Week 7 - Computer-Controlled Machining

Make something big out

of ply or foam

Shopbot – CNC milling

machine. A shopbot is a large CNC router that uses a bit like

the Modela to cut files. It is necessary to screw the board down

onto the bed and essential that the bit does not hit these

screws when routing.

I

decided to use this opportunity to work on my final project.

Starting with Partworks

to draw up and prepare

my designs to cut out on the Shopbot. Having not used Partworks

before this took some time but actually was quite straight

forward. Having prepared the design I then went on to using the

Shopbot.

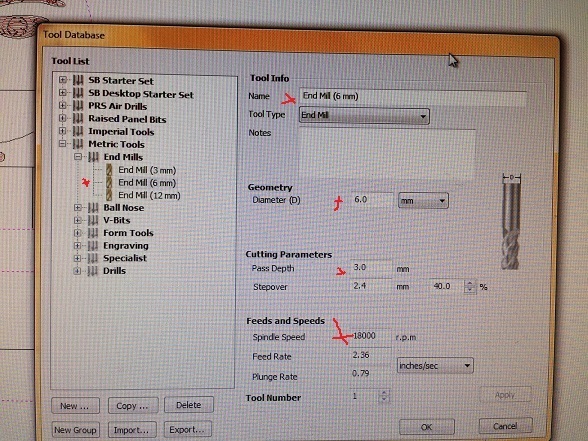

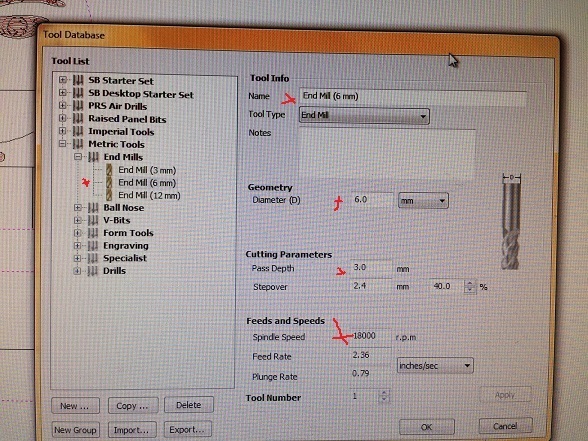

Tool data set in Partworks below

File formats I used

2D

Inkscape save as PDF

3D

designs save as STL

Partworks

saves

as a CRV file

Shopbot

saves paths as an STV file

Materials

12mm

plywood 2440 x 1220mm

My settings for the

Shopbot

I

used a dowcut 6mm bit at spindle speed of 18,000rpm

I

prepared 2 different pathways. Pocket cuts for

milling out shapes at a depth of 2mm and Profile cuts at a

depth of 14mm for cutting out the outlines

SAFETY

NOTES – be clear on 3 ways of turning Shopbot off in emergency

Space bar

Big red button mouse

Remember to add tabs carefully spaced on all

parts to be cut out

add tabs for all pieces that are being cut out

Work with a friend not on your own

Wear safety goggles

Workflow

Set

up board on milling table secured with screws check position of

screws and if others needed

Choose

bit 6mm downcut, collete 5 – 6mm tighten and setup

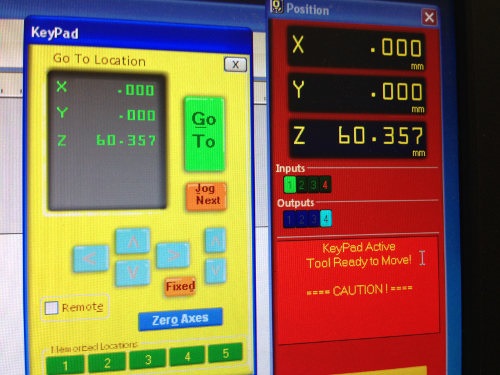

Set zero x,y

axis see below

Set

z height for 6mm drill

Practice

moving

the bit around the board without spindle on to get confident

using the control panel

Check

toolpaths

– I noticed I needed to add ramps and set toolpath cutting order

for the profile cuts to be last and pockets first

Run

a preview – at this stage I noticed a mistake, I hadn’t saved

all the files so short delay while all files were added and

another preview made

Spindle

on with key

Check

spindle speed, extractor on

Goggles

on

Start

job

When

job finishes turn off spindle, then extractor and check job,

I then added another toolpath at this point.

First prototype of structure for robot face below and

picture of lines next to it not matching up with cut - I need to

work this out for next