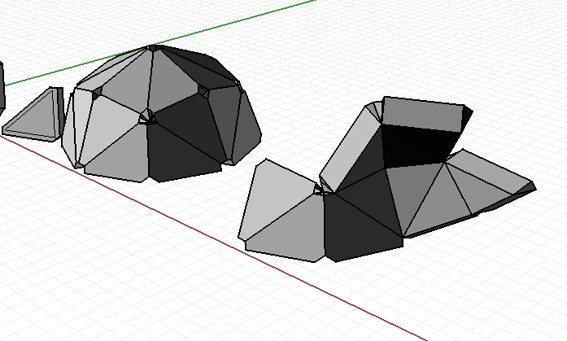

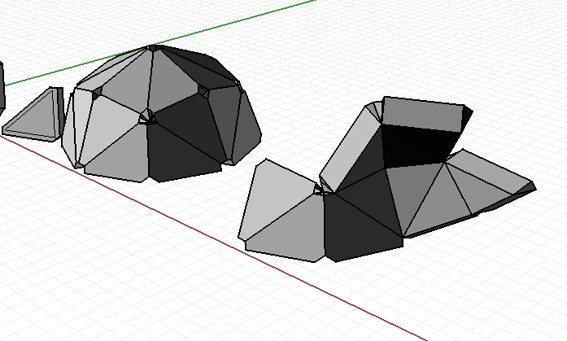

For my mold and casting assignment, I am using a component that 48 of

them create a whole sphere.

My intent is making the components together by tighten with a rope that is

going through.

By this way I could also flip some components to create different

surfaces from the same component.

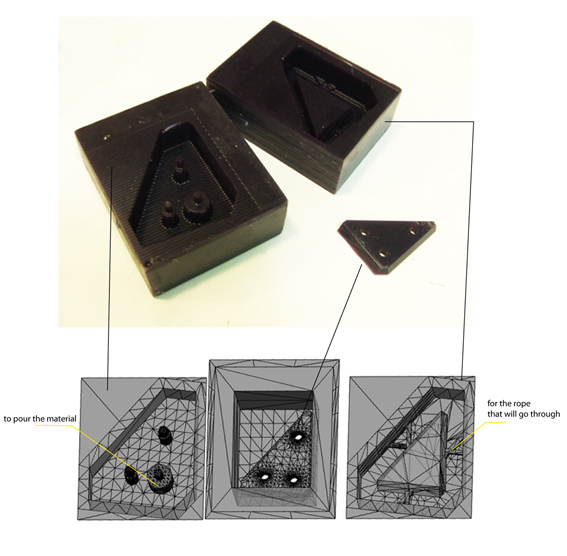

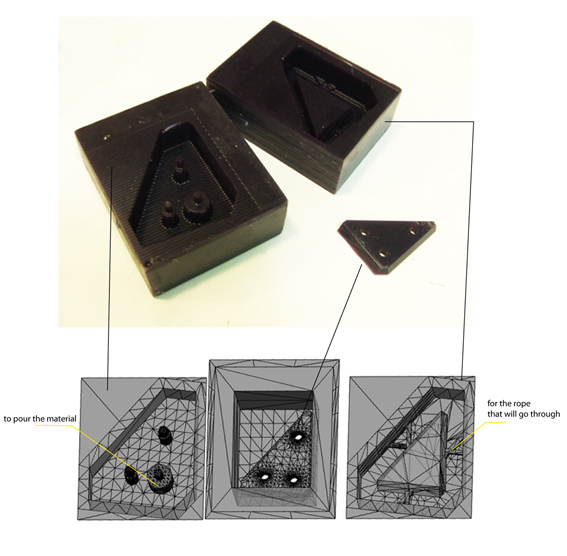

Since I am using modela to mill the wax and using the tools that we

have in the lab. I did some restrictions. I should only have slope to

one side (it is because I have 3 pieces) and since the tool that I use

for finish milling has a limited milling depth, I have decided to make

only rough milling to the parts that may stress the tool since these

parts also seems not to make difference to my final casted piece.

(plus I will gain time by this way)

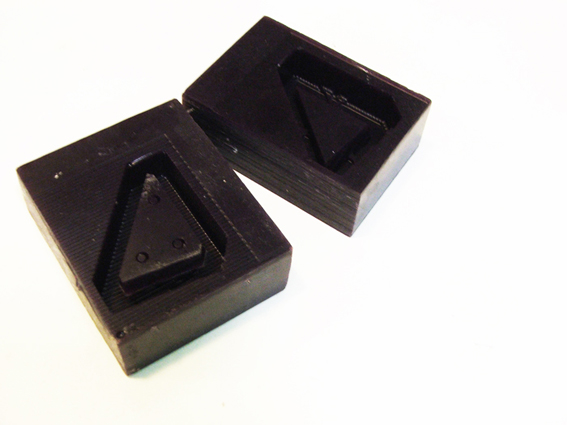

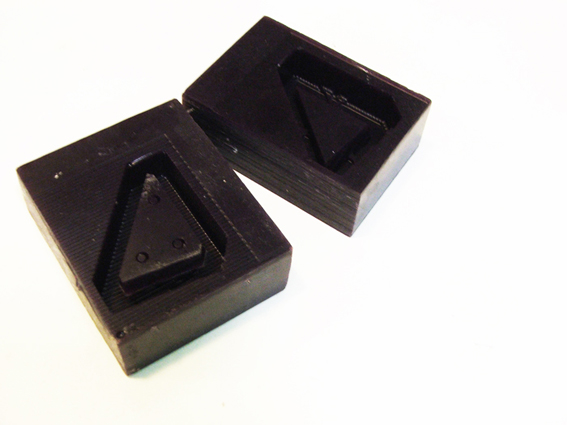

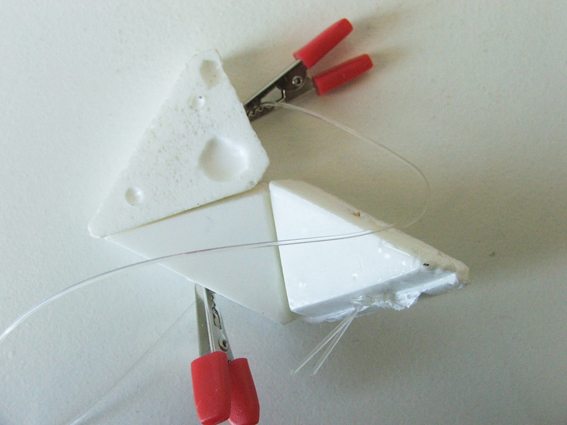

The final mold to cast the component...a photo that is showing the

place of the small piece........

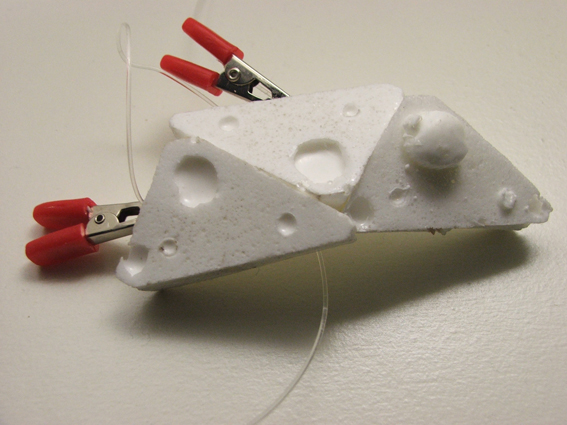

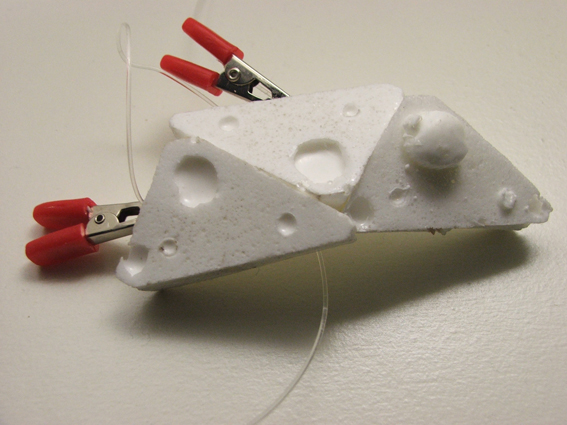

I used wooden sticks and sprey an

oily liquid in order to have the holes inside.

Through this holes, a rope is passing through. So when the rope is

tighten up, the force is holding the pieces together.

three of them showing how to tight them with a rope and flipped

variations.....