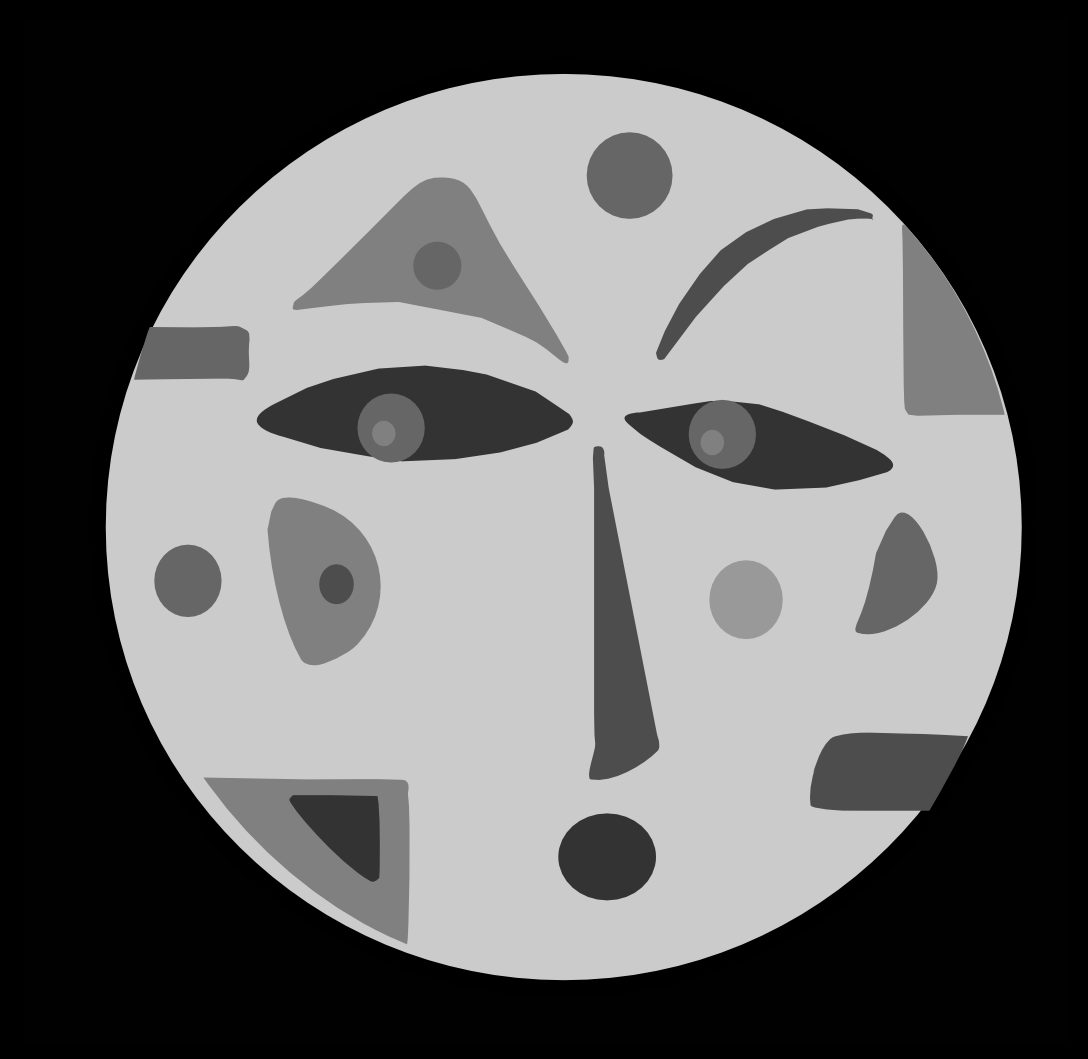

I designed a tile in

Inkscape using the robot face from my final project as a

starting point and followed the tutorial Molding & Casting

using Machinable Wax. I designed the tile using shades of grey

(grayscale) to define the different heights. Black being

bottom of the part and white the top, then exported as a .png

image. Save as STL file for 3D models and 2D save as PNG

files.

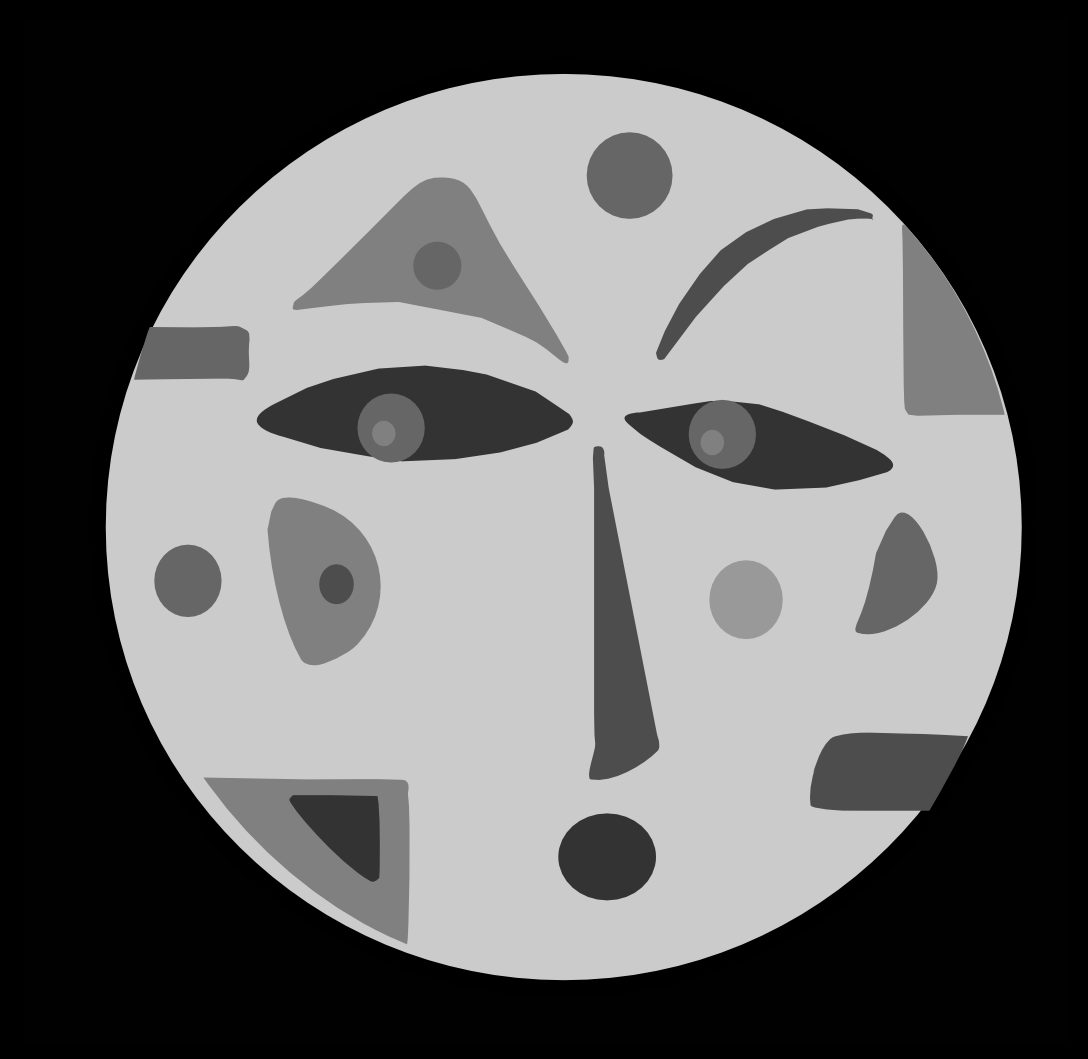

My designs below

showing the grey scales, the first one I changed as not enough

grey scale. Second shows more grey scale to create depth and

third shows inverted gray scale to make it easier for the

1/8th bit to access the detailed shapes. This did help and I

managed to cut a successful mold.

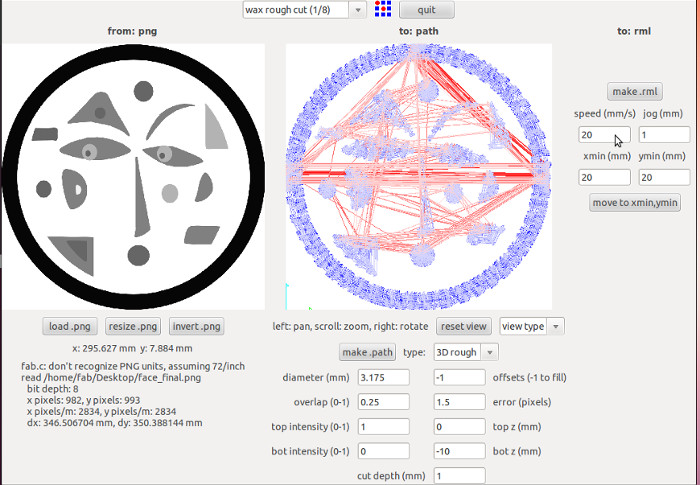

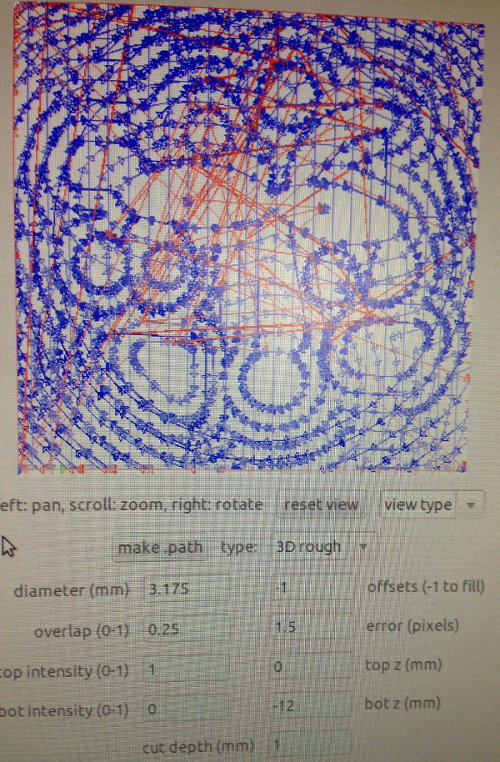

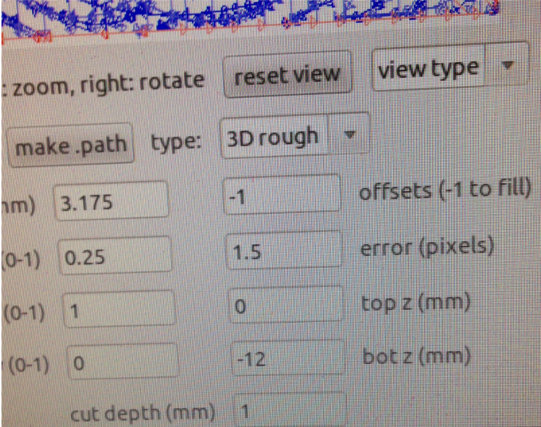

settings for

make.path on larger scale design

final settings below

Mill the wax on the modella

Having set up the wax for milling I choose the

bit. Selecting the appropriate bit I originally thought of

changing to a smaller 1/32 as my pattern is detailed but

having thought it through was unable to do this as the drill

bit could not of managed the depth. Having chosen my drill bit

an 1/8th inch endmill for the modella I used the

Fab Modules and set x y z zero settings and checked my design

would fit on the wax with a little extra space. I had to get

the settings exact because my wax block was small in

dimensions. At this stage I set my pattern to fit the wax

block several times which became time consuming. Having scaled

my design to fit the wax block and set xyz, I choose wax rough

cut and went to make path.

At this stage I hit problems

At first I thought there was something wrong with my design

but after lengthy problem solving and advice we realised the

design was too small for the 1/8th inch bit and was why

some of the cutting paths were not showing. At this stage I

inverted the gray scale ( see image above) to make it easier

for the drill bit to access the more detailed shapes. This

worked well for the rough cut.

At this stage hit another problem

When pressing view to to see the wax block the drill cut

through the wax block unexpectedly and I had to hit the stop

button. This was annoying as I lost all settings and had to

kill the setting in terminal to reset. Having lost all the

settings I did try to reset them but it didn't work. I have

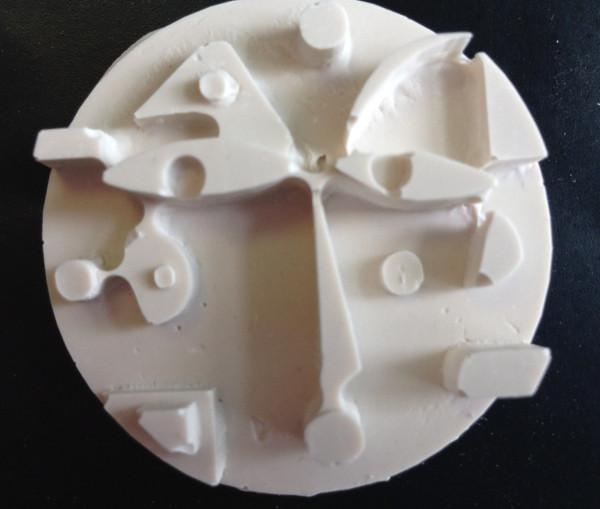

now used the first rough cut quite successfully to create a

mold and caste. ( try not to turn the machine off between cuts

as you loose the settings)

wax roughcut below

Things Learnt

I enjoyed this process and would like to experiment with it

further. I was impressed by the quality of the wax mold made

on the Modella but not by the time it took to cut!

I went on to make a mold and take a cast from the above.

Knowing more about the process I would have chosen a different

design for the tile and made it double the size suitable

for a 1/8th bit. Fit the design to the process.

I made another simple 3D model using the modella

Files