Week 14

Composites.

This week's assignment is to design a 3d mold and produce a composite part in it.

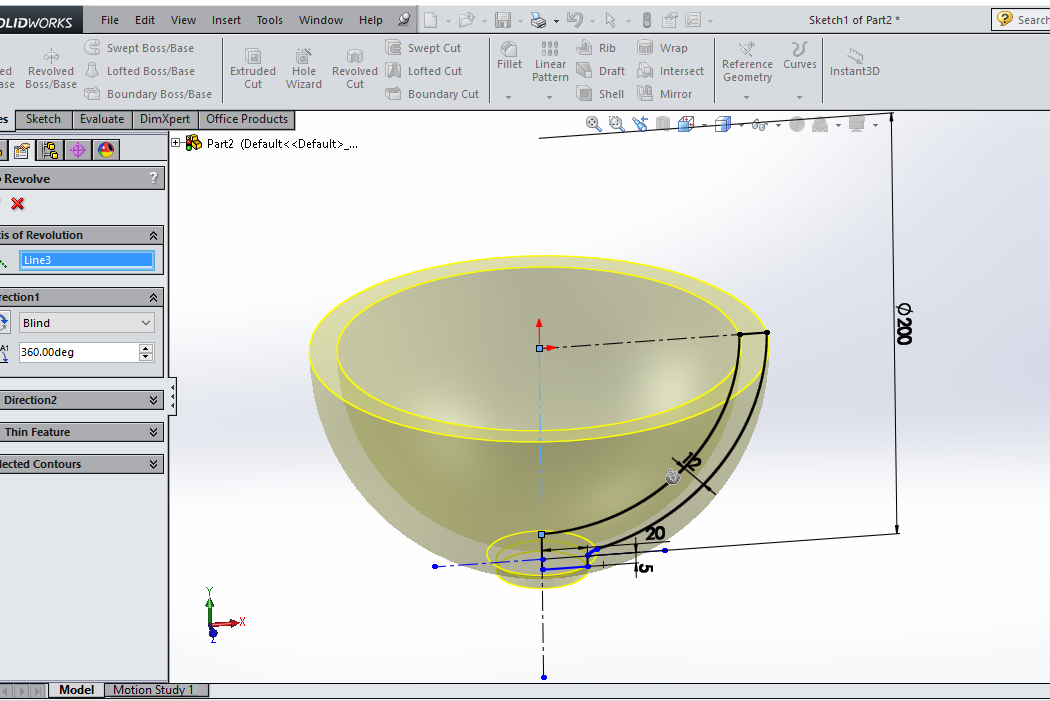

I designed a bowl that can be used to add fruit or food in it.

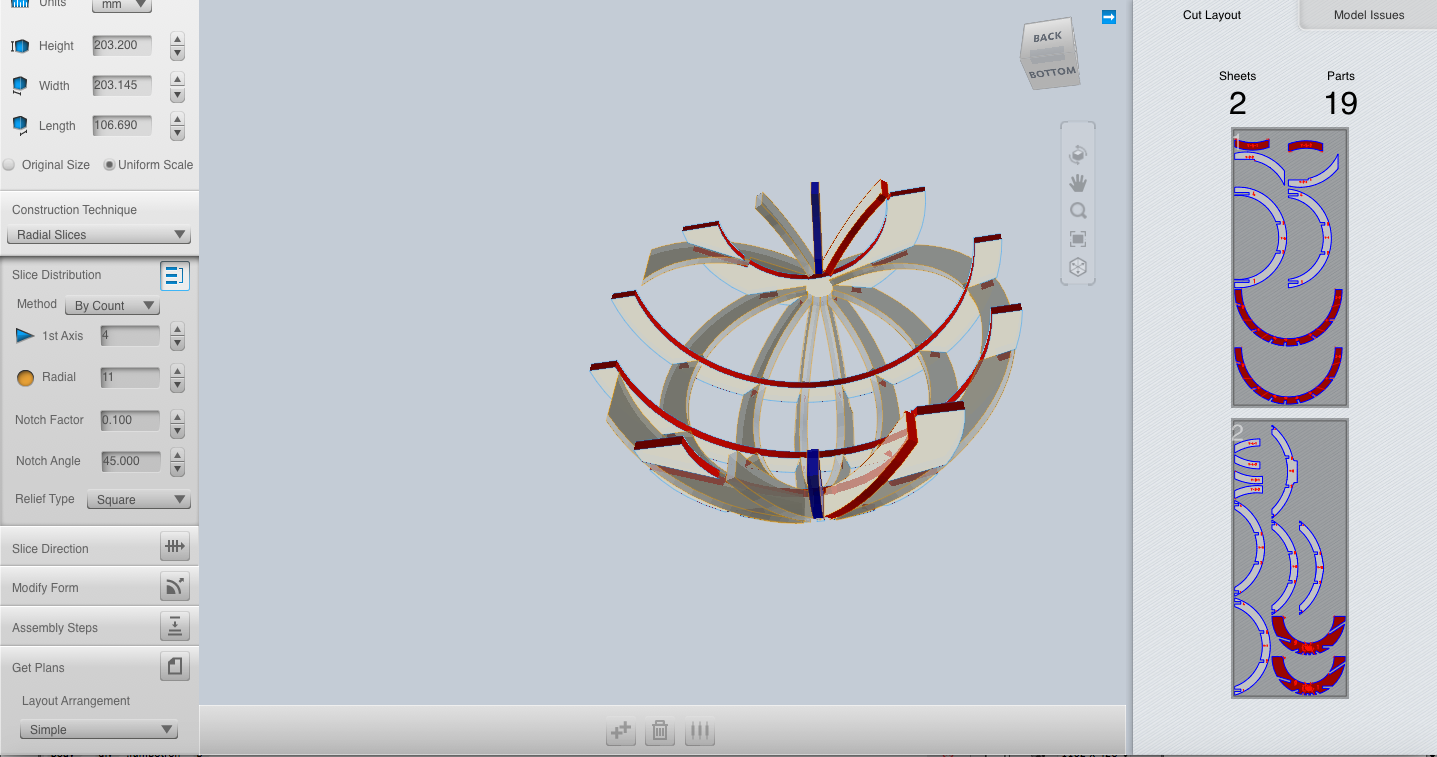

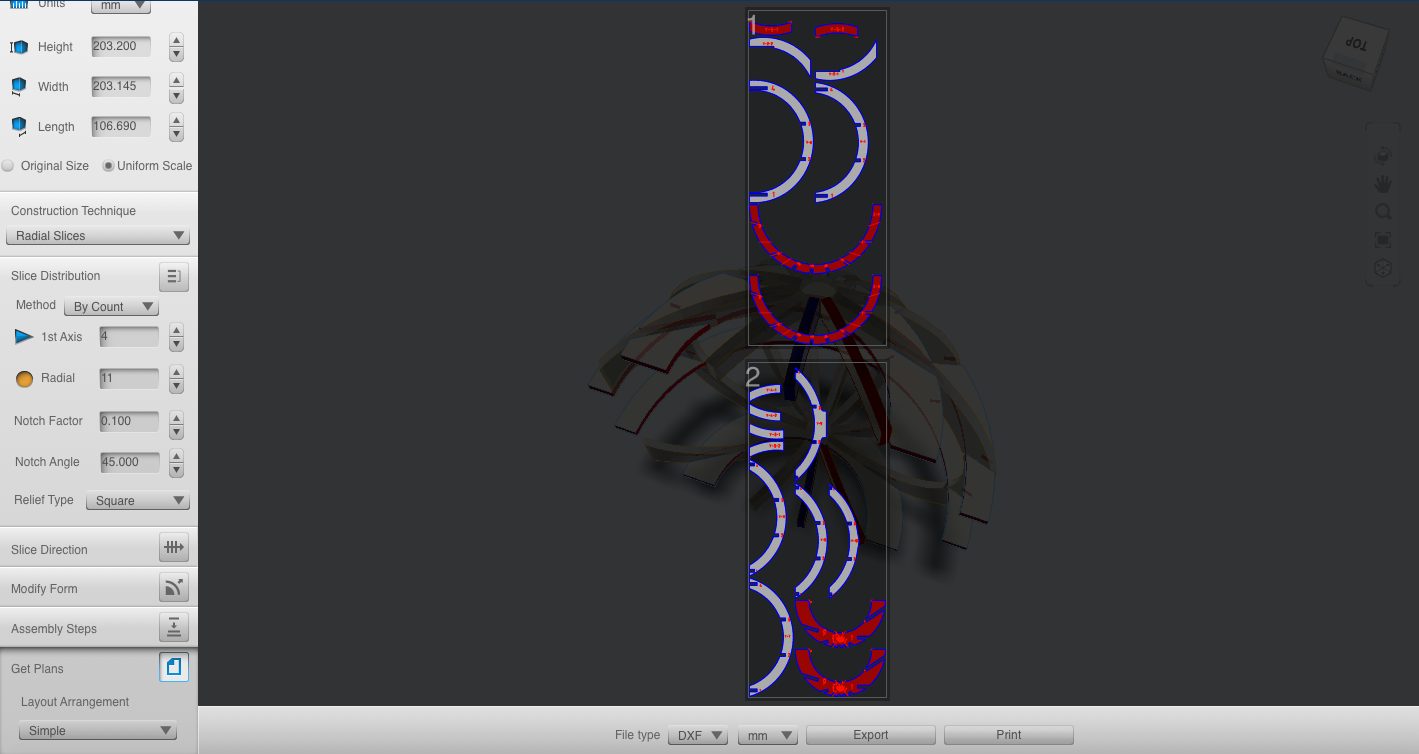

After i designed the 3D model of the part, i used 123make to slice it so i can machine the mold using the laser cutter. The software is so easy and helpul, i just had to determine a few parameters and it did everythin for me and even numbering the parts for assembly.

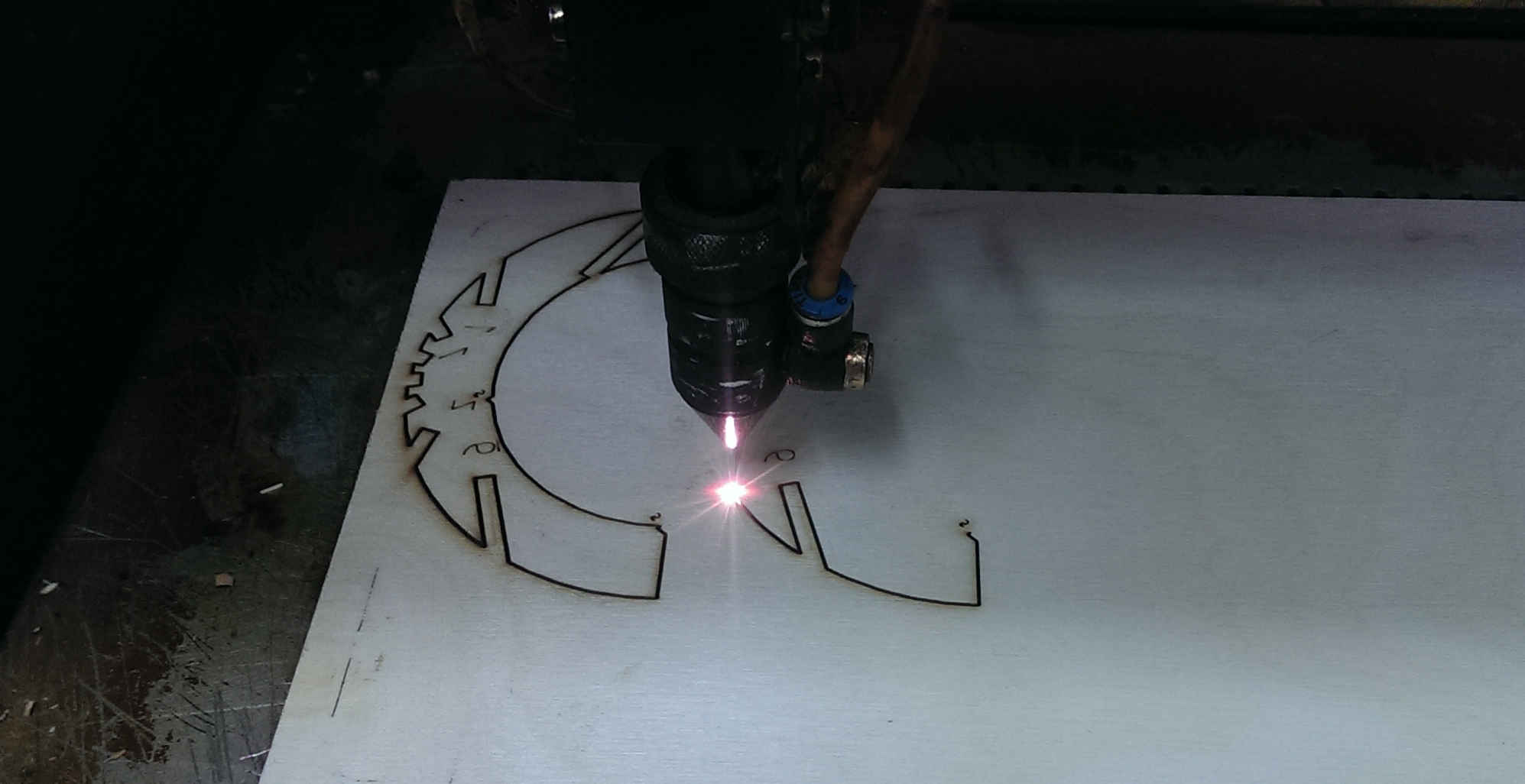

Then i cutted the exported DXF from the software on the laser cutter using 3mm Plywood.

The parts are labeled for easy assembling. The software shows step by step how to assemble the part. For the assembling the part i used glue to hold it together.

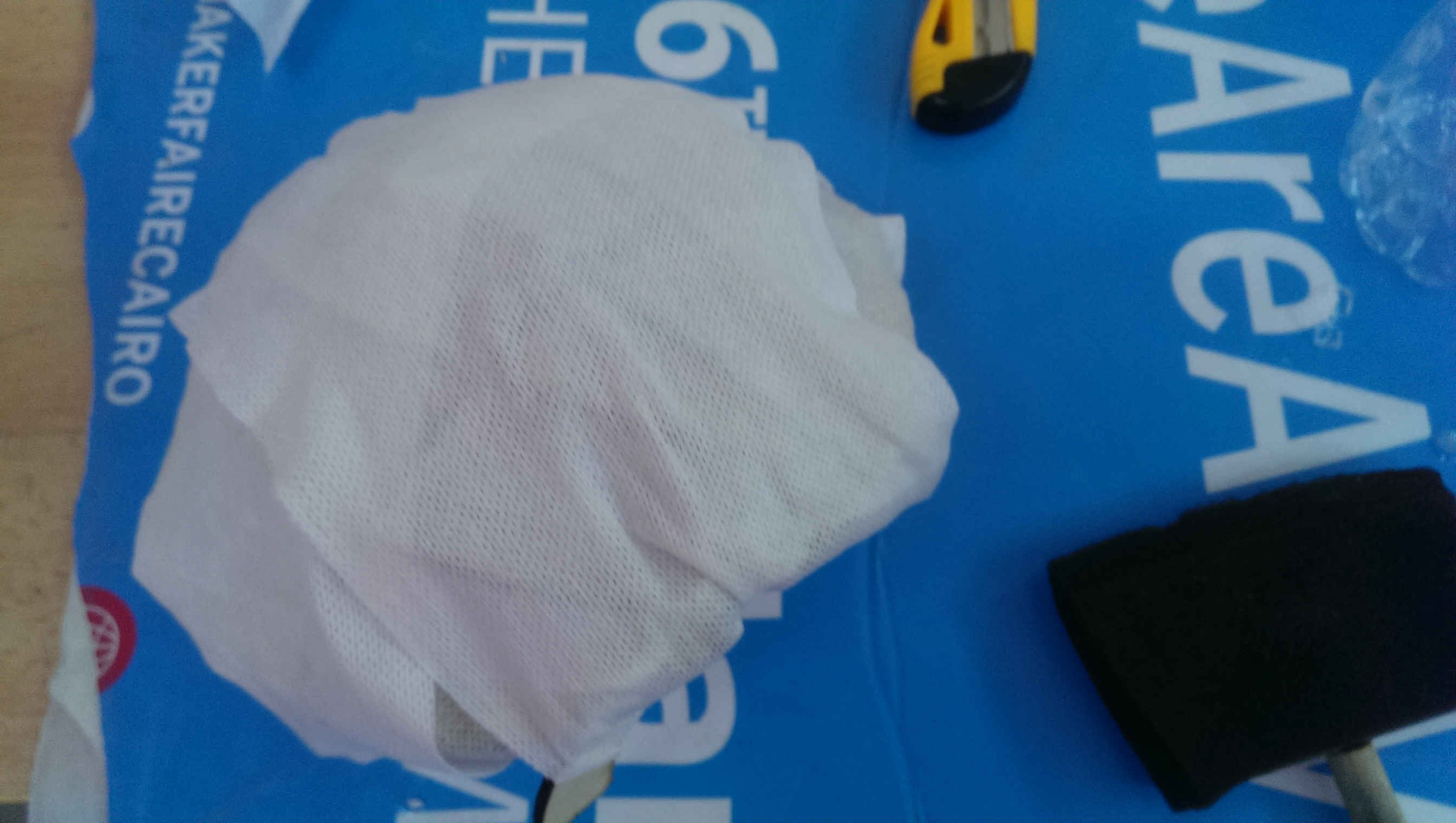

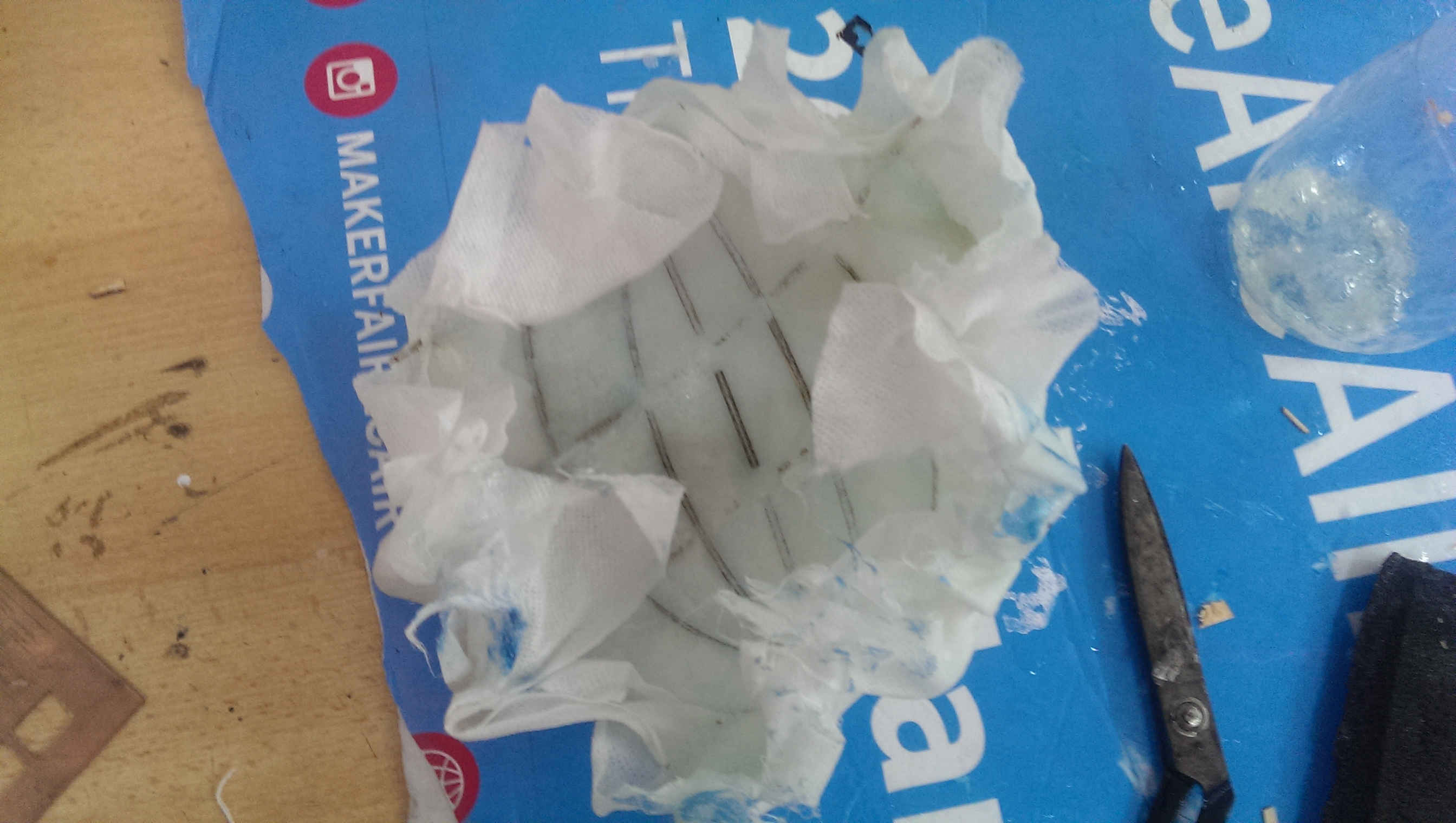

I used gauze as a fiber. I wanted to test something new in this assignment, I used the fast molding plastic instead of the exposy. I had the idea that this material will give the strength, adhesion, and very fast molding.

I wrabed small pieces of gauze around the part then covered it with the plastic. In this process i kept adding gauze and cover it with plastic, and finally left it to dry.

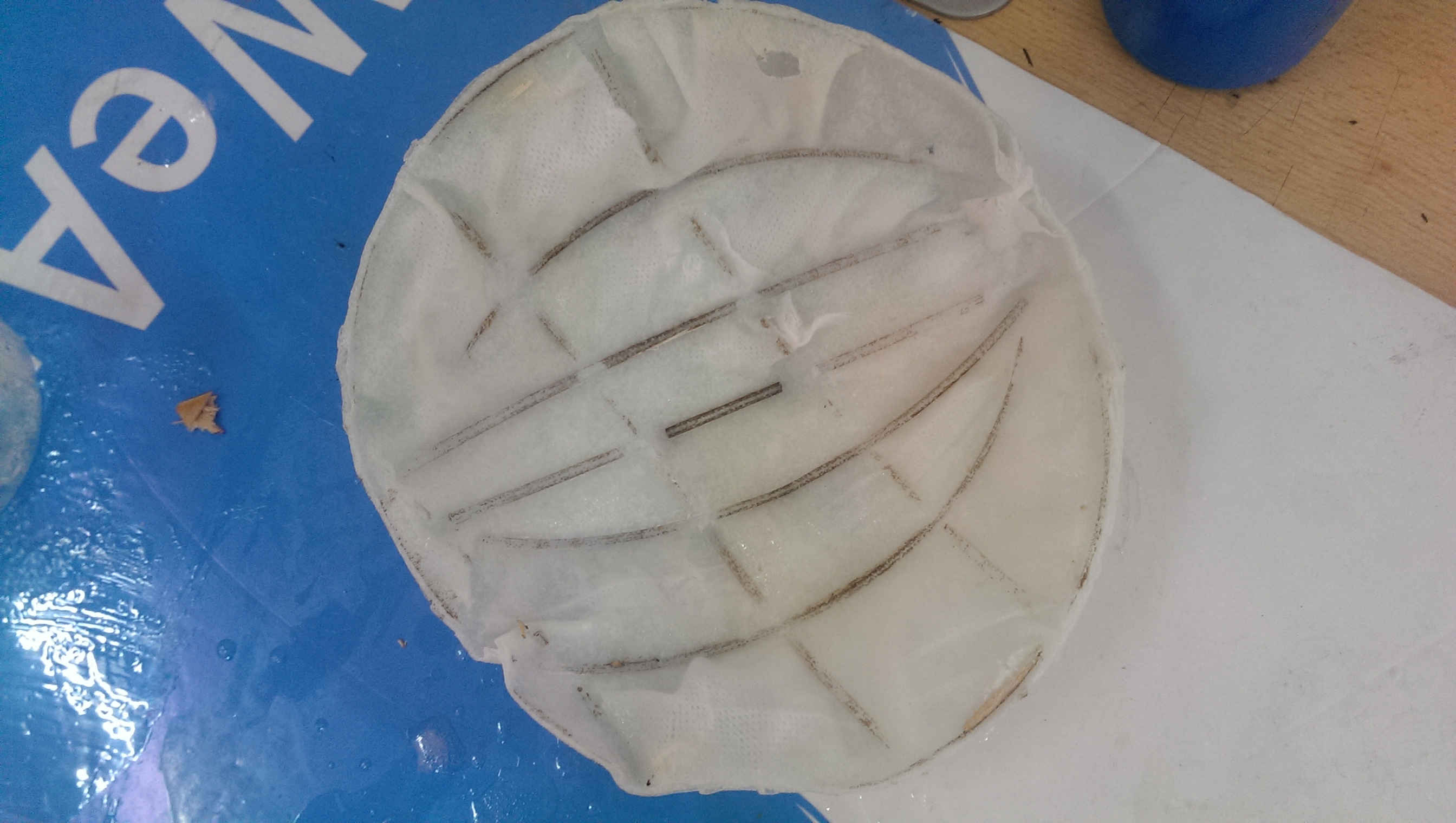

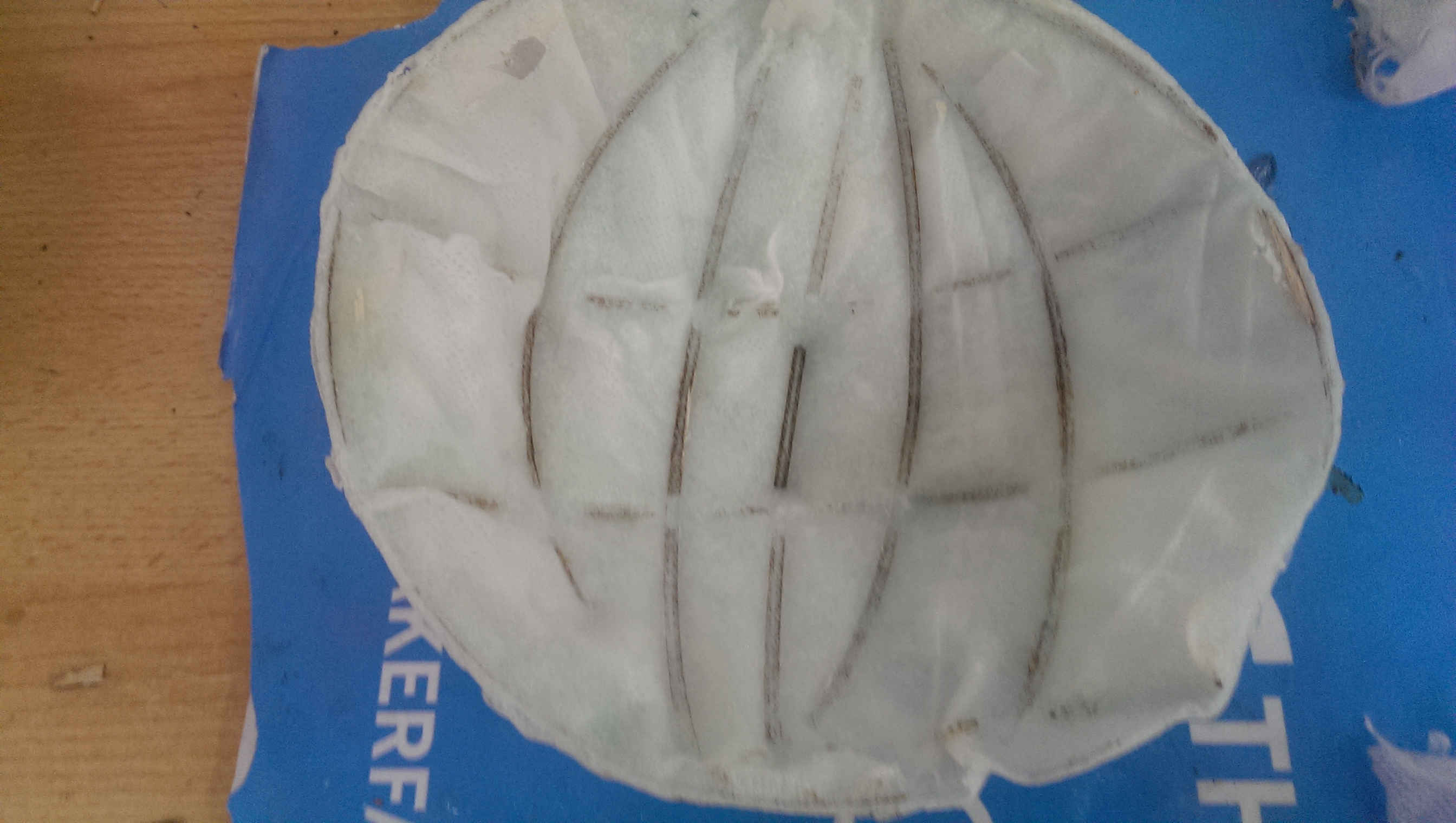

The part took around 1 hour to dry. I removed the wooden backbone of the part.

I chopped off the edges of the part using scissors.

The final part

I sprayed the part with acrylic spray to give it a good finish