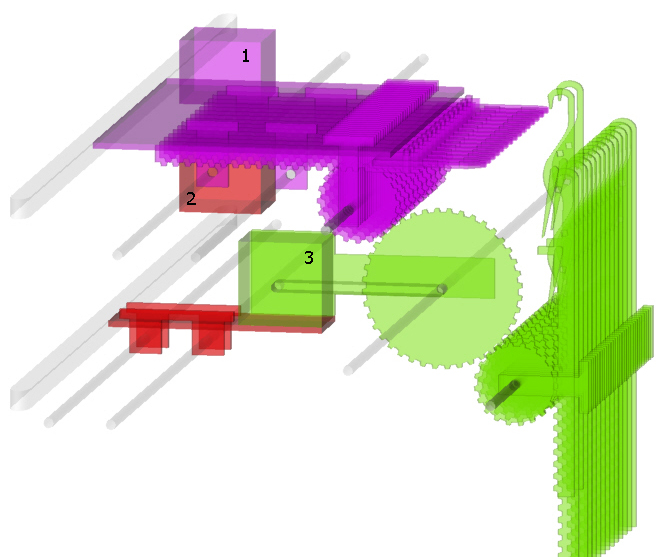

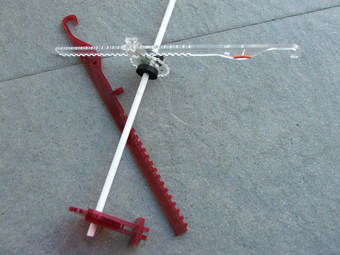

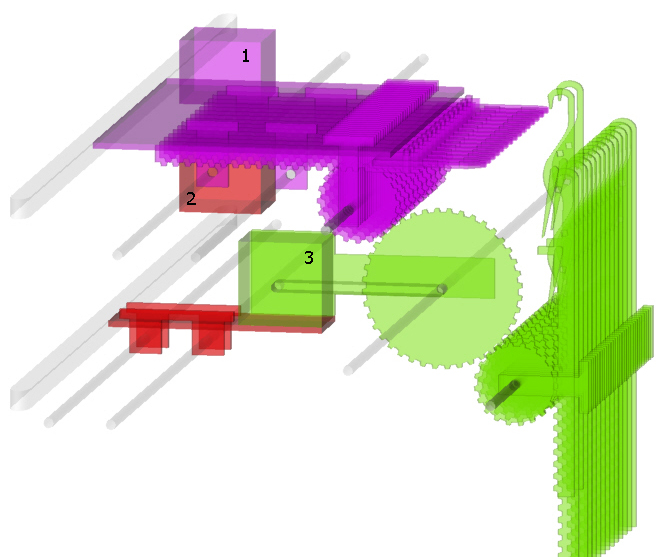

Mechanical Part//

parts:

purple part: to decrease the stiches

green parts: to make stiches

red part: to align the main gear with the desired needle(stich /

decrease needle)

motors:

motor 1: moves the decrease needles to right/left-the wool will be

attached to this platform

motor 2: moves the main gear to right/left(to align the main gear with

the desired needle)

motor 3: rotate the main gear both direction(that moves both decrease

and stich needles behind/front)

+The overall design is almost finish.

+Since the pieces for needles are so tiny, milimetric change makes so

much difference... One of each needles should be done physically to

make the final file to send the laser cutter.

*I need to find out how to use the motor3 to rotate main gear with "x

or multiple of x" angle in order not to hit the needle gears while

making the linear movement.

**There may be some problem for moving the wool to make the stiches...

I should have more time to make experimentation on this....

***the last image of the machine won't be something that seen so

professional- it will be more like a test model.... Mechanical parts

should be developed for future machines...

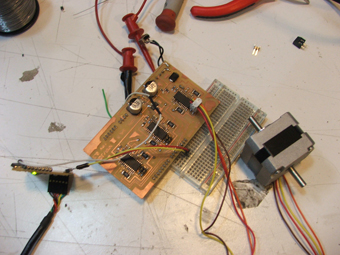

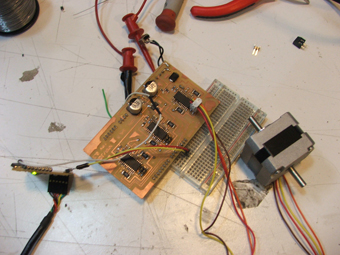

Electronics//

My board should be the same as Jonathan Ward have designed for

the milling machine.(except the spindle holes).

I fabricate exactly the same board that we made for the machine design

assignment and some components are already soldered....The missing

components were ordered....

(I am using the one we did, for handling to operate it)

Software//

one stepper motor was moved by usign the arduino uno...

needs to be cover it with fabduino( which I have already made before...)

I will try to connect the three motors and sending a gcode that will

run the motor in the air....

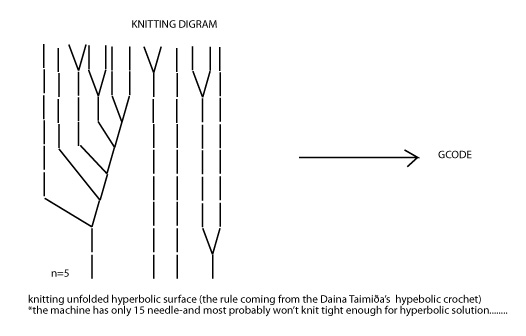

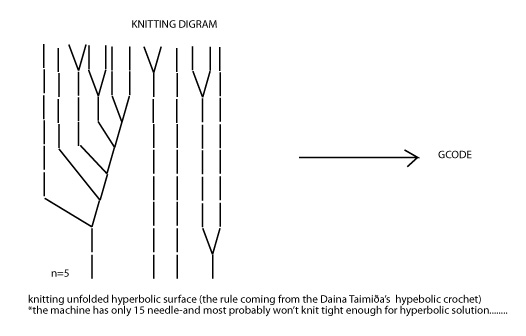

Writing Gcode//

I need to write my own gcode since it will not be the same as gcoding a

3d model.....

I may handle to write it manually...????

"how to convert a diagram to gcode"