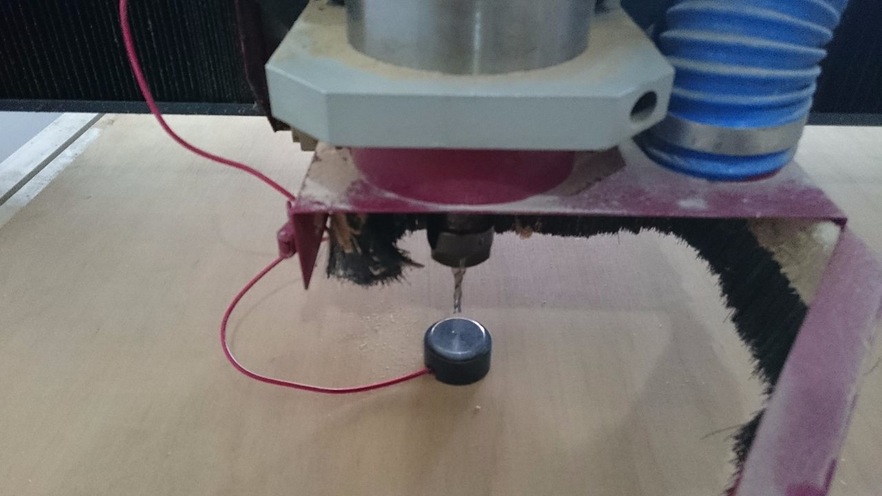

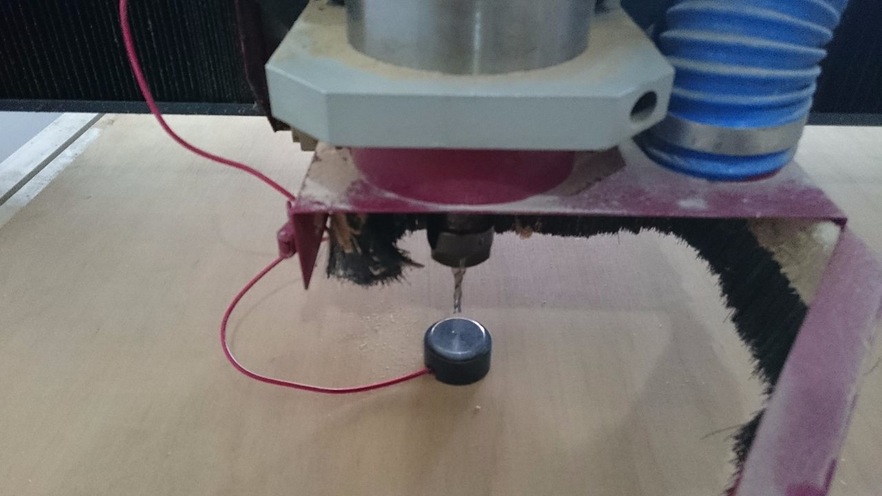

The use of knives were on the knife. Z-height is determined.

使用對刀器進行對刀。確定Z軸高度。

Use USB controller to read just the presence of G-code. And begin processing.

使用控制器讀取剛剛存在USB的G-code。並開始加工。

Processing time is about 45 min, so that the wood does not exhaust the accumulation of powder on the board.

加工時間約為45min,沒有抽氣使得木頭粉末堆積在木板上。

In order to confirm whether the vacuum cleaner to clean up after a smooth cut.

以吸塵器清理乾淨後確認有無順利切斷。

Destroy the lock set up the link bridge, remove all items.

破壞所設定連結的橋,取下所有物件。

Used climb milling when cutting (milling with the feed), observed no traces of straight cutting edges, but also has lateral cutting edges polished the need arises. Use sandpaper hand mill or electric tools to help.

切割時已使用順銑(milling with the feed),可觀察到直向的切割痕跡沒有毛邊,但橫向切割同樣有毛邊出現需要打磨。使用砂紙手磨或電動工具協助。

The completed board assembly. To stay originally designed card tenon joints, after cutting is consistent, error is very small after cutting and does not come loose. I think you can then enhance the appearance of design, can be more curved, soft lines, so that works more beautiful.

組合並使用。起初所留的空間吻合,誤差很小不會鬆動。我想可以再加強外觀設計,能更有曲面、柔軟線條,使作品更美。

Troubleshooting:

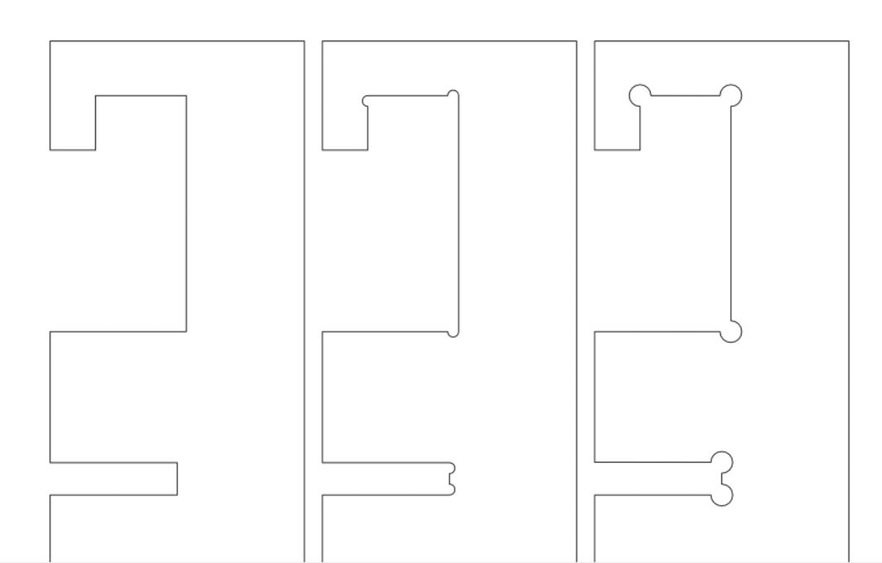

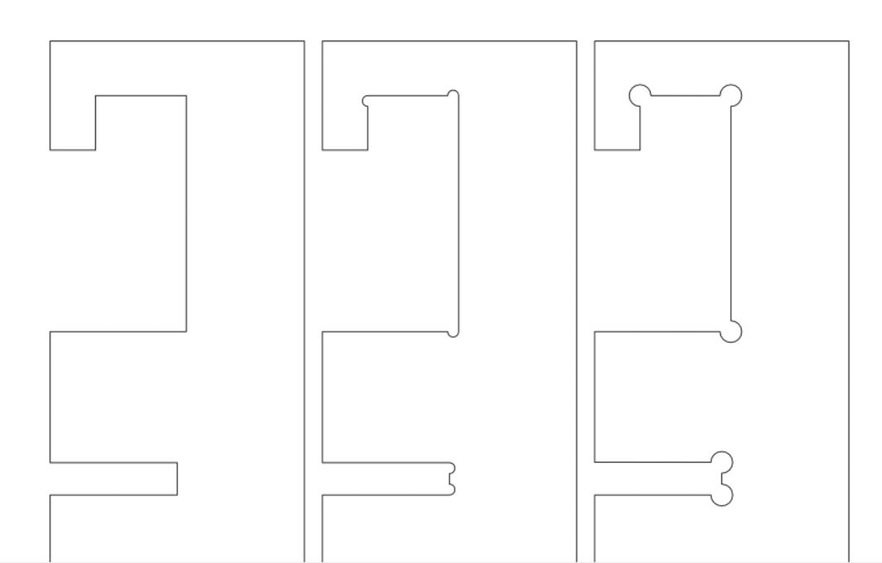

CNC machining at the junction, due to the use of CNC tool rotation is not part of the cut, because the relationship between the tool radius while leaving an arc when cutting inside corners, and can not be cut with a laser, as presented vertically. If the right angle without proper design, because the arc cutter radius caused over tenon joints can not be smooth, you need more than design chamfer (Fillet) as a solution. The following figure shows from left to right; the original design (can be laser processing), T-bone shape chamfer (T-Bone Fillet), dog-bone shape chamfer (Dog-Bone Fillet). Another also set aside a number of general chamfering tool radius depth (Normal Fillet), but I think the T-bone shape chamfered cute, preferably the actual processing work.

CNC在加接合處時,因CNC是利用刀具旋轉切掉不要部分,所以切內角時將因刀徑留下圓弧,而無法與雷射切割一樣呈現垂直。直角若未經適當設計,將因銑刀半徑所造成的圓弧而導致榫接合面無法平整,需多設計倒角(Fillet)做為解決方案。下圖由座左至右分別展示;原設計圖(可以雷射加工)、丁骨型狀倒角(T-Bone Fillet)、狗骨型狀倒角(Dog-Bone Fillet)。另也有多預留刀徑深度的一般倒角(Normal Fillet),我覺得丁骨型狀倒角覺可愛,選為實際加工作品。

Because the blower is damaged and can not be cleared up in carving wood carving down, causing the dust flying.

鼓風機損壞,造成無法及時清理雕刻下的木屑,造成粉塵飛散。

Remove the object struck by the way, it may cause damage to parts of the board connection, it is recommended to remove the entire piece with a saw after treatment.

用敲擊方式取下物件,有可能因連結部分造成木板損傷,應整片取下後用鋸子處理。

Tools:

Woodworking engraving machine

Inkscape

ArkCAM

File:

bookshelf

Reference:

Speeds and feeds

Fillet (mechanics)

Mortise and tenon

CNC 公母榫接口的設計