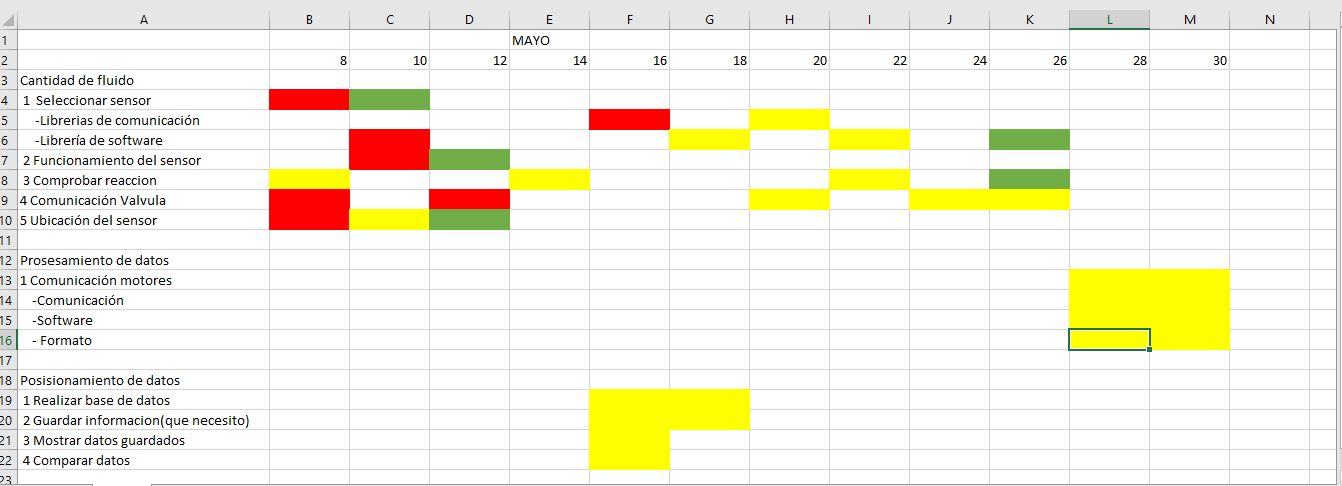

What will it do?

I going to be a machine to facilitate a production prosses in a ceramic workshop, this machine is based in the movement of the CNC machine, the idea is that the machine saves

the position and inject a paste ceramic inside of the mold, this proses is important because requires a constant control, the mold is made of plaster and in the contact with the

paste ceramic the mold absorbs the humidity and the paste begins to decrease and need to fill it.

In this process, I have two variables number of molds and the amount of ceramic paste that each one needs and for this the machine should save the position and with a sensor

control the amount of ceramic paste.

Who's done what beforehand?

I did not find the exact example but is the combination of these two processes, the first machine is known as filter press ceramic and in the second video you can see the

injector to paste ceramic in the first process until the second 0:35.

How much will it cost?

For the components, they are not in fab inventory:

- - Photoresistor 1$.

- - Laser 9$.

- - Electro valve 3$.

- - Stepper motors 20$

- - Transistor 0.30$

- - Relay 1$

- - Iron Rods 30$

- - MDF 2,40$

- - Square tubs 23$

- - Miscellaneous expenses $25

How will it be evaluated?

Make some tests, first check all the circuits made and when all the circuits are right make test with the paste ceramic and correct some errors, check fluid behavior.