The aim for this week was to:

1. Make something BIG

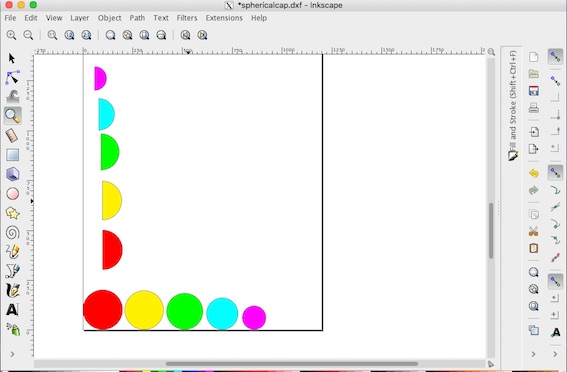

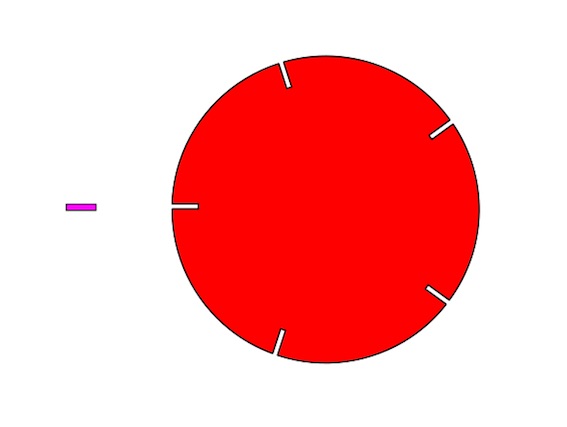

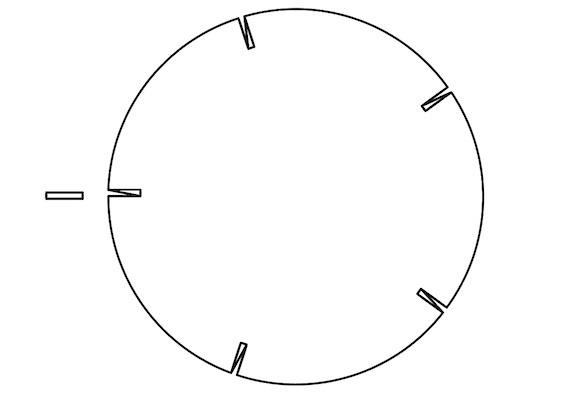

I set out to make a plywood globe as applied research for my final project. I want to make a scale model on the laser cutter as a prototype before cutting it out on the router (as suggested by Wendy N.). My first choice of software was Inkscape. Making a globe in a two dimensional vector graphics programme is not simple. I had to calculate the changing diameters as they moved away from the equator. I found this calulatorand used it to workout the diameter at a known distance from what is called the spherical cap. I will use this approach for now because it gives me a better understanding of what I want the machine to do for me. It is basically old school drafting without pencils, paper, a ruler and a compass.

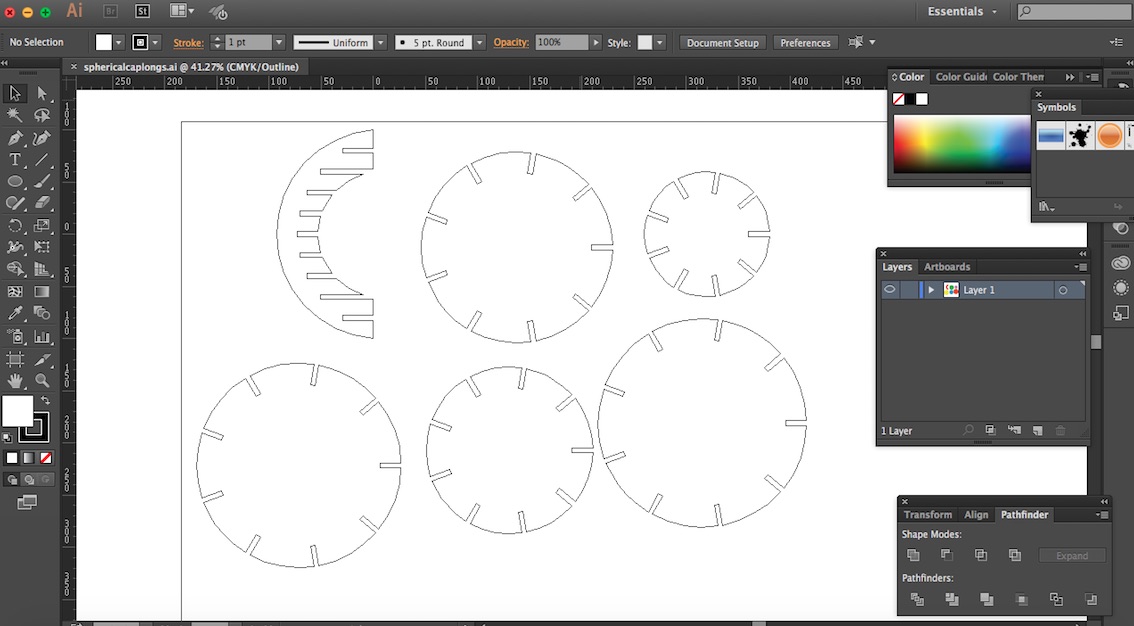

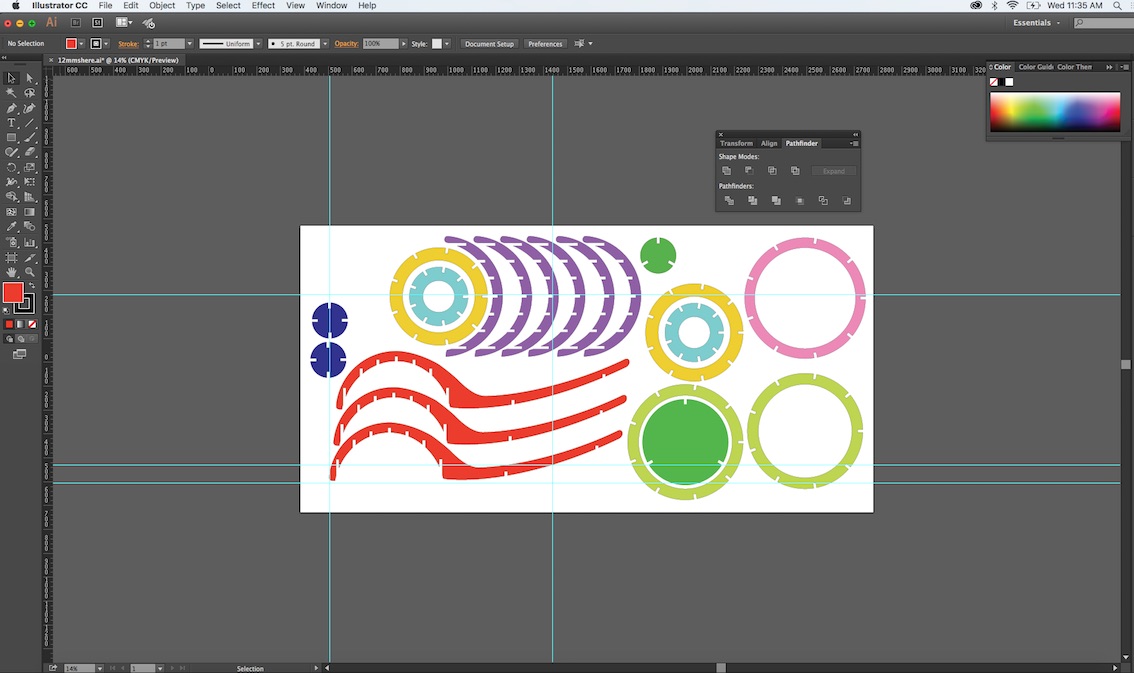

I solved the file sizing problem that Inkscape creates when it is exported to Illustrator. But all the path problems are going to have to wait for another day. Our Fablab laser cutter uses Illustrator files so I made my vectors there. I still intend to use open source software because it is free and anyone can access it. But it does take more time to learn, so for now, I'll stick with Illustrator on this high octane course!

I made some cutting paths for a scale model on Illustrator, ready for cutting on the laser cutter. I had carefully measured the nominal 4mm plywood and found it to be 4.8 mm. So I made the notch sizes 4.7. Then later in the day when the laser cutter was available, I grabbed a piece of plywood that I assumed was the nominal 4mm, but no it was 5.7mm. I found this out after I had cut all the parts twice. During the first run the laser cutter was using a 4mm default setting. I was also growing unpopular by exceeding my laser use time.

I took the parts home and hit them with the belt sander so that I could put half of it together and see if my theoretical calculations where correct. They were! Then I moved onto developing the design to be something massive using the same work flow. I can also see room for a few aesthetic additions now that I see it constructed.

My design has improved. I have a 1/3 scale marquette which is cut on the laser cutter. I was more diligent about selecting and measuring my material this time. I ran some test cuts and discovered the kerf on the laser cutter meant my parts would be a loose fit. I wasn't concerned. I changed the size on some of my test pieces just to make sure I was comfortable with the routine.

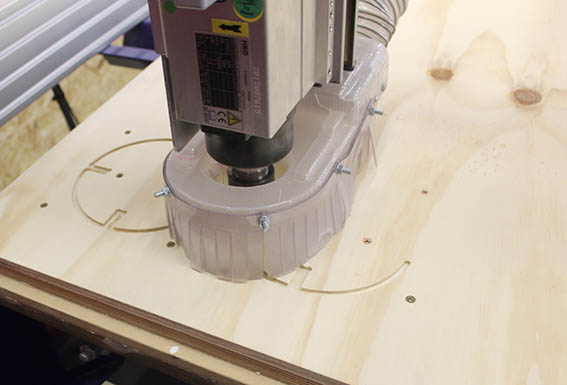

The shopbot obviosly has multable dangers...

The test cuts are designed to give me notch size data and cut quolity. We are using a 6mm down cut tool for one pass, then a 6mm up cut to compleat the job in two passes. One of my test pieces is convention the othe is climb.

Convention leaves a far better finish as seen in the above photos. It also cut closer to what I wanted than climb. The notch sizes in my convention test are about .05 smaller than My files asked. The notches are about .1 smaller.