Week 12: Molding and Casting

Assignment

The assignment for this week is design a 3D mold, machine it, and cast parts from it.

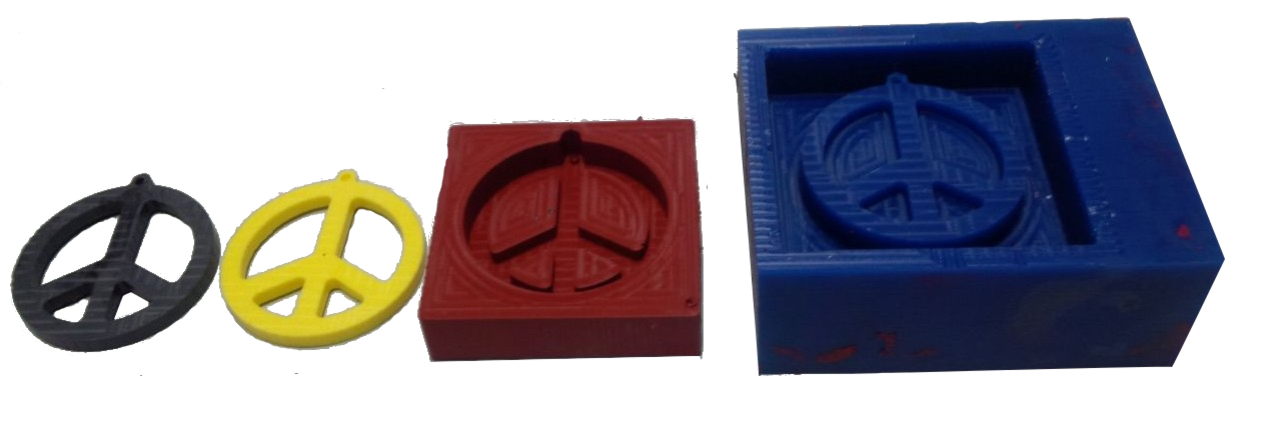

Designing the mold

I wanted to design a locket of Peace, I started to design the mold with solidworks.I first created small box of size of my mold and cut the small portion to place the locket.Then created a small circle with a star at the center. And I created a peace logo. Another one is before the Designing we want to understant our Project is 3d mold for that we want to design a negative molt design or a postive mold.in hear i used a negative mold design.

3D Milling in Wax with Modella

After the Designing I start the milling process.I Milled the design in a wax block using modella. I used two bits in this milling process one is 1/8 rount bit and another one is 1/8 finishing cut bits.

Milled in a wax block using Modella Fab module. I selected from fromat model(.stl) to process Roland Modela(.rml). then with program make stl rml.

Mould..

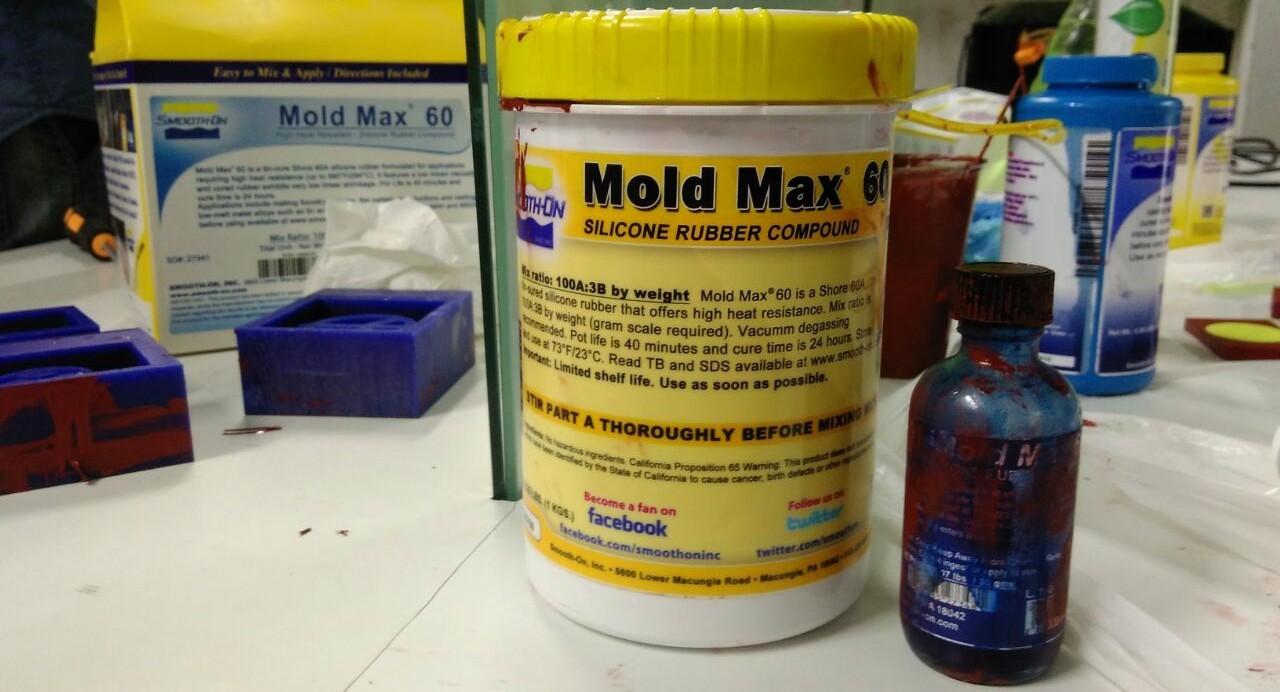

## Casting next step was casting the silicon mold.for the casting i used Mold max 60 High heat resistant silicone rubber compound. For high-heat resistance applications and will withstand up to 560°F / 294°C. It features a low mixed viscosity and cured rubber exhibits very low linear shrinkage. Parts A & B are mixed 100A:3B by weight. Pot life is 40 minutes and rubber cures in 24 hours to a relatively hard Shore 60A.Applications include making foundry patterns, flat pattern reproductions and casting low-temperature melt metal alloys such as tin and pewter.

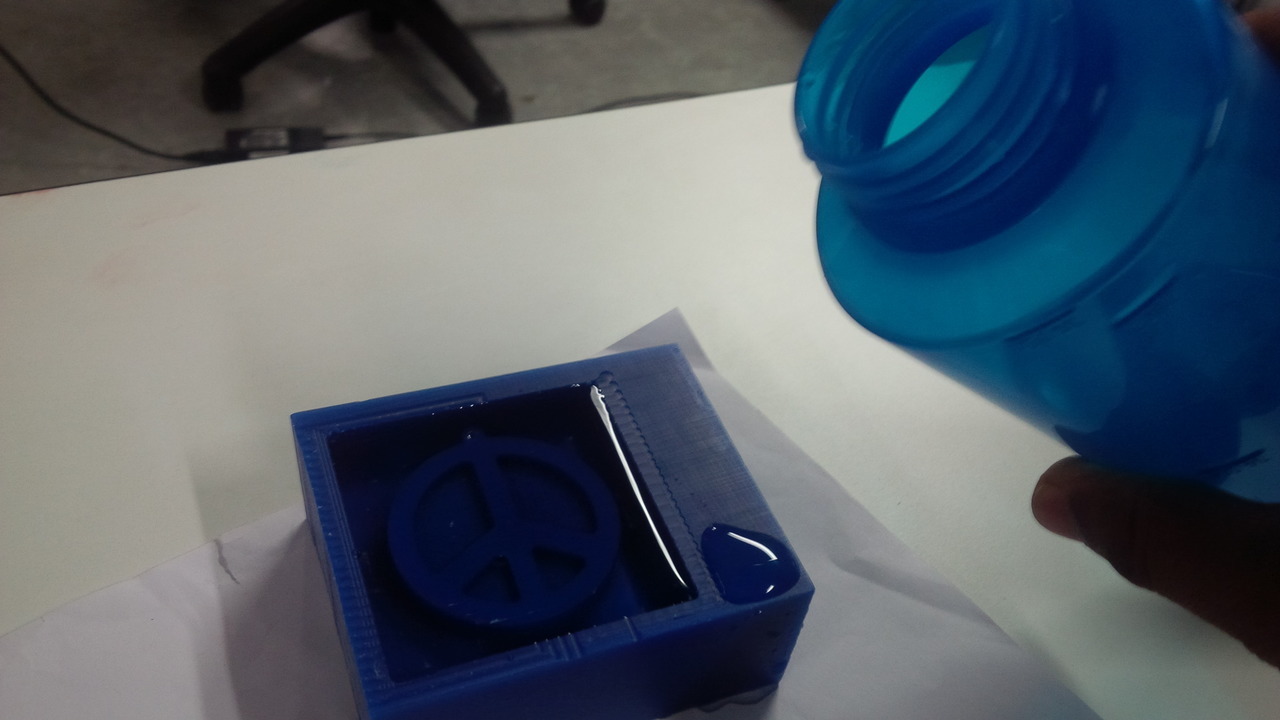

In a seperate glasess and i try to add colour for that i mix blue colour in partB . dont mix colour with part A.after that i mix part A and part B in same glass,mix it 3 to 4 minute very well.then the siloicon mixture part A and part B Poured in the Wax mold.

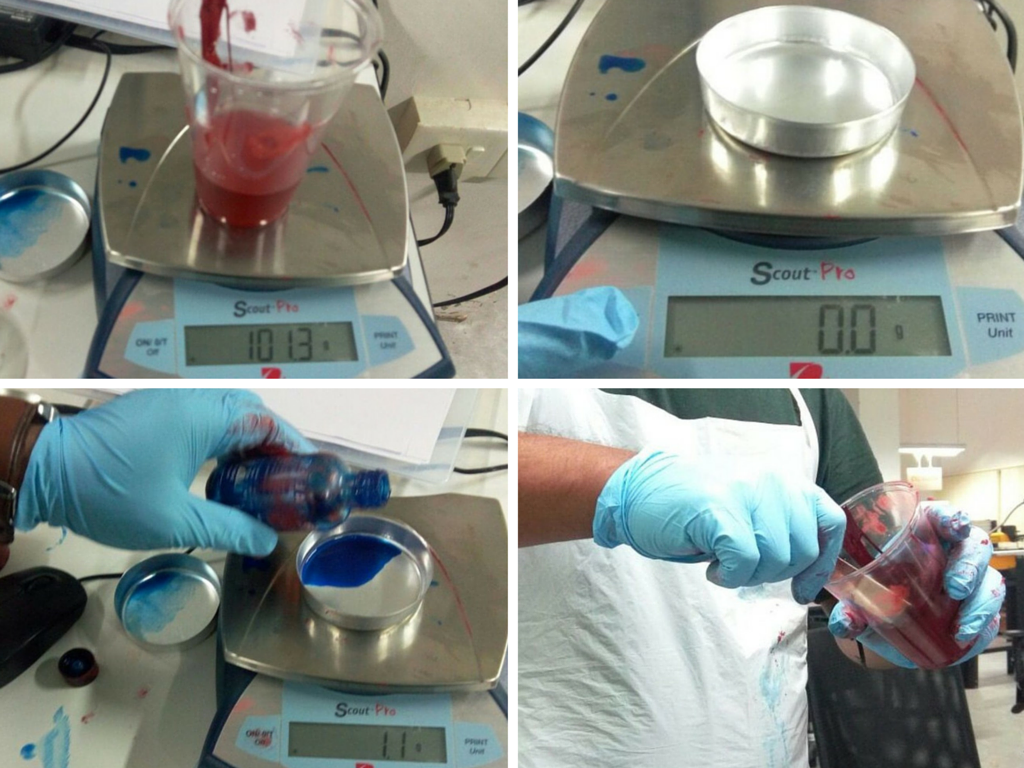

first i take the volume required by pouring water in to the molding wax after that i epmtying water in to a cup.then i took the equal volume of part A. I took measure the volume level. then I weigh the plastic cup on load cell. Zero it.

Then I took the part A to the level which I marked previously. And weigh it. I got 101.3grams. For collecting the weight of part B I took a aluminum cup.zero the weight of cup. And collect up to 3grams

Then I smixed for 3 minites. Scrape the sides and bottom of the container several times. And pot it on the wax mould carefully from a side. Optionly we have no vacuum bag so I used to hit the pot mold on table for escaping the air bubbles. Waited to complete cureing a day.

Product Casting

Liquid plastic is a perfect for pouring into rubber molds. it turns from a liquid to a solid plastic and reflect perfect detail. Smooth cast bright white liquid plastic. Used 1A:1B white liquid plastic by volume. which is ideal for dublicating a varity of original models or patterns.

Coloring Agent:

the colour mix with the part B and shake it very well.

I casted

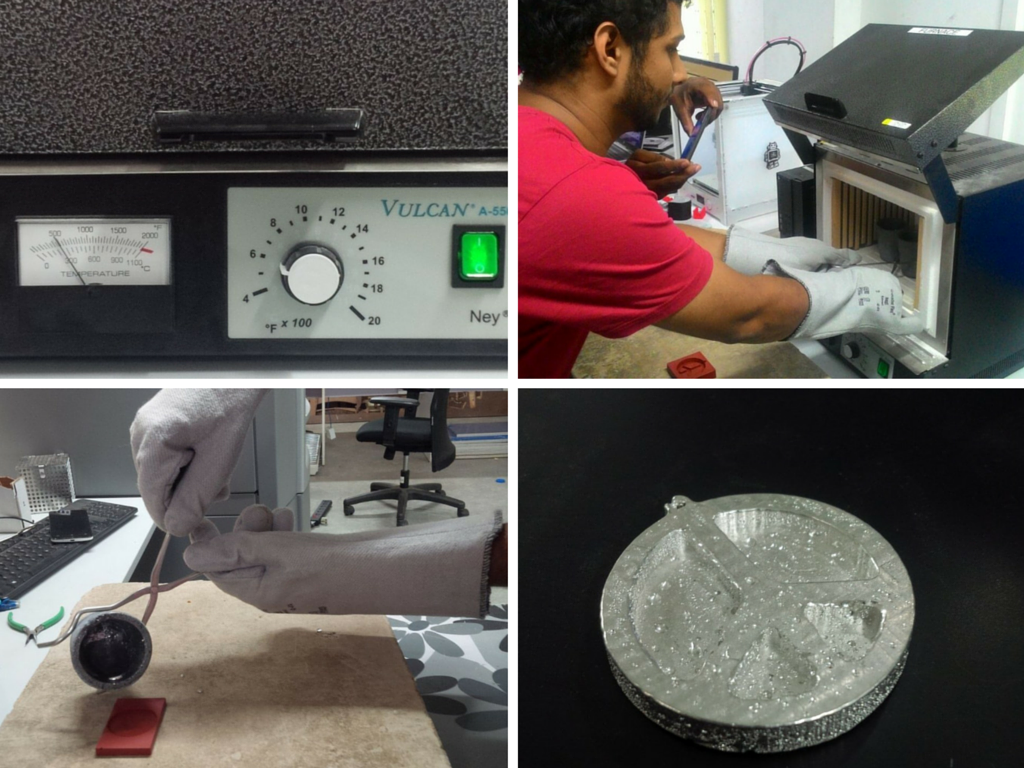

Metel casting

The next which I casted using metal Bismuth. Kept it on furnce by providing 500 degree celcius. wait for until the metal gets melts. I used talcum powder on the surface of silicon mould for reducing the surface tension. care fully I pot it on mould. Wait for to cool. Got the cast product.. But some air bubbles on the surface of the casted product.

This is which I made on this week.