Mechanical Design.

Ninth week

In this week we have a group assignment.

The objective was make a machine, including the end effector. Build the passive parts and operate it manually, document the group project and your individual contribution.

Those are the basic instruction for this Task.

The package contains:

- 4 Stage: Stepper + rod bar.

- 8 Guide bars.

- 4 Gestalt circuit boards.

- Misc materials (as nylon bearings).

- RS485 Connecting cables.

- 4 Resistors.

- Plugs.

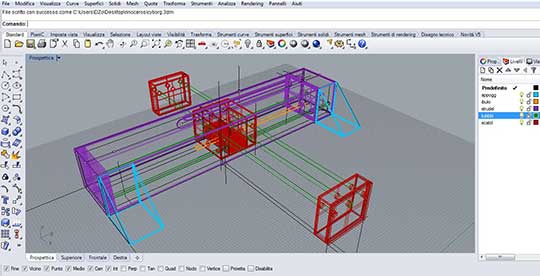

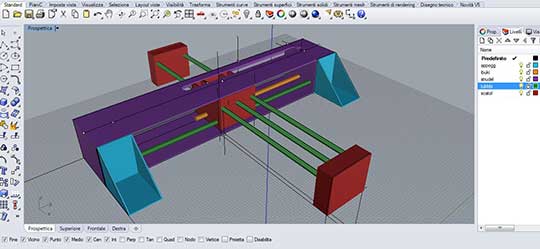

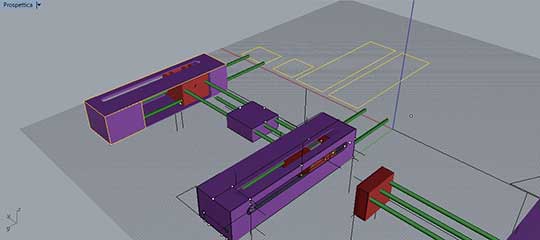

We must split works to build a machine: Damiano on the machine programming, and me for the machine modellation.

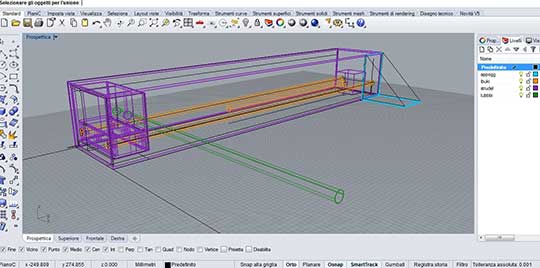

So I started my travel for the machine 3D model!

Rhino file: Here.

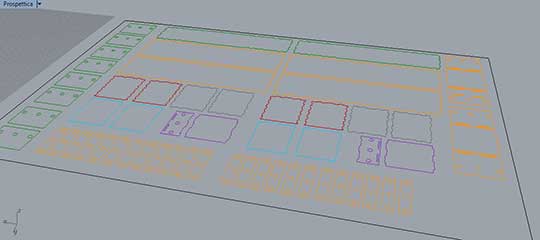

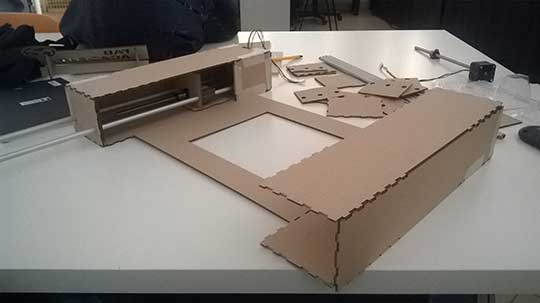

We considered the idea to make a cardboar prototype, to be sure of the passages we must take, without wasting a lot of material.

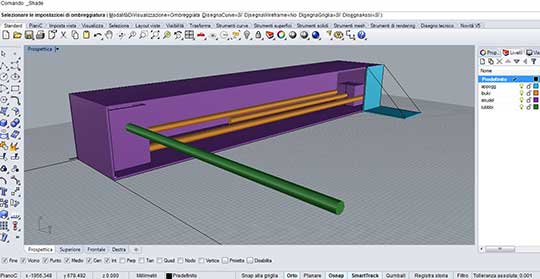

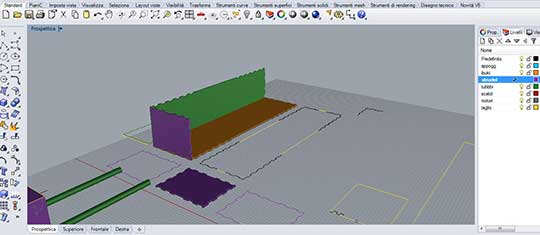

I started making the structure and I considered the cardboard (2.54 millimeters) for the thickness. Initially I projected the structure with a mono box, however I was unsure about the overall solidity.

In the second approach I made the structure with a double box, to make it with a solid balance.

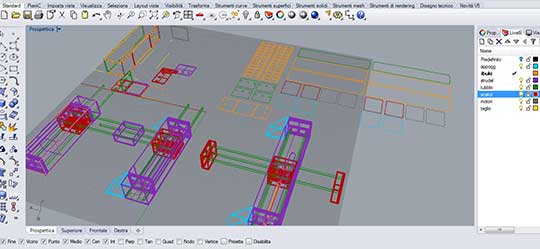

As always I see troubles exporting files, this time I got some parts rotated by millimeters (I don't know why) probably because an accidental bad pression of the mouse!

I resolved turing those object singularly, because they remain crooked with a group torsion.

I cutted a mobile base, to fix the drawing paper better however, in the final model, I opted for a solid one. Because in this way the structure was more compact.

In the cut I forgot some holes (that I made later) and I used adhesive tape to make it solid but, in the end, the prototype result wasn't so bad.

An understimate problem that we can face was the assembly order. We must mentally organize the parts and recover all the the youth Lego knowledge, to avoid huge wasting of time!

Copyleft © Alessandro Patrizi 2016