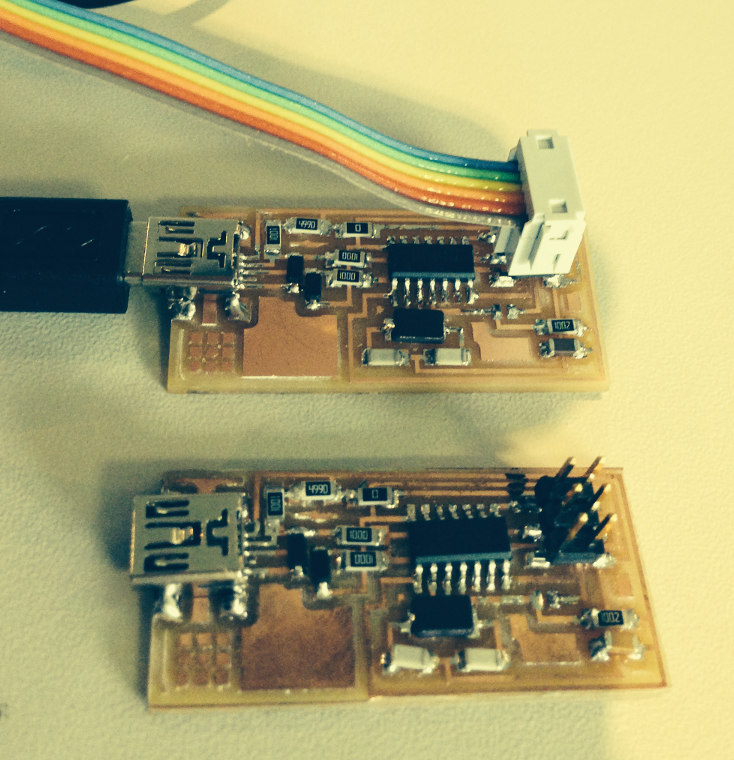

Making circuit boards,

soldering of electronic components onto the circuit board to

create a FABISP in-circuit programmer and finally programming.

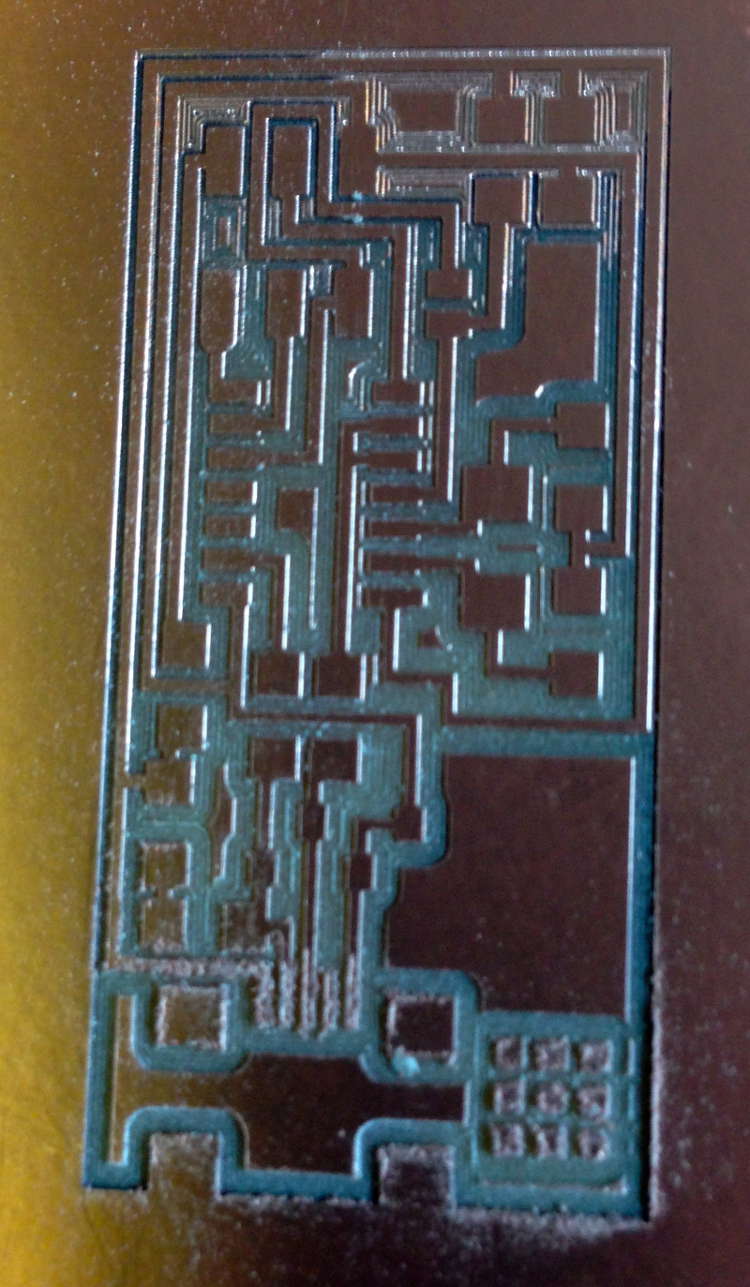

We used the milling machine Roland Modela to make the traces and

cut the outline of the board.

Steps

to mill the board on the Roland Modela – workflow

Fix

board to the Modela

To set up the Modela we first

protected the bed with a sacrificial board. Ensure the surface

is flat and clean then add double-sided tape to the back across

full width of your

copper clad FR1 PCB board to hold it firm while milling. Leave a

bit of tape overhanging the board to help removal.

We choose to build the crystal

based version in our Fablab.

Open terminal type password

fab

Fab module opens

Choose image (.png) then

Roland Modela (.rml) see photo below

I

followed these steps to set up the modela software

Load .png file – for

Roland Modela (.rml) find on desktop in FabISP Files/hello IS

p.44.traces.png

Select the type of job – mill

traces (1/64) the pre selected defaults for cutting PCB traces

based on using a 1/64 inch end mill bit.

Select make path

Set the x,y,z origin

Set x,y use the move button,

measure distance required and set the origin

Set z origin (the distance the

bit will travel down when milling) by moving the bed up

setting the bit in correct position then carefully lowering it

so it touches the board. Check bit is secure

When origins are set make an

rml file

Guard back in place and send

to machine.

Traces take about 10mins to

mill.

When finished press view to

see board and use vacum cleaner to tidy up

To cut out the board

Change bit to a 1/32 inch

Download ISP.44interior to cut

out board

Make path

Set x/y and then z by first

centring the bit in middle of board

Make.rml

Guard back on

Send it

Remove the board with care as

it’s easy to damage the delicate copper which I did on my second

board.

Gently de-bur with a steel

ruler and wash with soap and water to remove residue then we are

ready for stuffing the board.

Some of the problems I encountered

Ensure the surface is flat and

clean before securing your board. I had this problem with my

first board, the traces cut deep one end and not at all the

other! I started again. We changed the 1/64 bit as well due to

the cutting problems I encountered. Another problem I

encountered which was tricky to sort out was the shim/wedge for

the cover interlock switch that the modela uses to detect safety

cover is in place. It had worked loose and the modela refused to

move! It took sometime to work out the problem.

Picture of my first

board below, traces deep one end and no traces cut the other end

Soldering

the board

Soldering was completely new

to me so it’s been a steep learning curve and I have had to

practice lots before starting the final board. I started with

the smaller components as recommended but then leaving the USB

to last was very stressful as it proved to be so tricky. I found

work flow was very important laying out a copy of the Eagle

board file next to me with an ipad to look up component

identity.

Smoke Test went well, no smoke!

Programming

the board

Having

installed the software for AVR programming I followed the Fab

Academy at AS220

FAB ISP Tutorial which was very helpful, thank you. All went

well with the

programming but when I later came to use it to programme other

boards I got

error messages. After much trouble shooting and advice it turns

out the board

was fine when I put back one of the 0 ohm connectors to power

the board.

I now have 2 boards working, so exciting! I've learnt

alot this week, particularly trouble shooting FAB ISP boards.