DESIGN

-This week we are doing composites. i

decided to experiment more and not

just use it as a rigid surface

composed of layers,

but as a resilient surface that

bends but still holds it's shape.

-My design was so simple while

modeling but was difficult at

milling yet more difficult at adding

the composites. the digital design

was made with RHINO 4 . then i

used RHINOCAM to get the GCODE for the

CNC cutting machine

-I used

two files one for the rough phase

using the 12mm pin and the other was

the fine one using the 6mm pin. The

rough phase is

basically done in horizontal

lines with a bold pin moves only along

horizontal line roughing the material

. while the finalizing one is in the

opposite direction with a finer

pin for a finer resolution.

-On the left

img is the ROUGH job Gcode, if you

opened gcode on your computer using

word-pad you will get this image,

bunch of vertices.

that's what rhino cam does after

setting the pin's radius and depth it

coordinates each vertex to the zero

point resulting a digital code

for the machine. so basically rhino

cam is like a translator between the

digital model to the physical

world.

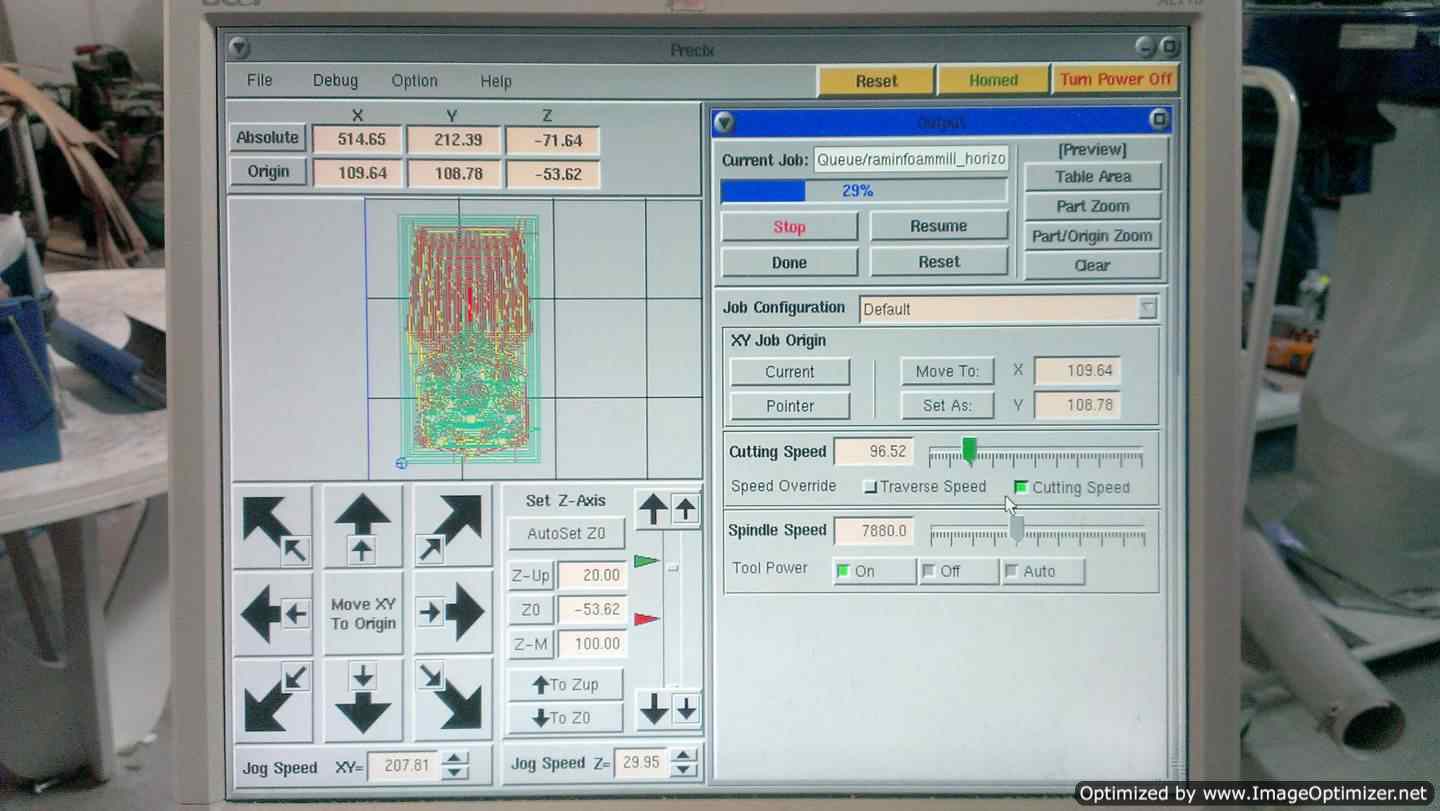

MILLING

after sending the

files to the machine and fixing

your foam piece, you start

calibrating the zero point to move

the X & Y you do them manually

with the arrows the big ones

move faster than the smaller ones

and the Z has to be above the

material and it's adjusted with

the up and down,

the green arrow is the

maximum up while the red sown is

the maximum down which will be 100

according to the materials

thickness. Speed

you can increase it up to 96 as

foam is a flexible material will

not the break the tool. you send

jobs one by one, first the rough

then after 100%

you click DONE then ADD NEW FILE

TO THE JOB and send the other one

after changing the tool

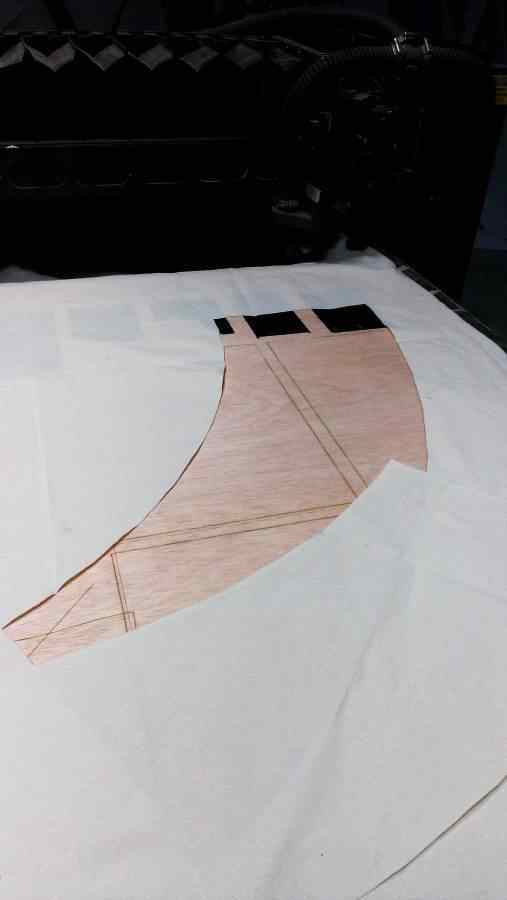

LASER

CUTTING

While milling the

model i prepared the fabric layer

using RHINO5 to unfold the model

using the command SQUISH.

Cut it with the laser

cutter on a cotton fabric. CAREFUL

while

unfolding any file rhino explode

the shape automatically don't

forget to either join the segments

or redraw it in a neat way

if you had to. because if you send

it to the machine the same way you

got it from rhino the machine will

read the line

in pieces and you will just

use more power and get an

inaccurate result.

-IF that

happened DONT pull the fabric,

use a cutter not any force

because natural fabrics are

like a mesh with perpendicular

grids so if

you teared the connected

part you will screw the whole

part.

-Be aware that the unfolded

shape rhino5 gave you probably

wont fit your mold due the

probable inaccuracy of the

milling machine. for

example here at my

design the sides were too

steep so that the pin didn't

penetrate the foam exactly the

way it is in the model. So i

had to cut

the extra parts even

after laser cutting.

cooking

-After two hours

of milling and laser cutting, both

the mold and the fabric are now

ready for the cooking. I

then started mixing the

EPOXY with the HARDENER

with ratio 2:1 respectively.

then i dipped the fabric in it

make sure it's all covered with

the mixture, then

squeeze it to get rid of the

extra past.

this transparent layer

facilitates the removal of the

composite off the foam after

finishing so you start with it

then you composite

layers then another

additional one to protect it from

the white cotton layer. TIP my

design was complicated it had a

lot of imperfections

so a tip for you in the

future add the layers separately

from the model respectively as

mention then apply them all

together at the same

time on the model to avoid

wrinkles or sticking into your

gloves.

EVACUATING

-Preparing the bag

by cleaning the inside from the

previous job and making sure that

both the front and the back side

are perfectly

closed to prevent air from

entering the bag. the tool has to

be perpendicular on the foam

preferably away from your design

and on the

cotton sheet.

After a nearly six hours i took

the model out IT WAS A MESS!

FIRST the

cotton layer wasn't easily removed

i had to pull it off by force,

which means the fabric wasn't

completely covered with the

transparent paper from above SECOND

most of the folds were

wrinkled which means either the

fabric was too much, or it wasn't

put properly

and in my case it was both

THIRD the tips were almost

impossible to remove because they

weren't covered very well with the

transparent sheet from beneath

SECOND

TRIAL

i simplified the model made it with

less edges and tried a new material now it was

CORK, by goin through same steps regardless

the material

took more time but the results were good

enough

>Proposal

>Digital model

>Laser Cutting

>Electronic

production

>3D Scanning

& Printing

>Electronic Design

>Molding & Casting

>Embedded programing

>Computer-controlled

machining

>Input devices

>Composites