Introduction

In recent years, organic agriculture has taken relevance, solving the preoccupations of the consumer about the use of chemicals for the care and fertilization of crops.

In Central America it is also an economic solution for the farmer, using this handmade product, but this means that the farmer has to invest time in the production of this fertilizer, especially because it needs certain cares and constant tracking during the process.

Because of this I want to implement a partial automation of this process, but in a smaller scale as a first approach to a larger scale solution that is optimal, sustainable, accessible and convenient for users.

State of the art

What is Bokashi?

It is an organic fertilizer that is obtained by the fermentation of its components, provides the necessary nutrients for the development of the crop and makes them available to plants to stimulate the growth of their roots and foliage.

Ingredients

- Chicken coop or other manure

- Coal dust

- Rice bran

- Rice husk

- Lime

- Molasses

- Bread yeast

- Clay soil

- Water

Elaboration process

- Prepare the ingredients, if there are some components that are too large we have to chop them

- Tend the solid ingredients and mix them without a specific order until we get an homogeneous texture

- Prepare mead, apply slowly to the mixture

- Sprinkle small amounts of yeast each time we add an ingredient

- Make the first flip of the mixture

- Measure the temperature and flip the mixture before it reach 45°C or three times per day until the fertilizer is cool

- After that the fertilizer is ready to use or storage

Proposal

My proposal is to make a machine to automate this process and to encourage and facilitate so anyone can produce it for their orchard or farms, without experience.

What is Bokashing?

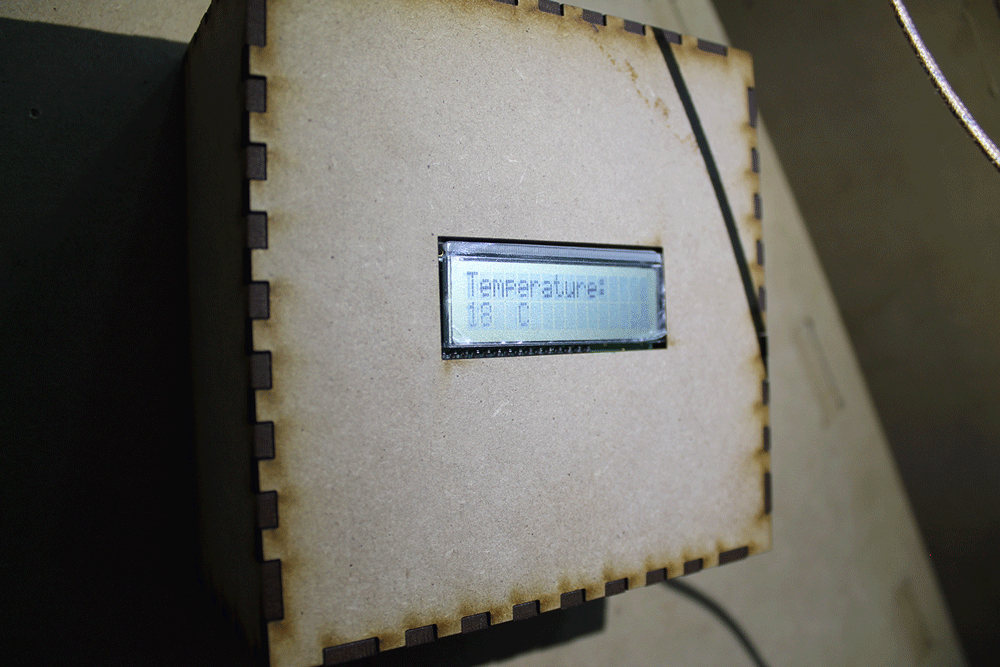

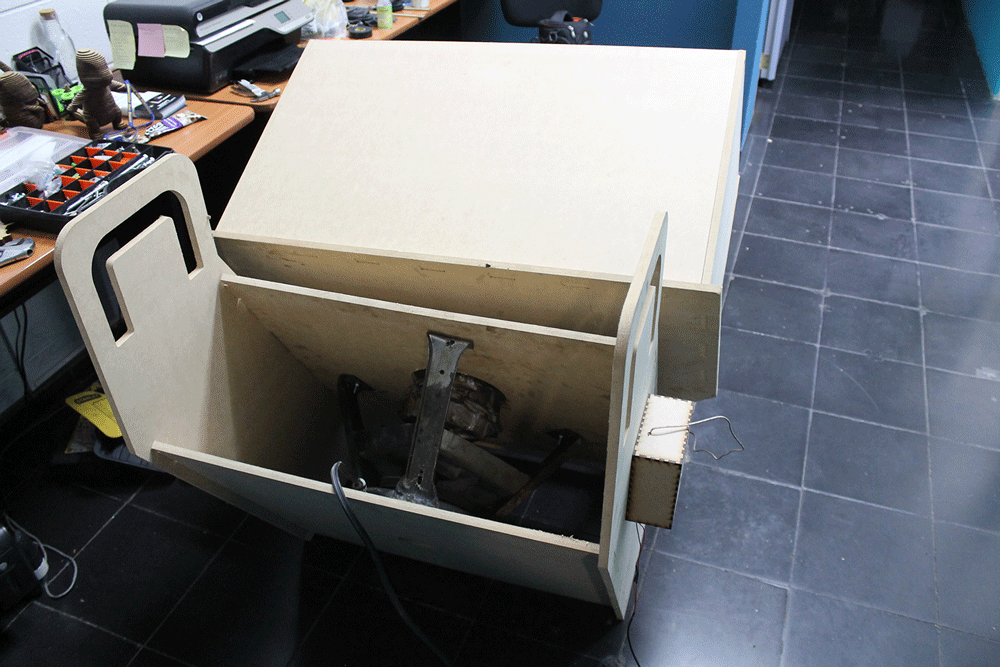

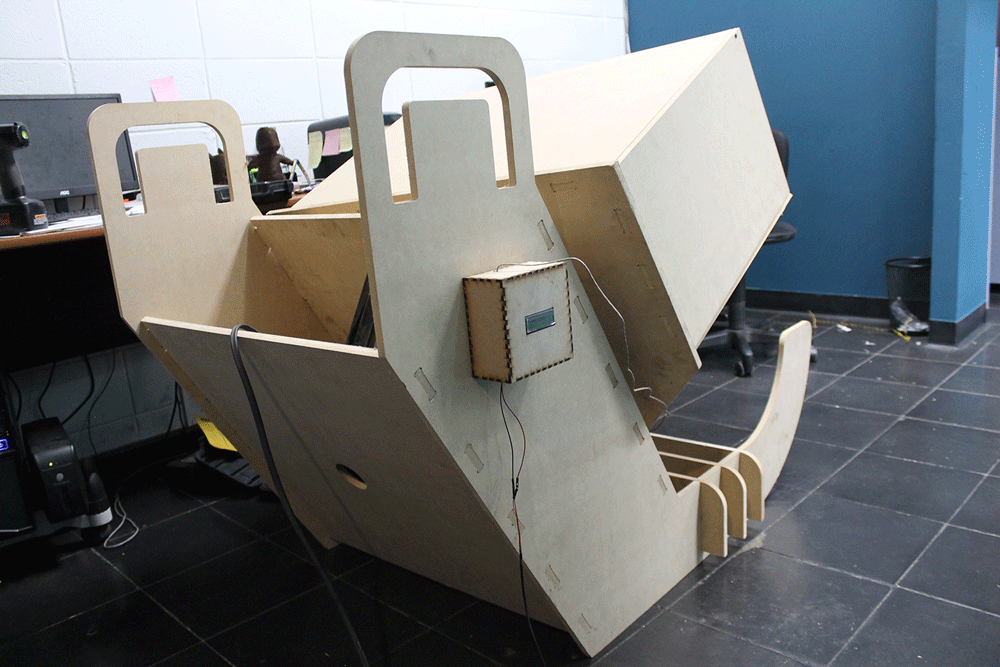

It is a low cost machine that is sensing continously the temperature of the mixture by a thermocouple, when the mixture get more than 45°C the controller will turn on a motor through a relay, that will move blades into the Bokashi container, this will let to the fertilizer to cool and will oxigenate the mixture, which is necesary for the fermentation process, and so on until the fertilizer stabilizes it temperature. It has 3 position to facilitate it use for each activity.

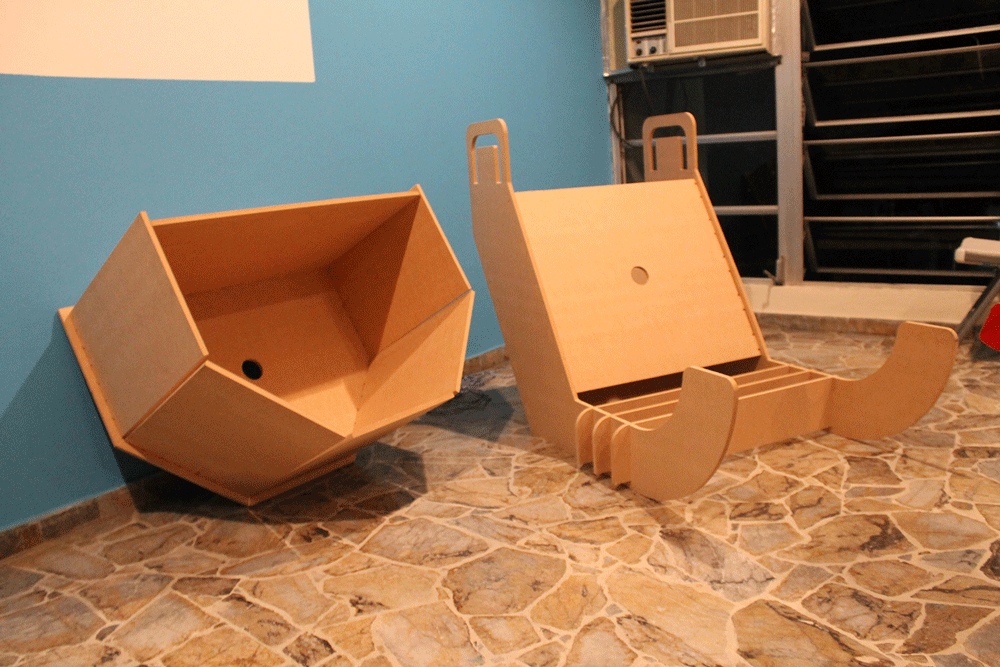

One of the most important aspect besides the function are the materials, Bokashing intends to keep the organic and green concept, that's why the whole body and container are of MDF, and the mechanical part are completely reused from a washer machine!

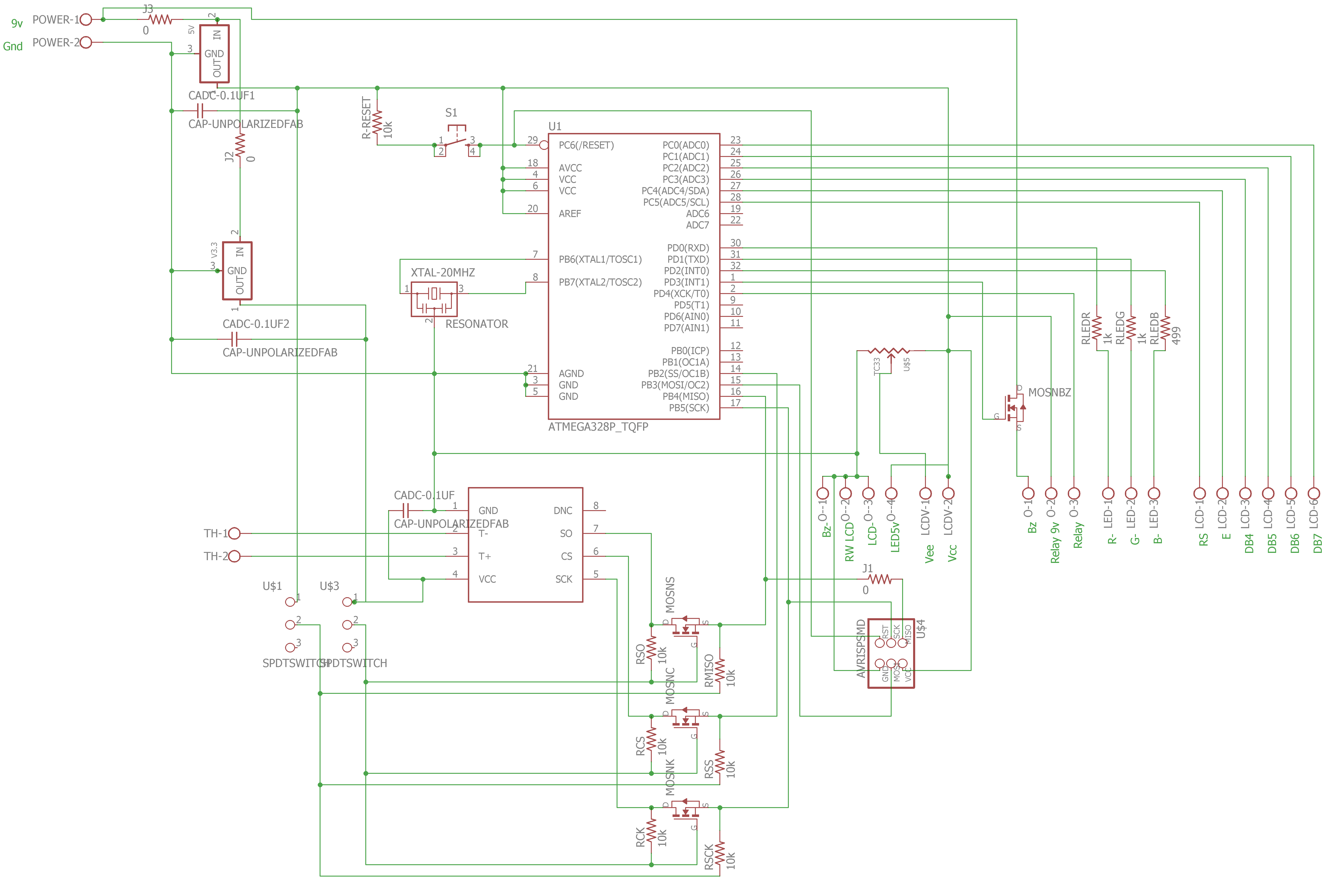

Electronical Components

- Control components

- Control Board

- Atmega 328

- MAX31855

Thermocouple-to-Digital Converter - Voltage regulators

- Logic level converter

- Resonator

- Swithces

- Buttons

- Resistors

- Capacitors

- ISP Header

- Clamps

- LCD

- Power Components

- Motor

- Relay

Structural Components

- MDF Body

- MDF Container

- Grip

- Motor leather

- Shaft

- Bolts

- Mechanical Support

Process

Electronics

First of all I decided the outputs and inputs that will need my project then I started to design the schematic circuit on Eagle, then the Board and then I exported the traces

Then I followed the same method and steps as Week 6 to make my control board:

- Cut

- Paint

- Etch

- Paste

- Solder

For programation I used Arduino IDE and FabISP as we made on week 8.

As I said before, what my program does is to sense the temperature through a thermocouple J type, but microcontroller can't read it directly, that's why we are using MAX31855 Thermocouple-to-Digital converter that can read thermocouple and send the information to microcontroller by SPI that is a synchronous communication protocol, it means that the communication is driven by a clock signal.

As we can see, for reading process we need to set low chip select pin and then converter will send 32 bits of data, one for each rising edge of the clock signal.

Here we can see what is each bit that is sent by the converter to the microcontroller, and as we can see we are going to use only the 14 most significative bits, so we are going to use bitshift right command ">>" in this case we need to displace 20 position to the right, discriminating decimal data, since for this application they are not determinant. temperature = data>>20

That was the most complicated part of the program (at least for me), beacause the rest of the code is to display the information, warnings when the motor is about to start and turning on and off a motor by a relay.

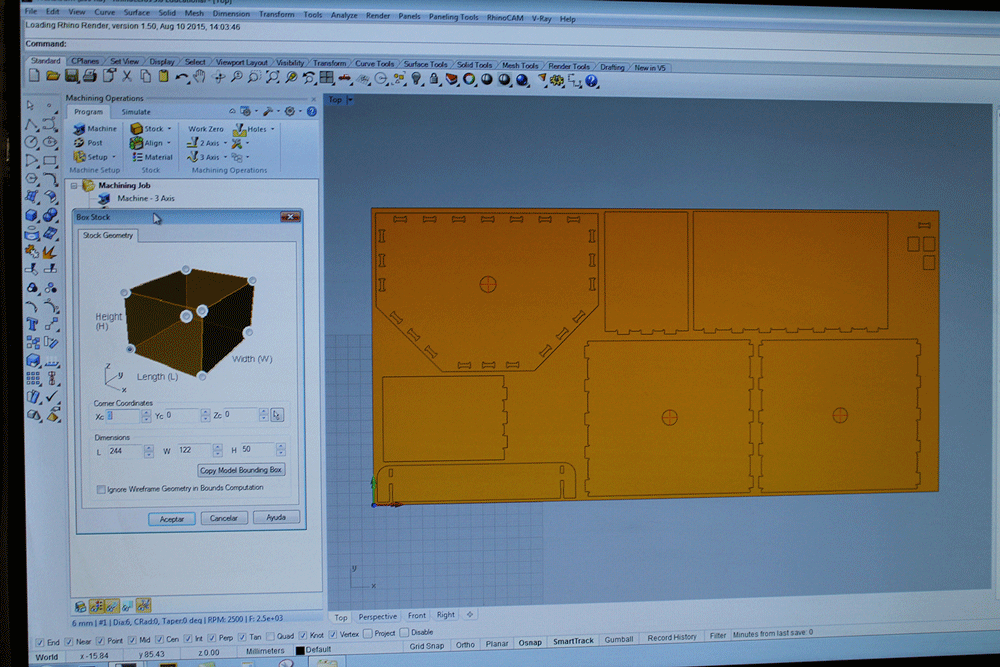

Structure

First I made a CAD of the machine on SolidWorks, with the real measures and with the locks, I validated by simulating the movements and making changes. Then I get the nesting plans.

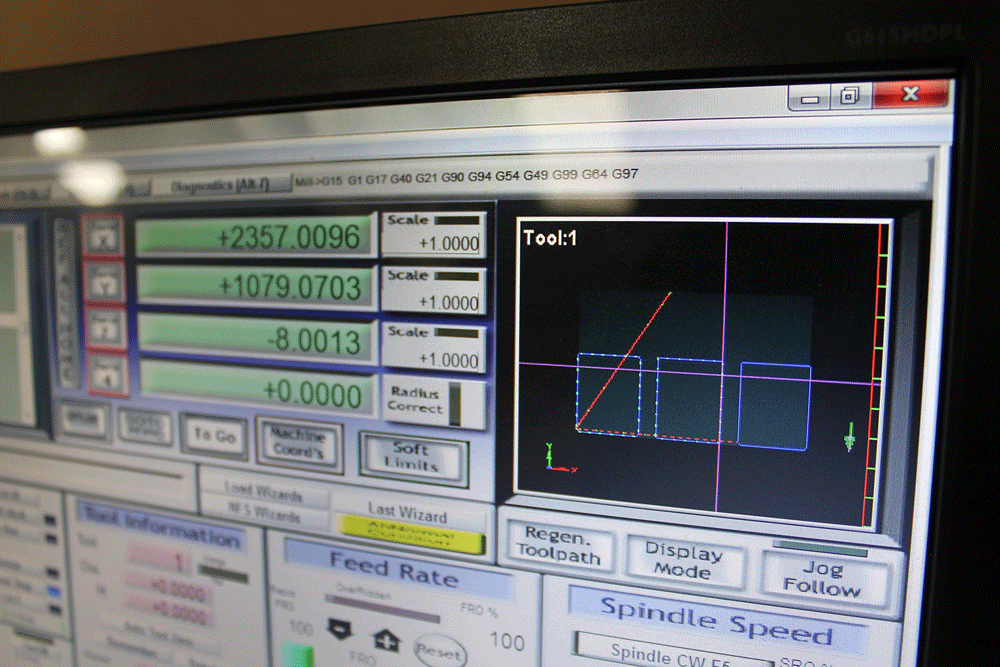

Then I generated G code with RhinoCAM by setting axis alignments, reference point, work zero, tools and operations

Mechanism

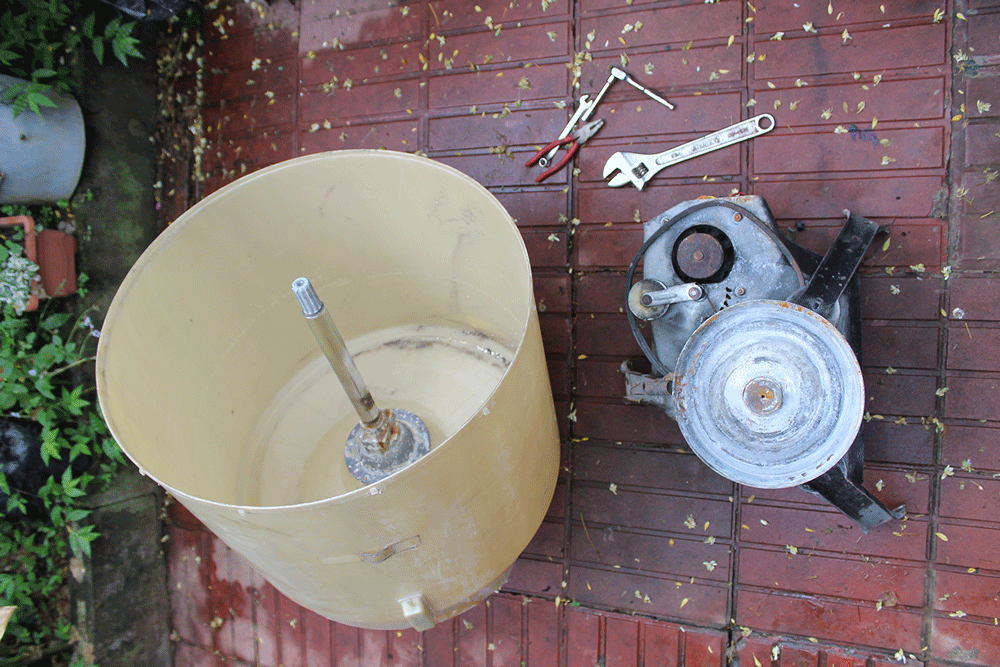

This part is completely reused, I dismantled a washer machine a took off the motor, reductor, shaft, pulley, belt and the metal structure that support all previous; clean them, quite the old container and assemble again

Results

After assembling everything this are the results:

Final Project - Bokashing from Ivan López on Vimeo.