COMPOSITES

COMPOSITES

Composites assignment

For this week assignment we had to design and make a 3D mold, and produce a fiber composite part in it.

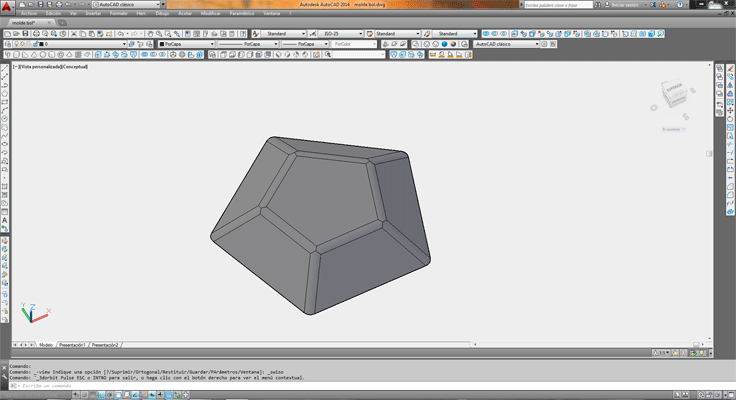

Design the 3D

The first thing I did was to design a fruit bowl, I draw it in Autocad and export it as stl.

Machining

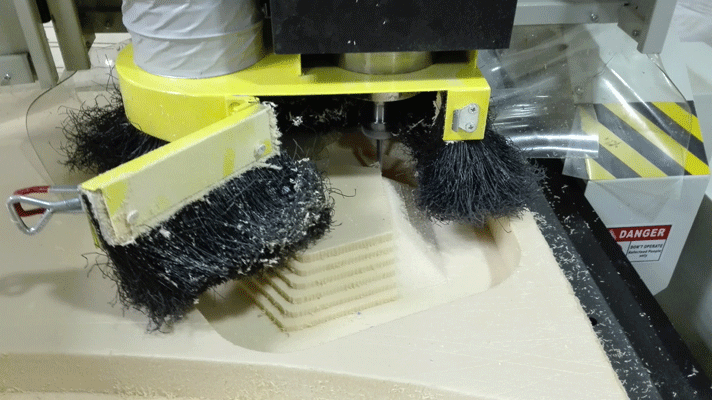

I cut the piece with the CNC machine, our CNC machine is the TEC-CAM 1003 CNC and the fixturing system that we use is vacuum, I used a piece that covered two of the for quadrants.

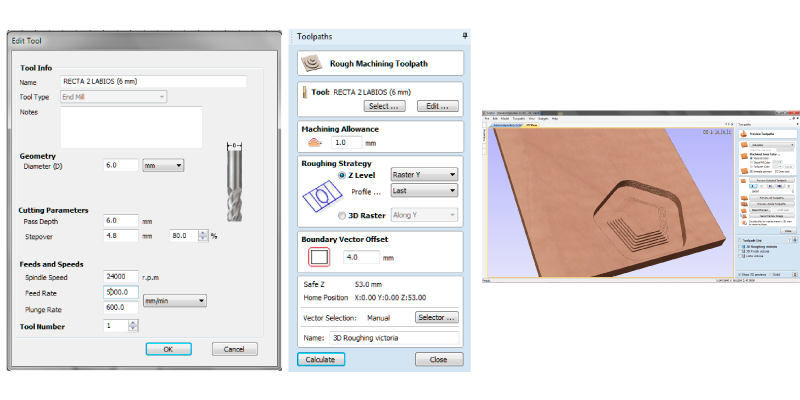

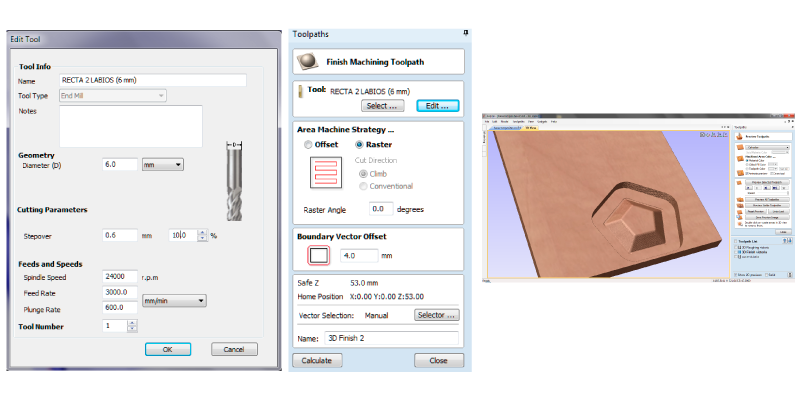

I milled the piece with 6 mm end mill, and the program that we used to 3d milling is Aspire.

The material that I used was 1200x60x6mm of expanded polypropylene so we opened two quadrants of the machine to fix it.

I did 3 files of cutting:

Roughing:

- I used a 6mm End Mill and a roughing strategy Z level.

- Stepover :80%

- Feed Rate: 5000

- Machining allowance: 1mm

- Boundary offset: 4mm

Finish:

- I used a 6mm End Mill and an area machine strategy raster

- Stepover :10%

Final cut:

- I used a 6mm End Mill, 2d Profile Toolpath

- I used tabs and zig zag ramps

- Pass depth 12 mm

Fabric

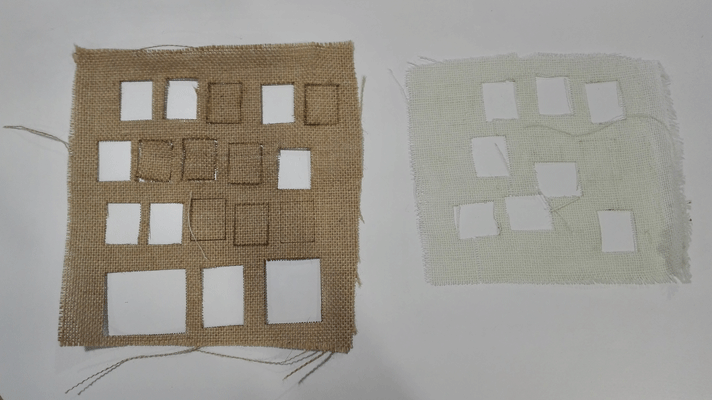

To cut the patron I used the laser cutter, as we didn`t have the cut values of the jute fabric that I used, I did a few test to obtain it.

I cut three layers of jute fabric.

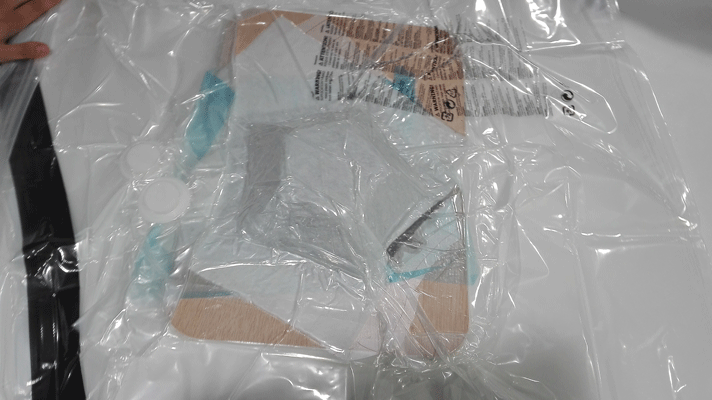

Vacuum Practice

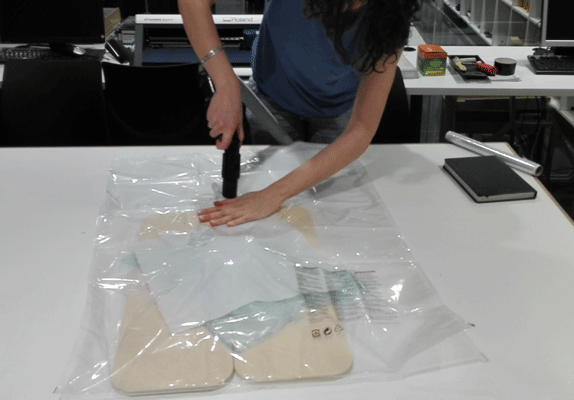

The resin that I used was epoxy, reading the data sheet of it, it said that the time of work is 25 minutes so I practice to do the vacuum in the time before doing it with the resin.

Safety

The resin that I used was epoxy, and reading the data sheet of the resin and the hardener, it said that the hardener could cause irritation if it is inhaled and it could cause eye and skin irritation, so I used mask, eye protection and gloves.

Vacuum

I did the vacuum but I realized that some air enter so I put other bag and I did the vacuum again.

Steps and layers

- Mold

- I covered the mold with plastic and put spray vaseline on it to unmold it

- I put the three layers of fabric with resin

- I put a fine cloth to remove extra resin.

- Then I put a porous plastic allows you to remove extra resin if there was too much resin.

- And finally a thick cloth to prevent the resin from entering into the vacuum.

- Now is ready to do the vacuum

- Wait between 5 hours and 7 days to cure the resin and the mold is ready.

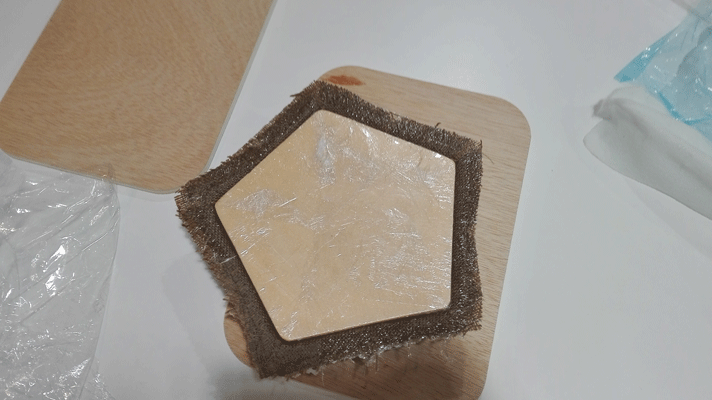

Result

I wait for 7 hours and this was the result: