Week 11

Composites

Assignment -

to design and make a 3D mold and create a fibre composite

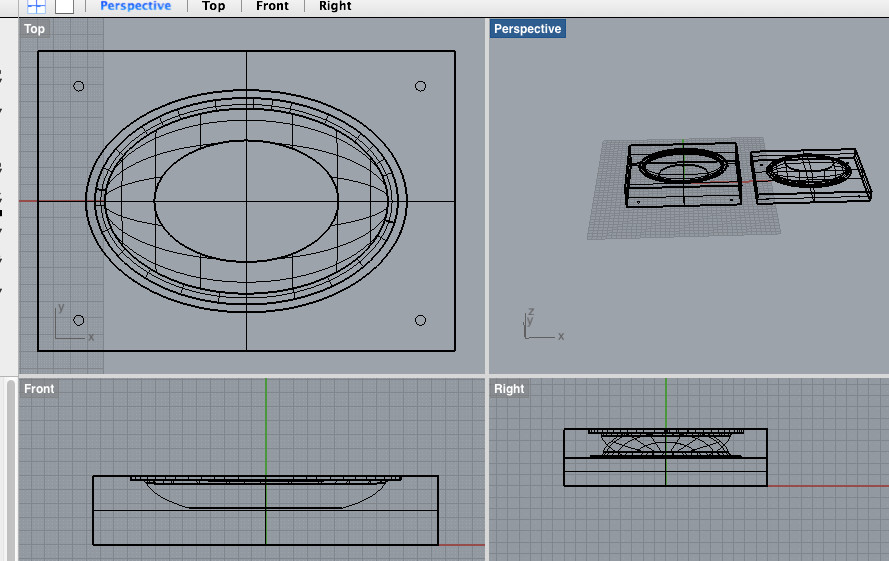

I decided to make a tray using and thought this was a good

opportunity to start by practicing my Rhino CAD skills. I really

want to get good at this! After following several

tutorials and with advice from our tutor Joel I made a two part

mold with register holes for 6mm dowel, see below.

Rhino files for tray

tray_small

tray_top

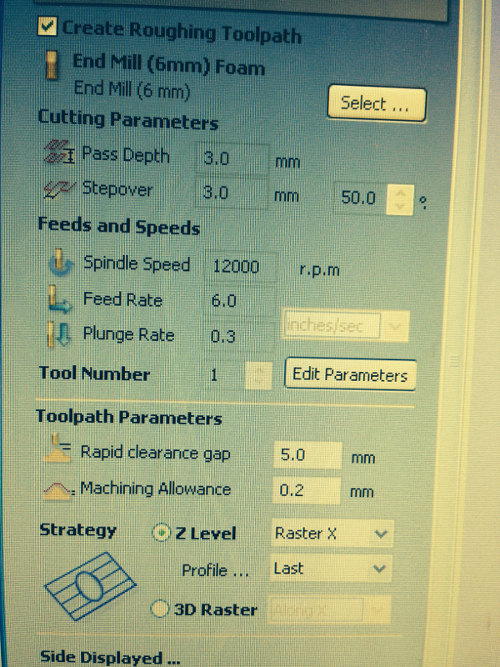

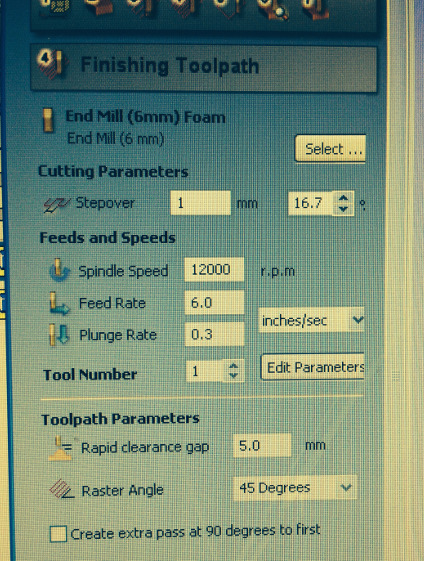

Next to use the

shopbot to make the mold. See the shopbot details below, 6mm end

mill cutting foam, 12000 speed

I was really pleased

with the results, a good finish, see above the results from the

first rough cut and then the final cut.

Next to prepare the

mold I covered it with vaseline to help remove the cast after it

has dried overnight and also cut the hussein up into

thin strips. I used

the Smooth cast below in equal parts and stirred well. It's

messy so be prepared especially when making a 2 part mold!

It seeps out in a guey mess!

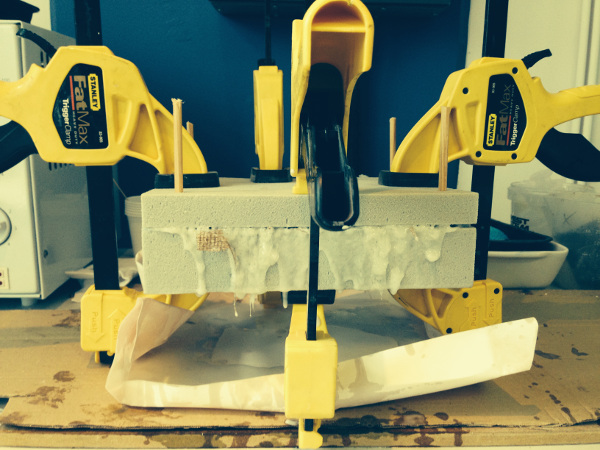

Making preparations

below for the mold and using hussein strips

Below the hessien in

criss-cross fashion to strengthen the composite having been

soaked

in the resin. I then added the 2nd part of the mold and fixed

both sides in place with dowel through

the 4 register holes

The two part mold in action held together with 4 grips hopefully

tight enough

but not too tight in case the foam mold becomes distorted. I

left it over night

unfortunately I had to

break the mold to get the tray out

unfortunately I had to

break the mold to get the tray out  the finished tray

working well. Great

the finished tray

working well. Great