Week03 - computer-controlled cutting //////

Assignment:

Design, make, and document a parametric press-fit construction kit.

DESIGN

How to calculate the dimensions for making joints? It depends on the machine but for the first test:

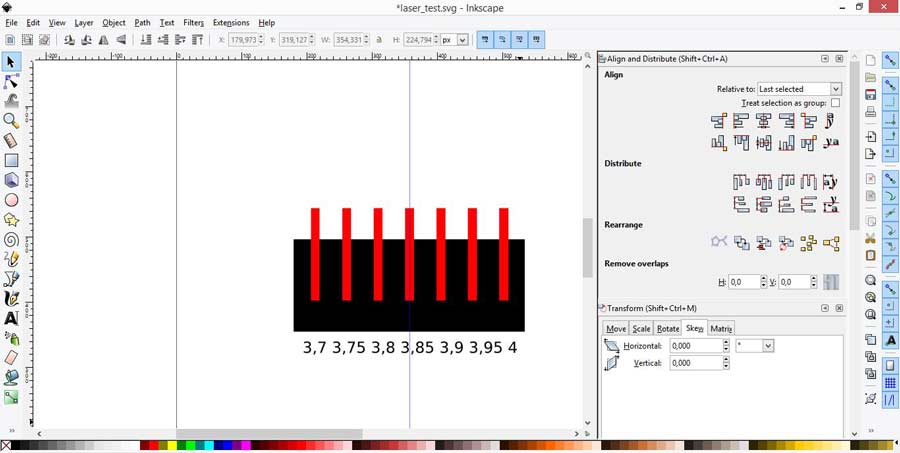

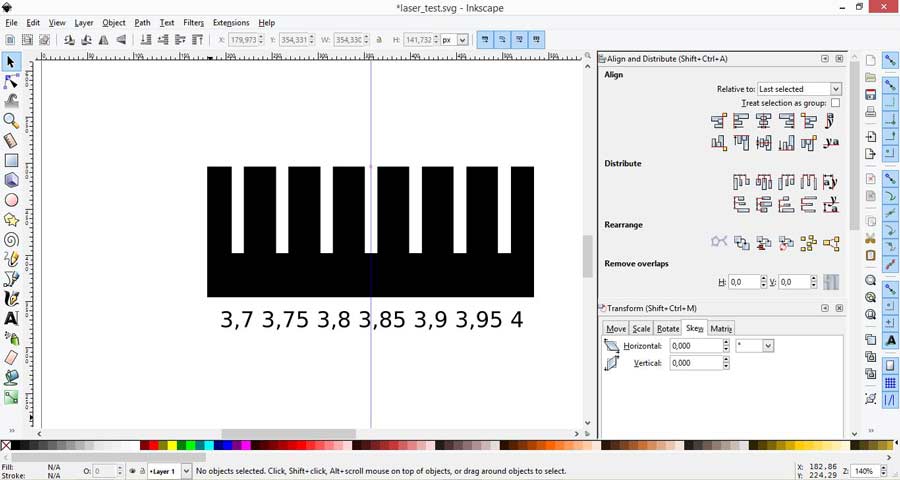

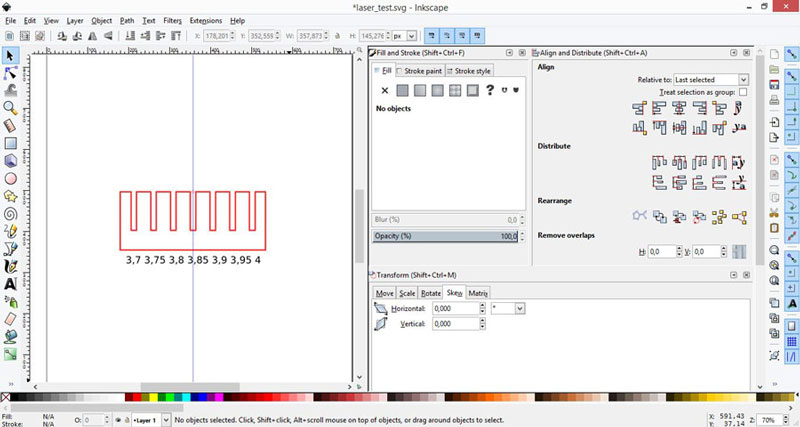

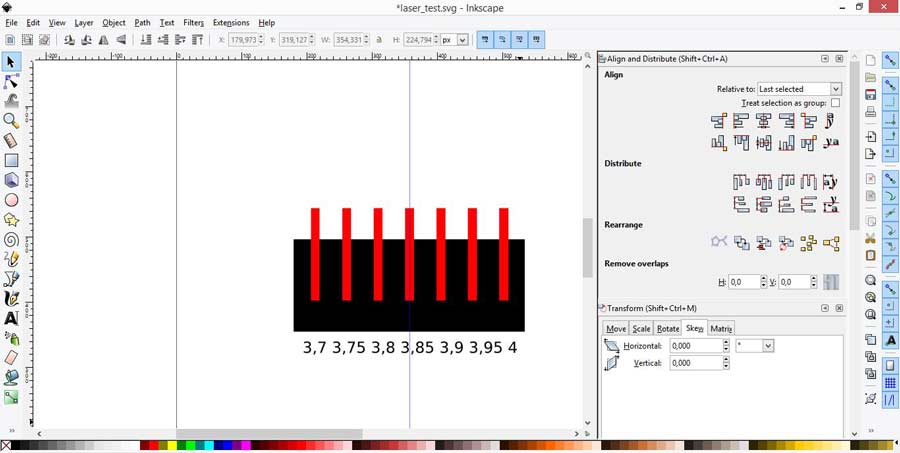

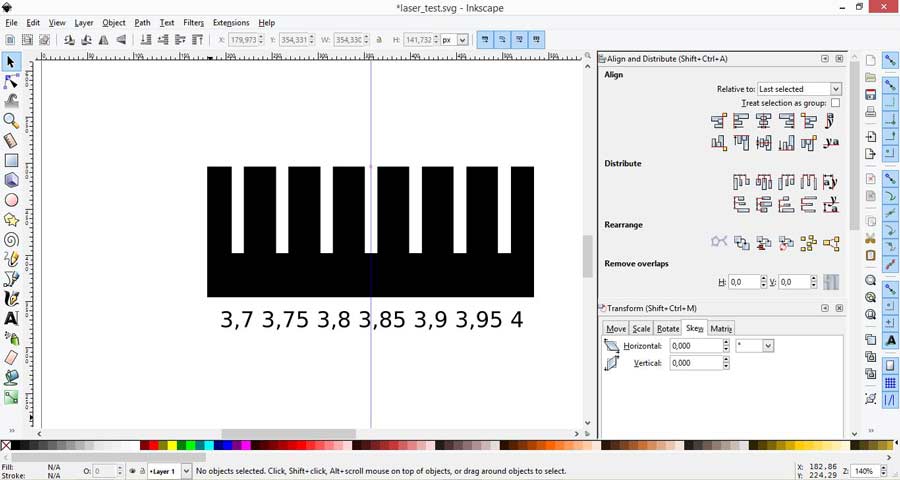

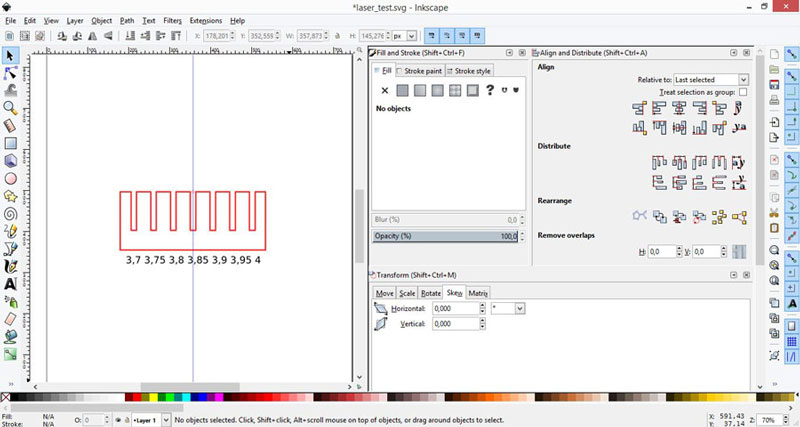

LASER TEST

Start with a simple drawing (in this case we use inkscape) without the stroke, testing different thickness, this test is for a 4mm cardboard. In my test the cardboard went from 3.6 to 4.1mm.

Save the file as dxf for the lasercutter:

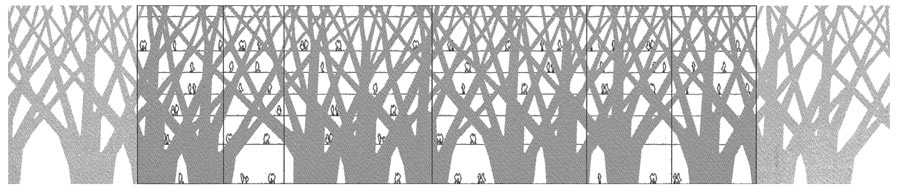

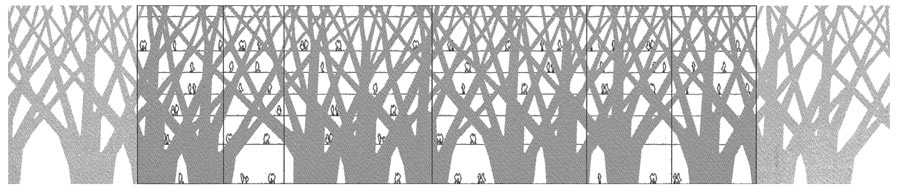

RASTER TEST WITH TOYO ITO

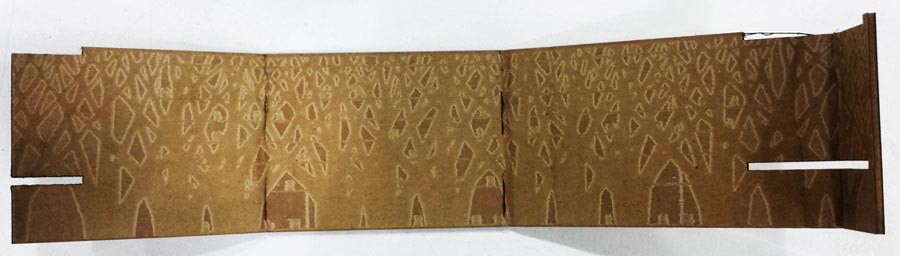

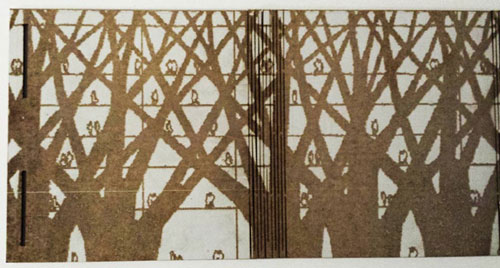

I did several raster testing with this image:

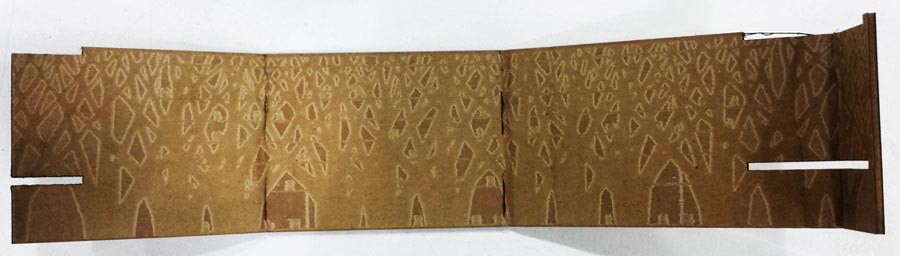

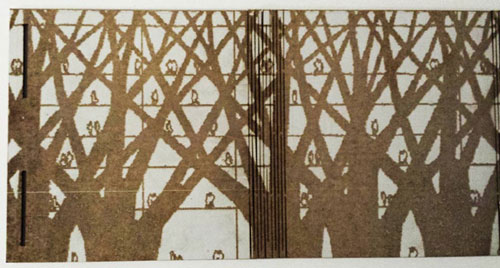

Test on cardboard, black and white image (jpg file, 72dpi):

Cardboard (3mm), Lasercutter (Epilog XT Legend 36 75w), time 10 min:

White Cardboard (2mm), Lasercutter (Trotec speedy 100), time 22 min:

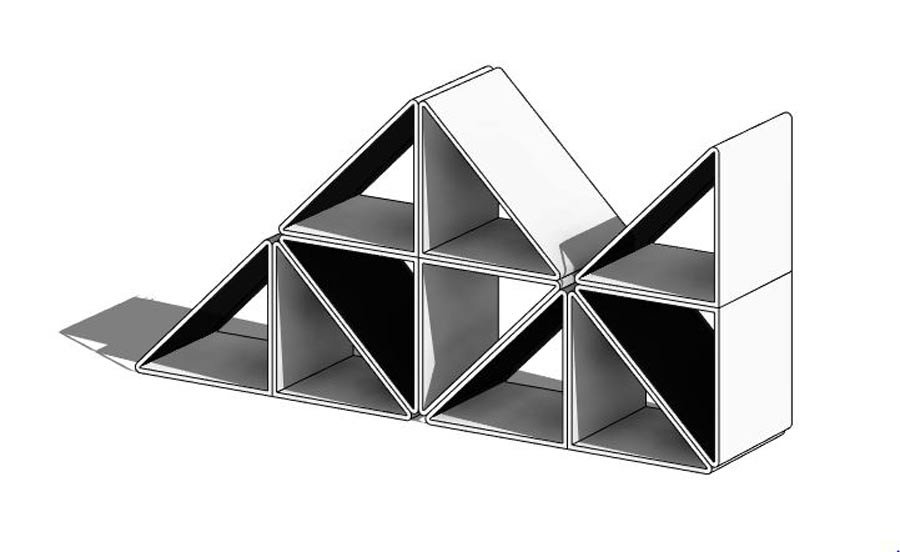

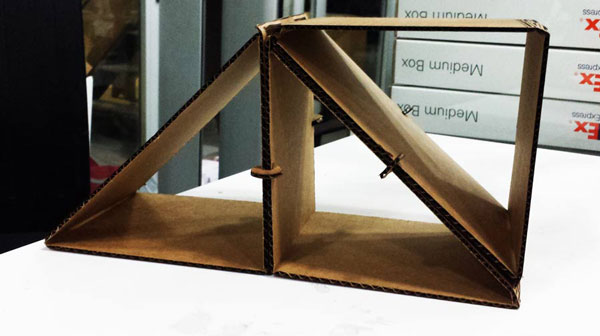

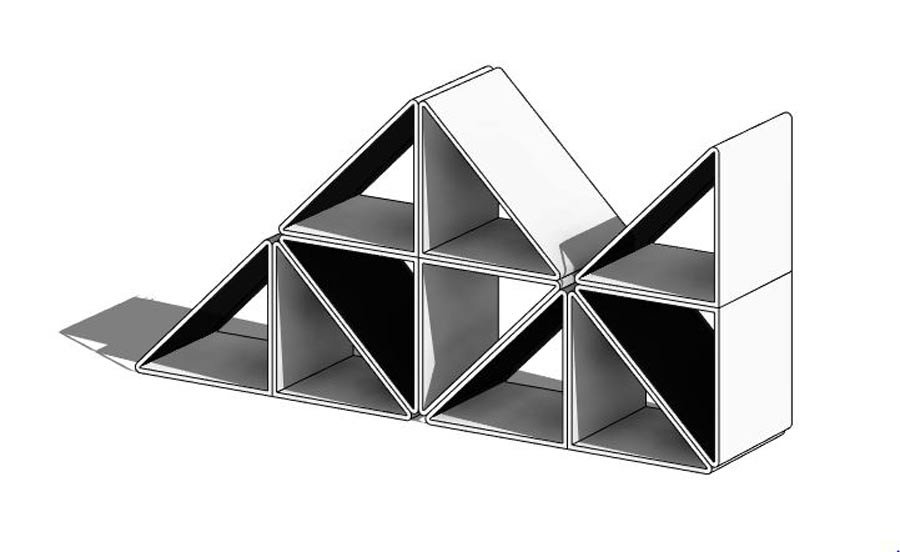

DESIGN-MODEL

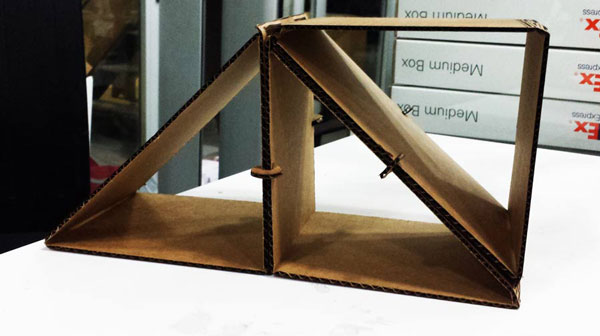

I don't know how to materialize my final project yet, so I wanted to do something simple and useful for this moment like a cardboard shelf.

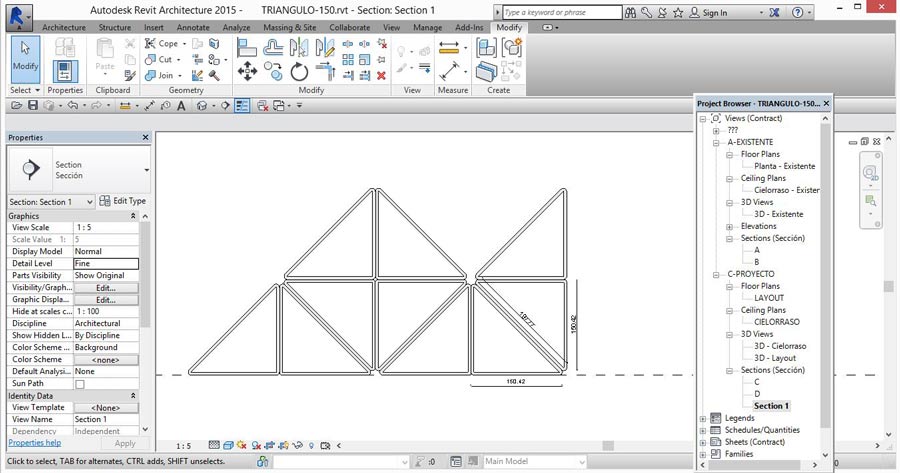

MODEL

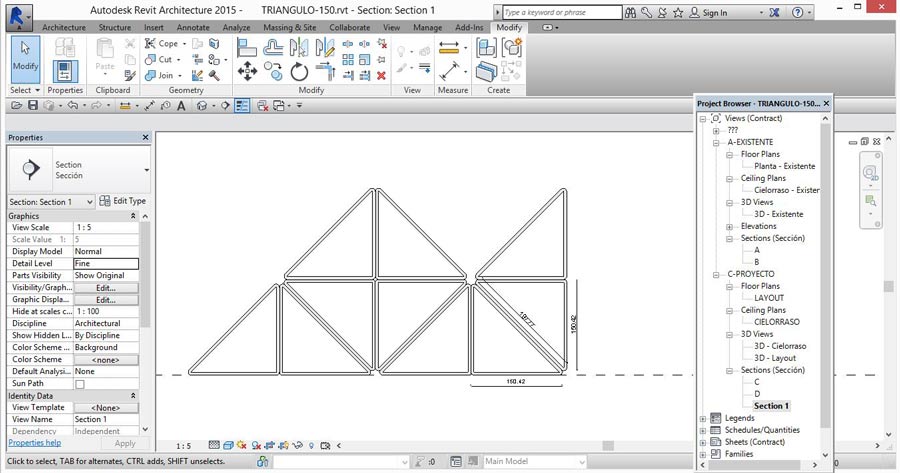

I made a simple model in Revit that can be modified very easily.

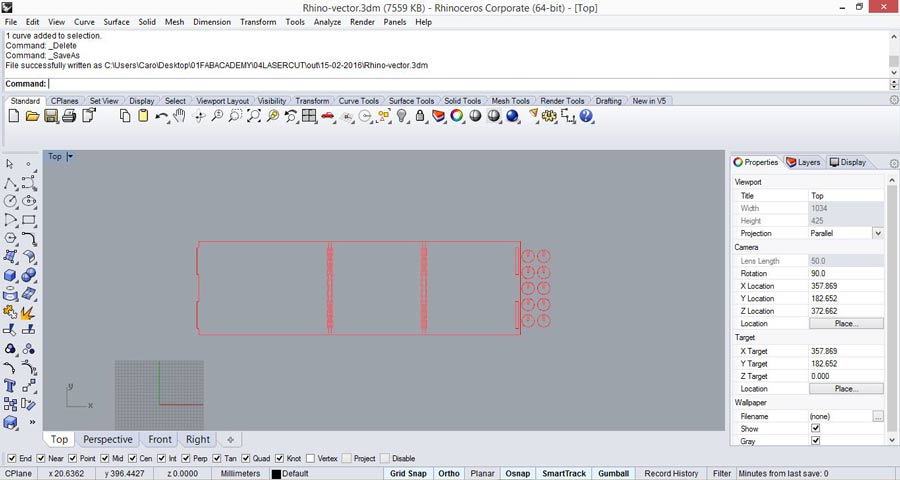

VECTOR

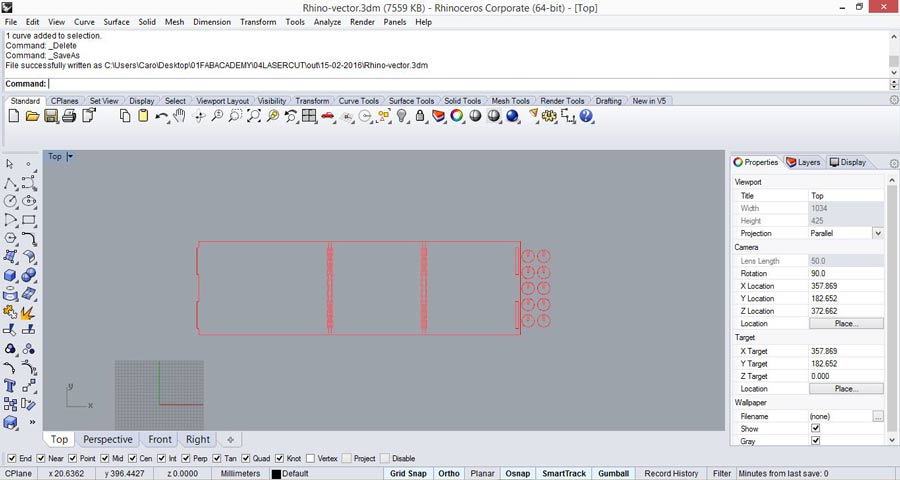

I made the vector design in Rhino.

MAKE

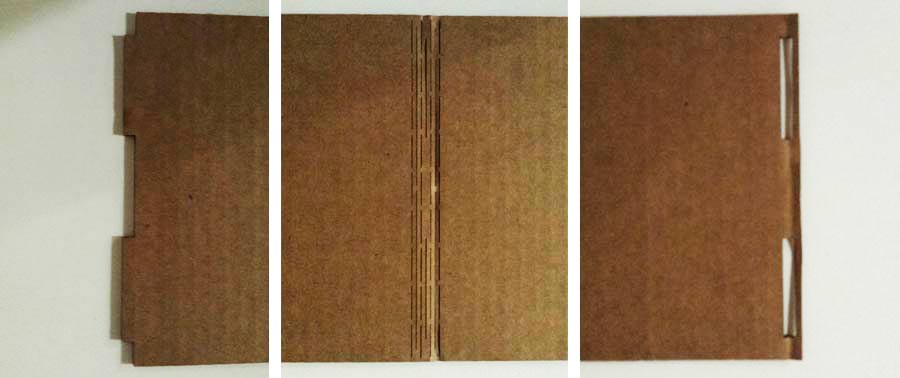

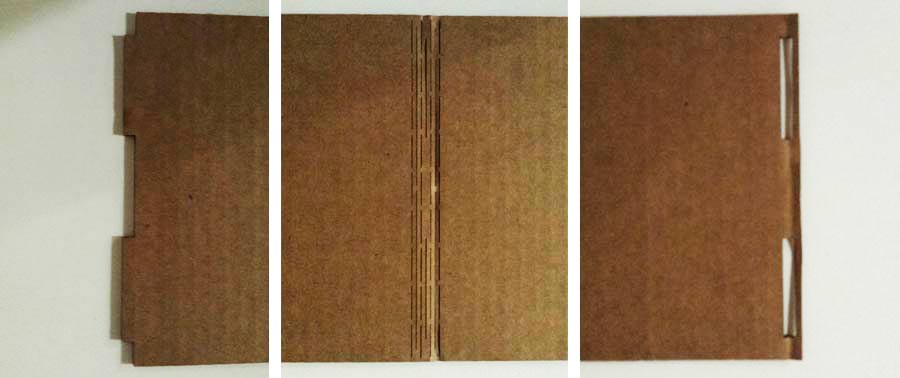

Cardboard (3mm), Lasercutter (Epilog XT Legend 36 75w):

JOINTS

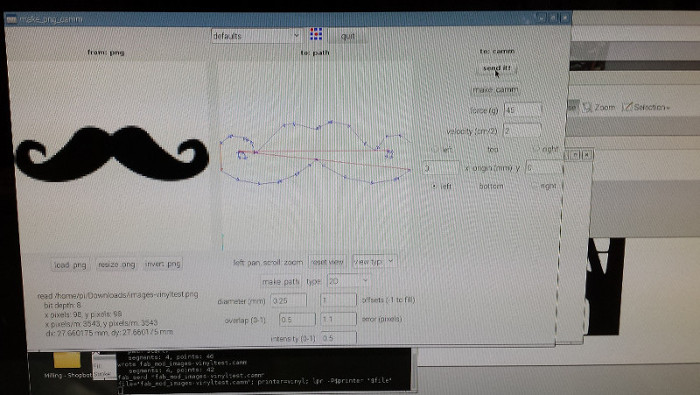

VINYL CUTTING

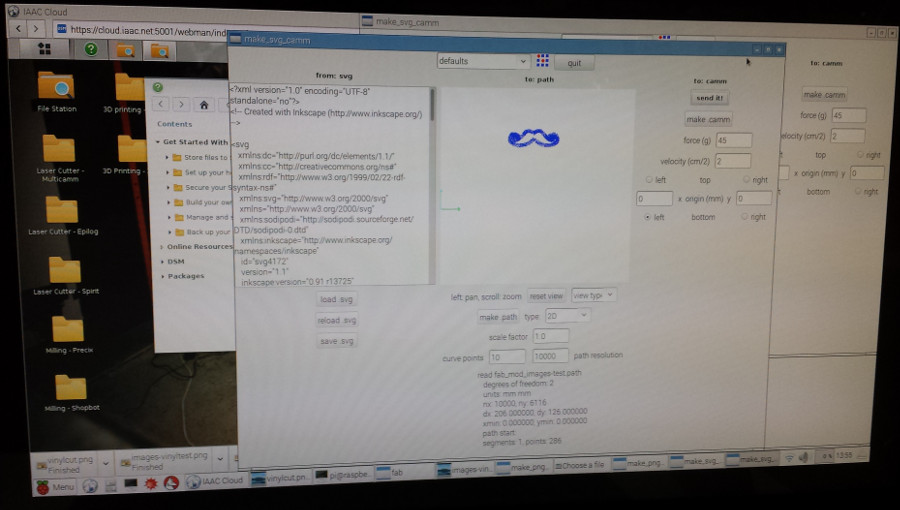

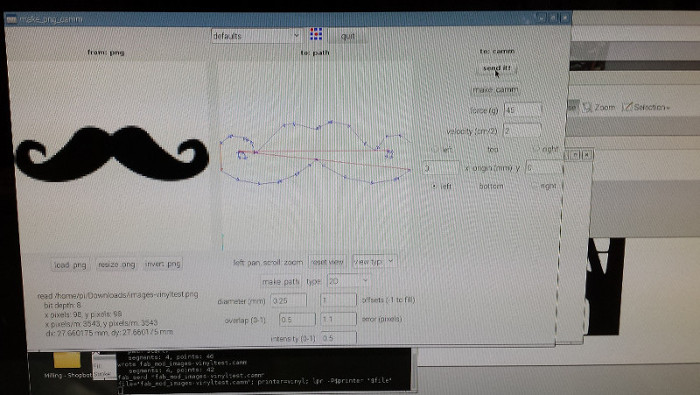

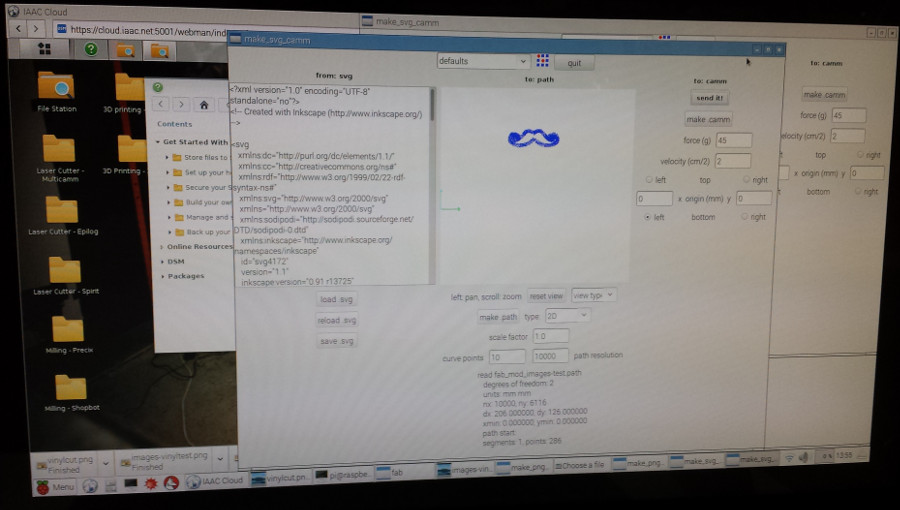

At first I only wanted to try the machine, so I downloaded a png image. I sent the file first as png but it didn't looks good, so I opened it in inkscape and set up the canvas with the dimensions that the Roland Vinyl Cutter gave me, I saved the file as an svg and I sent it to print using the fabmodules to generate the g-code (make-camm).

STEPS:

1-Set up the Roland

2-Open fabmodules

3-Open the file (choose the format)

4-make path

5-choose the material to cut

6-make.camm

7-send it

Download files

Download revit file

home