Assignment 12: Molding and Casting

I selected icosahedron as the object. I found a nice one in

Thingiverse: http://www.thingiverse.com/thing:37797/#files.

I imported the object to 123D Design. And made it solid for

splitting.

The I constructed the bottom and walls and filling pipe to the mold.

I scaled the design to half and exported it as stl-file.

Then I opened Roland Modela Player 4 and opened the design:

I set set model origin:

and zeroed the margins:

selected a new process for roughing:

with a 3,18 mm flat milling tool:

with default tool path:

and cutting parameters: I changed to speed to 30 mm/sec and path

interval to 1.5 mm, which equals ~47 % overlap.

The tool path looks like this:

and the simulated result as this:

The finishing:

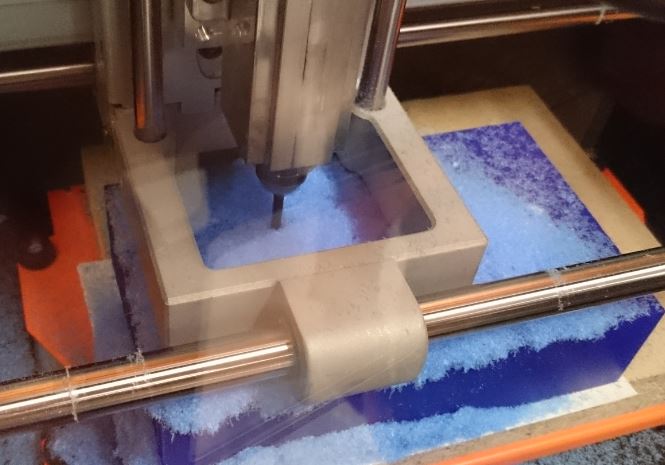

Milling:

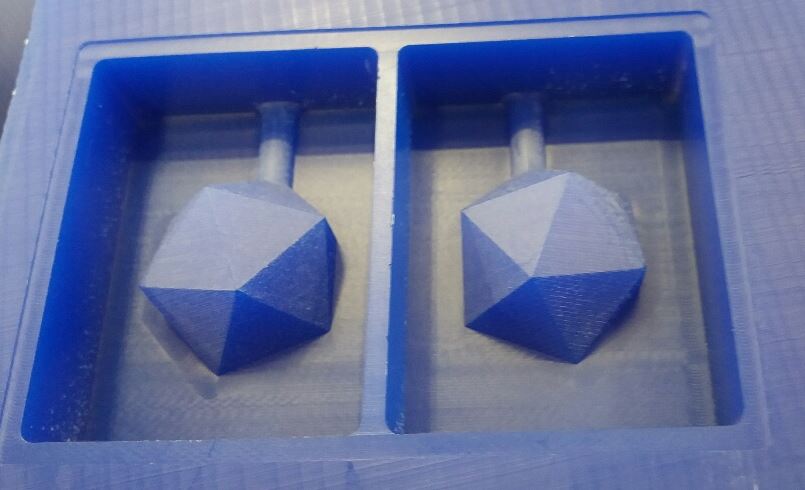

Wax Mold:

Rubber casting:

The liquid rubber is OOMOO®25 Tin

cure silicone rubber, which has a 15 min pot life and 75 min

cure time. The two components have one-to-one by volume mix ratio,

and it does not need vacuum degassing.

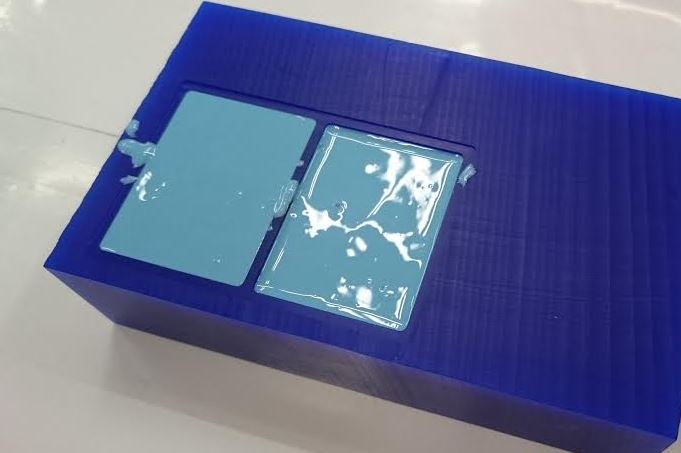

Rubber mold filled:

Rubber mold:

Plastic casting:

The liquid plastic is Smooth-Cast®310.

Also its two components are mixed one-to-one by volume, and it

requires no vacuum degassing. It has a pot life of 15-20 min. and

cure time of 3-4 hours.

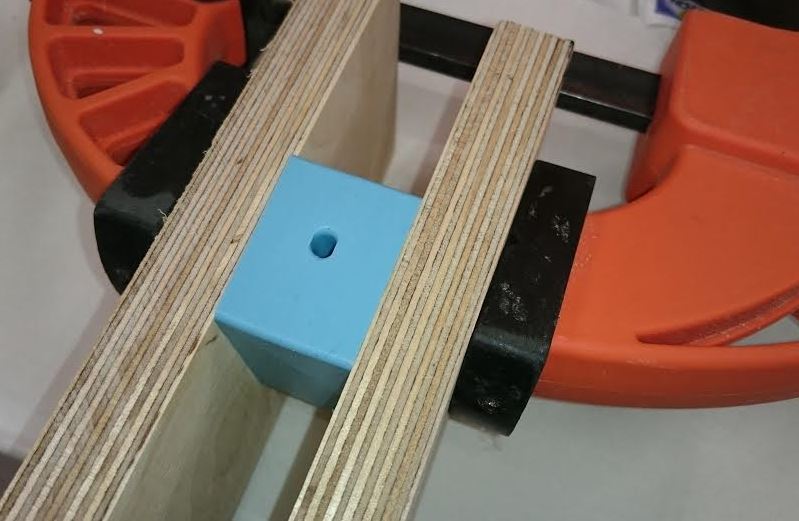

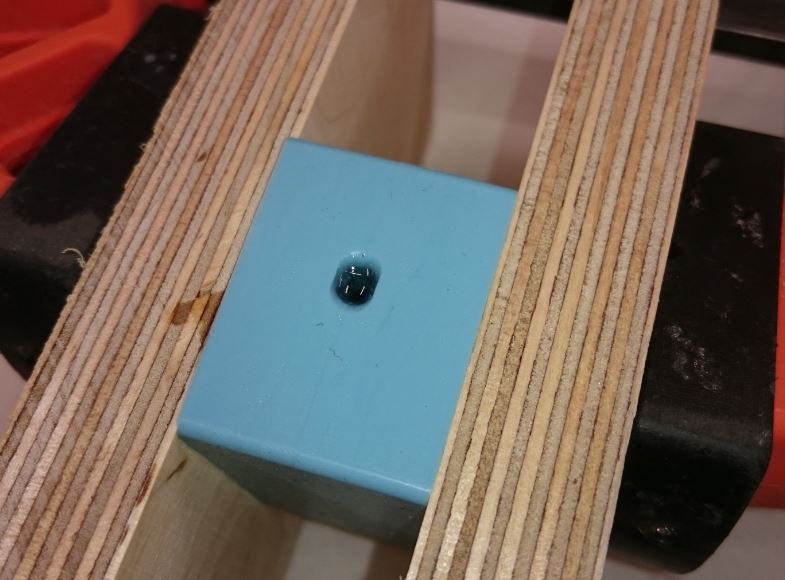

The rubber mold halves are exactly the same size, so they just have

to be aligned. With a clamp and two pieces of plywood I carefully

clamped the molds together:

Plastic casted:

Mold opened:

The part came out fine with a soft touch of knife and a file:

Files:

123DDesignFile

STL

Home