Week 7

Computer-controlled Machining.

Although This week is the most interesting one, i had no clue what should i make at first. I wanted to make something that i can use later. I had an idea to make a hut for my cats since they always interrrupt me whenever i'm working. So i drew a draft design on MYPAINT, then i started designing the actual one on soldiworks.

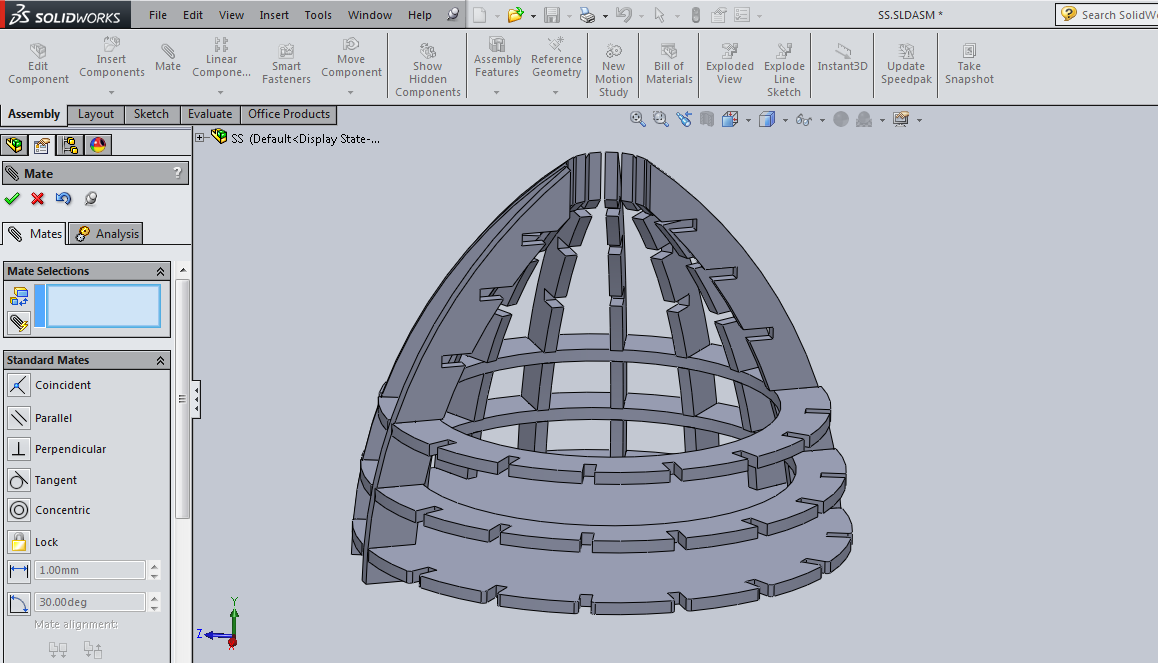

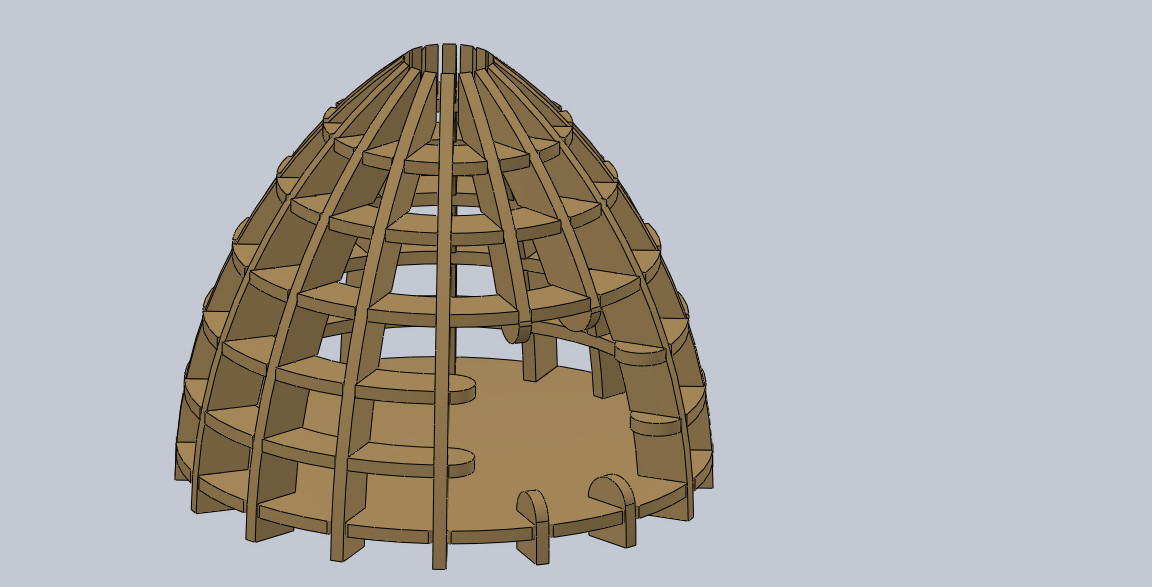

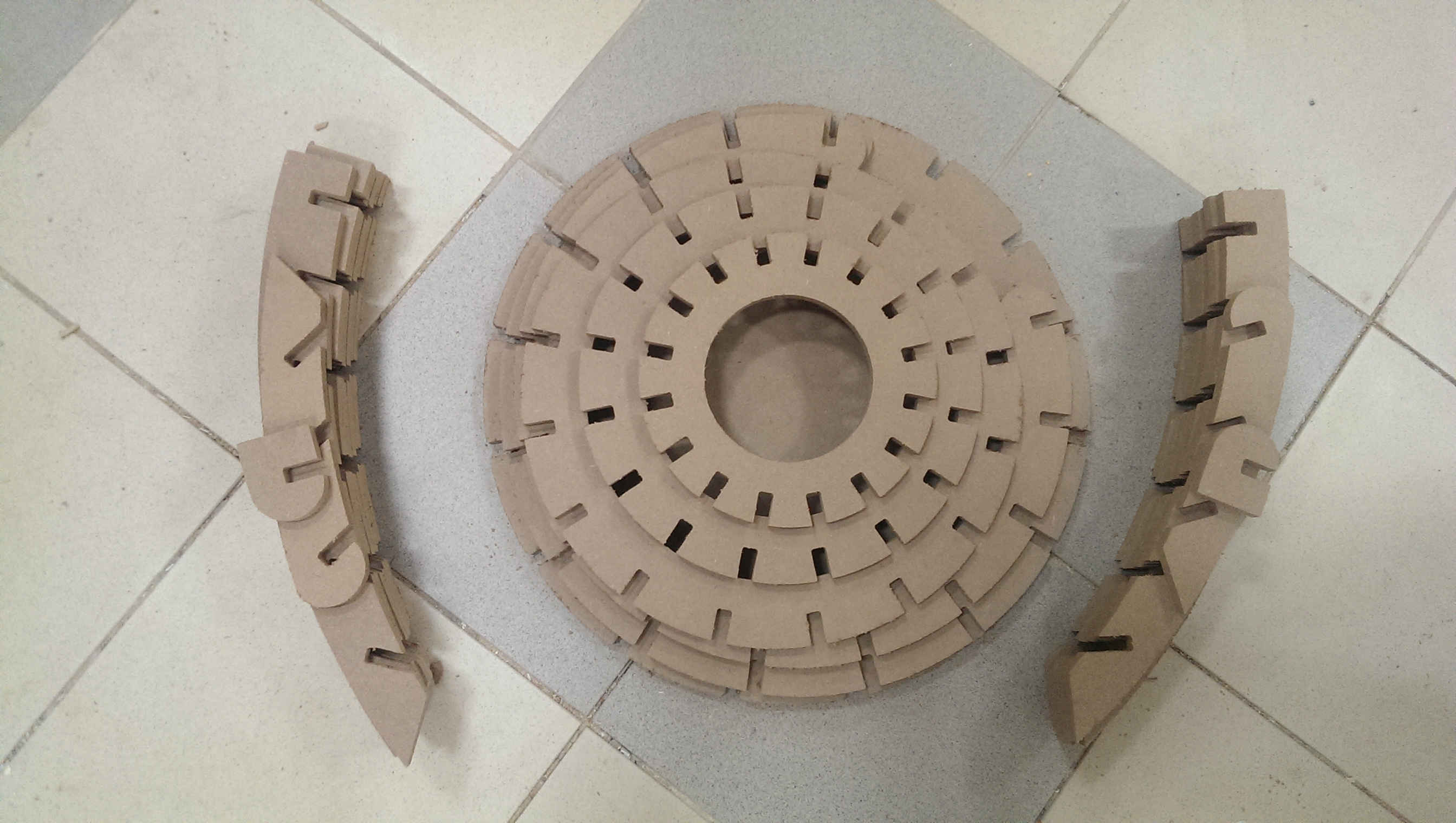

I used solid works to design the hut. Solidworks allowed me to assemble the whole design to check its final look and also check if the parts will fit perfectly.

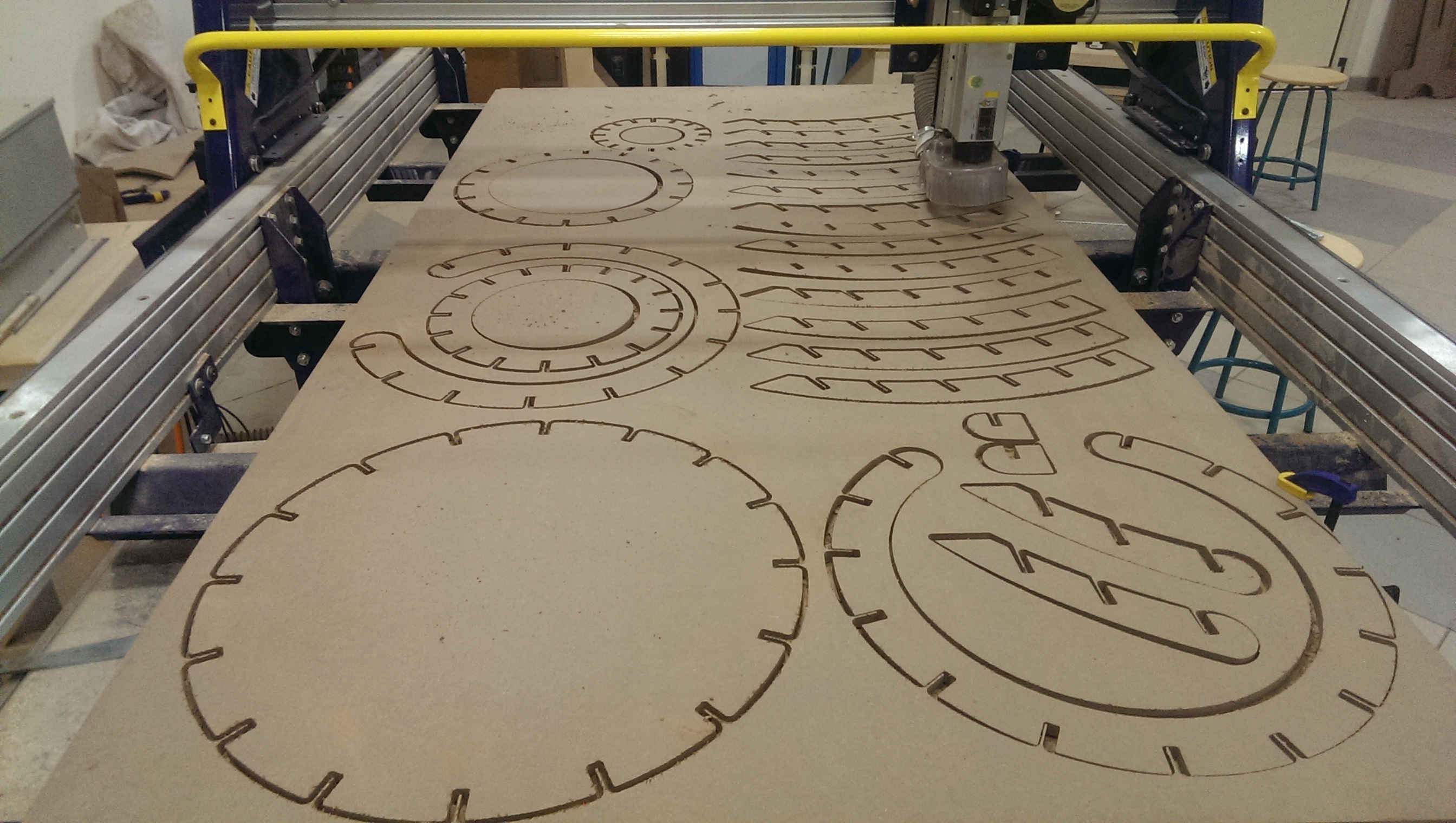

Vpart1.DXF 14 part.

Vpart2.DXF 2 parts.

Vpart3.DXF 2 parts.

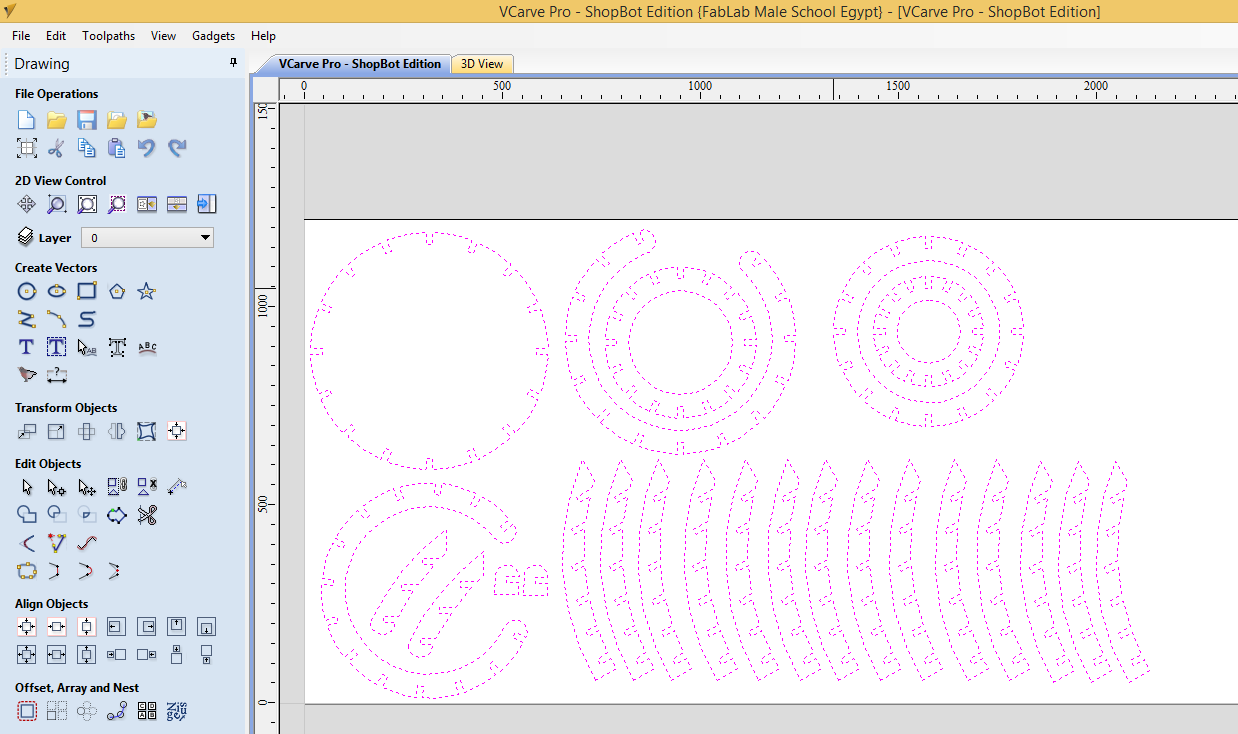

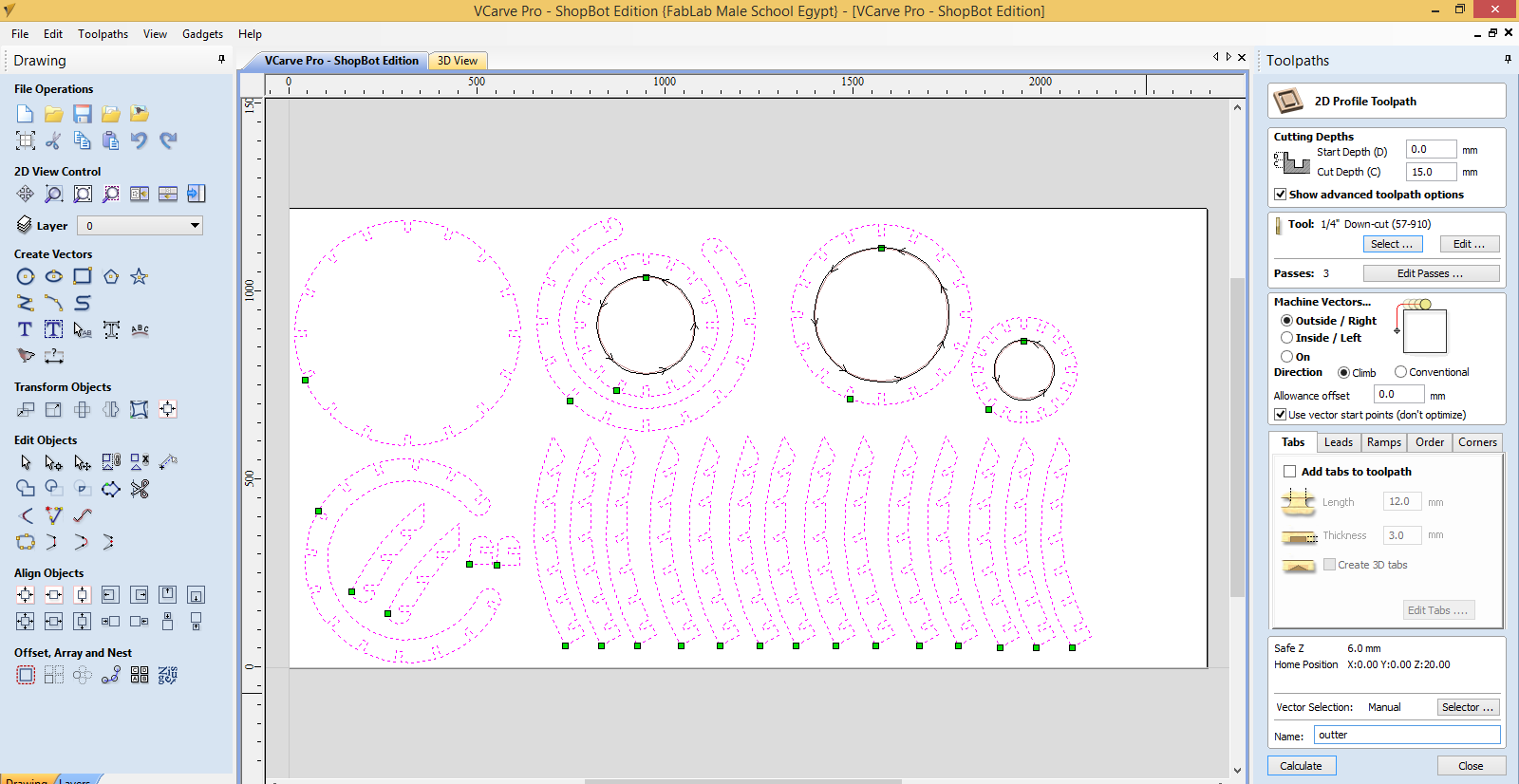

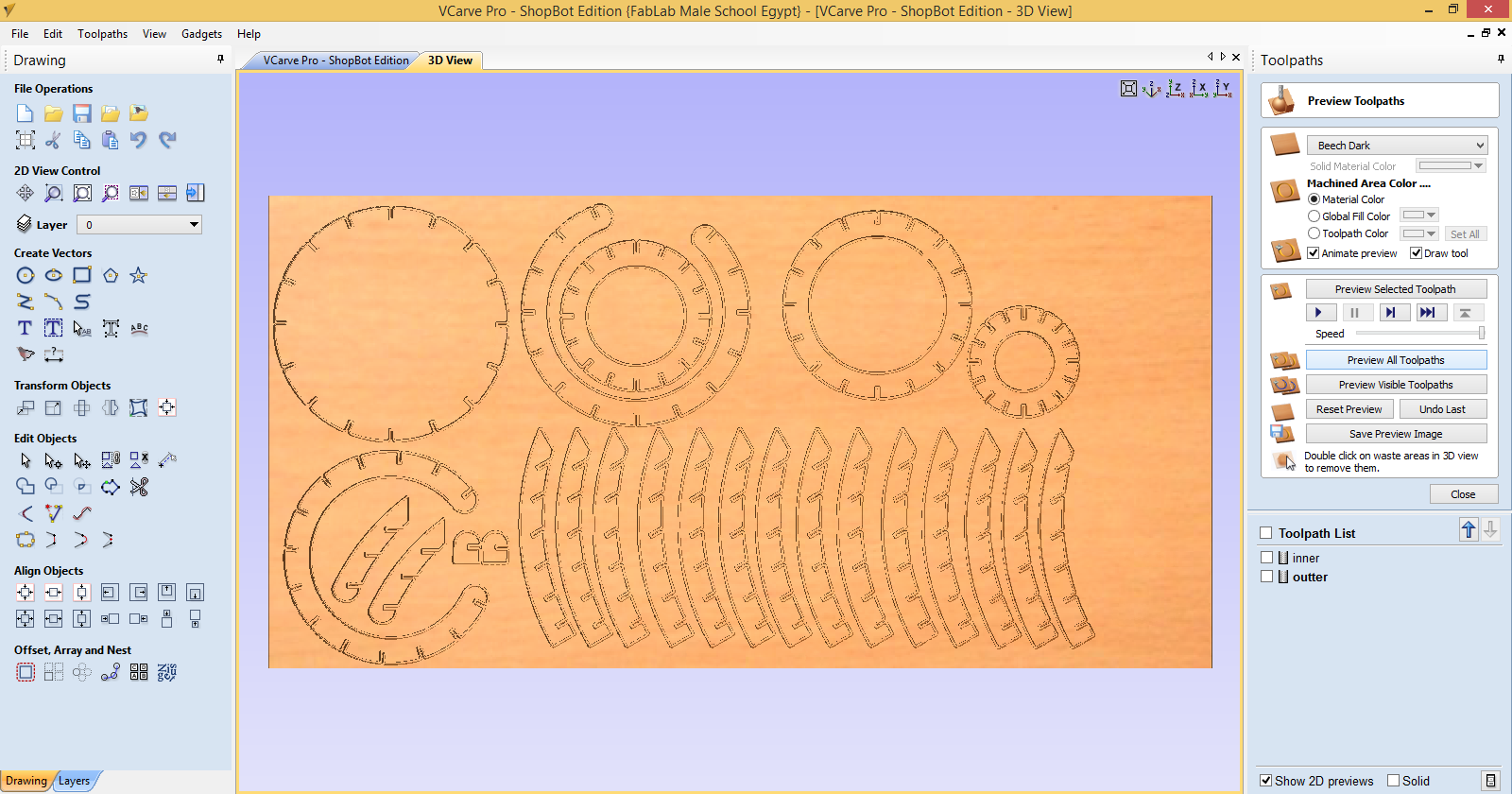

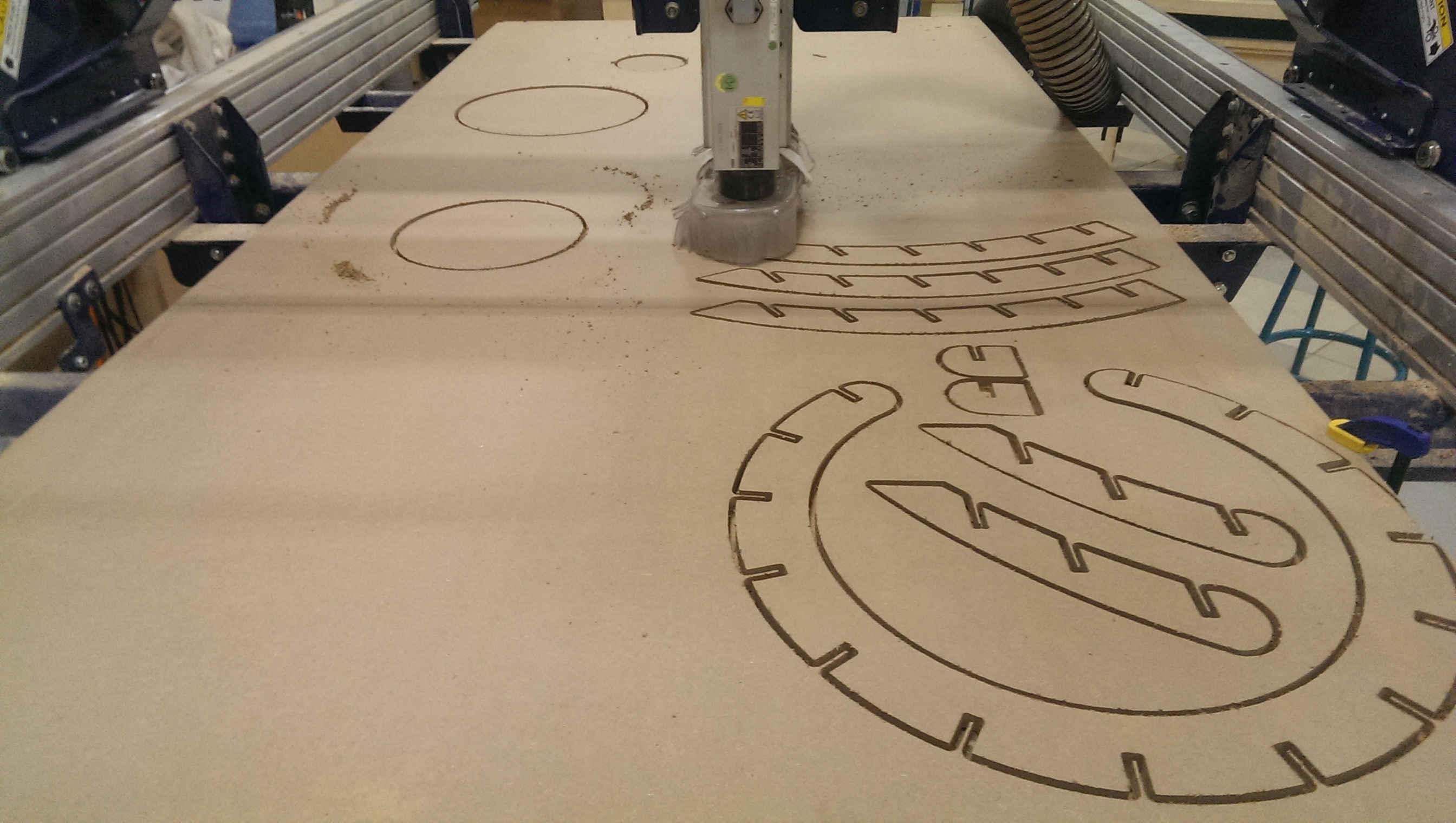

I imported the DXF files into vcarve. Choose 1/4 end-mill, edite cutting profiles, choose feed-rate to be 6 inch/sec, and 14000 rpm spindel speed.

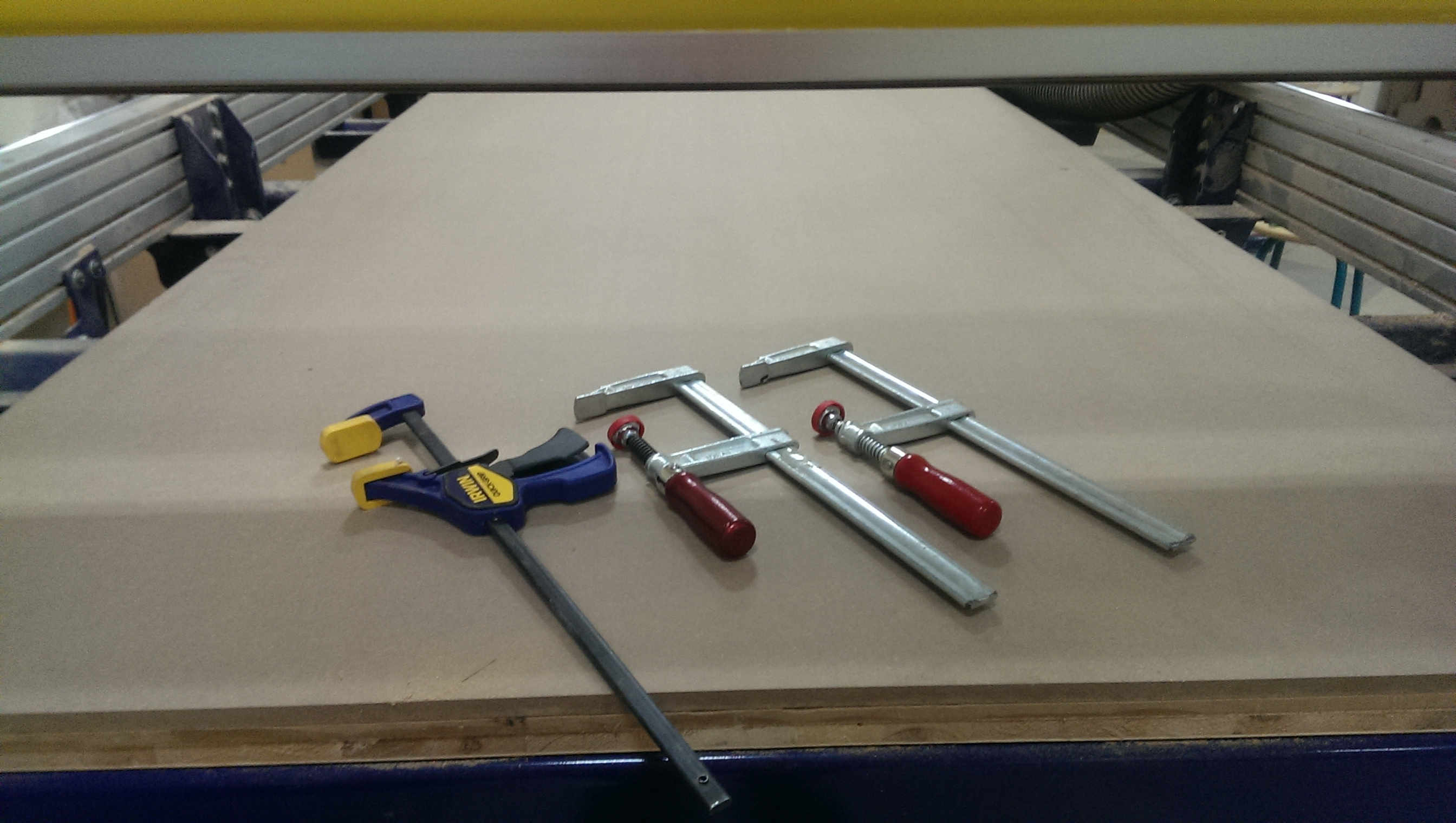

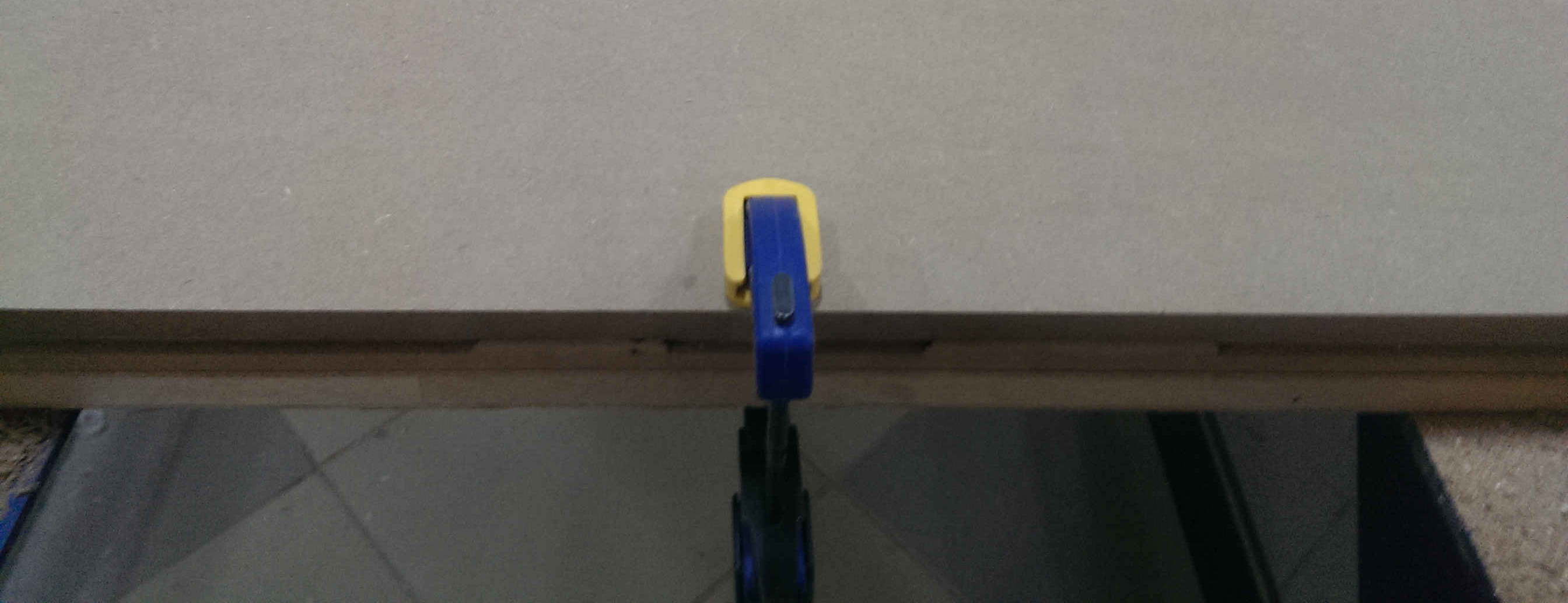

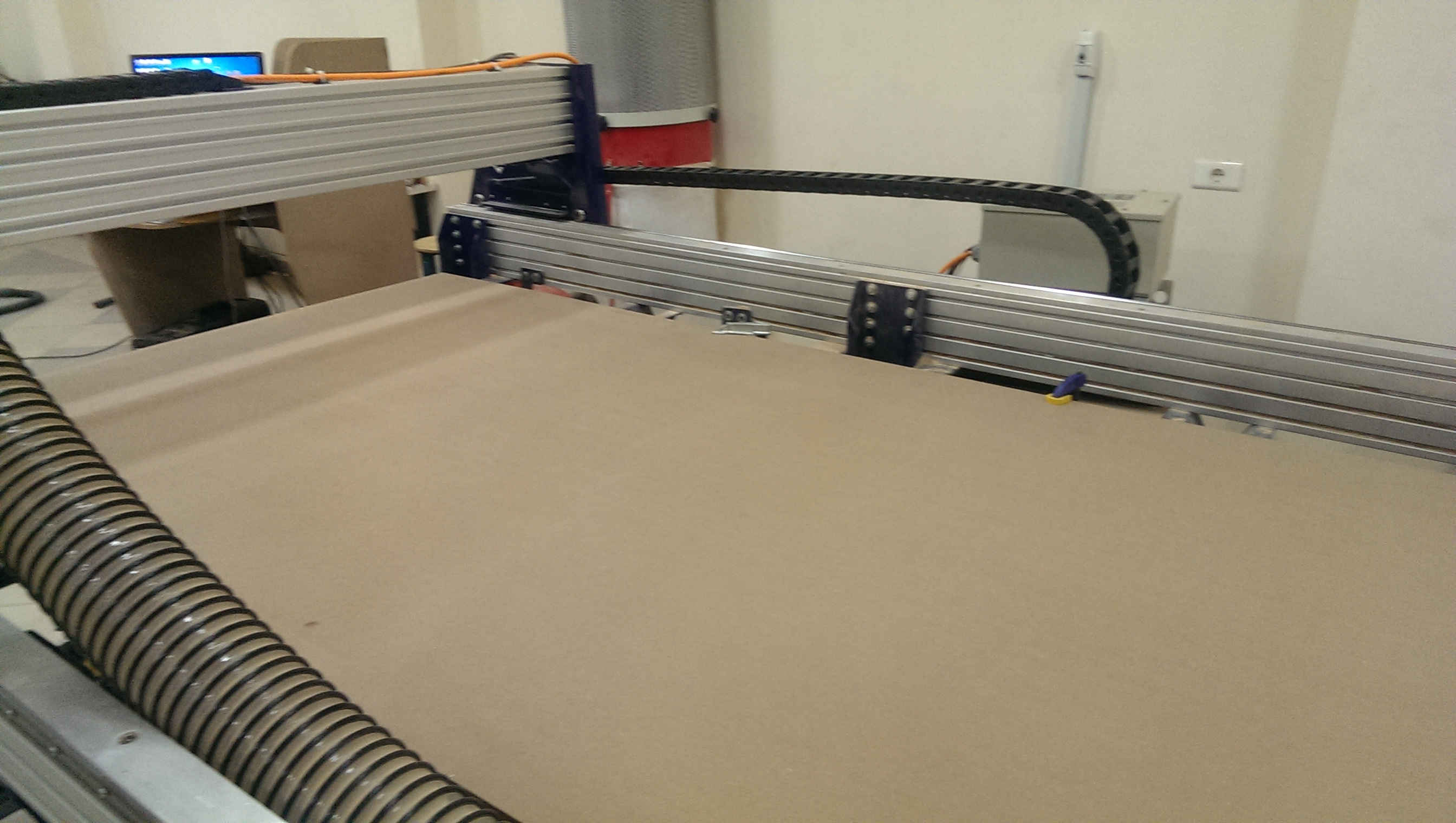

1- Change the wood sheet, and fixuring the sheet.

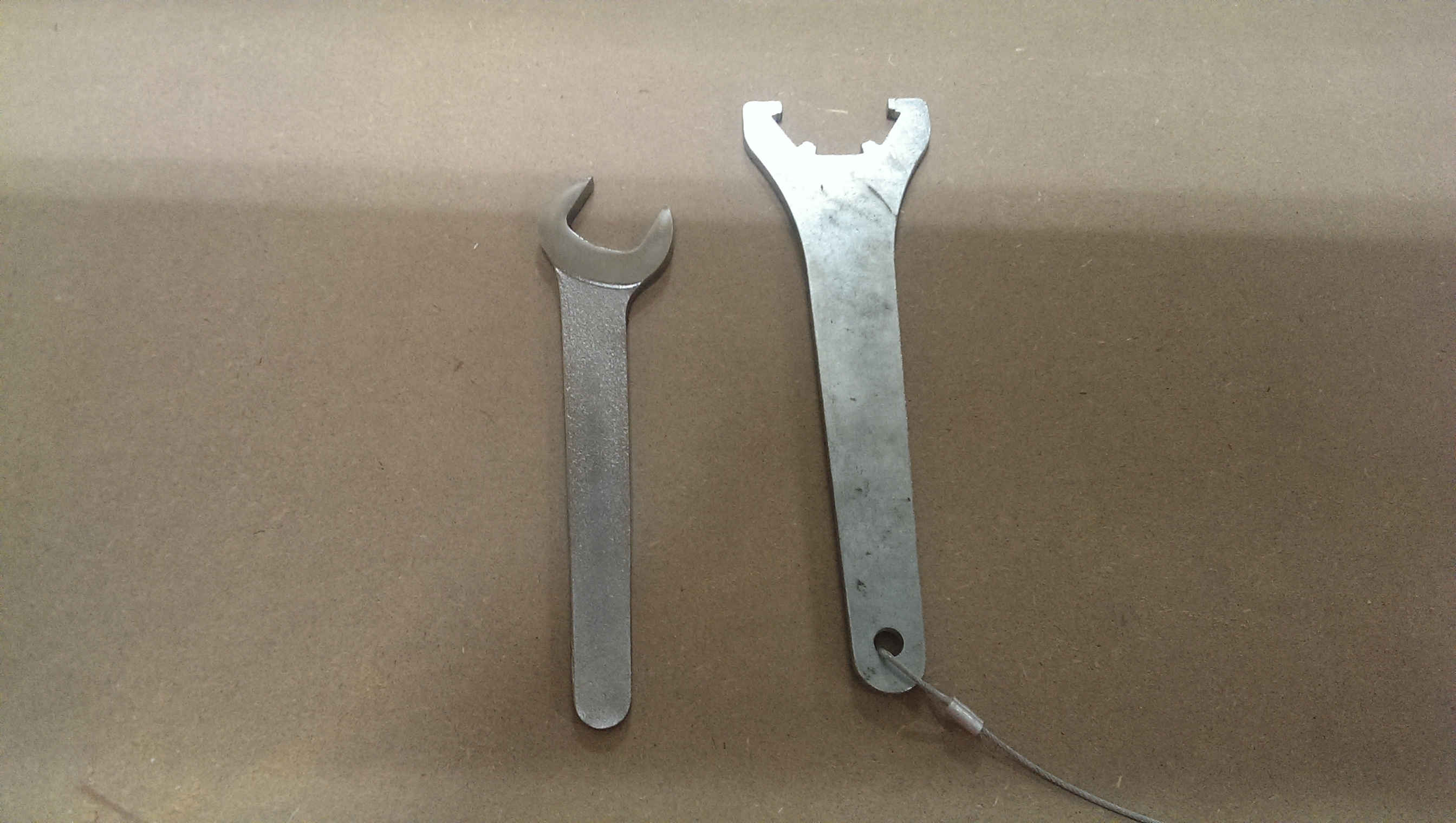

2- change the end-mill, i used 1/4 inch.

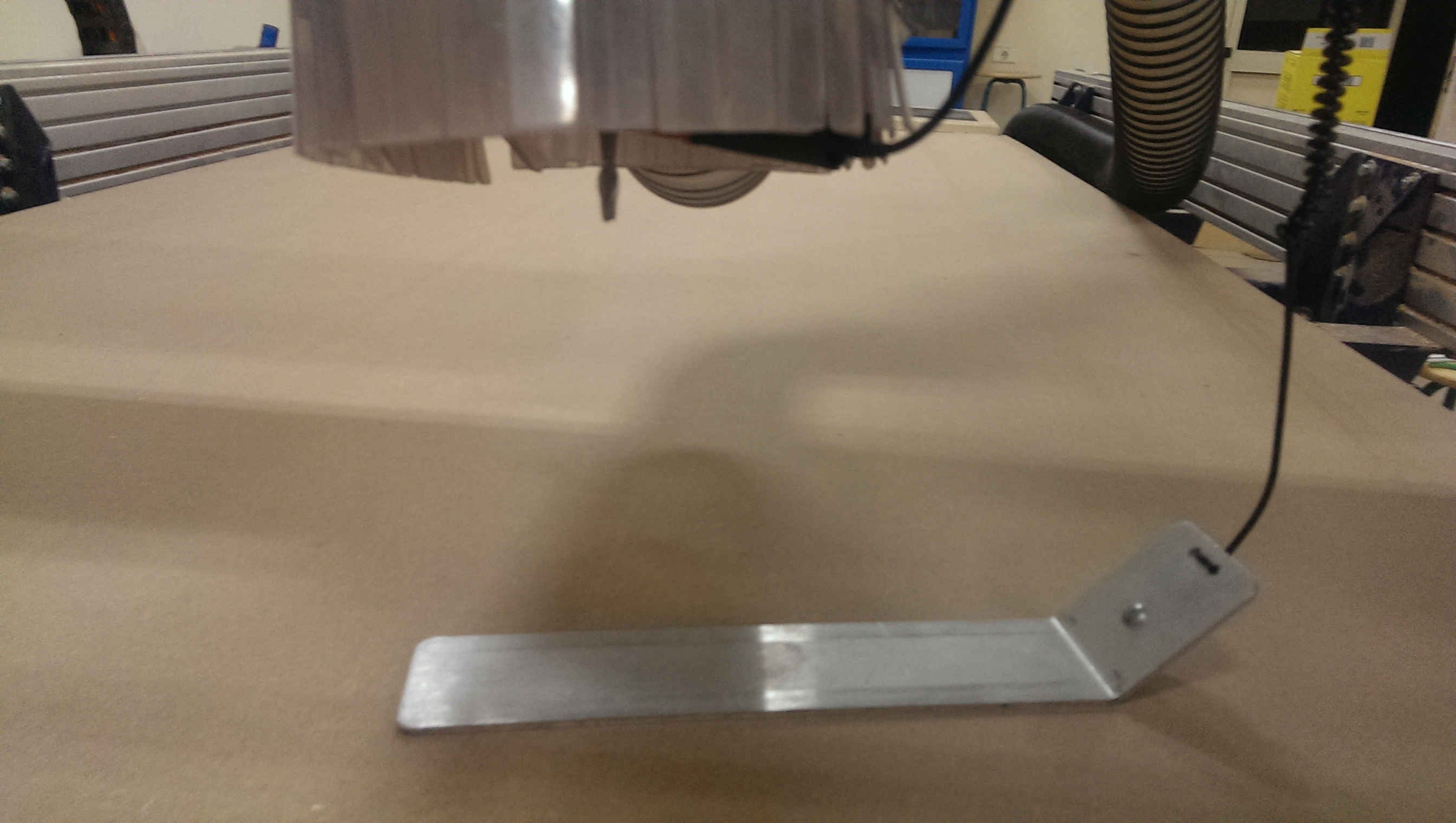

3- It is necessary to reset the x, y, and z origin.

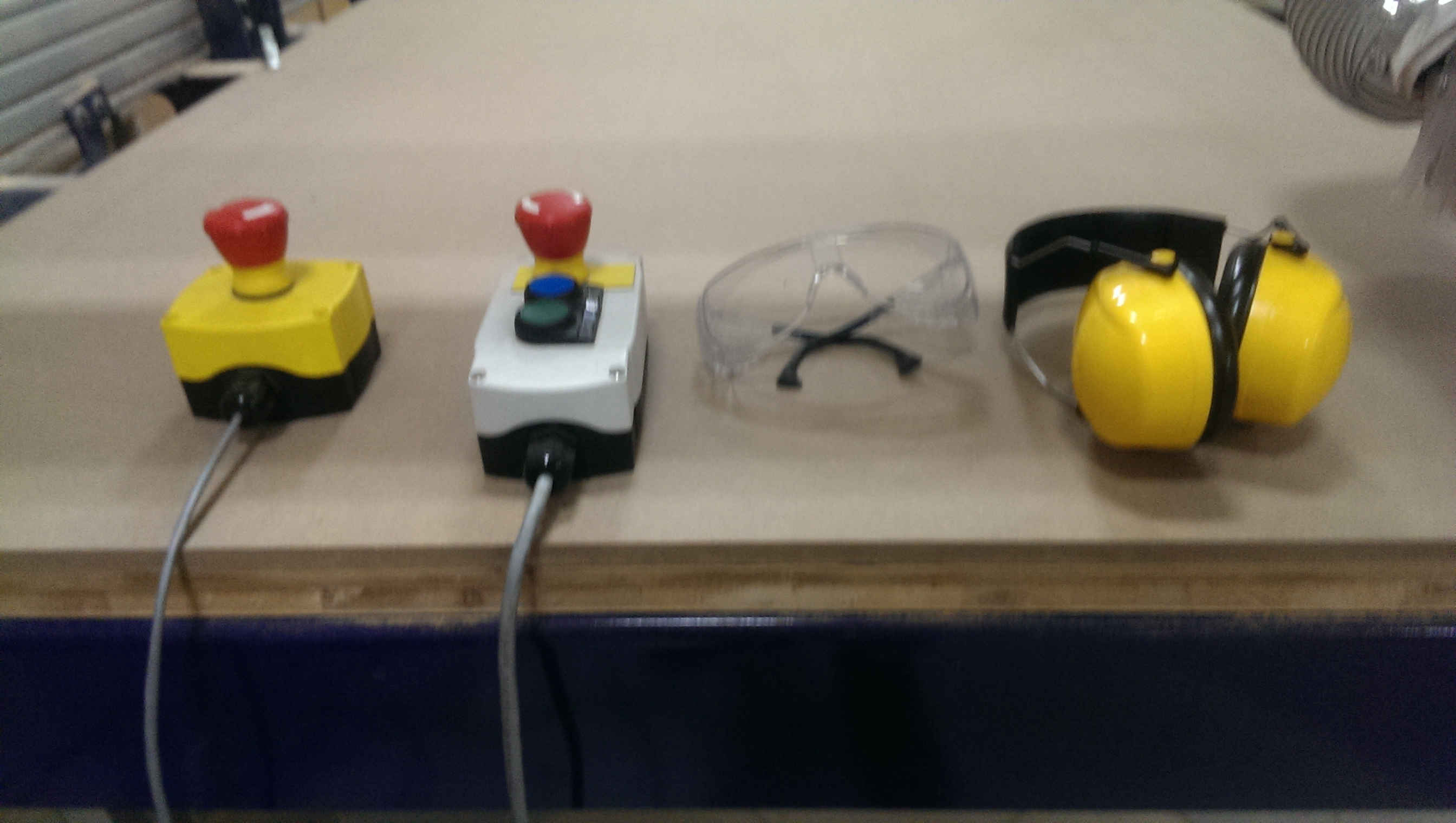

It is very important to wear the protection gear. And keep in mind to use the kill switch in any dangerous situation.

I imported the file exported from Vcarve into shopbot camm software and started execution.

Hands down the shopbot is the most interesting machine to work with. I really enjoyed this assignment. I couldn't move the hut to my home, but i will post a picture of the cats in their new house soon. See you next week !