hydrohack

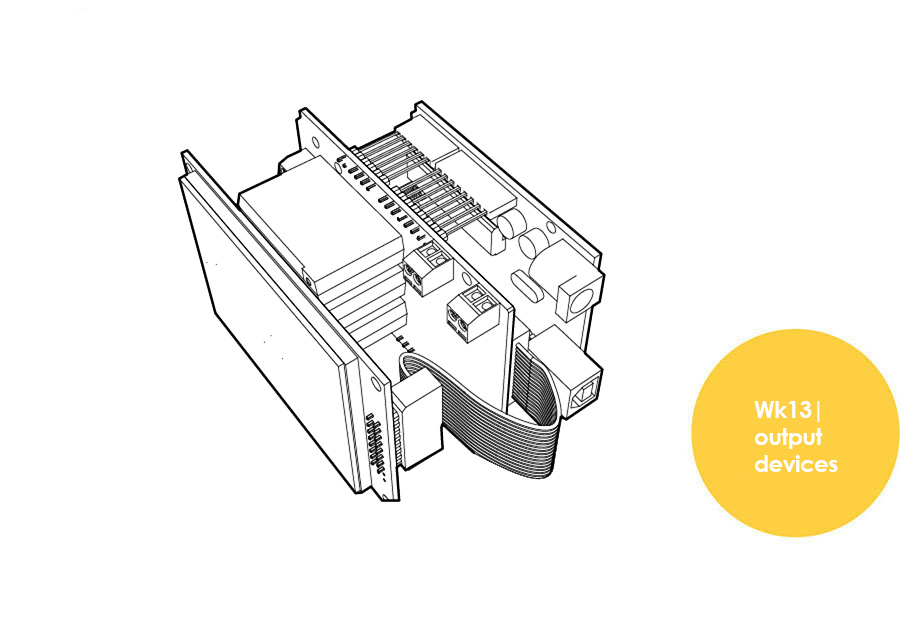

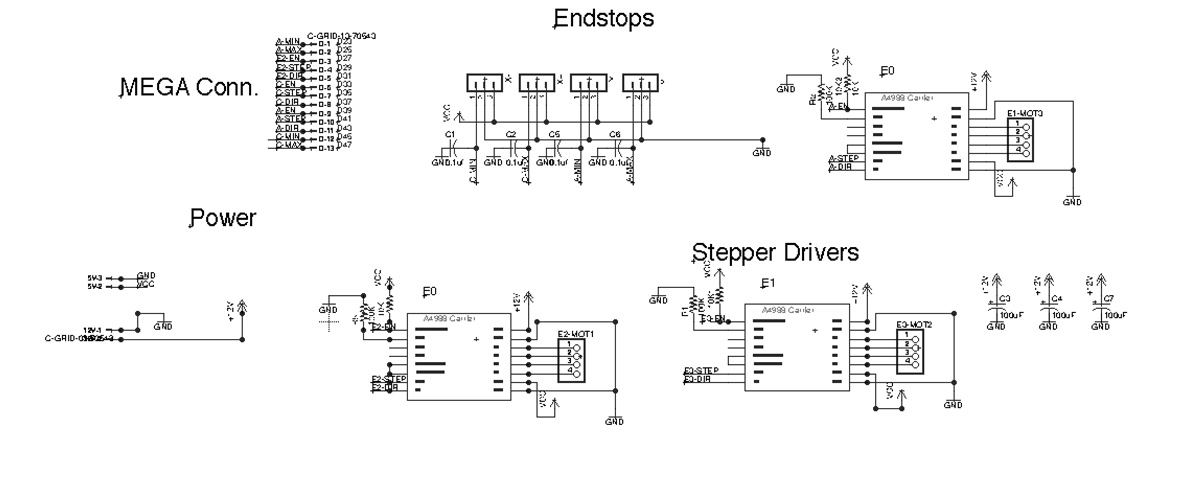

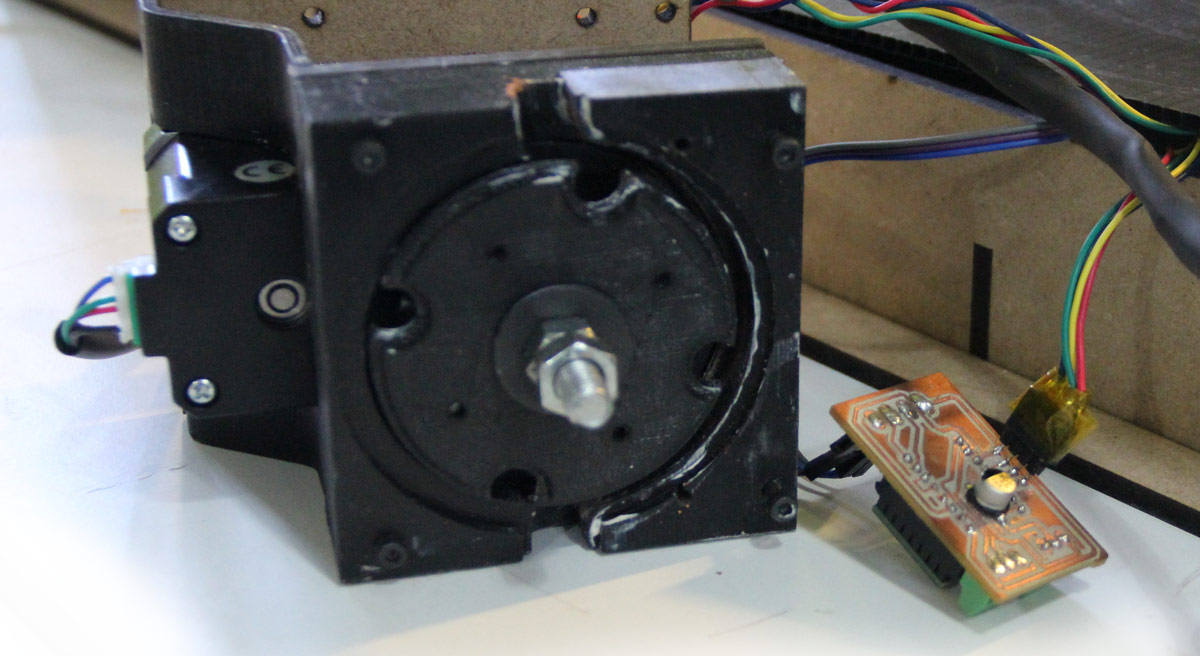

electronics|Hydrobot is based on Ramps 1.4 which uses an arduino mega. Ramps is usually used for 3d printers therefore a few hacks were made to suit better the needs of my machine. For example; Ramps shield; only takes two extruders therefore i created the "Hydrohack" as a stepper expander so that the machine is a cetralised as possible.

1. Servo hack: Ramps 1.4 has space for servos; you just need to add 5v my adding a jumper. More info here

2. vibrating motor: you can add a d.c motor in D9 and use gcode to control it (gcode is M106 S(intensity- i.e 0 is off; 100 is high))

3. place a potentiometer instead of thermistor and modify marlin code in configuration.h (#define TEMP_SENSOR_0 1)

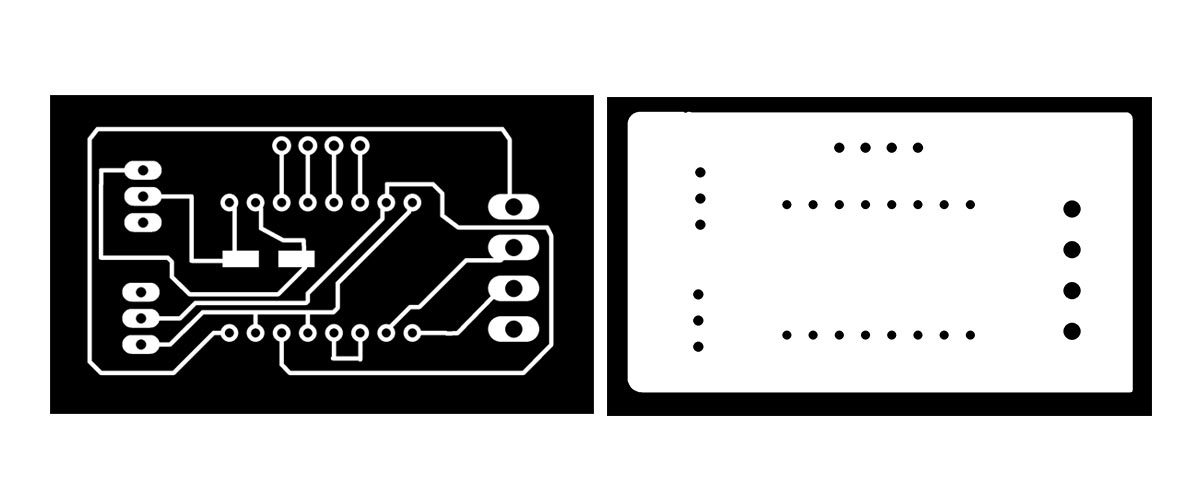

4. to create the stepper expander I downloaded the files of ramps and reduced the schematics to what was necessary for stepper motors only and chose free pins which would otherwise be used for an lcd from arduino to ramps. Schematics and bill of quantities can be seen below.

Note: stepper expander is a upgrade from week 13 which uses A4988 Stepper Motor Drivers.

front png

back png

front milling file

back milling file

holes milling file

holes milling file

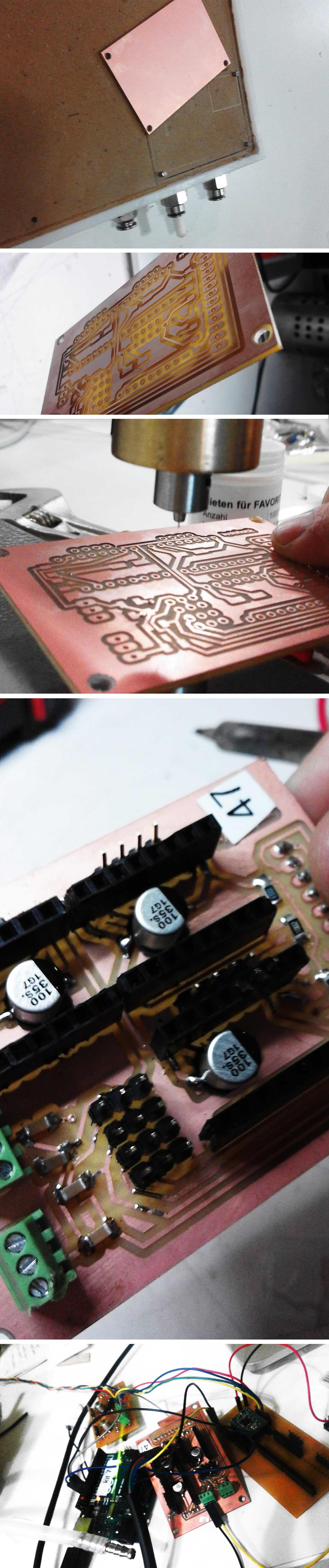

The shield was double sided. This required me to create holes at each corner of m4 diamter to allow an accurate flip. The png eagle files were also flipped horizontally (also make sure to make a bit of a boundary for space and flexibility to cut). First i cut the holes with the 32 bit; then place its in the m4 support holders connected to the bed. Then paths were cut with the 64 bit and then vias also using the 64 bit; but send an outline cut in fabmodules.

The vias were made once the board was flipped and otherside milled. but this is not necessary- and can be done before. Vias were then connected from one side to the other useing tiny copper pipes and pressed into place.

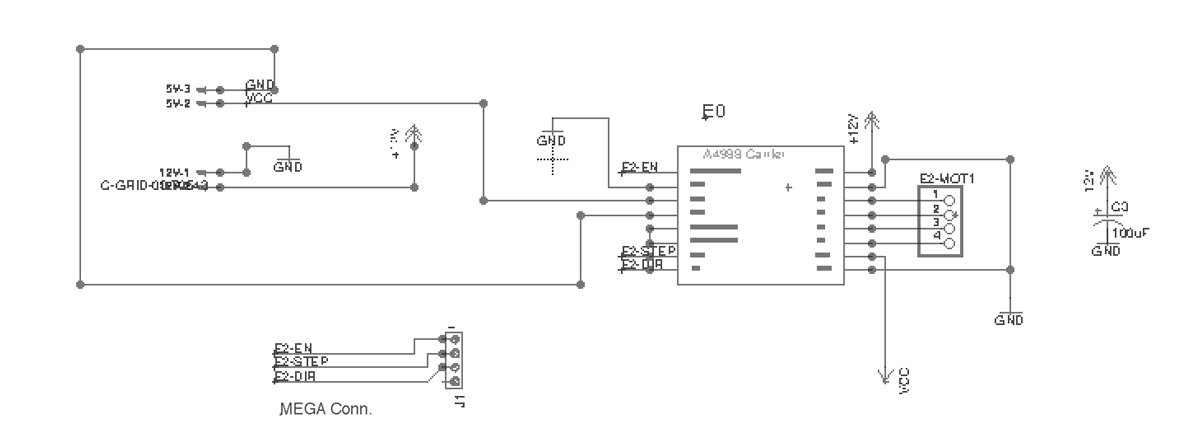

I did not have time to test the stepper expander on the machine and quickly made a more simple version so that troubleshooting would be easier considering the time.

traces png

traces milling file

cut png

cutmilling file

holes milling file

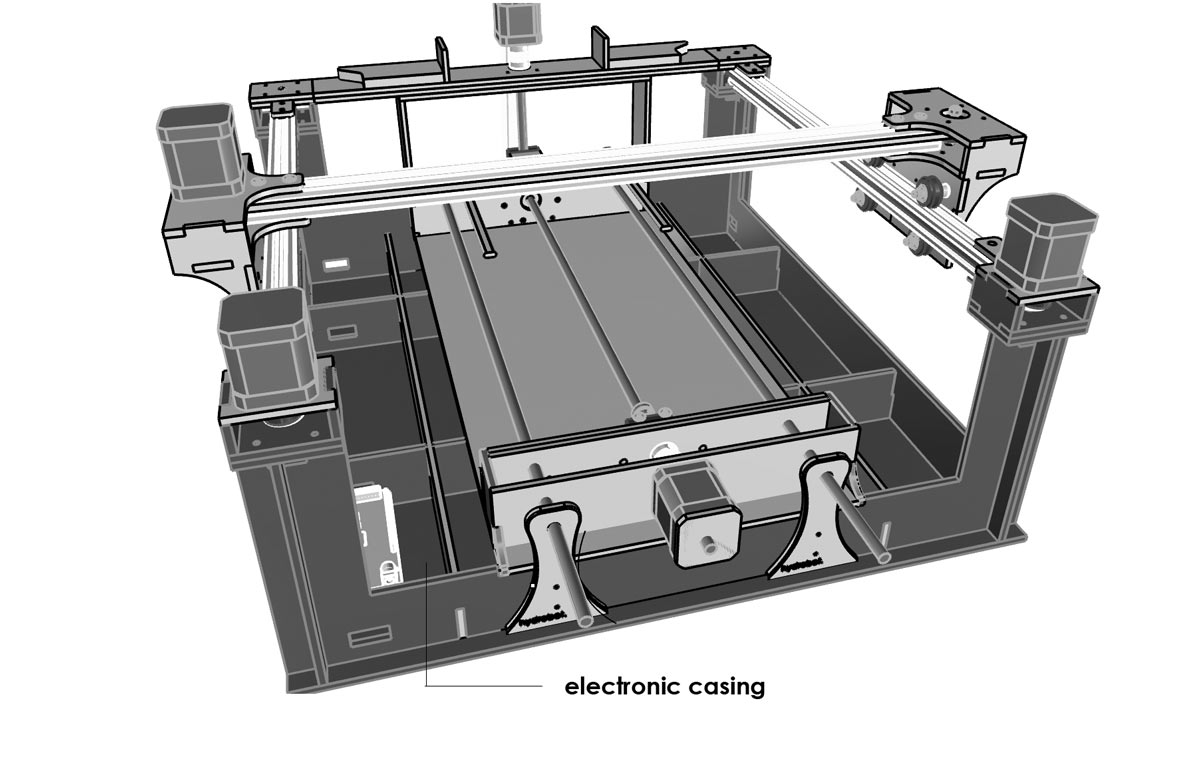

I also redesigned the base so that the electronics would all be hidden and tucked away neatly.

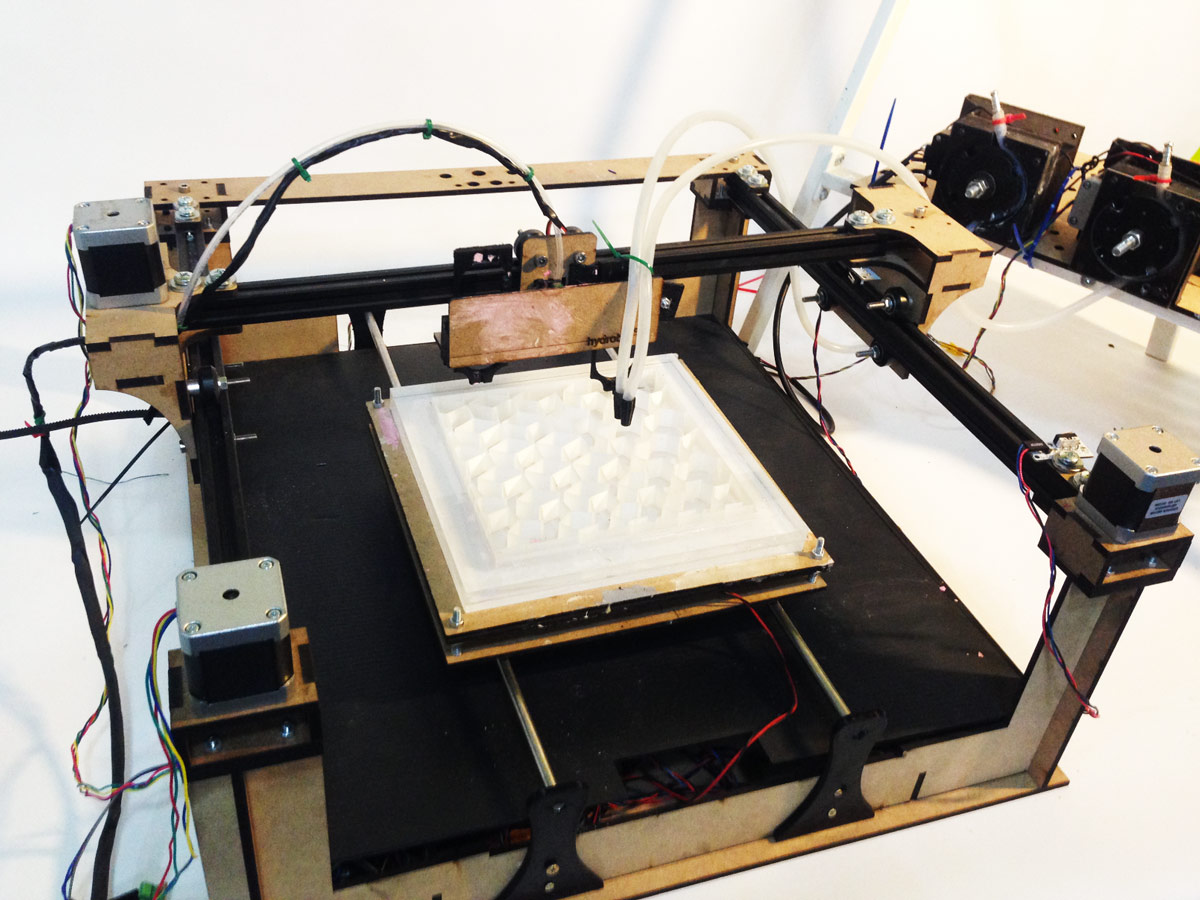

The code used was Marlin; it is usually used for repraps. However i made a few modifications to it for my machine. Namely in changing the bedsize; from 200mm to 400mm in x and y. Adding extruders by creating a new board such as rumba.h and adding extruder pins. Configuration.h was the main file in marlin which was modified and this is the final configuration used.

|Download all files

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.