* make something big

Assignment:

* make something big

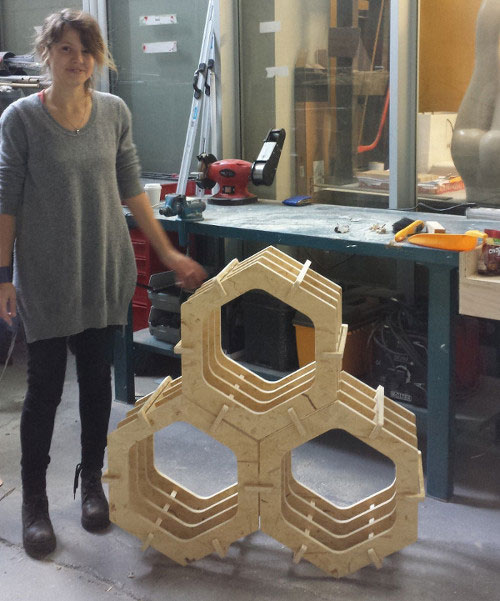

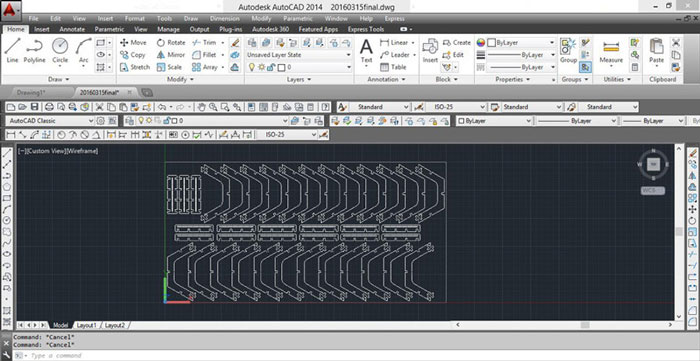

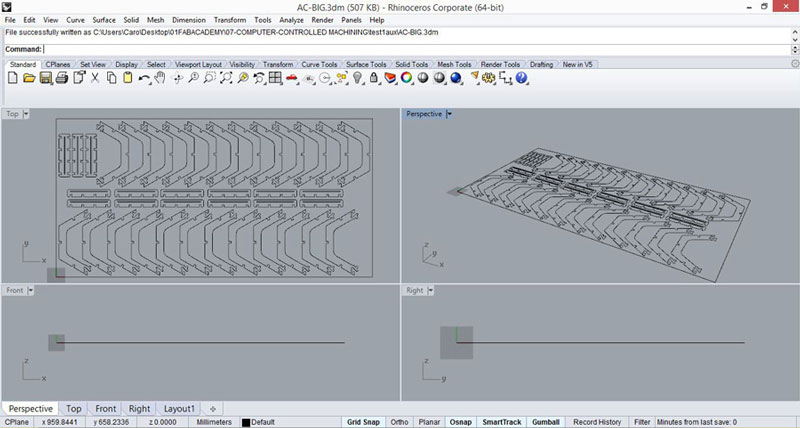

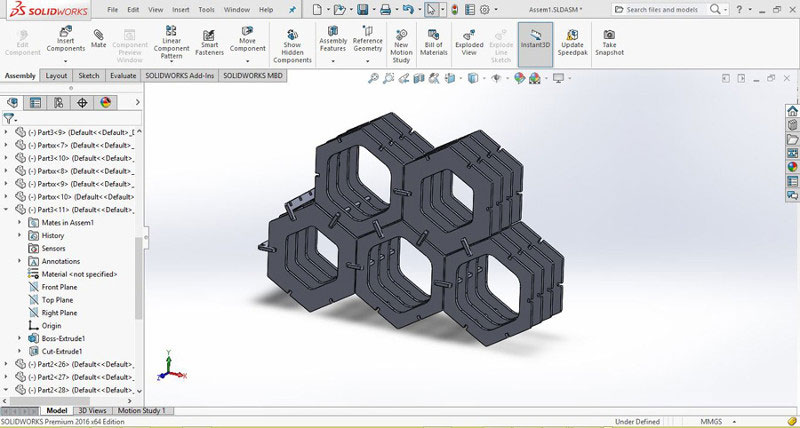

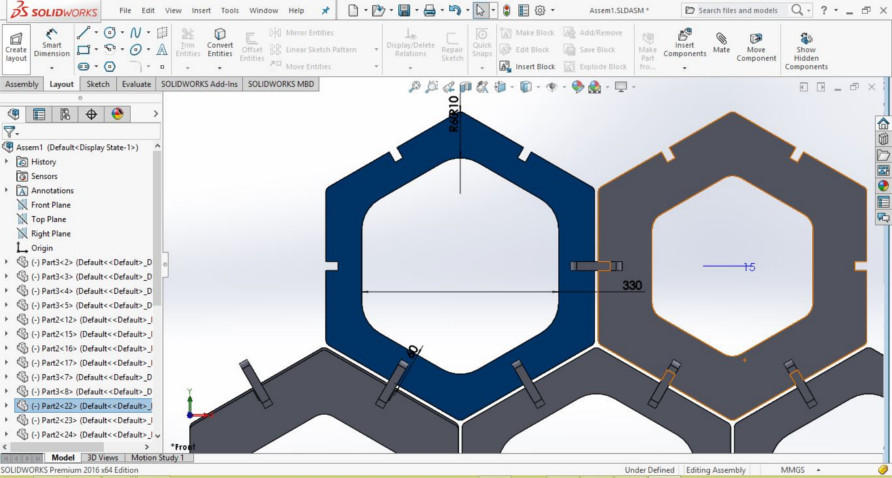

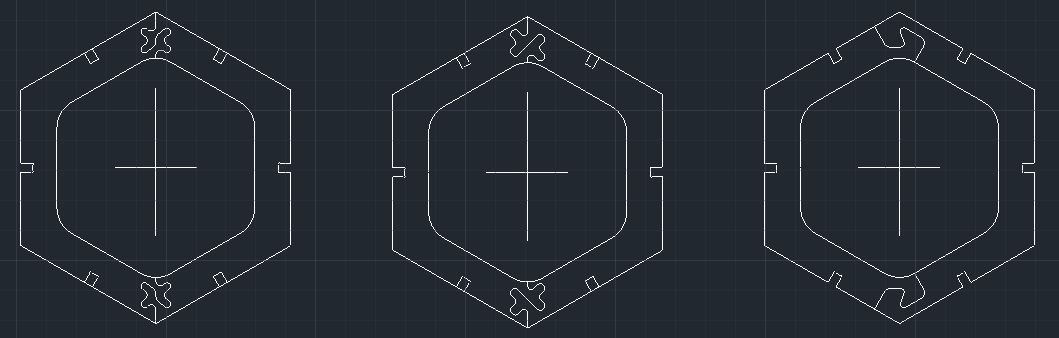

For this assignment I was inspired by the geometry of the honey, I wanted to use this geometry for making something big. At first I started drawing something by hand, then I made the model in 3d switching between Autocad, Rhino and Solid Works. This week we had a class of Solid Works by

Ferdi

so I wanted to use it.

LASER CUTTER TEST

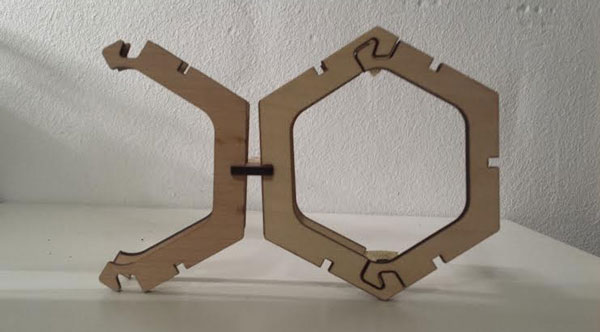

The milling machine was not working yet, so I did a test with a lower scale in the laser cutter to check the proportions.

G-CODE JOINT TEST

I have been trying with several joints, this video from

www.instructables.com, and this PDF Joints that Arnau sent to the group helped me with the design.

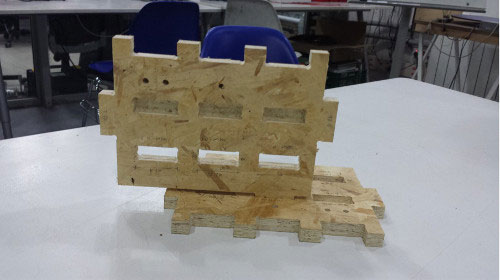

Finally I decided to do something similar to the joint of the video but more simple because the OSB is very nice but it doesn't has a very good quality like plywood.

With one of my classmates

(Cit)

we made a joint test before sending the whole design, to check different kind of joint and the 15mm OSB board thickness. We prepared the file in PartWorks:

* Exported the file from rhino as a dxf file and opened it in Part Works:

* Making the holes for the screws (for fixing the osb on the base of the milling):

* Adding the dog-bones, you can do it in Part Works or in your design:

* In Park Works you also can join the vectors that were open:

* Making the G-CODE for the screws (DRILL):

* Calculate:

* Making the G-CODE for the pockets (1):

* Calculate:

* Making the G-CODE for the pockets (2):

* Calculate:

* Making the G-CODE for the profile and adding tabs:

* Calculate:

Saving the files:

The order of the G-CODES is very important, that is the order how the machine is going to drill.

1-Drill

2-Pockets

3-Profile

My first experience with the machine wasn't good, I had a problem with the G-Code, I selected some holes for both files, drill and pockets.

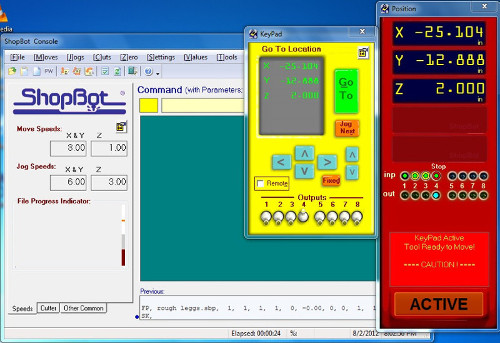

For this assignment I used the SHOPBOT:

* Set up the "Home" by moving it to the 0 position in X/Y (using the arrows from the shopbot console, it is important giving a safe height in the z-axis so it can be moved without touching your board).

* Set the Z axis (using the arrows from the console).

* Remove the tabs using the hammer and the chisel.

Sanding:

1 Module (the idea is that you can mill many modules as you want):