Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog

11. Composites

This weeks assignment is to design and make a 3D mold (around 1ft

square) and produce a fiber composite part in it.

So I decided to make some 'Gruffalo'

monster feet type stilts for my 5 year old son. We initially

did some process tests as a group which I've described towards the

end of this page.

11.01 Making the Monster Feet

After our process tests I decided that the best method was to keep a

foam core inside the composite as this provided a very rigid final

part that was most likely to survive 'abuse' from my kids.

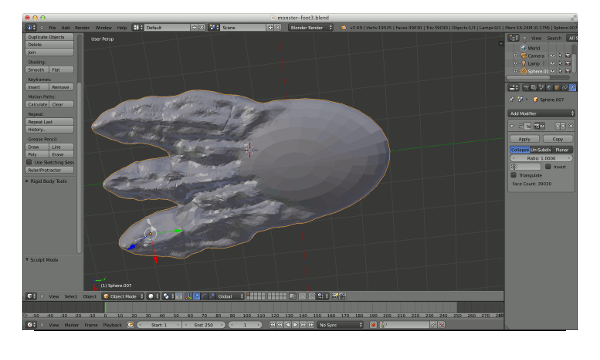

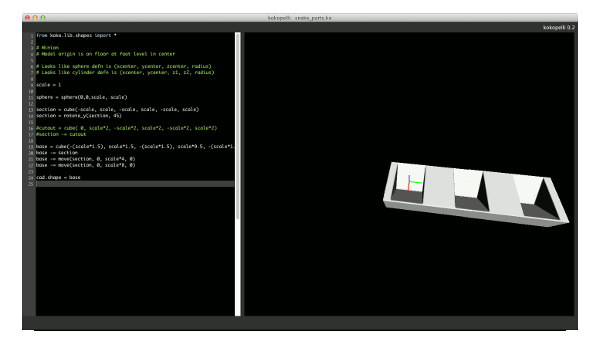

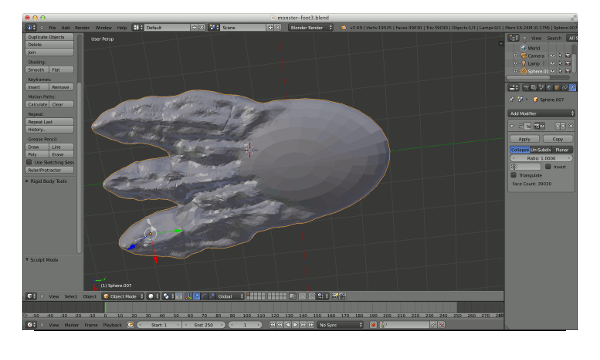

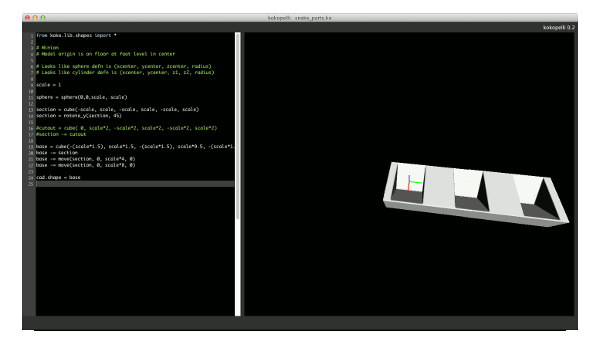

As part of this assignment it seemed like a good time to start to

learn a more 'artistic' 3D modelling package as most of my 3D work

up to now has been done using Kokopelli, so I started to learn Blender. I modeled a very

poor monster foot in Blender by first creating a sequence of spheres

that roughly matched the shape I wanted, squashing them, combining

them into one single mesh and then using the 'sculpt' mode to create

a more foot like object.

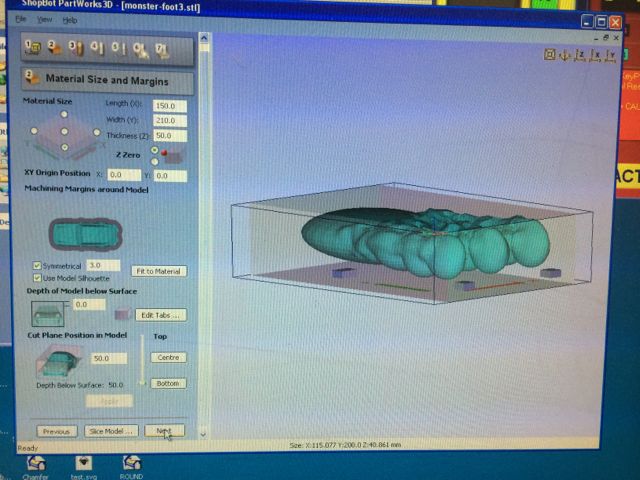

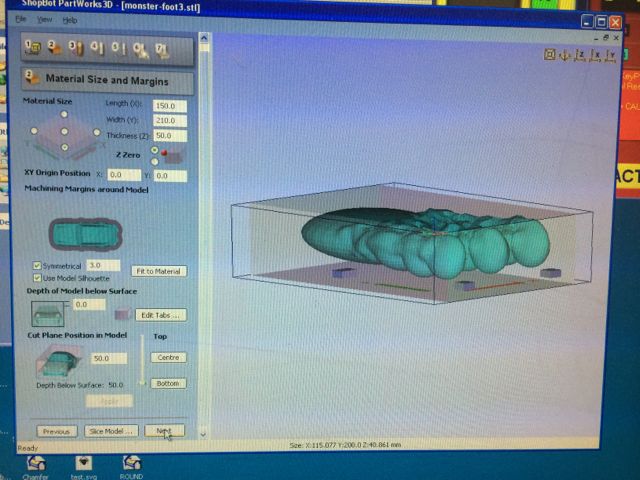

I then exported the STL file form Blender and used PartWorks 3D to

scale it to the maximum size that would fit on the foam offcuts we

had available. I ignored the fact that the object had a lower

surface that the shopbot wouldn't be able to mill and just set the

machine up to cut the top surface and then cut out around the object

leaving tabs so that I had a thick foam foot with a flat underside.

STL file here (sorry

it's nearly 800Kb!).

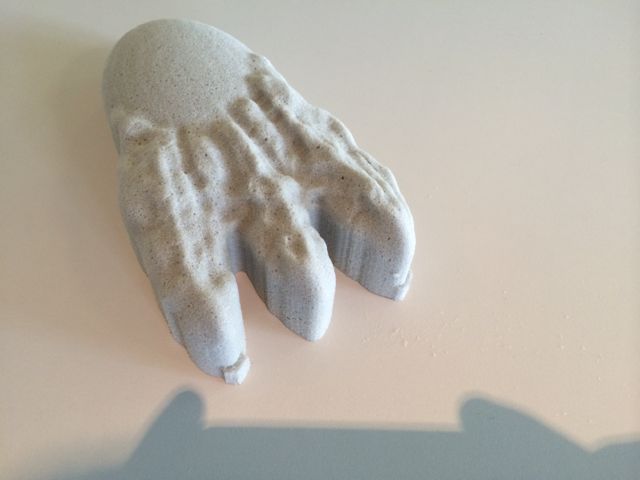

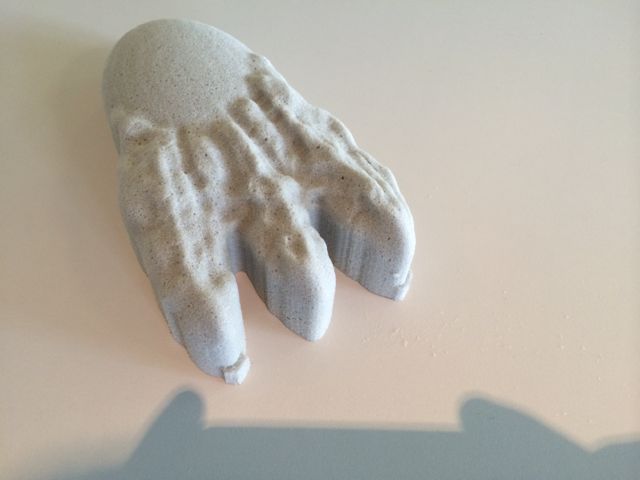

I machined two foam feet. I used a spindle speed of 12000rpm,

9 inch/sec feed rate for the roughing pass, 4.5 inch/sec feed rate

for the finishing pass.

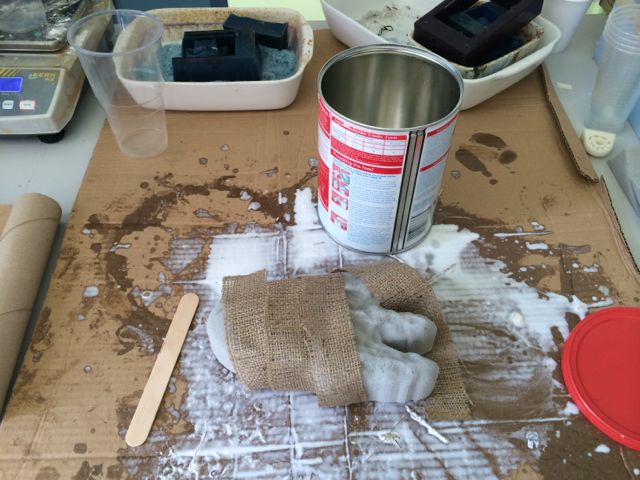

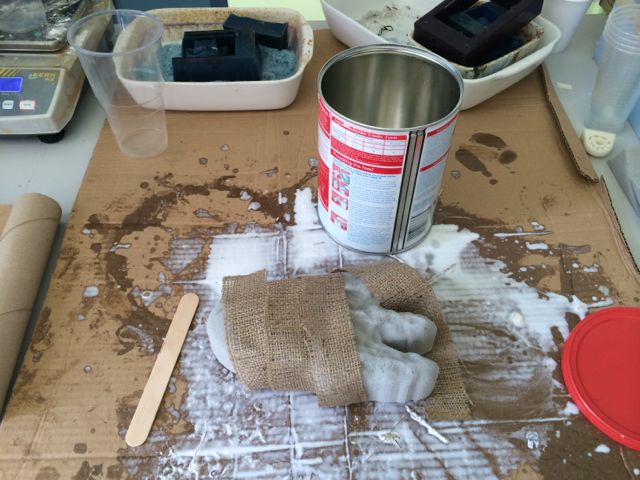

I then proceeded to cover them with two layers of hessian

each. I decided to use the Smooth-Cast 310 as my resin because

we had pretty much run out of West System Epoxy in the lab.

Before covering each foot I pushed a piece of 0.5 inch PVC tubing

through the foam at about the mid point of the foot to leave a

channel for the rope. I cut some teeth into the end of the

tube with a craft knife so that I could rotate it like a drill and

get it through the foam easily.

The first foot I tried to cover with with single sheets with darts

cut so that they folded to fit. This was a difficult process

as the Smooth-Cast material has a very low viscosity and doesn't

provide much natural adhesion between the hessian and the

foam. It was difficult to keep all of the layers in place and

we ended up using staples to hold layers whilst I tried to assemble

it all.

After a couple of hours at room temperature the part was cured

enough to remove from the mold. It was very rigid but required

quite a bit of cleaning up of edges with a Dremmel and sanding to

remove excess fabric that had 'escaped' in my messy assembly

process.

As the first foot proved so difficult to assemble I decided to try a

slightly different method for the second one. I cut the fabric

into 1 to 2 inch wide strips and soaked them in a bath of

Smooth-Cast before wrapping them around the foam mold.

This second attempt was much easier to assemble without resorting to

extra pairs of hands or staples. Although the final result had

about as much excess material that required removal.

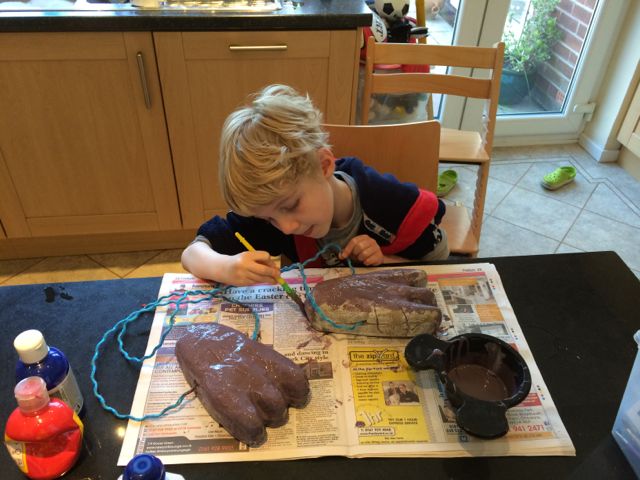

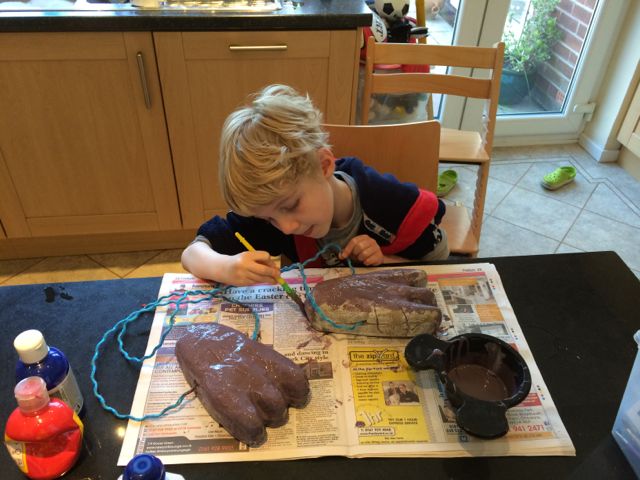

After a bit of tidying up here are the final finished feet. My

5 year old has promised me that he will paint them during his Easter

holidays.

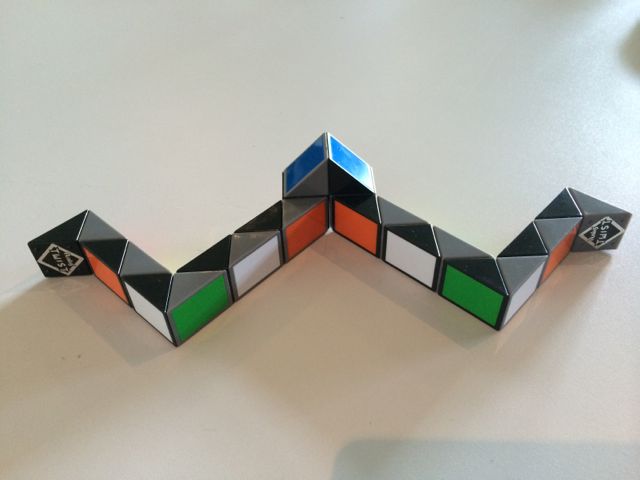

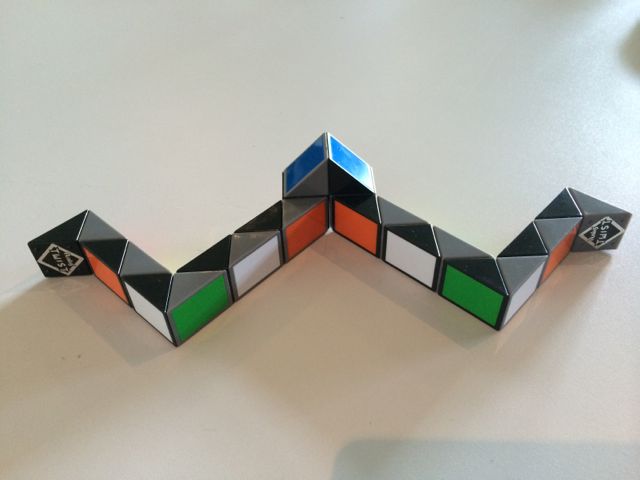

11.02 Rubiks Snake Segments

One of my possible final project ideas is to make a self folding

Rubiks Snake. So i did a quick test making a few Rubiks Snake

segments. I used an open one part mold and vacuum bagging

during the curing process.

I created a very simple test mold in Kokopelli with space for three

snake segments. After cutting the mold I tried to see if I

could seal the small surface bubbles with spray paint, but this

wasn't very successful.

I measured and cut fabric to fit so that I had two layers all over

the mold. I then covered the surface of the mold in Vaseline

to help release the parts before vacuum bagging all three segments

at once.

Even with the Vaseline it required a bit of force to remove the

parts from the mold and I suspect that I wouldn't be able to use the

mold more than a few times. After a quick clean up and sanding

I drilled some holes in the center of the square faces and assembled

my very short snake.

11.03 Process Tests / Experimentation

Composites don't seem to come up that often in our lab so we decided

to experiment as a group with the processes involved before deciding

exactly what to do for our individual work.

In the lab we had the following materials:

- High density weave hessian

- Low density weave hessian (Burlap)

- West System 105 Resin and 205 Hardener

- SmoothOn Smooth-Cast 310 liquid plastic

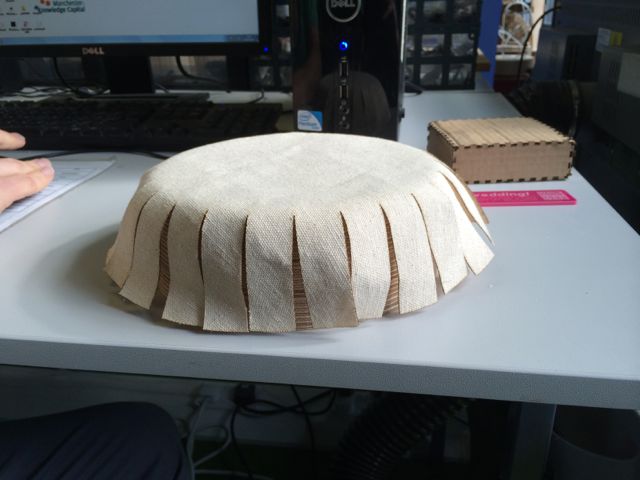

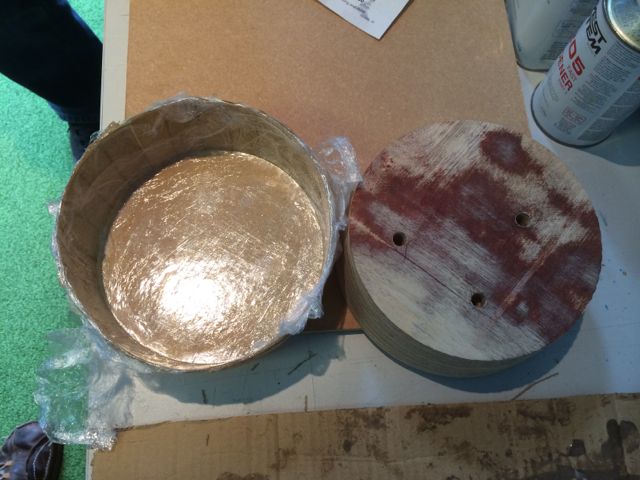

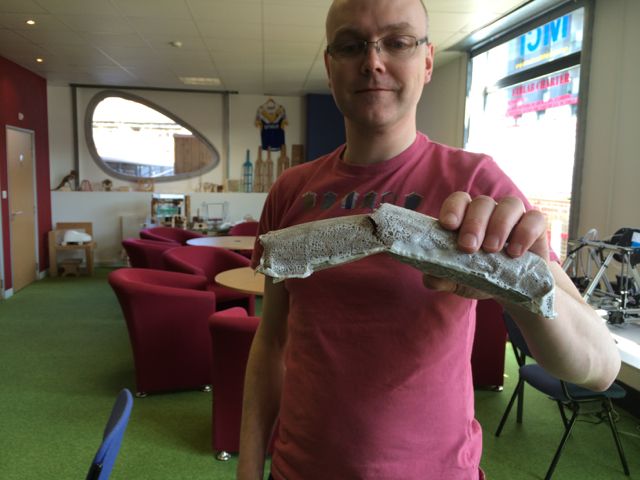

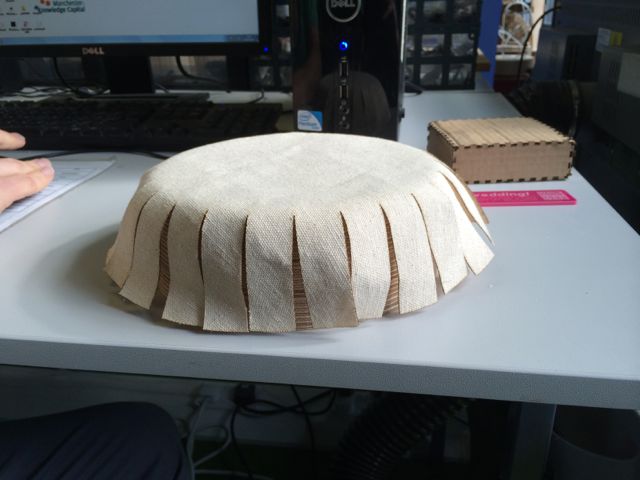

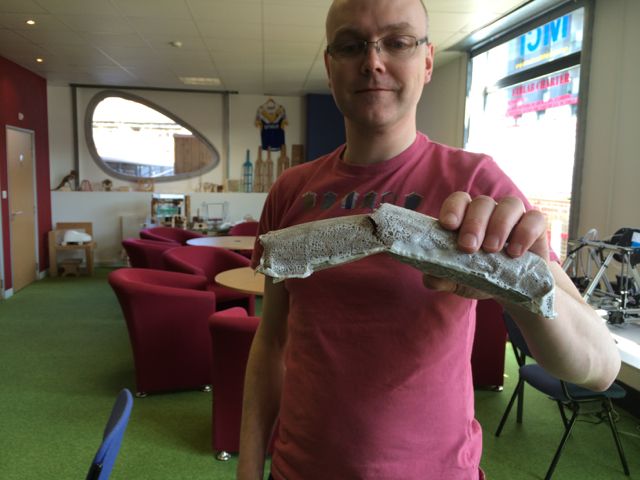

11.03.1 Test 1 - Open Mold

We found a large wooden object in the lab and decided to use it as

an open mold, just layering sheets of hesian and using the West

System 105 Epoxy.

As the object was almost a cylinder (it was actually a truncated

cone) we lasercut the fabric to fit. We decided to do 2 layers

with a different cut pattern for each layer to produce

overlaps. We covered the wooden mold in cling film to stop the

epoxy sticking to it.

We then worked the Epoxy into the fabric with an old paintbrush and

layered it onto the mold, left over epoxy was poured ontop and

worked into the fabric.

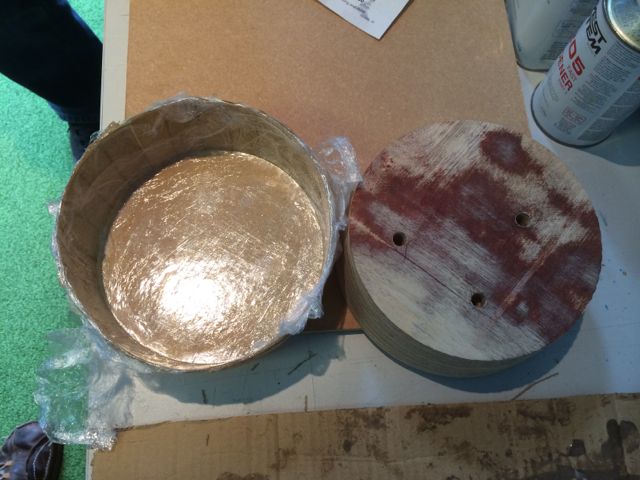

Final object de-molded.

When we initially de-molded the object it was still slightly

flexible. Over an additional 24 hours it became much more

rigid. Once it had fully hardened we all had a go at standing

on it to test it's strength. Not a particularly scientific

test, but fun.

What we learnt:

- Even a simple open mold can produce a very strong object.

- For a regular shape it's easy enough to laser cut the fabric,

but more attention needs to be paid to the joints on the sharp

edges.

- Probably needs more than 2 layers.

- Working the Epoxy into the material with a brush is too slow

and the epoxy starts to go off before we can completely cover

the fabric. It also renders the brush useless afterwards.

- The Epoxy goes very 'jelly' like once it starts to go off and

is difficult to use at that point.

- The Epoxy generates a lot of heat when it goes off.

11.03.2 Test 2 - Vacuum Bag

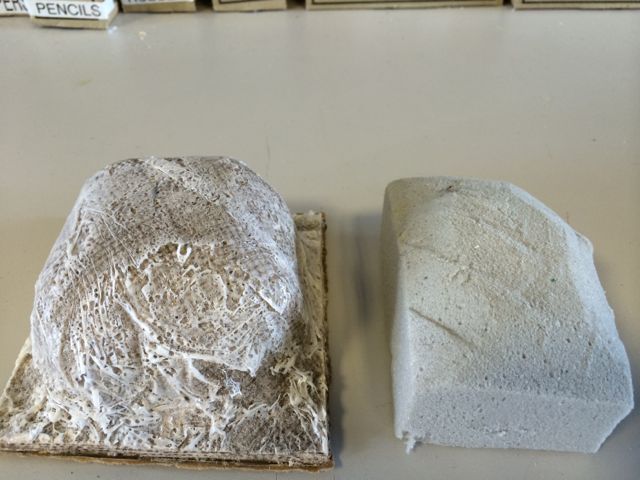

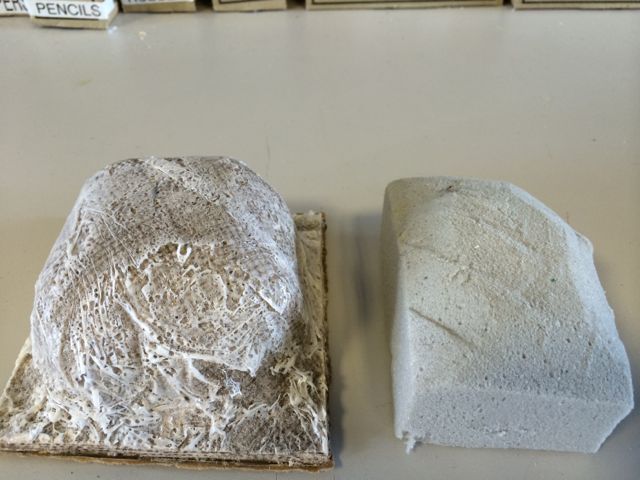

For our second test we decided to mold around a foam core using the

smooth-cast 310 and a vacuum bag. We cut a simple block shape

in the foam with a craft knife, layered a hand cut square of fabric

with darts cut into it, poured on the mixed smooth-cast and used a

wooden stirrer to spread it around. The whole thing was rather

messy, so we assembled it all on a piece of cardboard and inserted

it 'cardboard and all' into the vacuum bag.

For the vacuum bags we used 'clothes storage' bags and a standard

vacuum cleaner to generate our vacuum. The vacuum had to be

'topped up' every 30 minutes or so as the bags were slightly leaky.

What we learnt:

- This object proved to be very light and strong, stronger than

the foam core on it's own.

- The surface finish was very messy, with lots of ridges from

the folds created in the bag under vacuum.

- The smooth-cast 310 is very runny and much more difficult to

contain than the epoxy. However this means that its also

very quick to work into the fabirc.

11.03.3 Test 3 - Strength

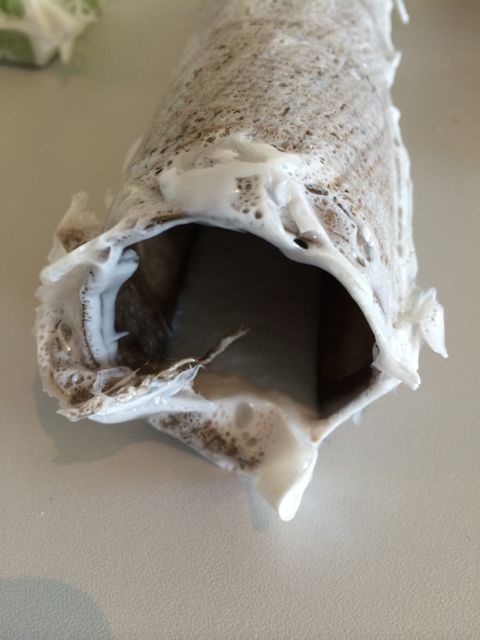

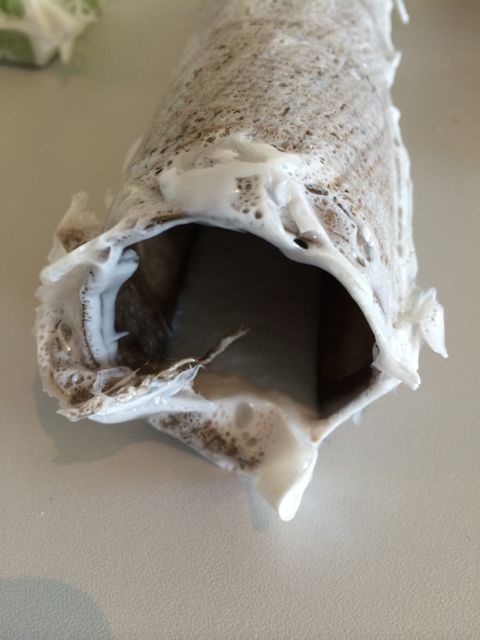

We covered a cardboard tube from the center of a roll of paper towel

to see if we could make a structural component. We used two

strips of hessian winding in opposite directions and Smooth-Cast

310. The final object wasn't very pretty but it did take my

weight.

After a while it finally failed! When we came back to this

part the following day it felt much more rigid. With more care

and longer curing time I think we could make genuine structural

parts out of these materials.

11.04 Conclusions

It's messy.

Care is required to make the final parts 'tidy' without the need for

lots of post process cleaning of edges etc.

Update

Oliver has painted his monster feet!

Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog