This weeks project is a group project. Since I am the only Fab Academy student at my lab, I am doing it alone

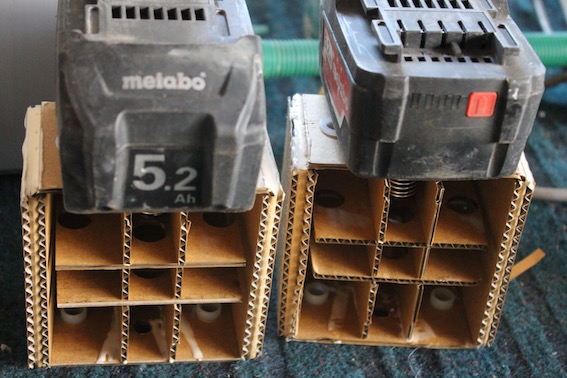

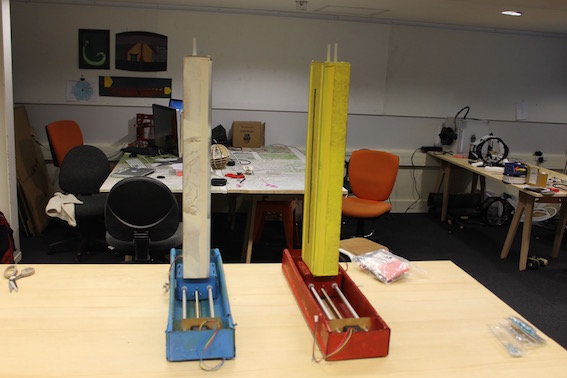

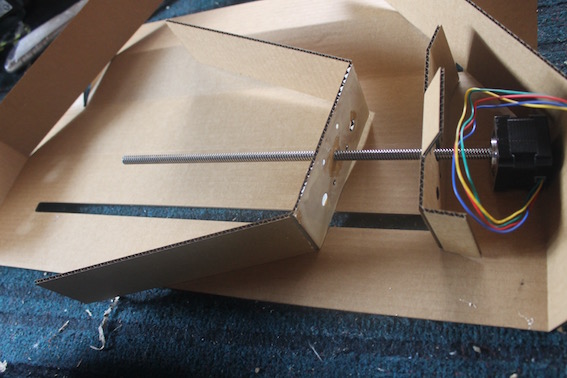

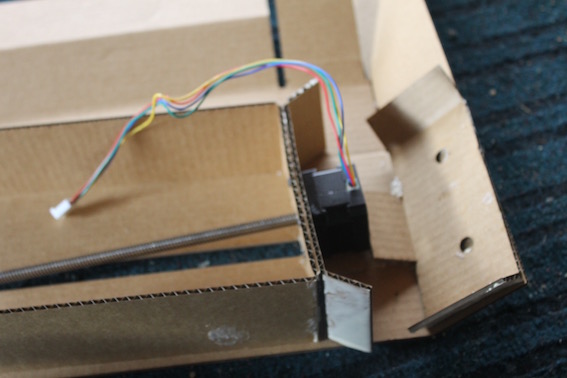

I unpacked the stepper motors, drivers and threaded rod kits. Then set about preparing the vector files for cutting out the cardboard parts to make the stages. The parts had to be scaled up by roughly 2500%. We figored that out by measuring the linear rail bushes which are half inch. Then we scaled the files up till the corresponding holes were also half inch.

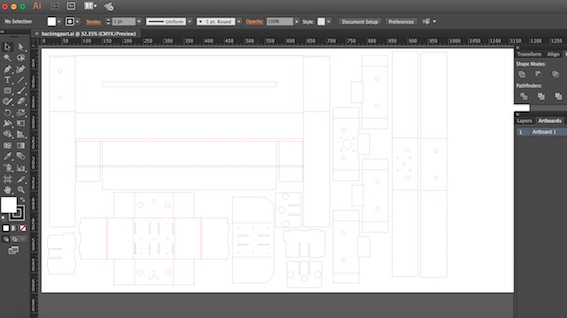

Our laser cutter has a 600mm by 1200mm cutting bed. So we chopped a chunk off.

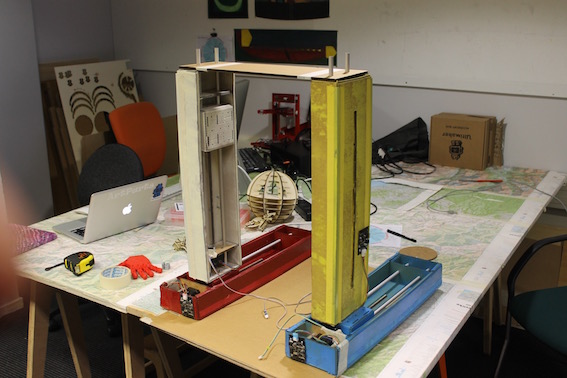

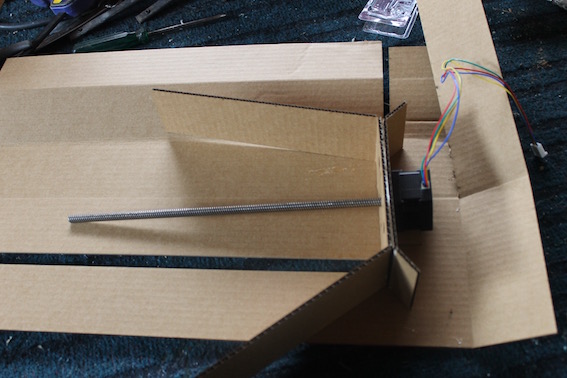

I tried to push the envelope using 4mm cardboard - did thicker = stronger and better? No! All the hacking and mucking around using 4mm cardboard was valuable. It gave me the opportunity to practice teaching Linda, my wife what I had learned about laser cutting and it threw up some extra problems for me to solve. A small but not insignificant discovery was when we needed to change the stroke color so that our laser would know which lines to cut and what lines to score. Fablab Craig showed me the Select lools in illustrator. Under that tab is the Same tool which allows us to select one vector then convert all of the same general colour to the graphic style that the laser cutter reads as ether a cutting path or a scoring path.

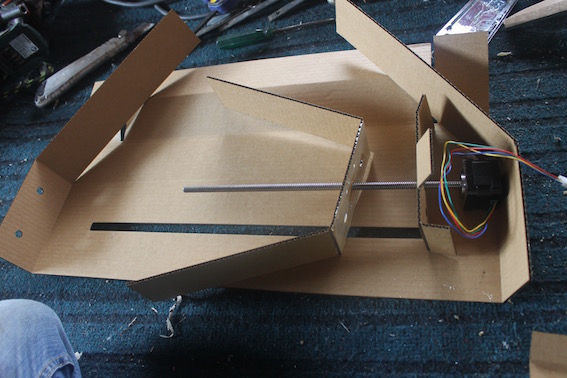

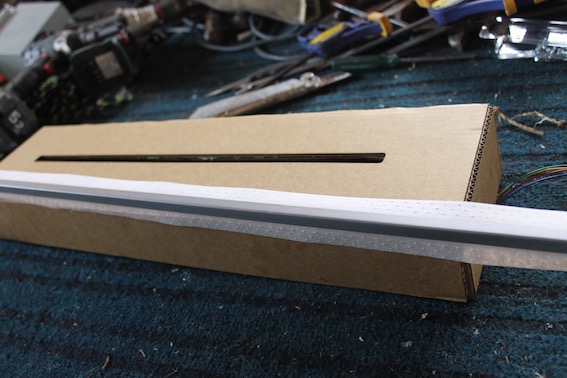

Because I chopped the side off of the thing, I decided to glue some plasterers corners on. The thin angle steel with paper is made for the plastering industry. It's cheap, less than tens of dollars.

The springloaded nut is fancy and good but its bolted to one layer of 3mm cardboard. To improve rigidity we poured glue onto everything!