Assignment 4: Electronics Production

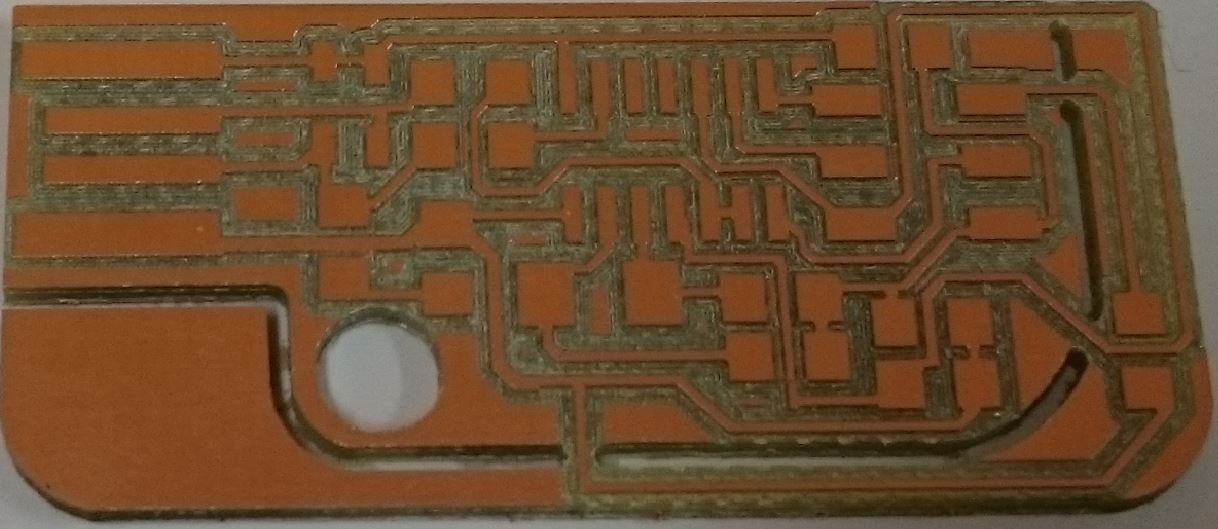

PCB fabrication

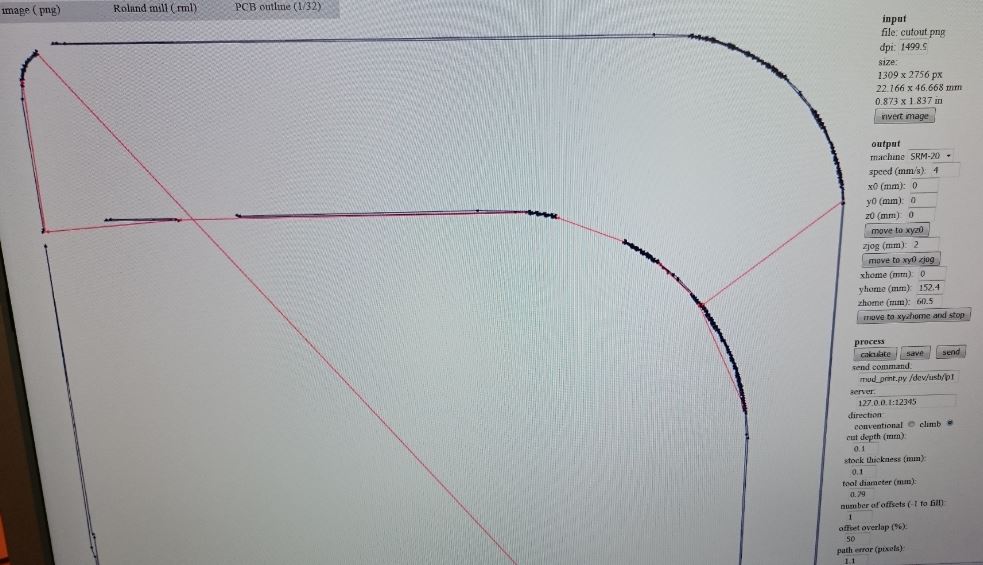

We decided to fabricate Valentin's

version of the ISP-board. At first I tested whether the cutout

of 0.1 mm is enough. The board billet was slightly curved in the

corner where the SRM20 origin was set, as seen in the picture below.

As a result the cut was not through the copper, so 0.2 mm cut

depth was used for the first board.

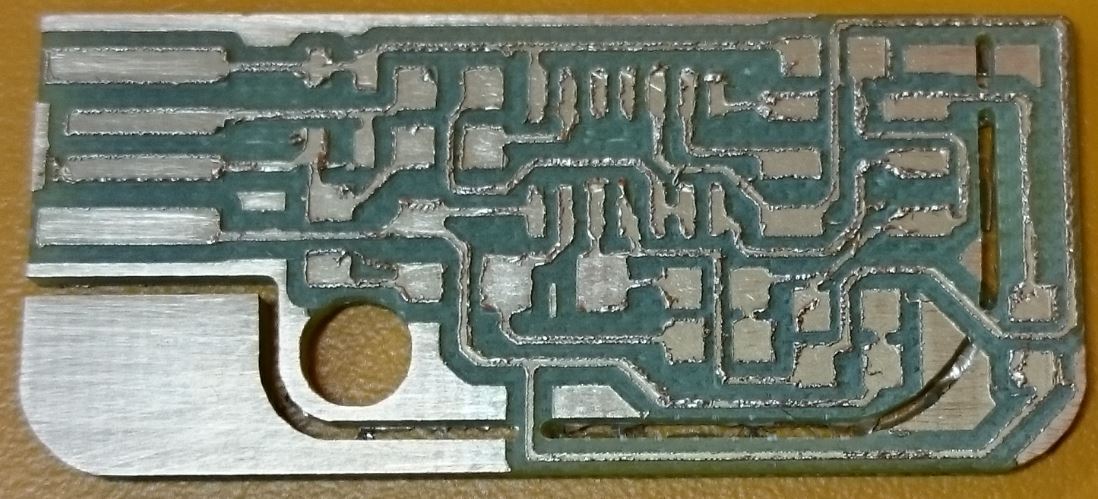

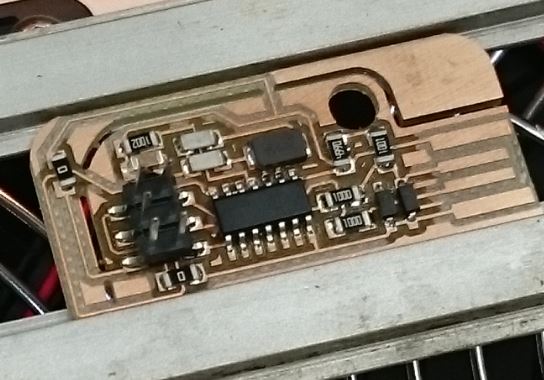

Actually, the first board didn't come out that well. Against Neil's

recommendation, we used FR4. The result is presented in the

following picture, in which the pcb was photographed after polishing

with steel wool. It was even worse before. The reason could be

a worn drill bit, but that needs to be tested.

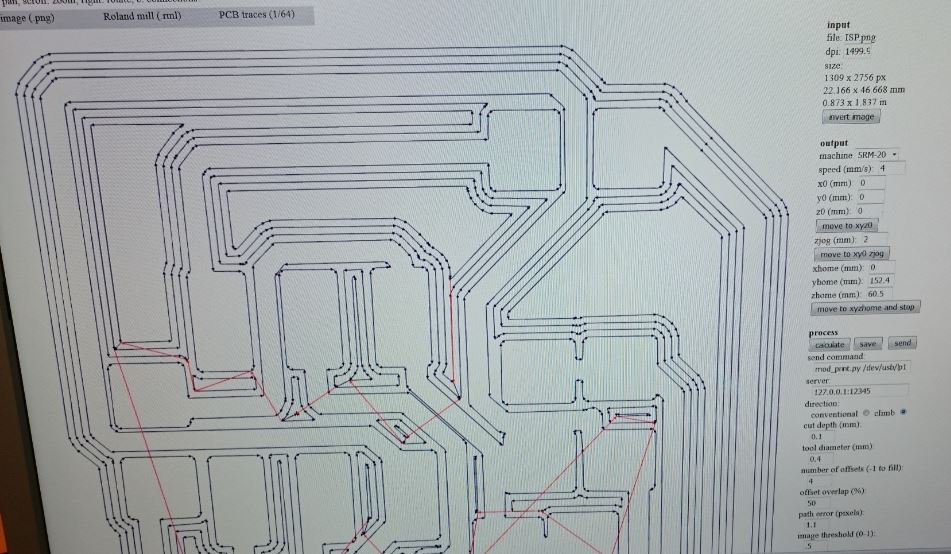

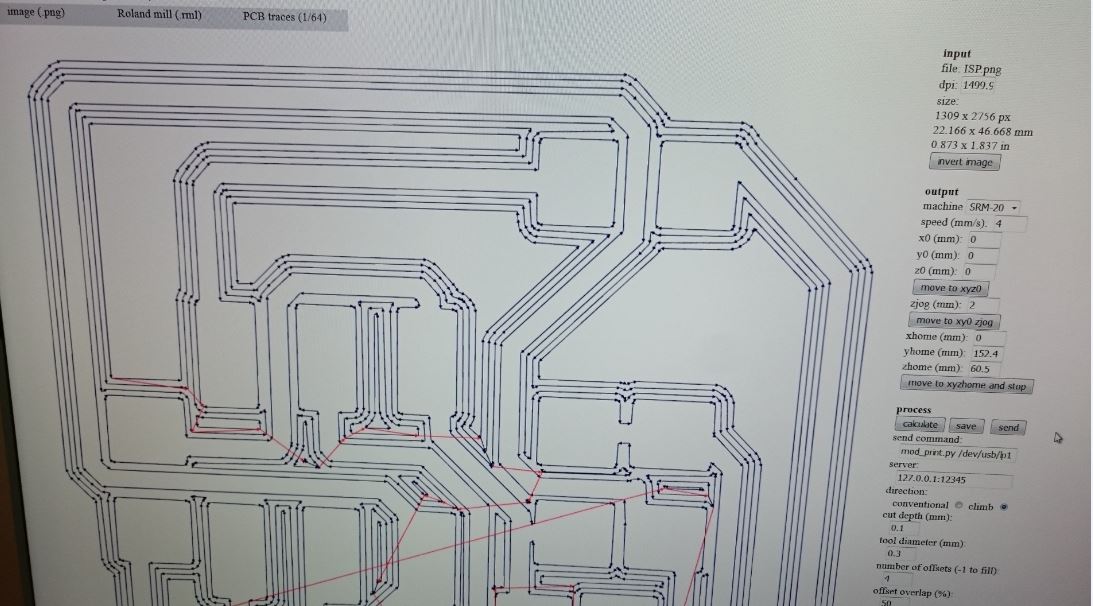

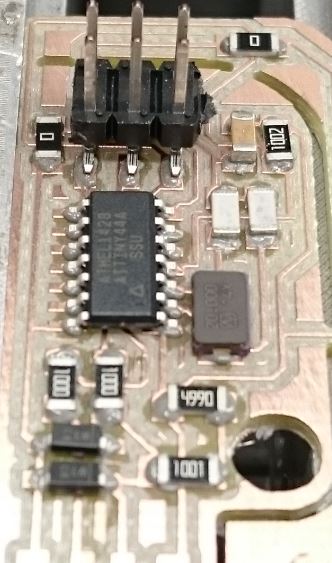

So, we changed the tool to a v-shaped one with a width of 0.2-0.5

mm, that looks exactly like this.

I changed the tool diameter to 0.3 mm in fabmodules. Now the milling

result was perfect to my eyes. Only the copper island beside the USB

data signals had to be removed with a knife. Later I was told by

Juha-Pekka Mäkelä, that there is a handy calculator

to determine the v-shaped tool cutting width depending on the

cutting depth. In this case 0.4 mm tool diameter would have been

better.

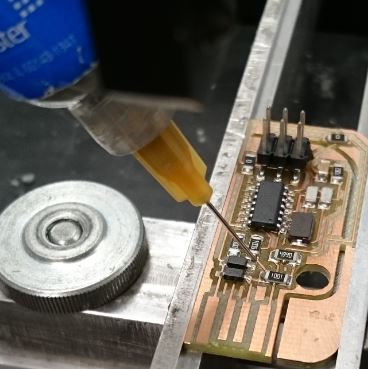

Assembly

I have about 40 years of experience in hand soldering, so I decided

to do the assembly with a proper surface mount component prototype

assembly line that we have in our Fab Lab, because I had to refresh

my skills in using those tools. I used the solder paste dispenser of

the Essemtec SMT assembly system to put soldering paste to the pads.

Then I placed the components with the pick and place system with a

vacuum nozzle. The picture in the middle is the board ready to be

soldered using a reflow oven. The left picture shows the paste

dispenser, whereas the picture on the right has a non-related

component held by the vacuum pick and place nozzle..

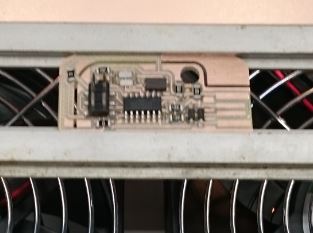

Soldering

After the warm-up period

the board was placed in to the holder.

The oven then preheats the board

and reflows it.

As the result, we have a freshly baked pcb.

Programming

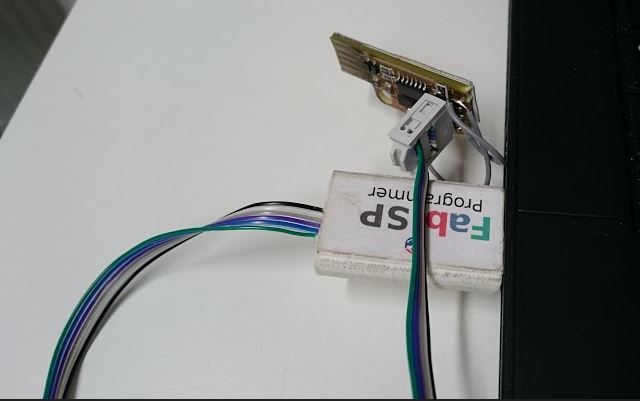

I had earlier programmed my usbtiny programmer with Juha-Pekka

and Dorina, without properly documenting the process myself. So

I went through everything again to my already programmed

usbtiny, to which I had to add the jumpers, which were remove

after initial programming.

The following resources were used:

FAB ISP programmer provided by Jani

Fabacademy.org tutorial

for FabISP Programming.

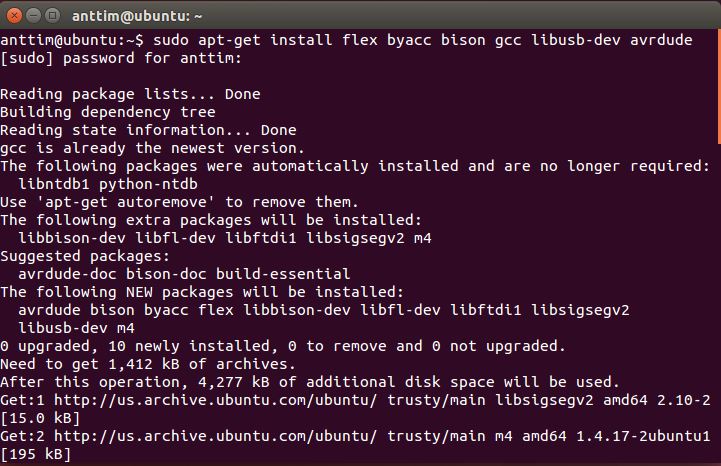

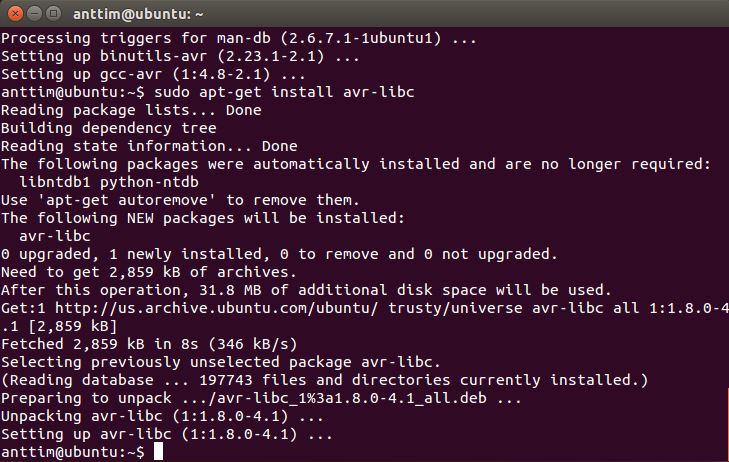

Install software tools:

Open Terminal and type:

sudo apt-get install flex byacc bison gcc libusb-dev

avrdude

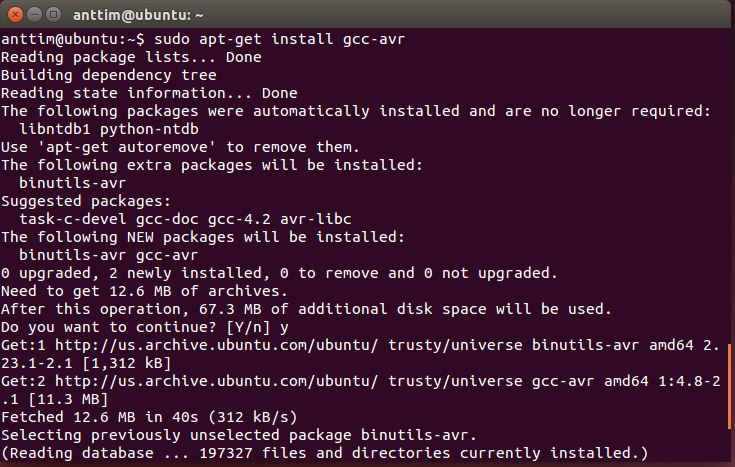

Then type:

sudo apt-get install gcc-avr

- type "y" when asked to do so by your system

Then type:

sudo apt-get install avr-libc

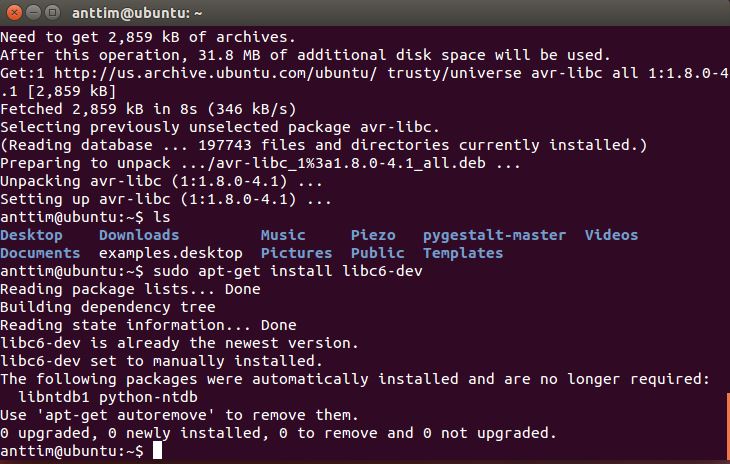

Then type (may already be installed):

sudo apt-get install libc6-dev

And it was already installed.

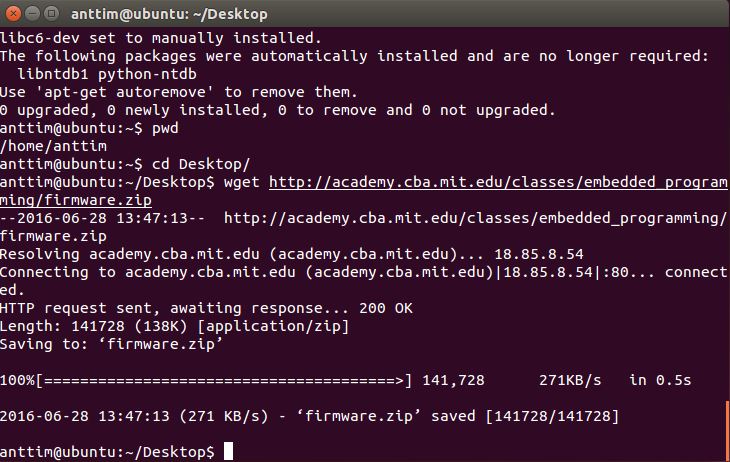

Download and compile firmware:

Download and Unzip the Firmware:

Move to the desktop

cd

~/Desktop

Download the firmware from the Fab Academy Electronics

Production page.

wget

http://academy.cba.mit.edu/classes/embedded_programming/firmware.zip

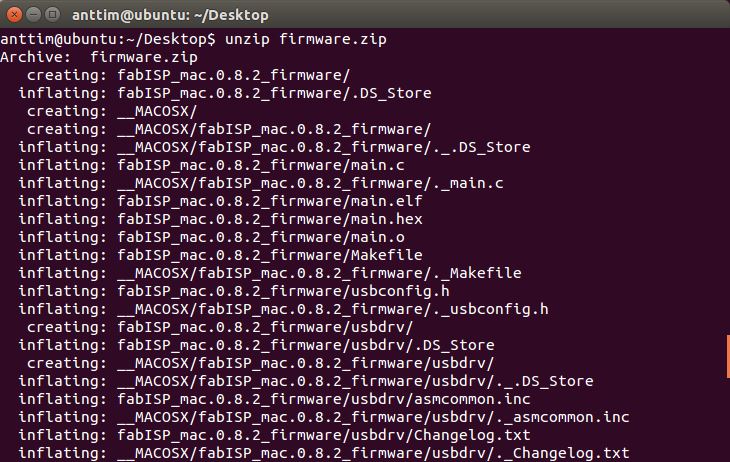

Unzip the firmware

unzip firmware.zip

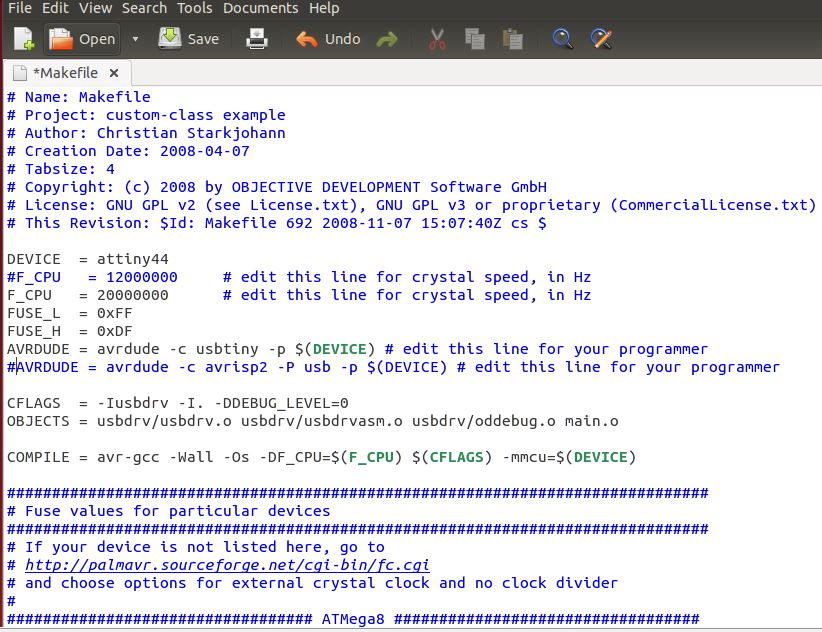

Edit Makefile:

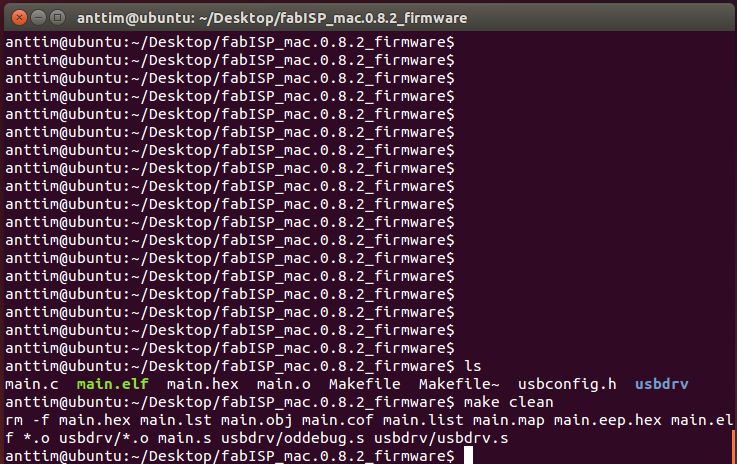

make clean:

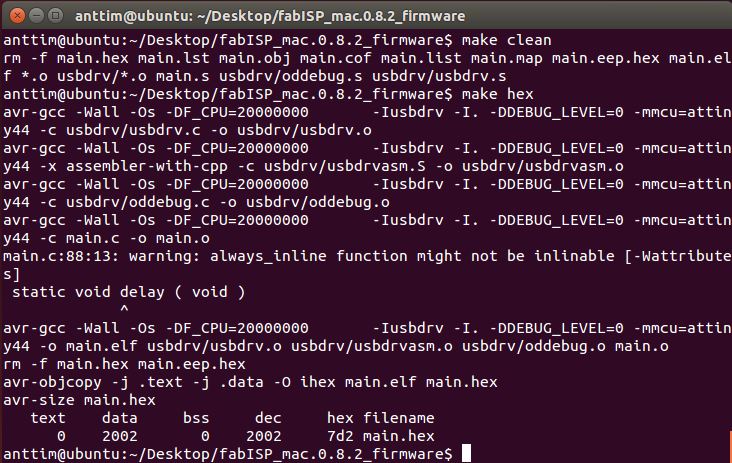

make hex:

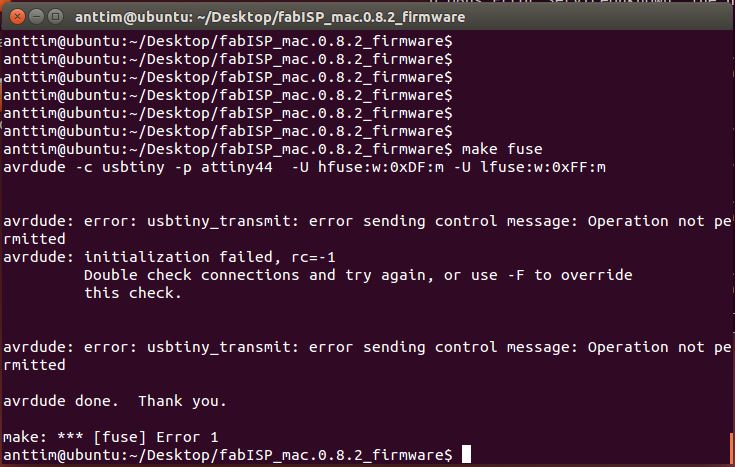

make fuse:

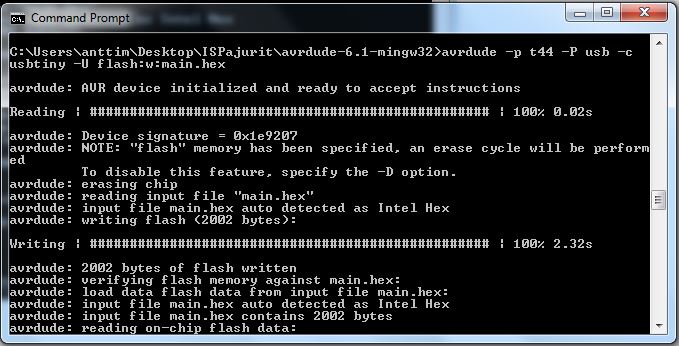

Make fuse gave me an error, as shown above. Googling the error

lead me to an instruction

suggesting, that I have to create a 10-usbtinyisp.rules file in

directory /etc/udev/rules.d with the content:

SUBSYSTEM=="usb", SYSFS{idVendor}=="1781",

SYSFS{idProduct}=="0c9f", GROUP="adm", MODE="0666"

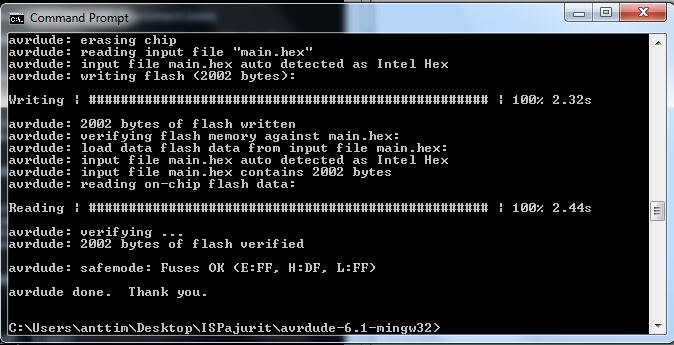

That I did, but it didn't help. However, I now had the main.hex

file, which I programmed in Windows with avrdude:

Update:

I remembered, that the faculty workshop uses chemical tin to

coat the copper with a thin layer of tin. So, that is what I did

to the USB-connector.

http://www.bungard.de/index.php/en/products/surfaces/bungard-sur-tin

Home