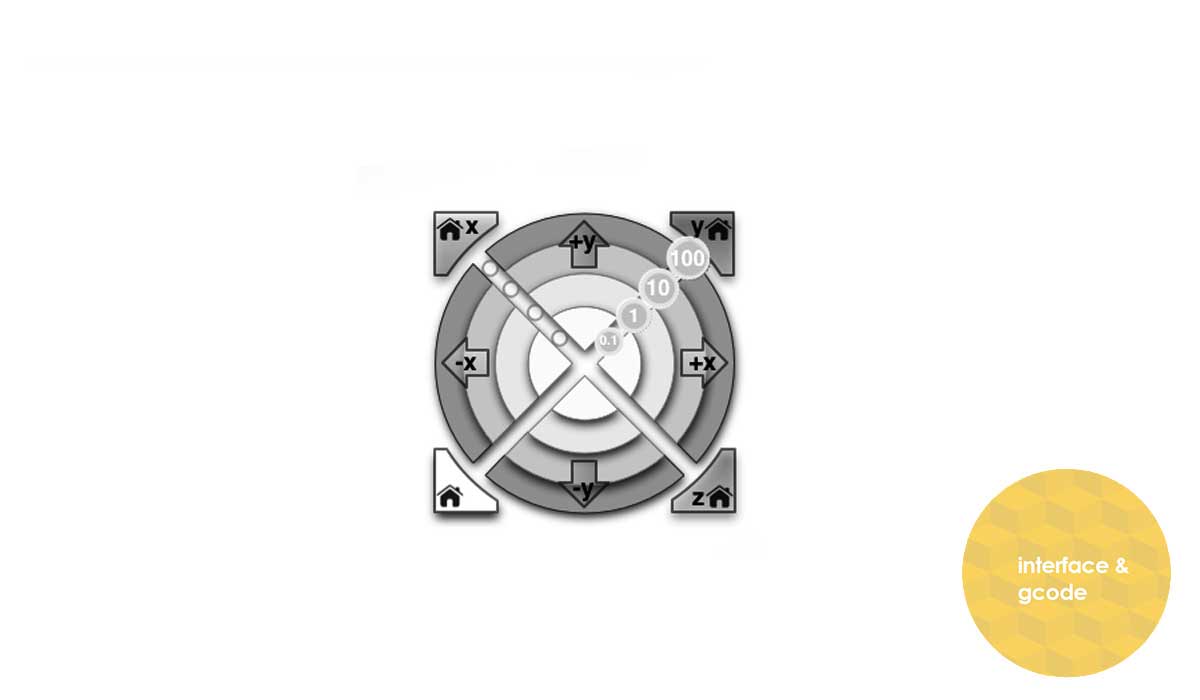

Interface & gcode

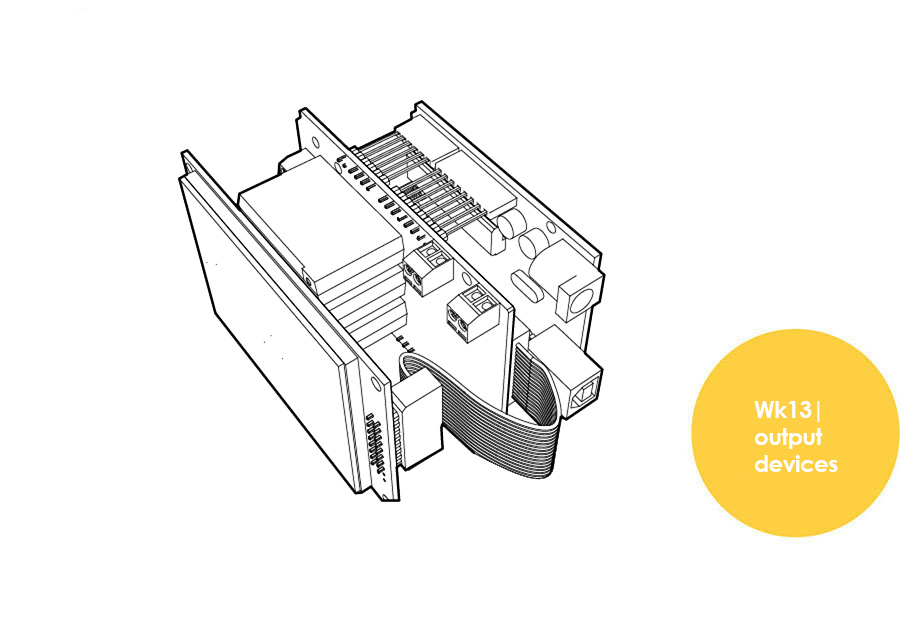

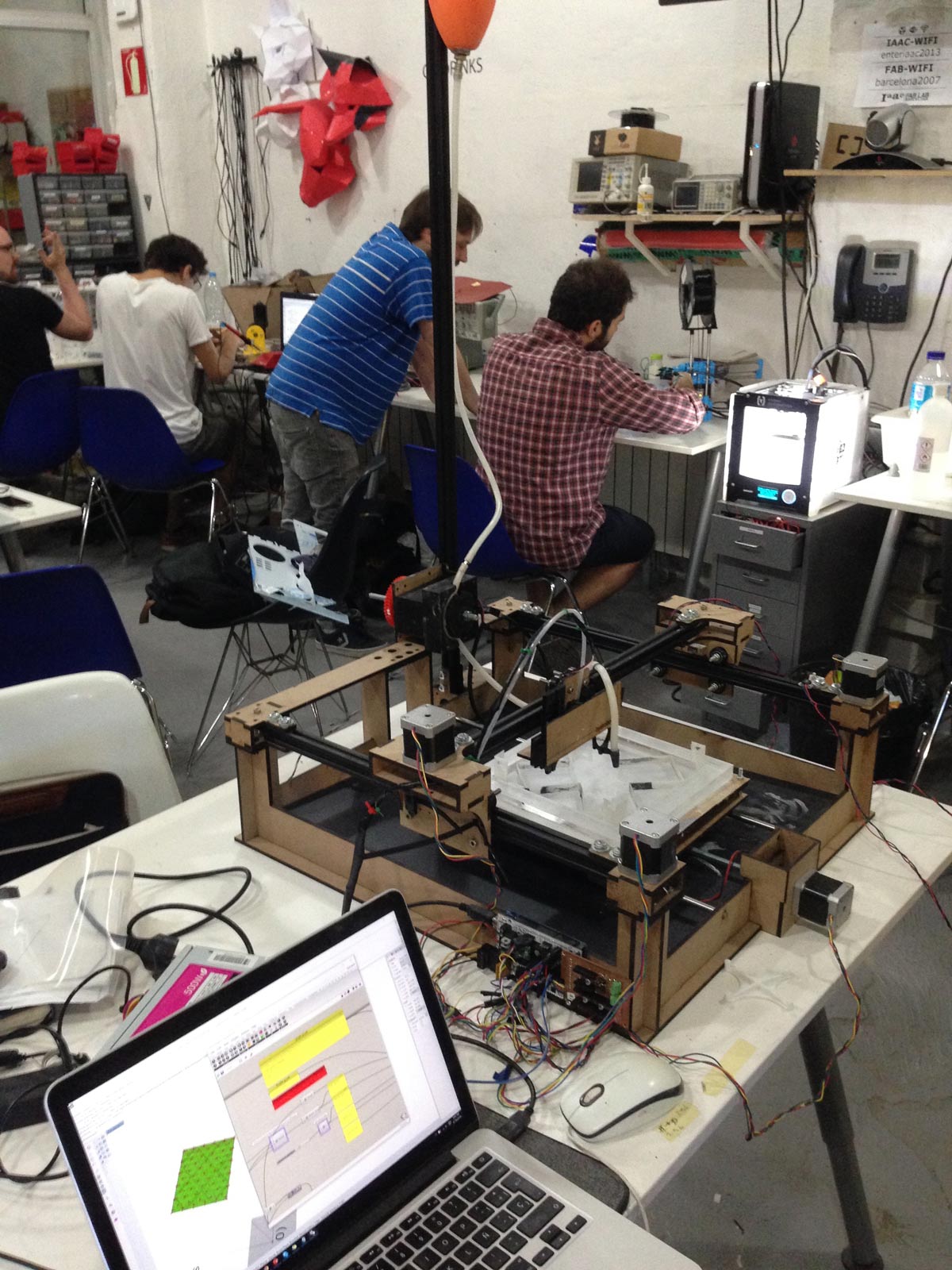

Marlin uses standard reprap G-code to run will all Gcode commands found here. I decided to organise my gcode by designing a grasshopper code. This would allow direct flow for designers to parametrically design and fabricate. Once the gcode is ready this is uploaded via Pronterface which also works as a manual interface.

Important gcode|

M280: Set servo position absolute. P: servo index, S: angle or microseconds (Marlin)- note for continuous motors S0 in down S180 is up

G4: dwell: Pnnn Time to wait, in milliseconds Snnn Time to wait, in seconds (Only on Marlin and Smoothie)

M106: Fan on Snnn Fan speed (0 to 255)- used as vibration motor in my case

G28 X0 Y0 : Move to Origin (Home)

G90: Set to Absolute Positioning; according to home position

G21:Units from now on are in millimeters.

Note: when setting the machine it is helpfull to use gcode M119 to check endstop status. For some reason i had to cut off vcc supply to the endstops for them to work.

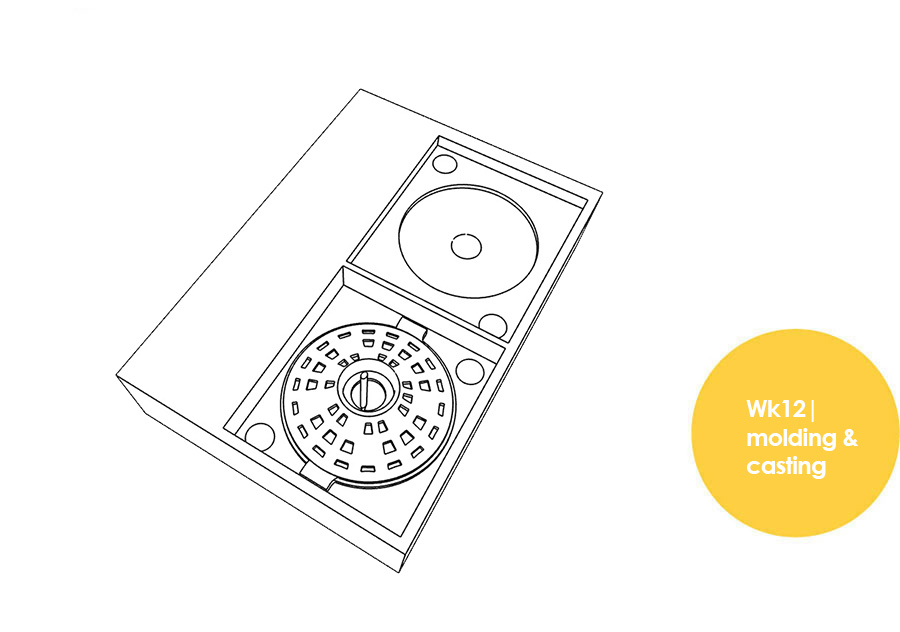

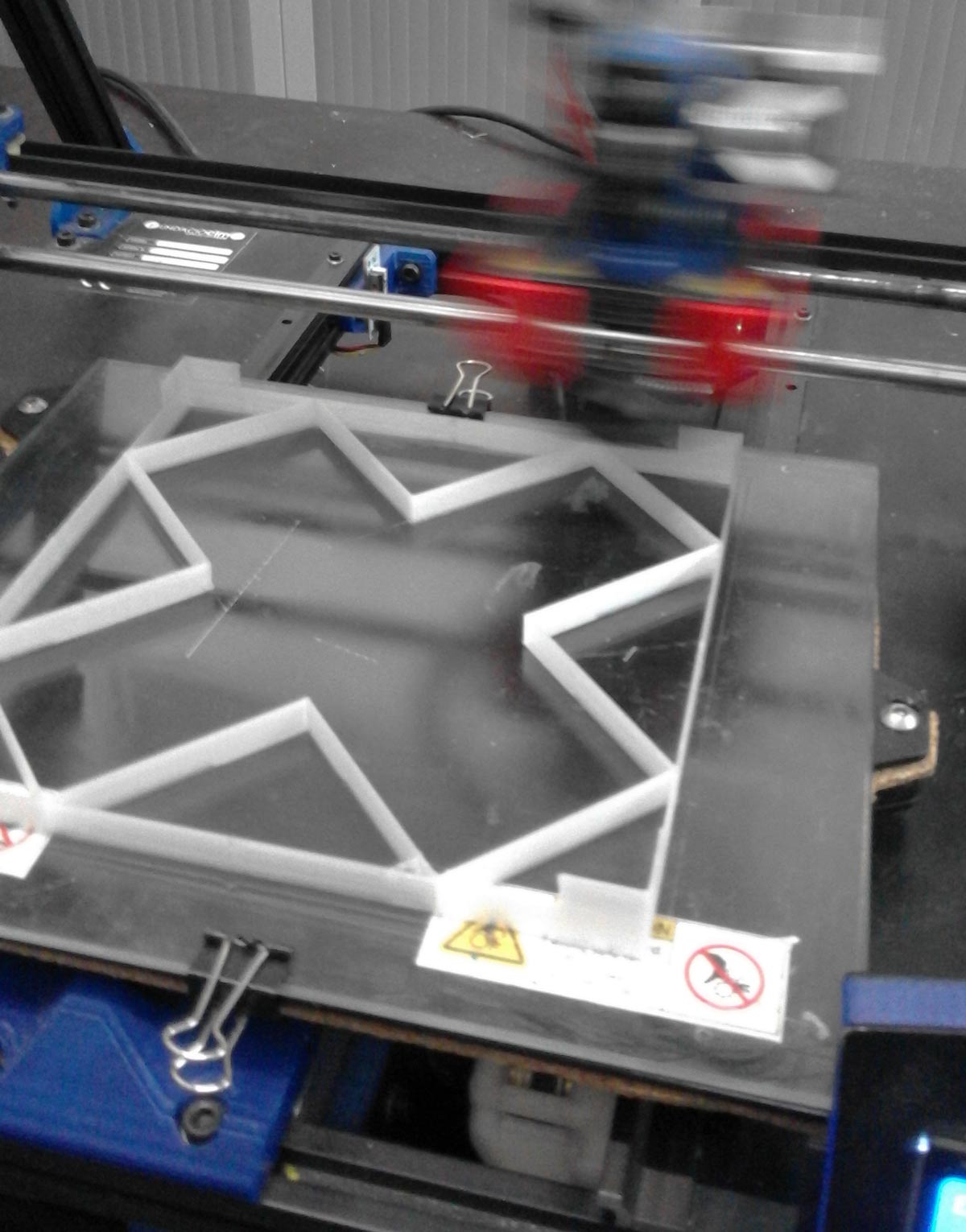

Below is the formwork generated from the design in grasshopper; which is 3d printed using a dfferent machine. The same defenition is used to create gcode for the hydrobot to extrude material in those chambers.

This is the scenario:- grasshopper creating the design and gcode; 3d printer to design formwork; hydrobot to infill prints with other material

|Download all files