Since I was in the remote country, I can not do some fancy stuff but I did my best. I'll build gas forge to casting my aluminium handle. So, keep follow me until the end of this Academy! ;)

I've use 123d catch to 3d scan my head that I can duplicate my face.

You need more than 40 pictures to get neat scan result.

With only 25 picture you can actually hard to get good stuff.

(may be not..)

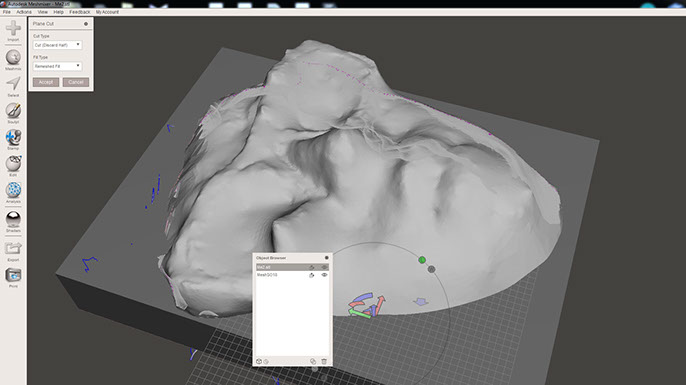

Even though 3d scan result wasn't that good I try few more things.

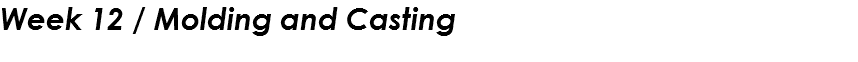

In Meshmixer, trim off unnecessary parts with plane cut tool.

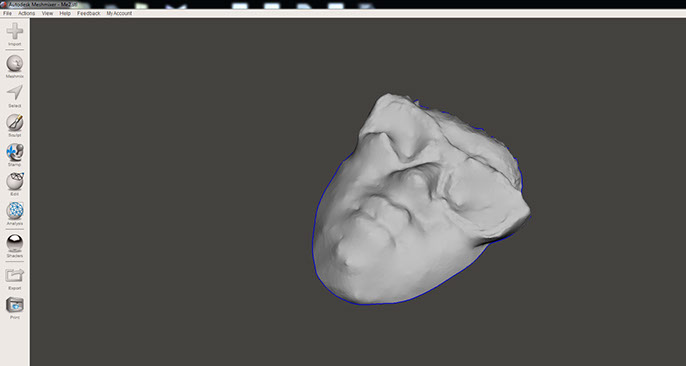

but now is hollow so you have to make this as a Mesh.

Click the make solid and make it solid.

Now you can use this .stl file in 3D printer or CNC router.

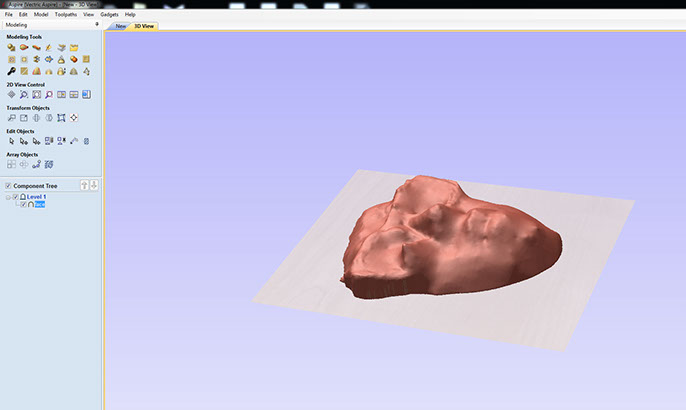

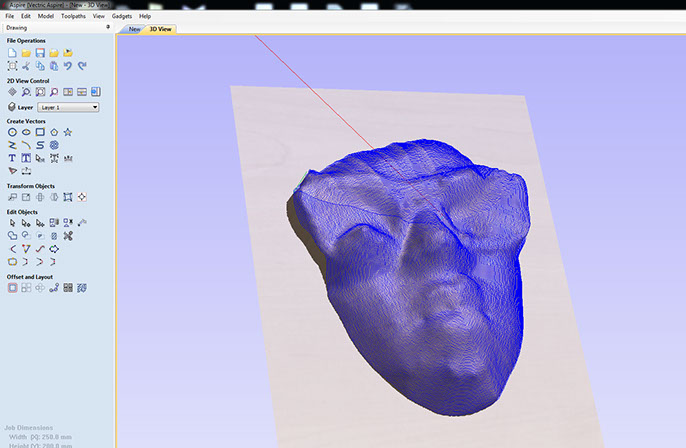

By using Aspire 8 you can make 3D tool path easily.

Use 3R 30mm ball nose end-mill

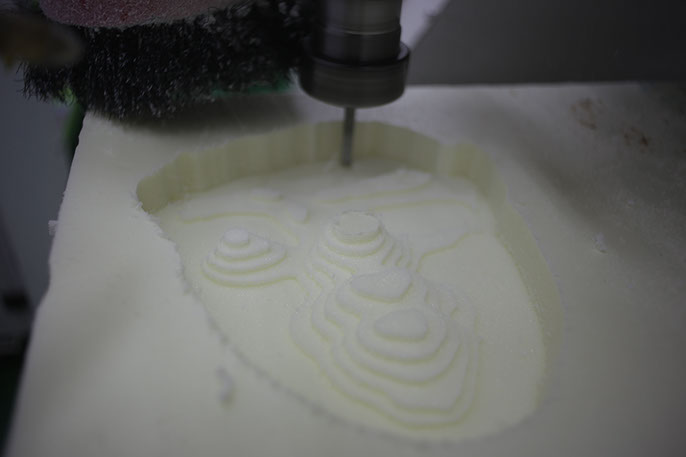

Total time that I spend only for cutting was 1.2hours.

It can be shorter I think.

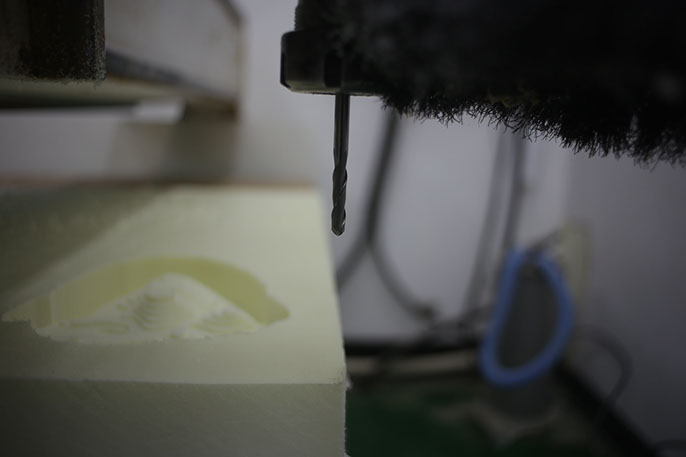

I am very use to handle Shopbot but in this time I had to use another CNC router and it reads pure g-code. when it saved as g-code file from Aspire it shows .tap type of file

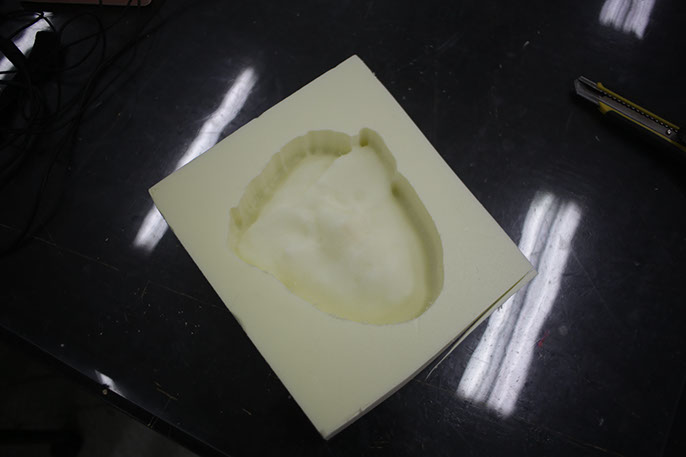

mill out the foam with 8mm rough cut. and after that use 6mm ball nose to finish it.

use 6mm ball nose

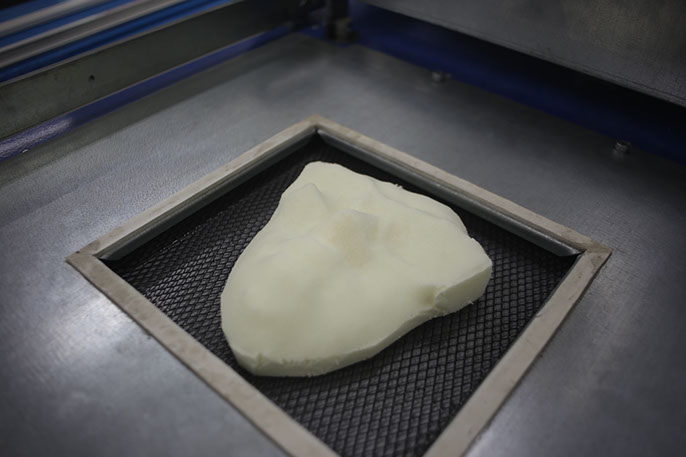

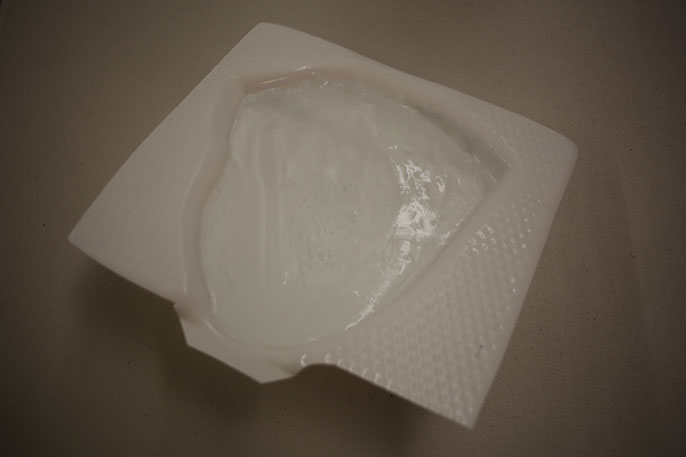

cut out the model that I am going to use from the foam and put it on the vacuum foamer

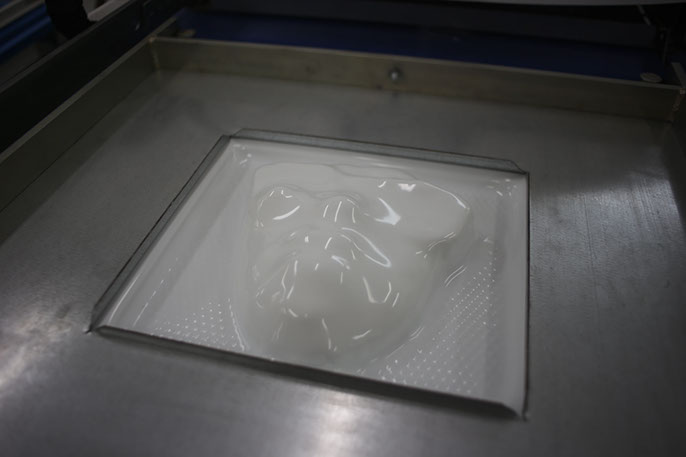

put the abs sheet on it and start vacuum.

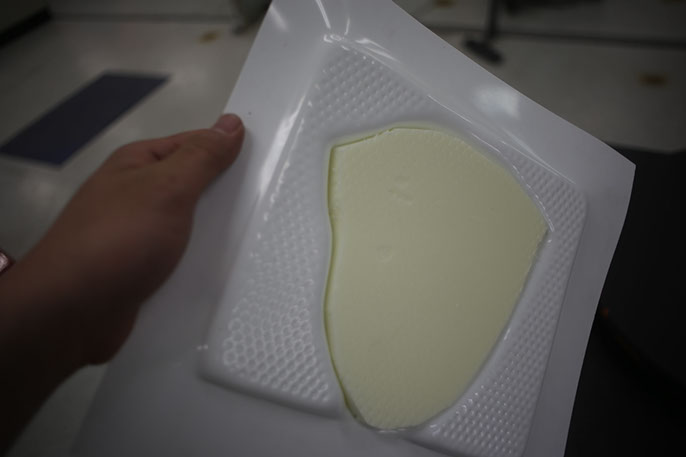

Tada~

But because of the heat it melts and stuck.

Use air compressor to remove the mold out from the foam

some defects are left in side the mold use cutter knife and accetone to remove this.

damaged because of heat.

I brought my mold to home and pour water in it.

Freeze it.

Freeze it.

make my face as ice.

break my face and

Enjoy your shot! :)

And I return from rural area I start to cut my wax mold.

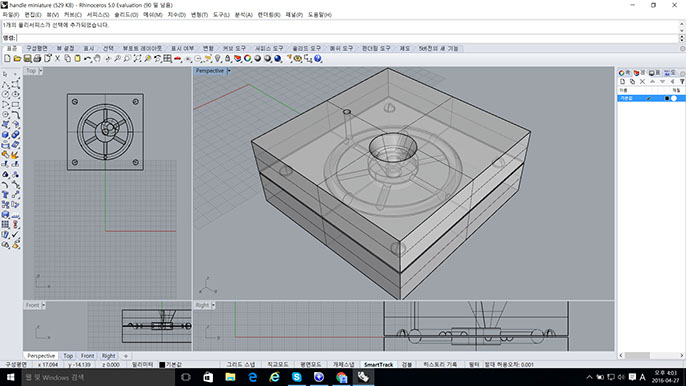

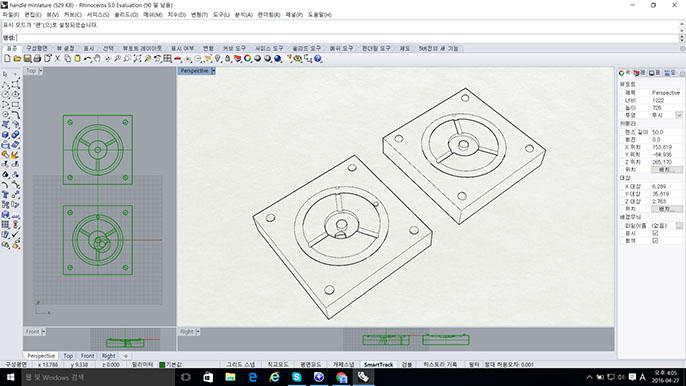

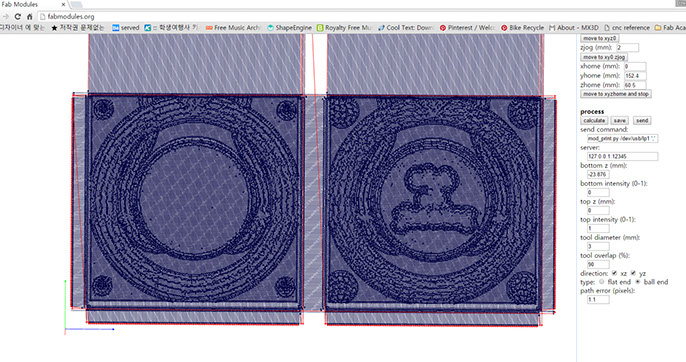

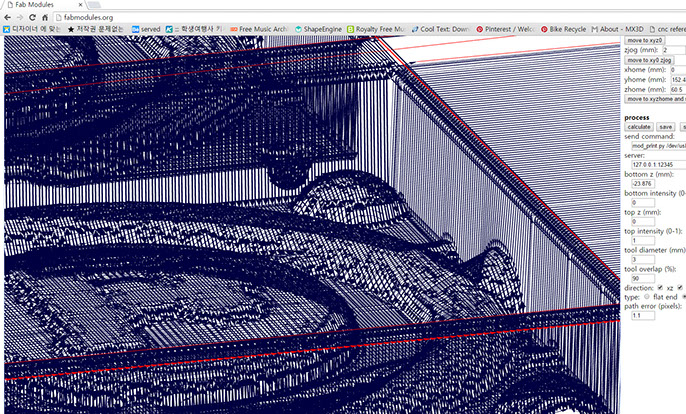

First I designed my plus mold with rhinoceros 5.0

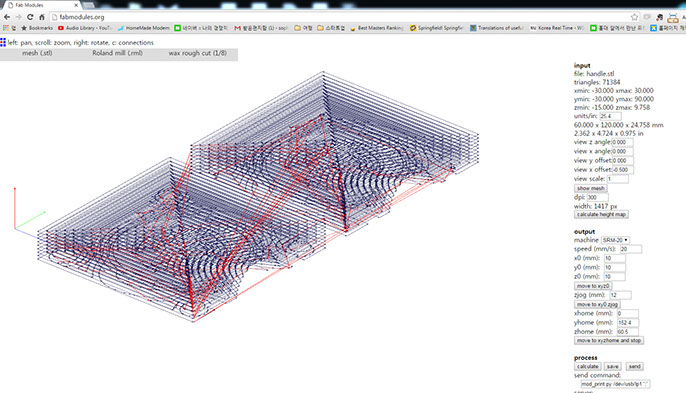

and save it as .stl file I made g-code through fabmodules.

rough cut with 3mm mill

fine cut with 3mm ball nose mill

If you tilt image you can look clearly the feature.

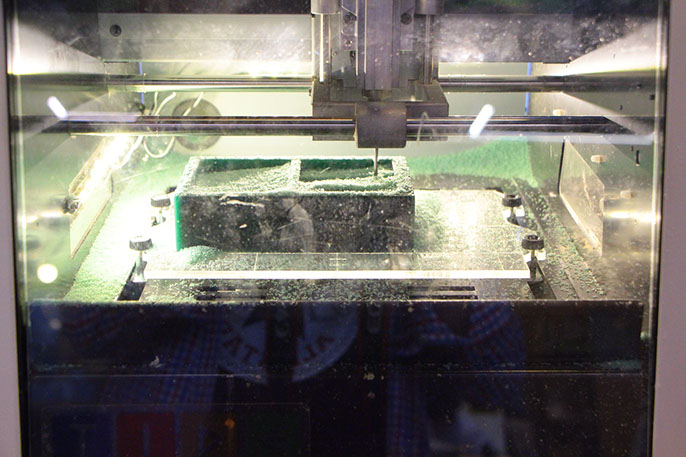

Cut it with SRM-20 and please save that was powder you can use it later again.

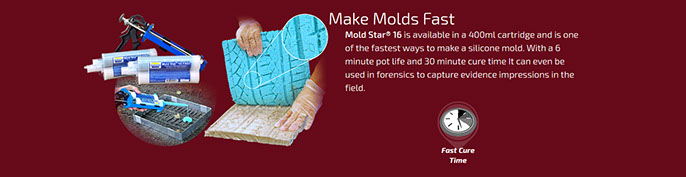

And I choose to make minus mold with mold star 16

before you do the mold you have to read datasheet of the material

how long does it takes to harden and curing also mixing ratio between main part and hardener.

after you make the mold hold tight with some wood panel or steel panel.

Something makes the mold flat and even.

I use crystal clear resin to cast out my handle keyring

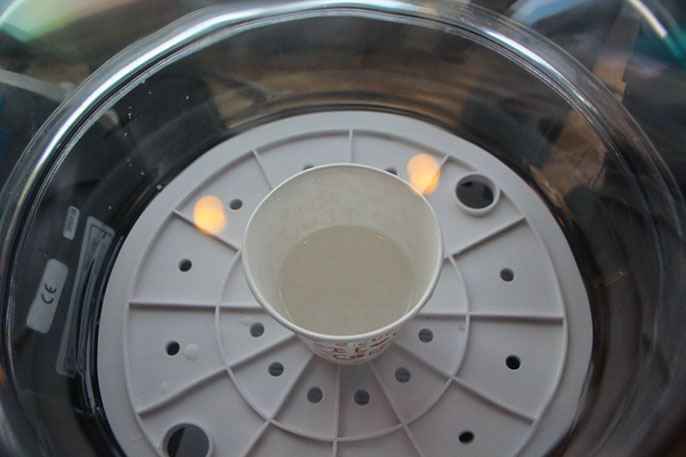

Use vacuum chamber to remove any bubbles inside.

Stir last of it

Suck it with the syringe.

And put resin inside of the mold with syringe. Wait couple of hours.

Open the mold

and

Tada~!!!

Beautiful!!!

Back to home