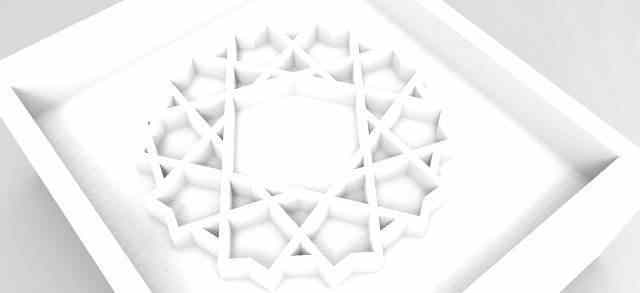

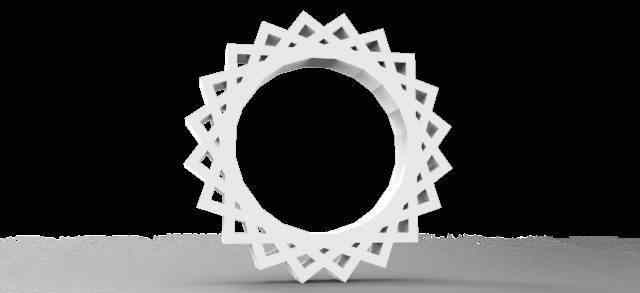

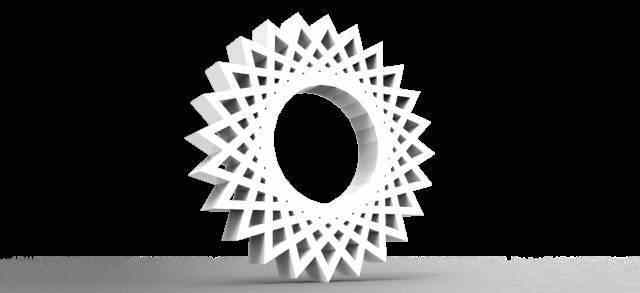

-while modeling i came up with more

than one design, most of them were too complex to be

exported as a STL I tried more

than one shape, square, triangle, rectangle and

finally i came up with an idea, to simplify the

connections between the shapes

makes it easier for rhino to recognize

By trimming the meshes it gave me

a more dynamic shape. also i tried to boleen them,

group by group till finally rhino managed to

union them all

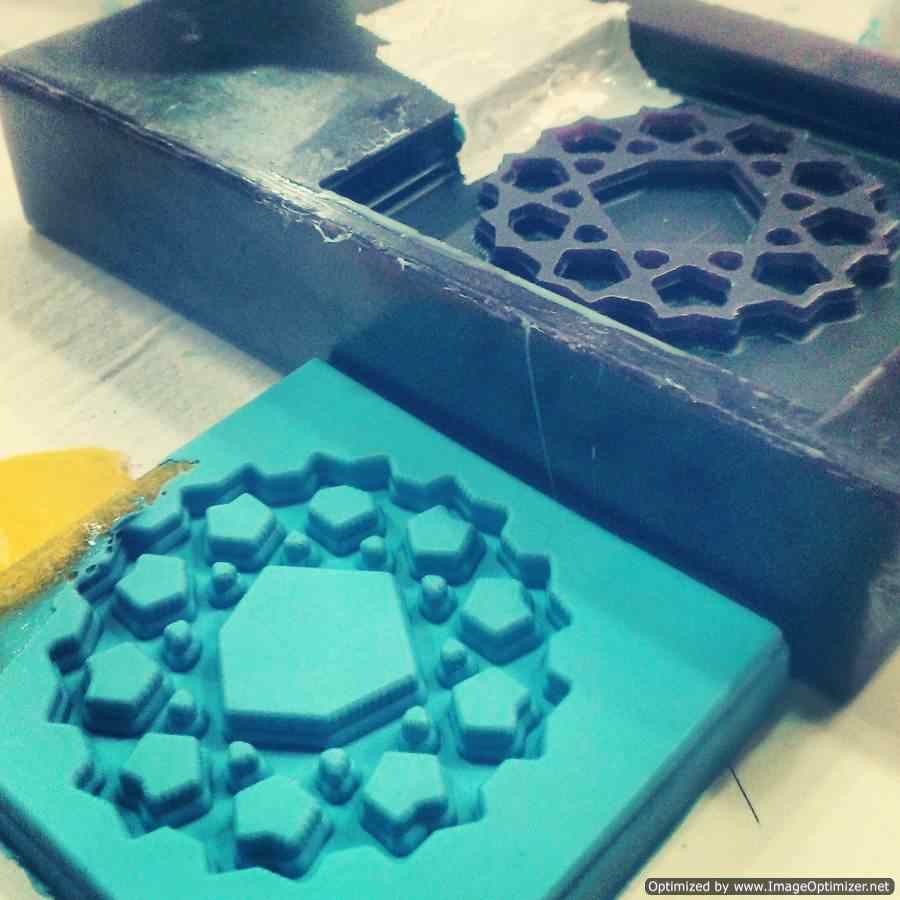

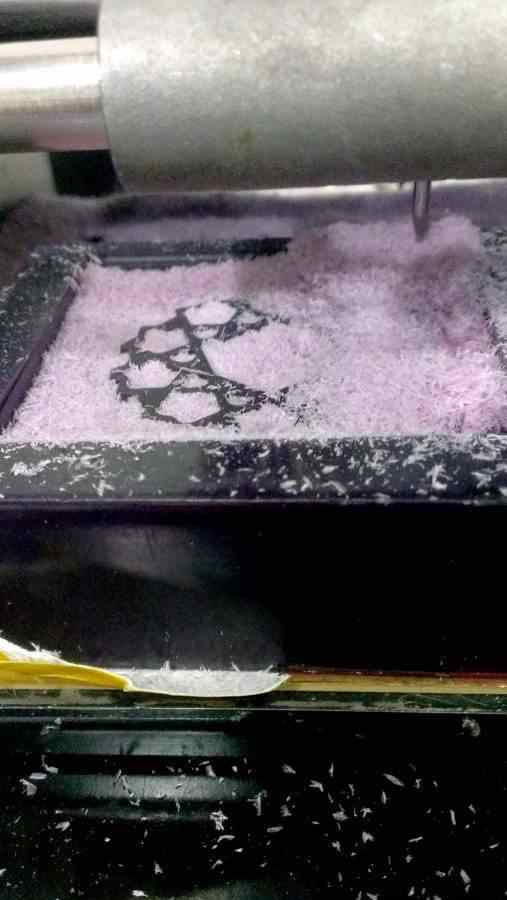

This box sounding the design is the Wax mold I'm

milling my design in. Actually after starting to mill

i though that if the outline of the

mold was circular like that of the design, it would've

saved time and material

TIP Take your time to modify your

design to save as much as you can, TIME AND MONEY

Milling

I used the IModela to mill the

design in wax. Before exporting your design from rhino

as a STL Make Sure it's LEFT

TOP point is at

the origin

(0,0,0) as the machine starts working from top to

bottom and from left to right and also make

sure its in millimeters other

wise the machine wouldn't

recognize it

The Machine mill STLs on two

stages, ROUGH and FINAL where the

Rough uses the bold pin, and it takes less time than the

final, it also

moves on both axis

(x,y) at the same time. While the FINAL, uses a

finer pin to

smoother the contours of your design, it will take much

more time than the first one, since it mill your design

twice on as

straight lines in the direction, then the second is doing

the same

thing but in the X direction. Both procedures with

variations of the Z

direction according to your design's

surface

t

i had an in individual problem with

the mold is that i was using a

used wax bar so the borders of my

design overlapped the old

design milled in the bar. i had

to fill the opening with tape

! let's hope it works

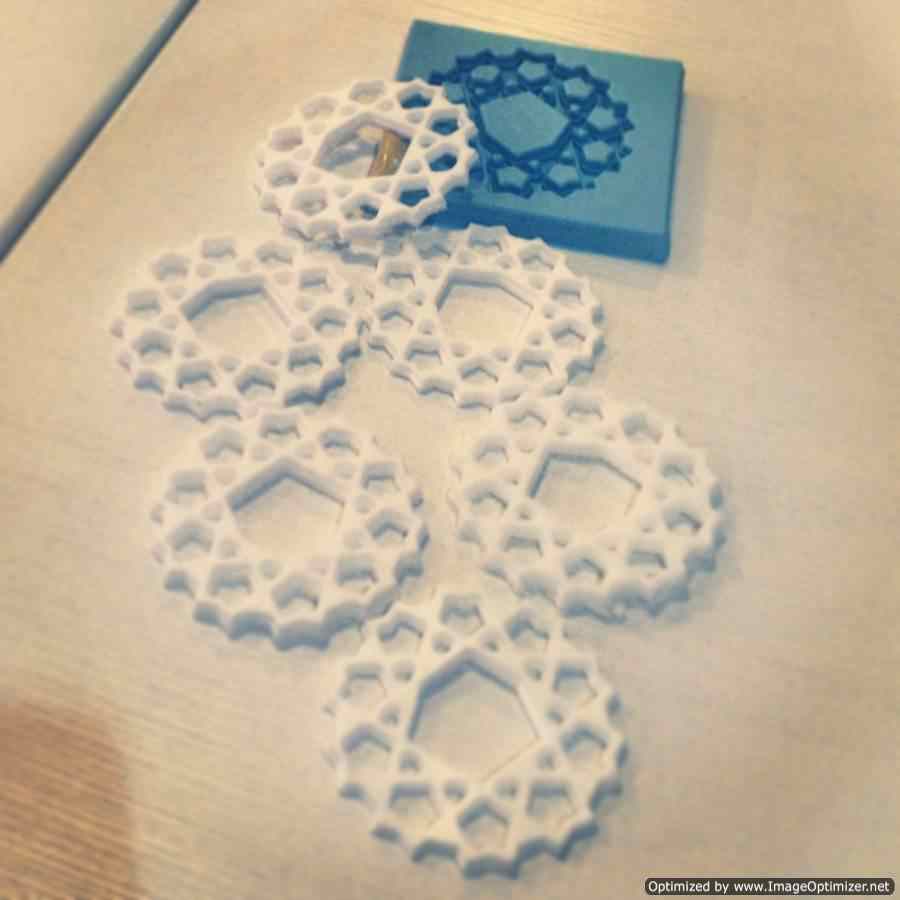

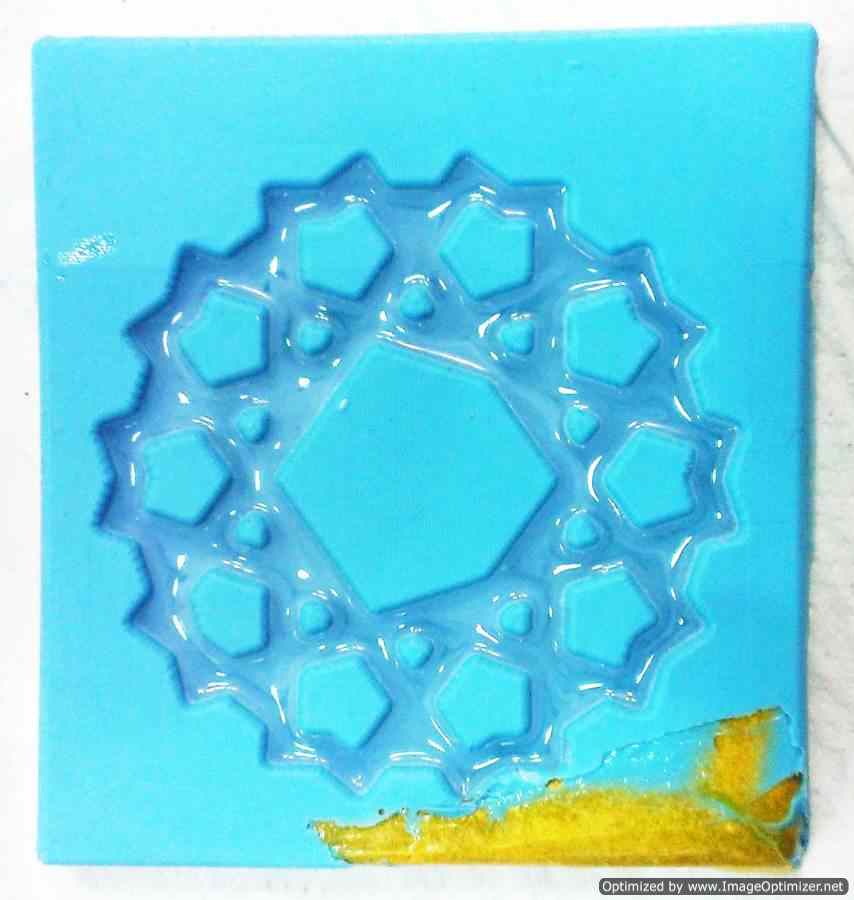

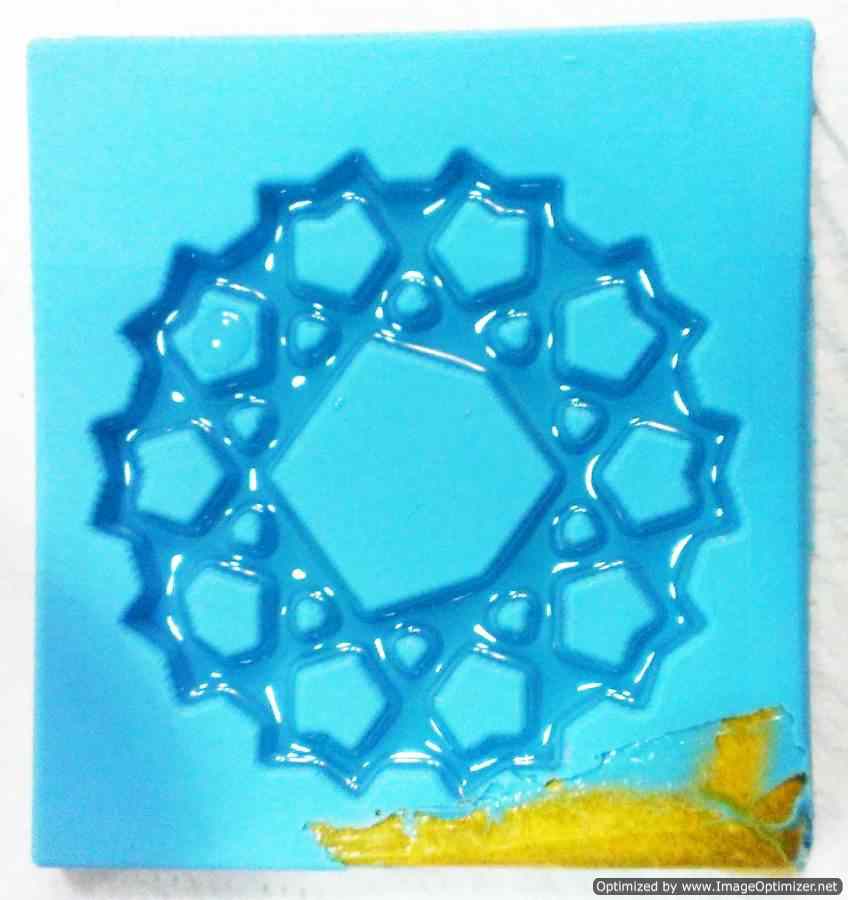

Finally i did the mixture

of the rubber mold and

poured it in the wax, it

still has six hours

to go!

IN 20 MINS

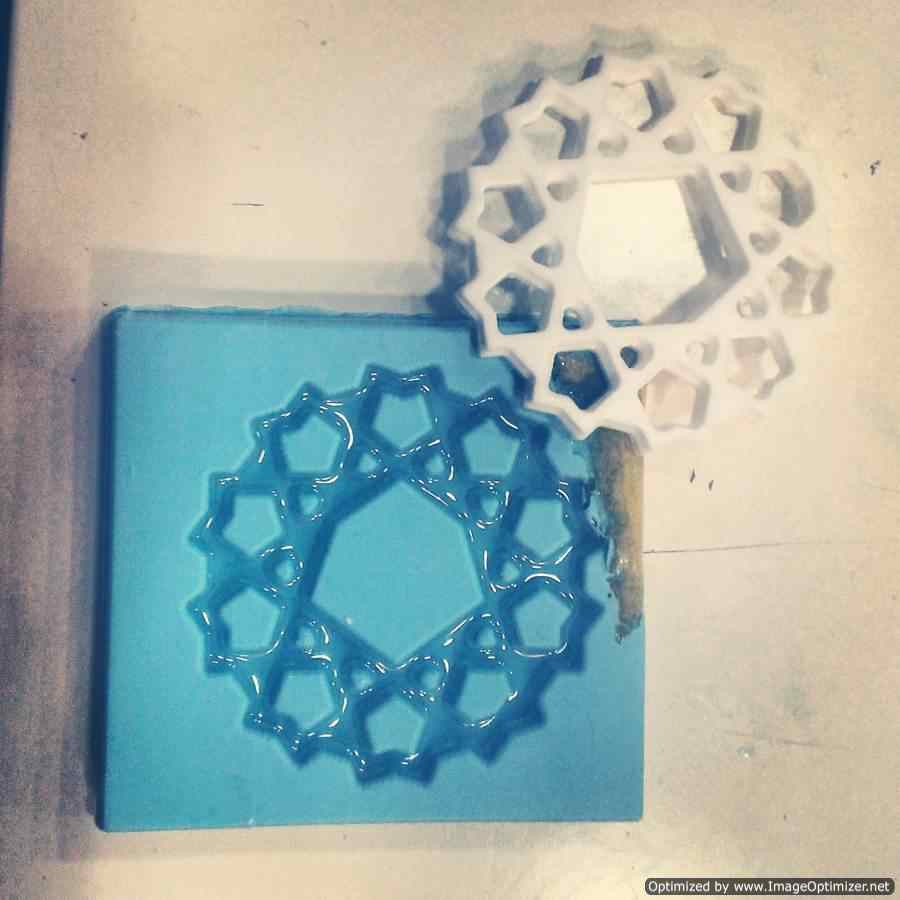

After

finishing the mold you take it off the wax, you then

get the negative of your design. Then you mix the

solution for your

final piece. you should use same amount from both jars

and mix them together then pour it to your rubber

mold, but by

changing the ratio between the two solution you can

control how hard or flexible your final piece will be

>Proposal

>Digital model

>Laser Cutting

>Electronic

production

>3D Scanning

& Printing

>Electronic

Design

>Molding & Casting

>Embedded programing

>Computer-controlled

machining

>Input devices

>Composites