Exercise 5 - 3D scanning and printing

3D Scanning

I'm using Fablab's Next Engine 3D scanner, Autodesk Remake and Autodesk 123D Catch as a comparison.

I will be using an Andriod figurine to scan.

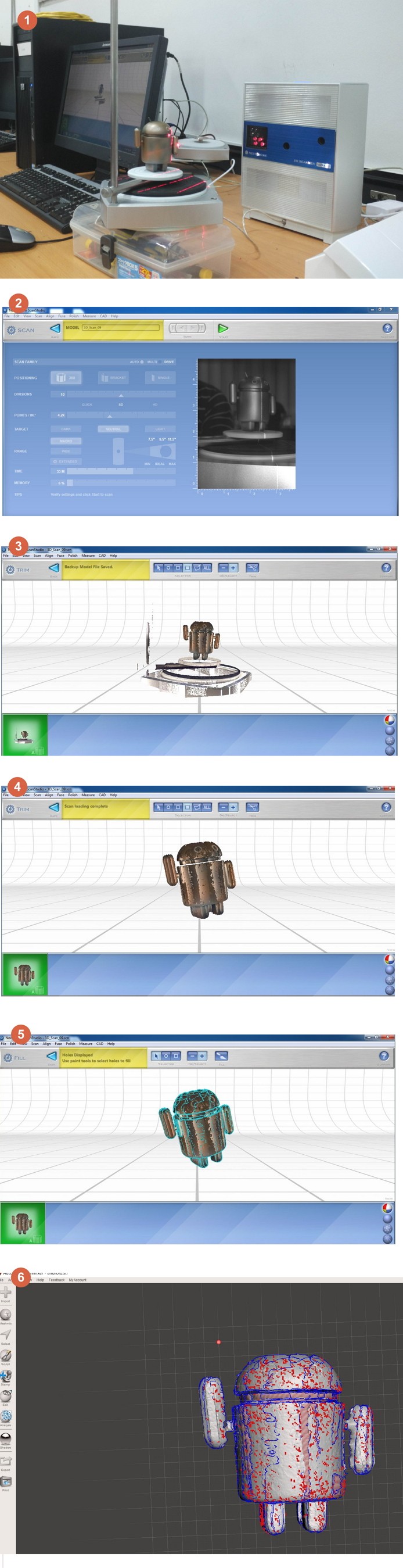

Next Engine

Using a small turntable connected to the Next Engine, it scans at least 10 pass for a medium low quality.

It takes quite a while, at least 20-30 mins to scan my object. The scanner projects a light and the Camera scans and it also uses lasers to detect the depth of the object.

We also found out that we are able to combine 2 scans, vertically and horizontally to achieve a better result.

I didn't have the luxuary of time, but will try it out when time permits.

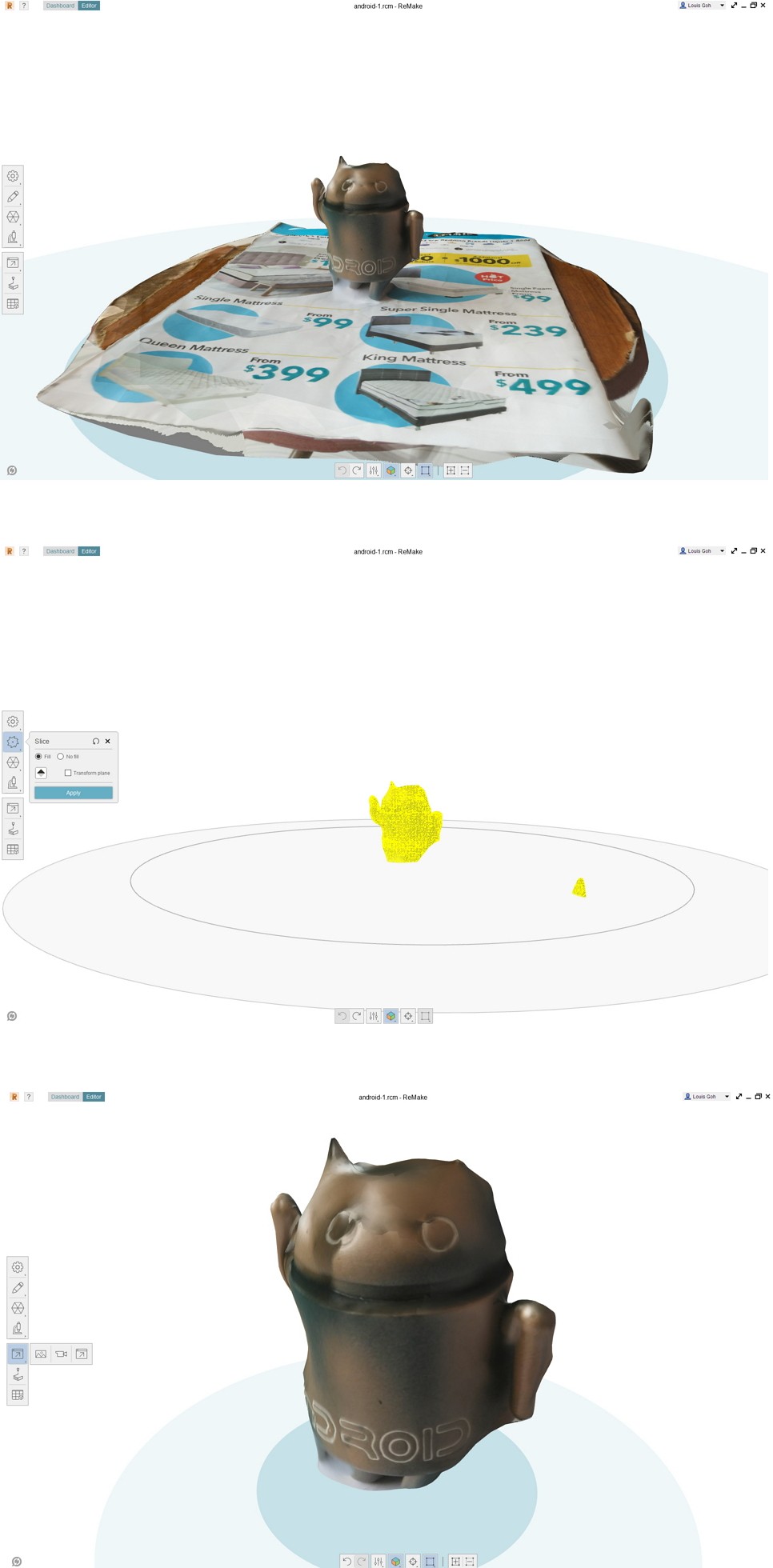

Next, I tried 3D scanning via Mobile phone pictures and upload it to Autodesk Remake. I had to take serveral pictures at different angles and upload it via the Remake. As my laptop did not meet the minimal specification, I had to upload the pictures and have it processed via the Autodesk Cloud.

I suggest taking pictures around the object and retake the object from the top too to provide more pictures for Remake to create the 3D model.

After a minutes of processing, it turns out alright. Wondering could it be not enought pictures to help generate a better 3D image.

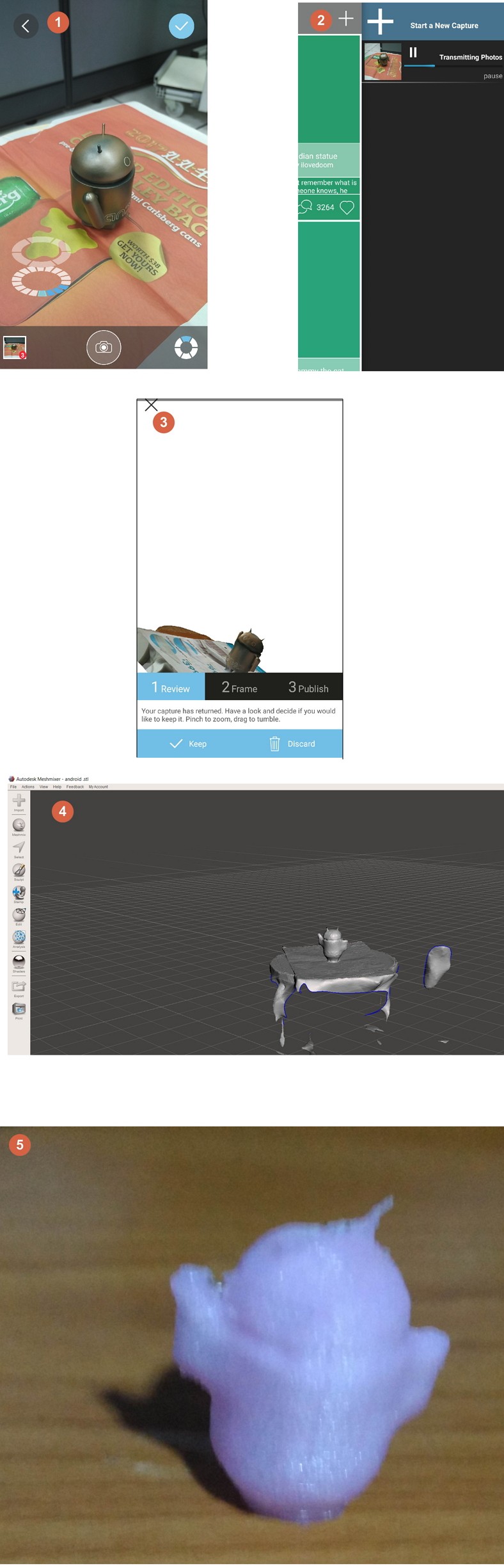

Lastly, I tried on 123D Catch, the interface was easy to use and it has a guide to show you which direction of the object is taken follow accordingly. The downside of this app is it takes a longer time to generate the 3D object, but it turns out to have the better result as compared to Remake.

3D Printing

3D printer

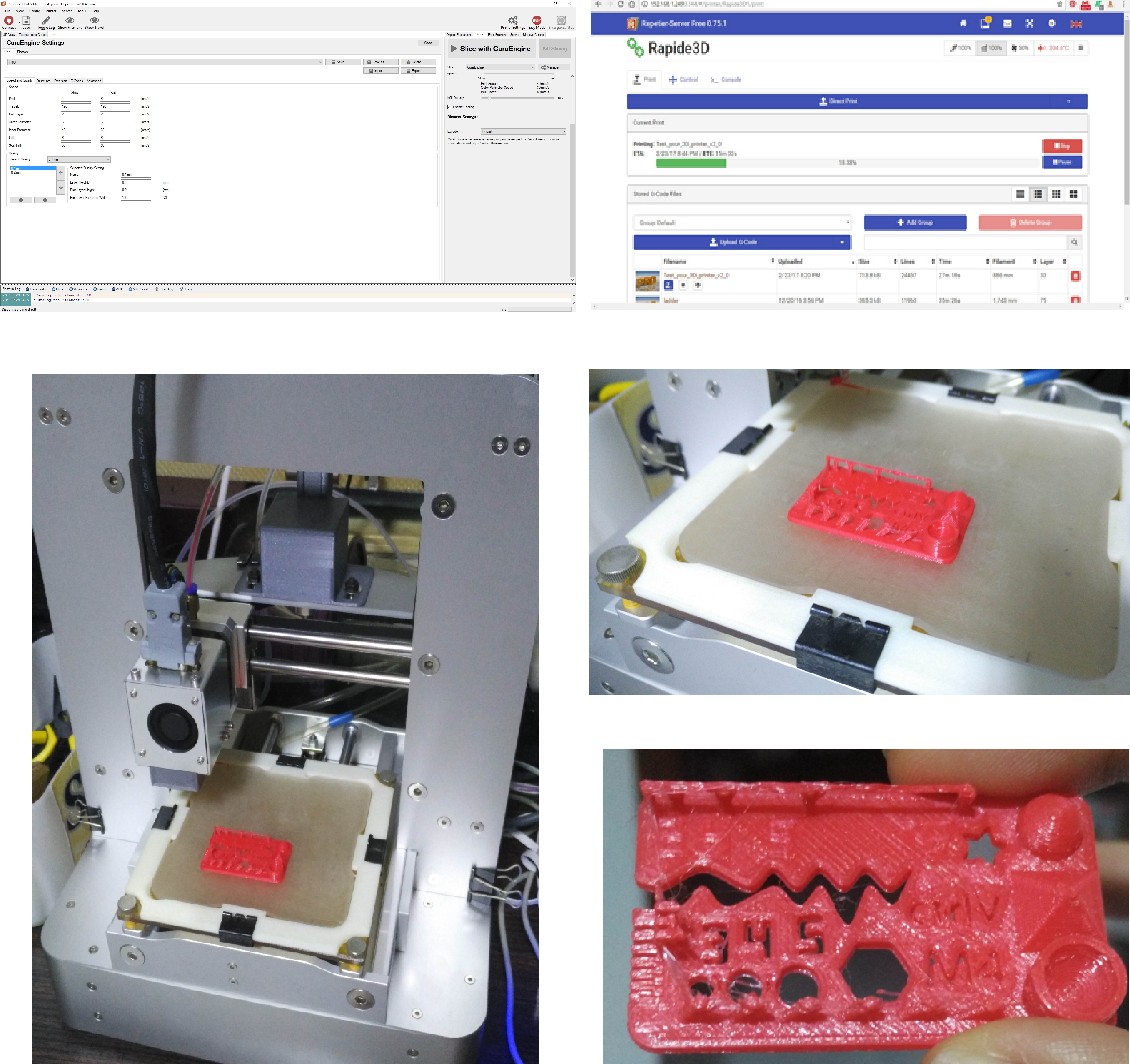

We found a printer test file on Thingiverse, we start to try on multiple printers, Ultimaker, Cubicon, Rapide3D & xxx

We are able to play with some values to identify the potential of our 3D printers.

The things we need to take note of are, materials, infill percentage, resolution(layer height), travel speed & optimal angle of the 3D printer printability.

Cubicon

Cubicon printers is using their own slicer software, in the slicer, there are advance settings that we can play about. In this experiment, we experiment with 2 different settings.

Cubicon has a very small nozzle (0.4mm) which can yield very high resolution with precision. The difference is the timing and the ability to print certain walls.

As shown in the screen shots below with the settings:

I was suprised that at 0.15mm resolution I was not able to print walls that is 0.4-0.1 mm range. Even on a higher setting it wasnt able to print the thin walls and even appears more "stringier" than 0.2mm.

One thing I can suspect is the slicer Software, it may not be able to slice the the thin walls.

Rapide3D

I've also experimented with my own 3D printer.

I tried with 2 settings.

Infill: 10%

Layer Height: 0.2mm and 0.1 mm.

Travel speed: 120mm/s and 140mm/s

Material: PLA

Slicer: Cura Engine

However, only 0.2mm was able to print out nicely. On the 0.2mm layer height print.

All of the test passed except the holes and the thin walls test. The holes were 0.1mm difference and walls below 0.5 were unprintable.

Conclusion:

Cubicon Style

Resolution/Layer height: 0.2 mm(more than enough in terms of quality)

Travel speed: 120mm/s

Rapide3D lite 100:

Resolution/layer height 0.2mm (best result it can get)

Travel speed: 120mm/s

3D Design & Print

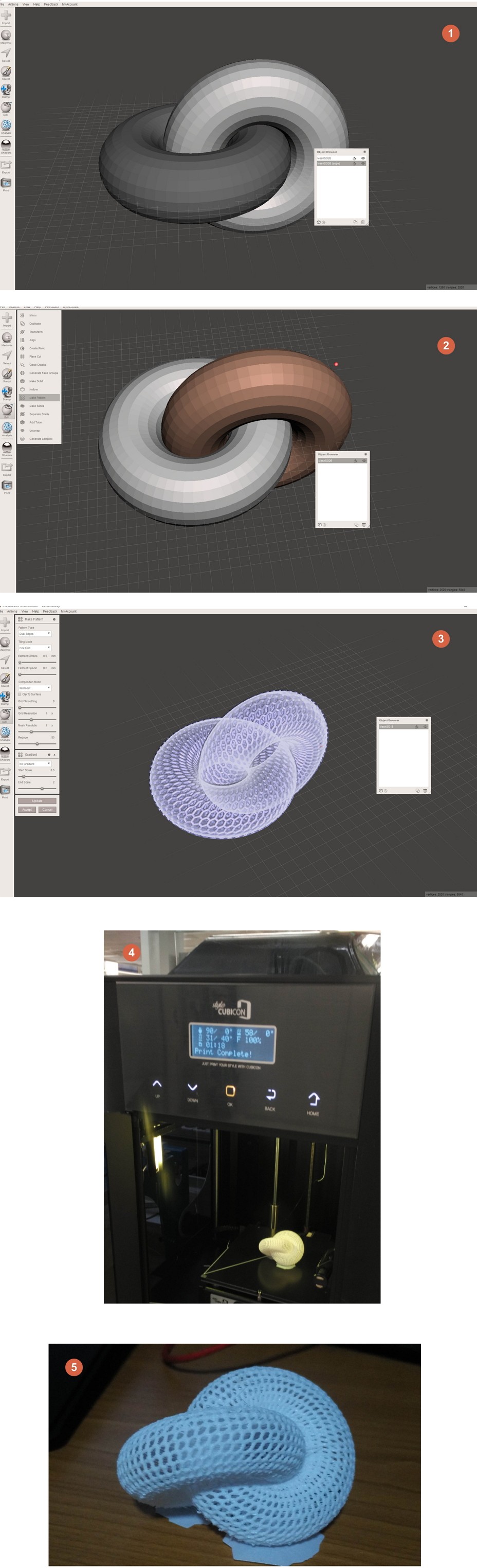

I am using MeshMixer to design something called Voronoi pattern. I had to design something that a milling machine couldn't do, therefore the designs of 2 Torus and making it with Voronoi pattern.

I designed it with Meshmixer with the settings, I was able to create the design with ease.

1) Click on "Import Sphere" to create scene.

2) Next, Click on Mixmesh icon on the right, click and drag 2 "Torus" into the scene and delete the Sphere.

3) Select all of the shapes by "Ctrl-A" and Combine them.

4) Then click on Edit on the left hand side and select Make Pattern

5) Lastly, select "Pattern type" to "Dual Hex". It generates 2 hollow torus which also means milling machine are unable to reproduce!

Next, I export it to my Fablab's Cubicon and printed it with only Brim and no support it turned out really great!

Downloads

Download Android stl Scan: hereDownload Donut stl design: here

Download 3D printer test: here