Week 09 - Mechanical Design

Assignment:

- make a machine, including the end effector

- build the passive parts and operate it manually

- document the group project and your individual contribution

- This week’s home work page

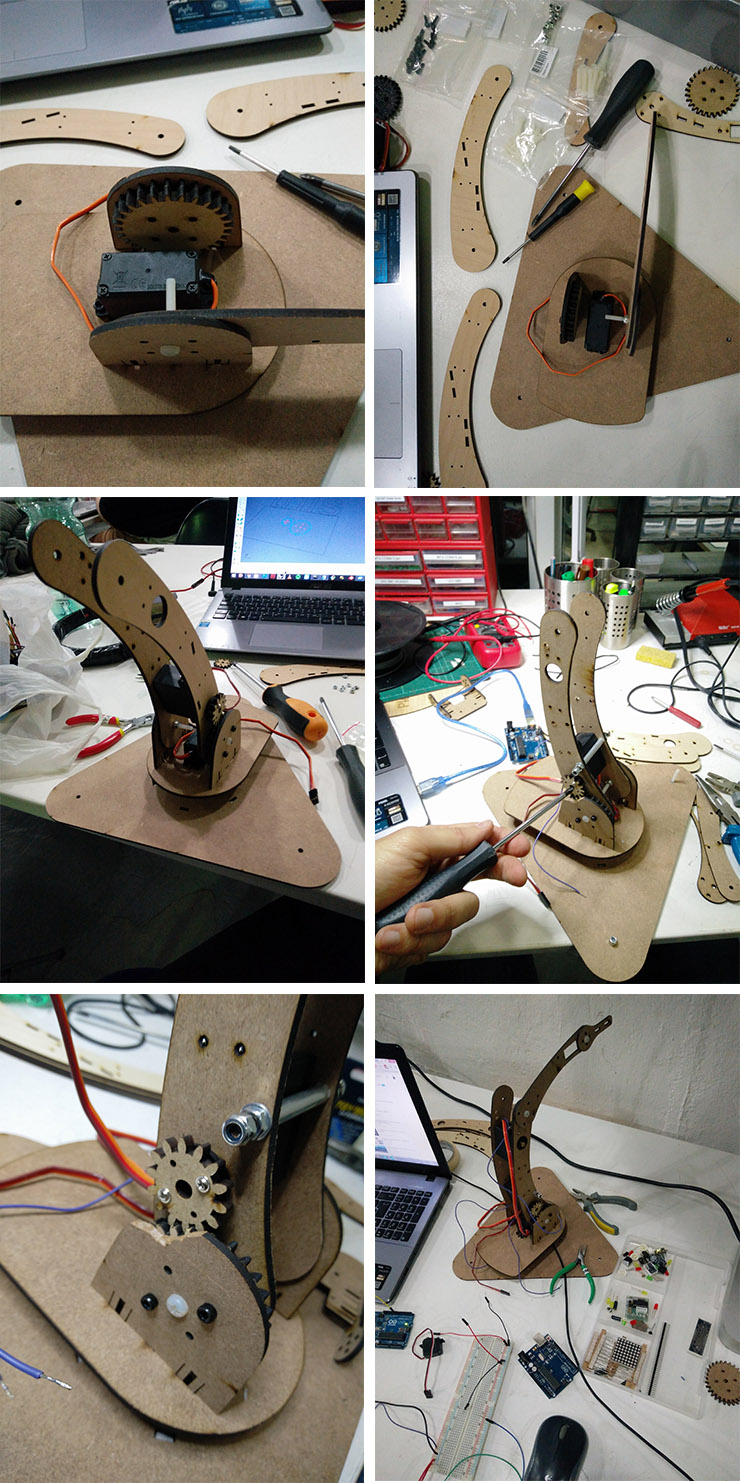

Laser cutted robotic-arm, servo assisted:For the group task, I couldn’t find anyone to join me since I took a project I have started back in Kamp-Lintfort and decided to go further with it. This robotic arm I started to design but never got to test if it would work. I did the design and Andreas Markwart was responsible to make it move (because before fab academy I have never had any contact with electronics before, It always sounded very scary to me.

I got the challenge to develop this robotic arm, because by then I thought I would use it for my final project. Also another reason why my fab academy colleagues decided not to join my project.

This task taught me a lot, made me face my electronic “fears” and after that I’m a huge electronics enthusiast.

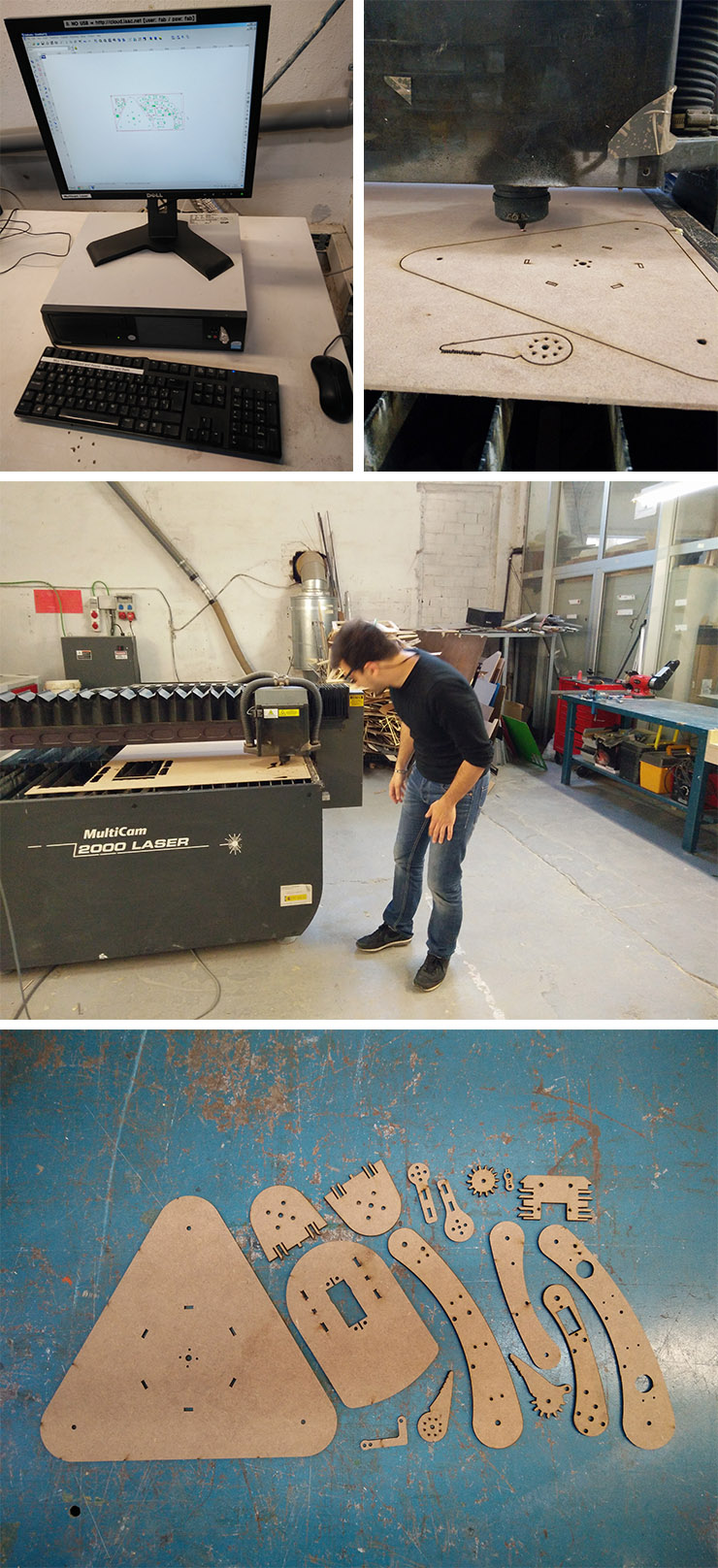

Laser cutting is much faster than 3D printing. Well, that's true. I'm not comparing them and their use. I like combining machines and tools, but this week I'm going for "fast" producing. I even tried 3D printing the gears but since the first try didnt go well and machines in our lab are much disputed, I decided to go for a full laser cutting robotic arm.

Combining these parts with an Arduino, screws and servo motors:

At this very own moment, I'm programming the servos. I got a 4th wire from the output of the potentiometer from the servo, to know and control its position.

Flickr picture's collection:

-Download my files::

...continues on week 10