05. 3D Scanning and Printing

3D Scanning

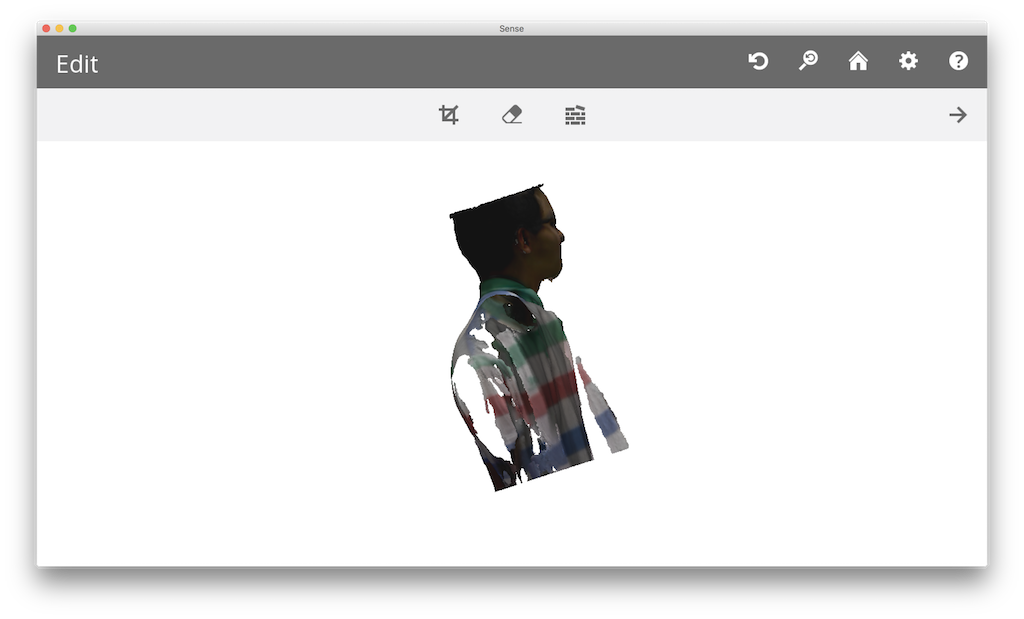

The scanner I used is sense 1st generation

Download the software for 3D scanning

I found it so hard to use it so I just try the 123D catch (it seems that it's not currently available at appstore)

I try quiet several times to use the sense - I try to scan myself a key rings and it just failed: ( too small )

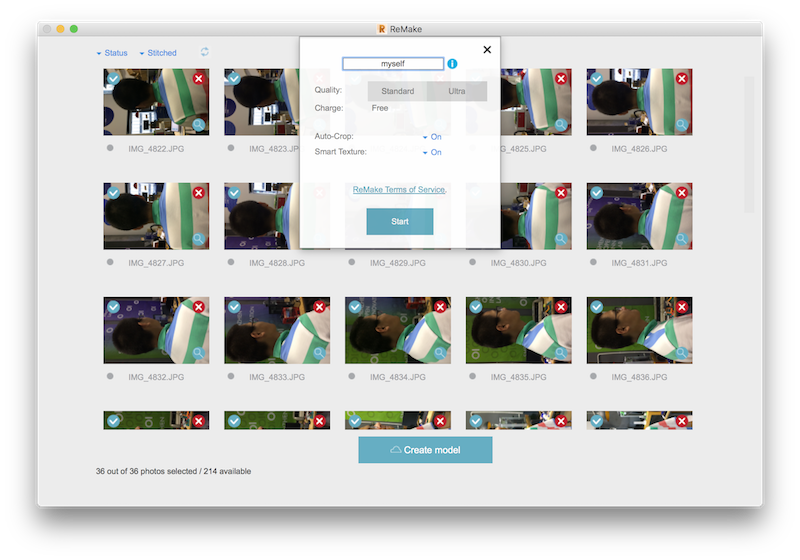

Then I download the remake - and took 36 photo for myself at different view point - my instructor assistance

upload it to the cloud and it will automatically register and calculate the model

It will take so many time for the cloud to calculate the picture and make it a 3D model

group assignmnet: test the 3D printer

Here is the major 3D printer in my lab ( We have four 3D printers in the SZOIL )

I am the only student in the local lab XD.

Move the axis

goto:prepare/change filament to change the filamen

You can select unload to unload the old filament - The old Filament is a black one

You can select load to load a new filament - I used the white one as a new filament

I waste a bit material since I don't know the load step need to stop manually XD.

After you see this, you need to stop the load step manually:

After moving the axis, I make sure that the 3D printer in our lab can print the max size:

x:145/y:145/z:145 for the smaller one;x:200/y:200/z:480 for the bigger one

You can use prepare/autohome to set the axis to the home easily

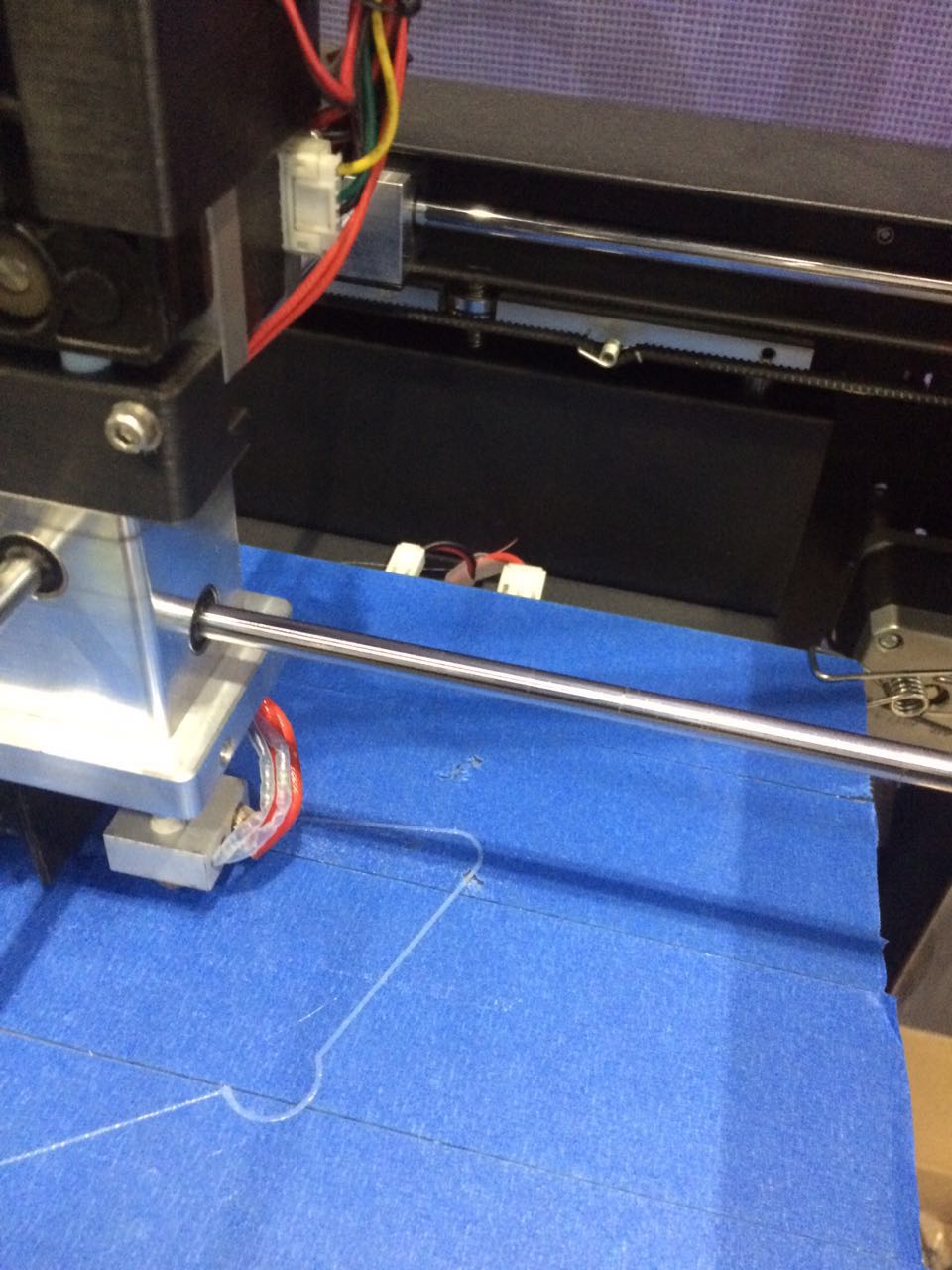

Warning:you need at least a raft to bolster your model or you will get:

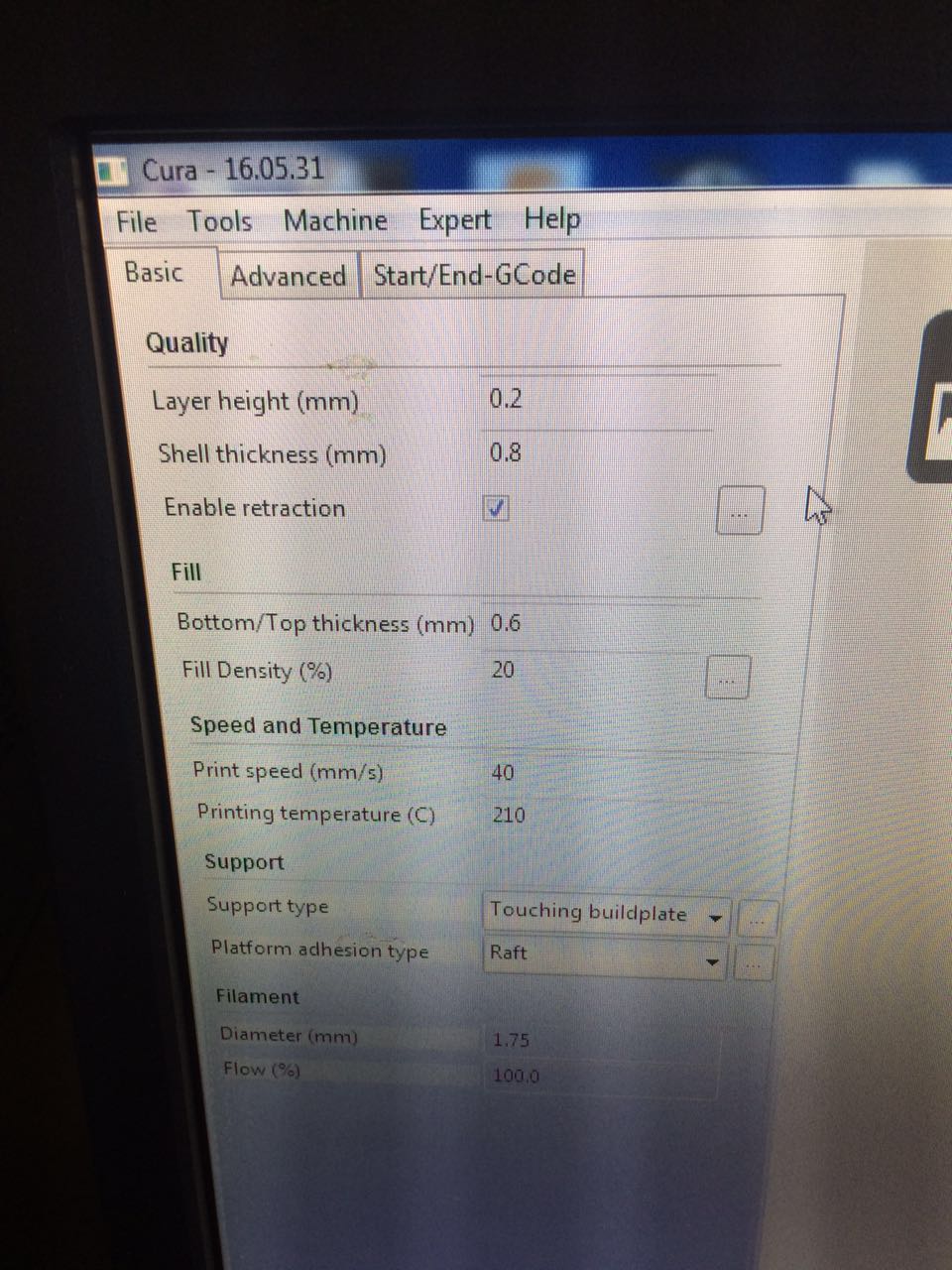

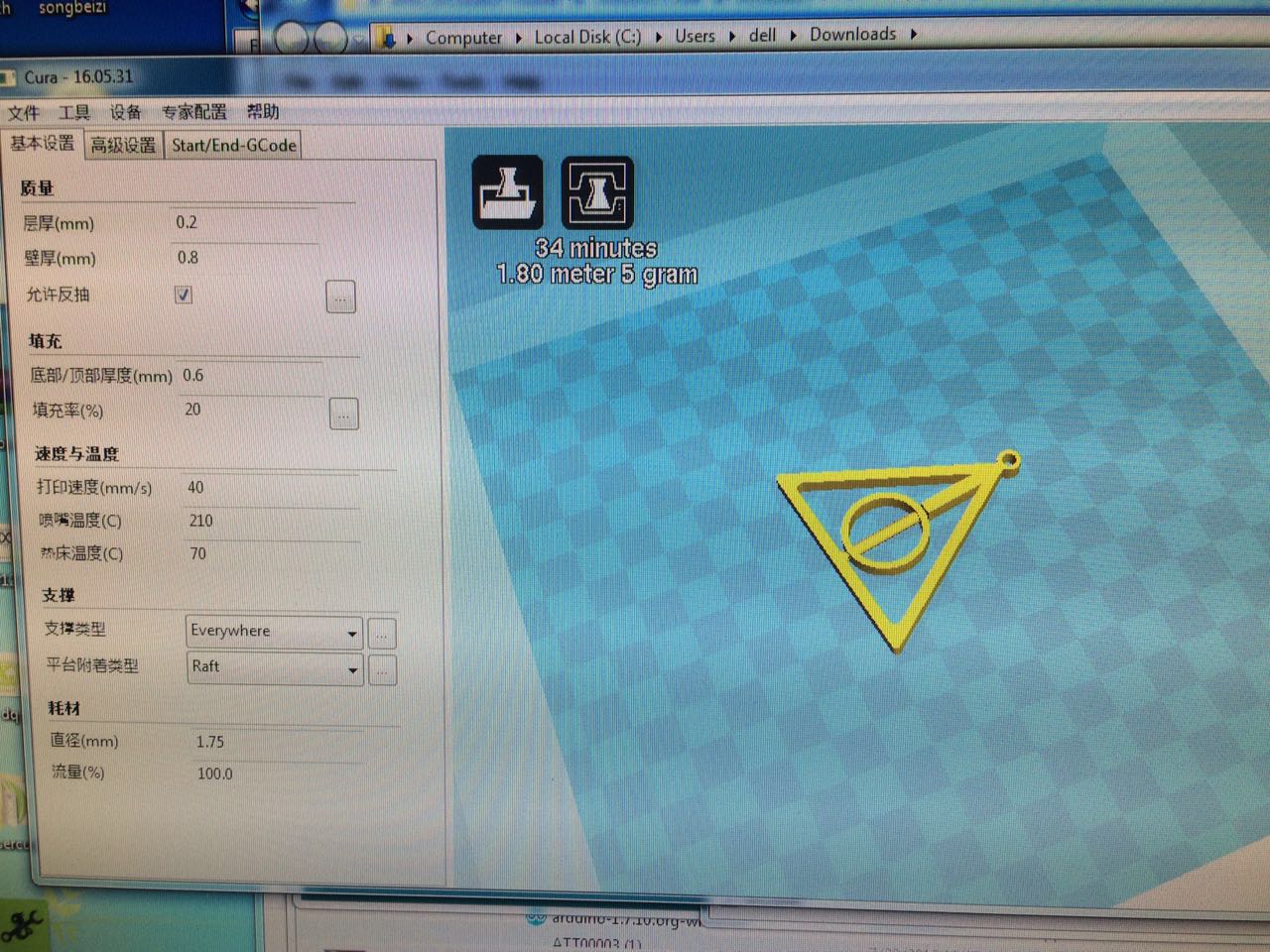

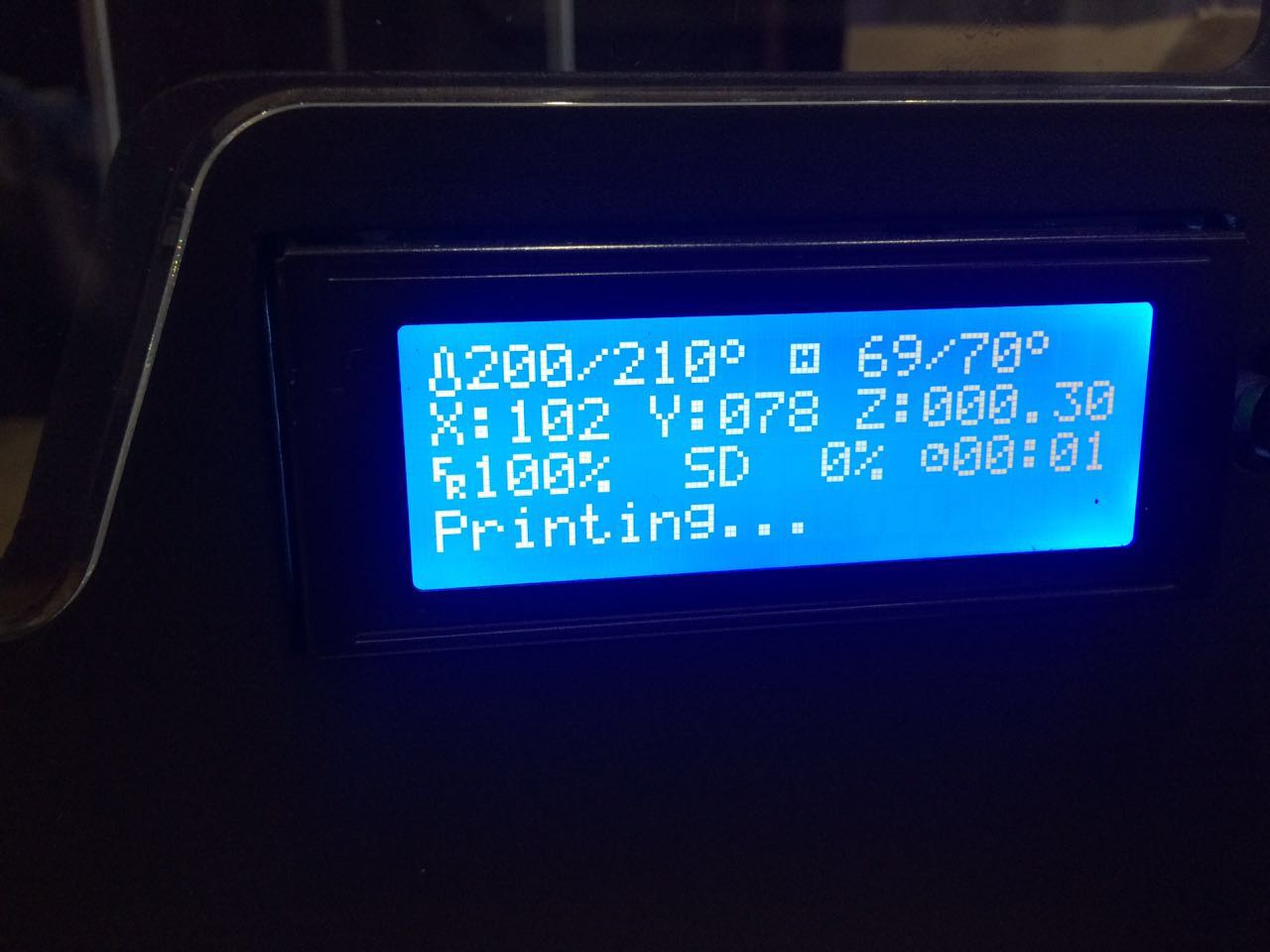

The setting of my file which is used in the machine (m2048)

Since the instructor in the SZOIL often used the 3D printer, so I just used the setting he used

I set the layer height to 0.2mm, shellthickness to 0.8mm and enable retraction.

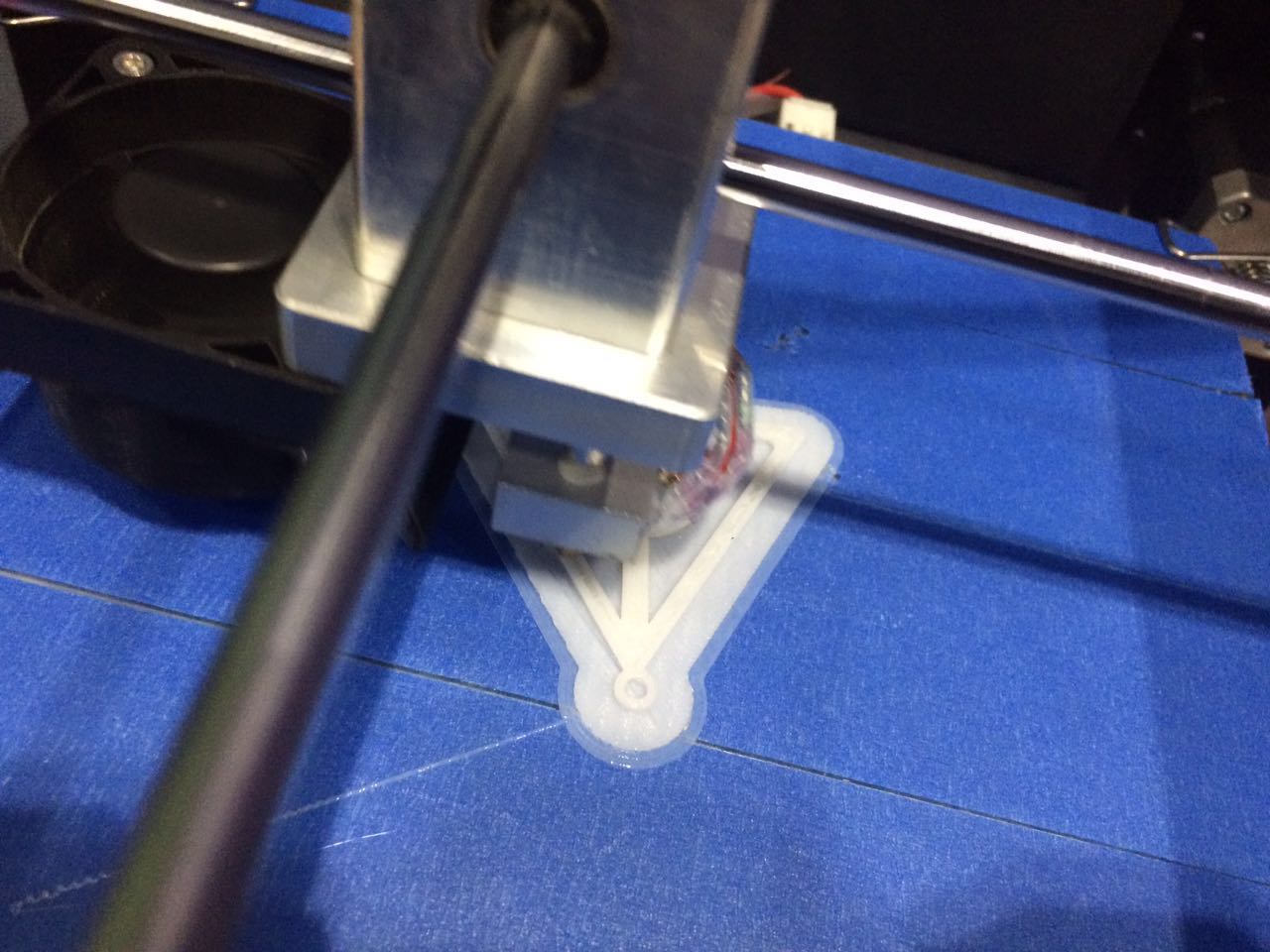

I set the bottom thickness to 0.6mm and fill density to 20% and used the Raft as a basement

So that I can get what I print out easily from the base board

I set the speed to 40mm/s and the temperate to 210 C - I tried to set it to 230 and it paint terrible - I also tried to set the temperate to 180, and this time , some part can't paint out. At last, I used the default setting

I set the filament diameter to 1.75mm and flow to 100%

And I just test the default setting and it worked - so I didn't change it.

At last, I used the big one, and everything goes fine

Additionally, I found that there are some errors in the small 3D printer, and I set the temperate to 195 when painting this, here you see the problems:

So I used the m2048 to paint later

The test part of our 3D printer ( The big one )

Here is my test file

Then, I sent it to the 3D printer in my lab and printed it.

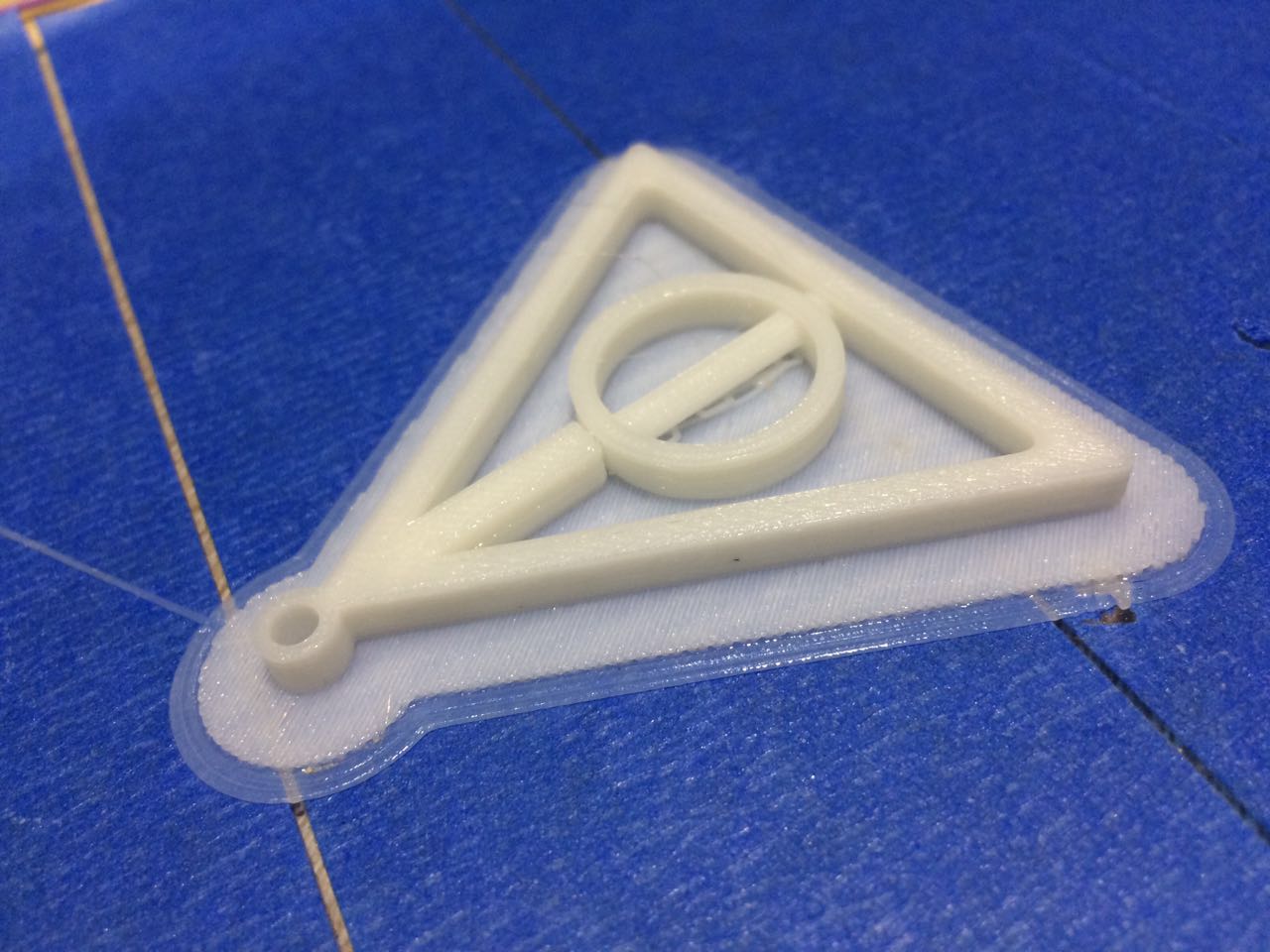

( I small down the scale then - so that I can print it out in 3 hours )

( The original one will take 16 hours to finish (cura's calculating) )

Here you see, our 3D printer's limits are:

1. It can't paint the thing less than 0.5mm in daimeter

2. It can't paint thing smoothly when it is too thin

3. It would take really a longer time comparing to the CNC

However, the advantage is obvious:

I can make a my ring once without assembling it. If I use the CNC to mill it out, I need to mill some parts of it and then assemble it.

Build a 3D Model

Foremost: measure the parameters of the thing you want to paint:

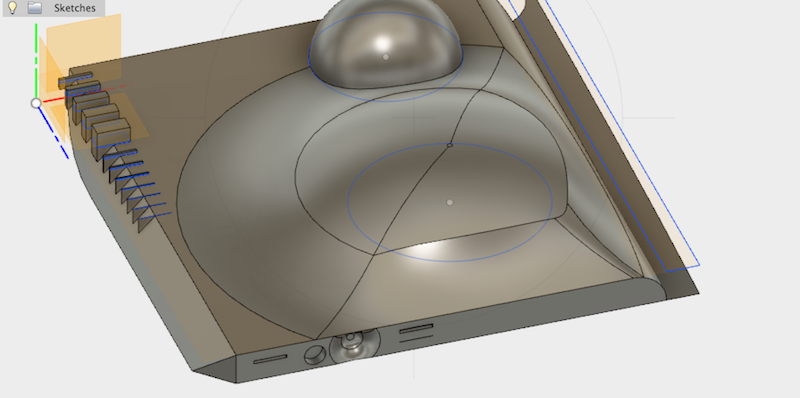

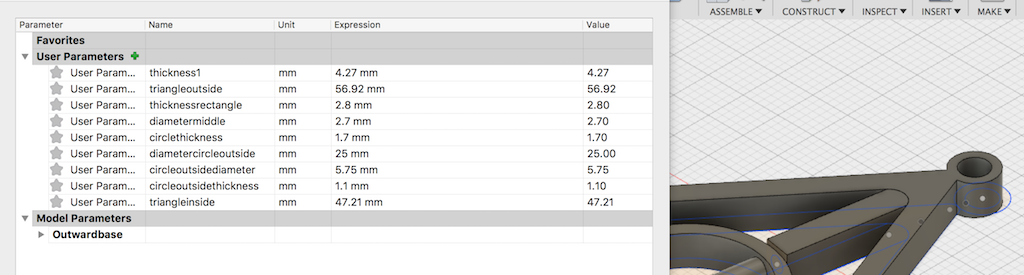

1.Use the Fusion360 to build a 3D Model

I just want to build a key rings

The tool that I used in Fusion360 - New Sketch/Line/2 Point Recgtangle/Circle/Fillet/Pull/Parameters/Combine - Cut|Jion|Intersect/Move

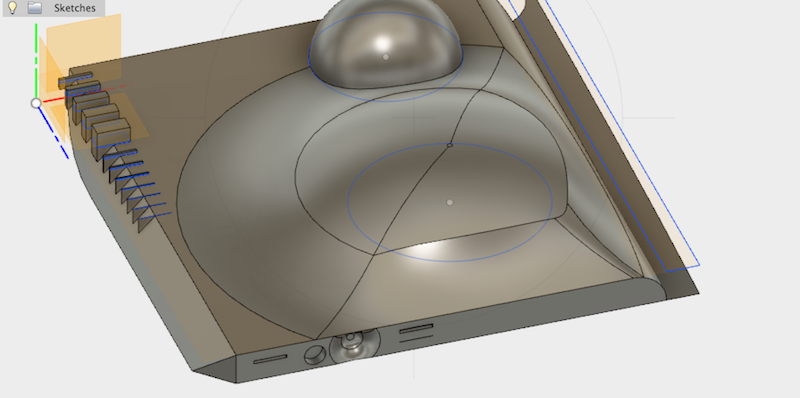

I use the parameters to build my work - so that I can change the scale of my project easily:

(and also, it might be more easy to let some line be in the same length

Build my 3D Model:

3D Printing

Download the software that you need - Cura

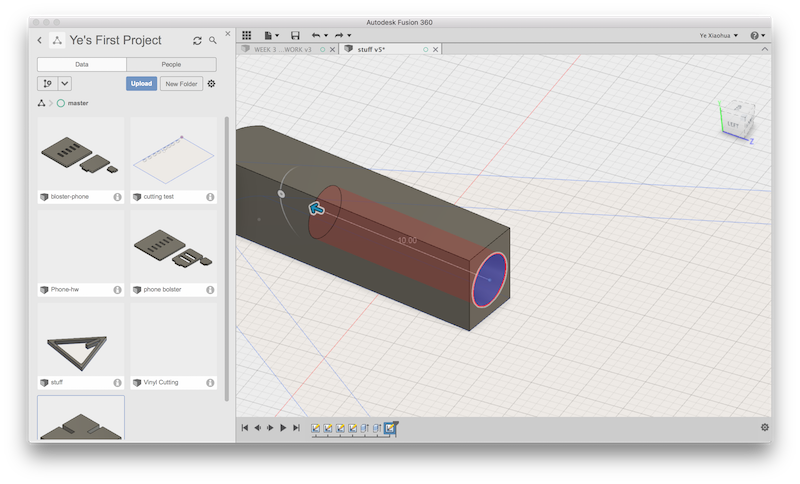

Save the Fusion360 file with .stl and use the cura to open it

set the parameters for your machine and rotate it to a proper situation to print.

save it as a gcode file to the SD card and sent it to the 3D printer

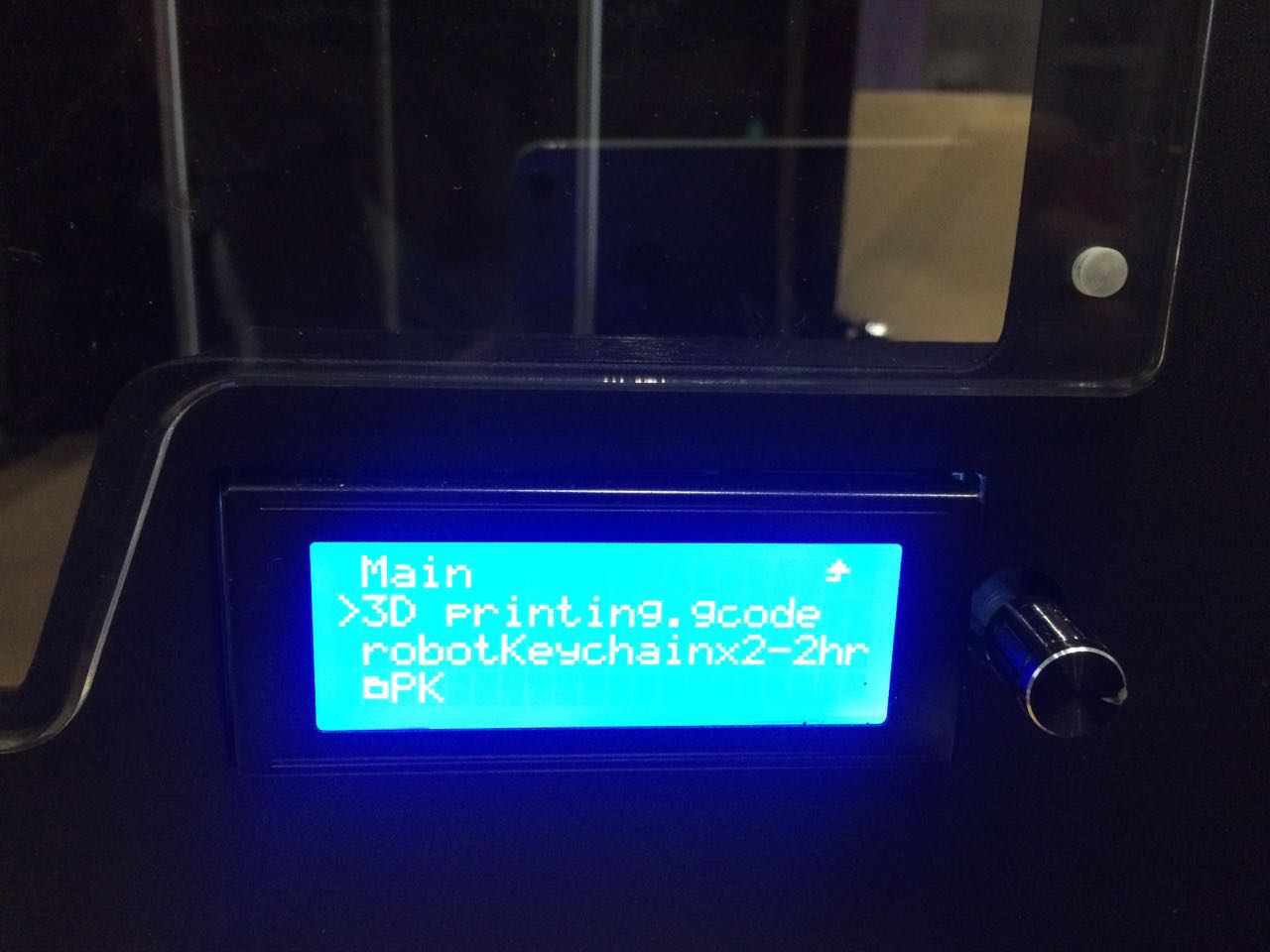

Select your file that you want to print:

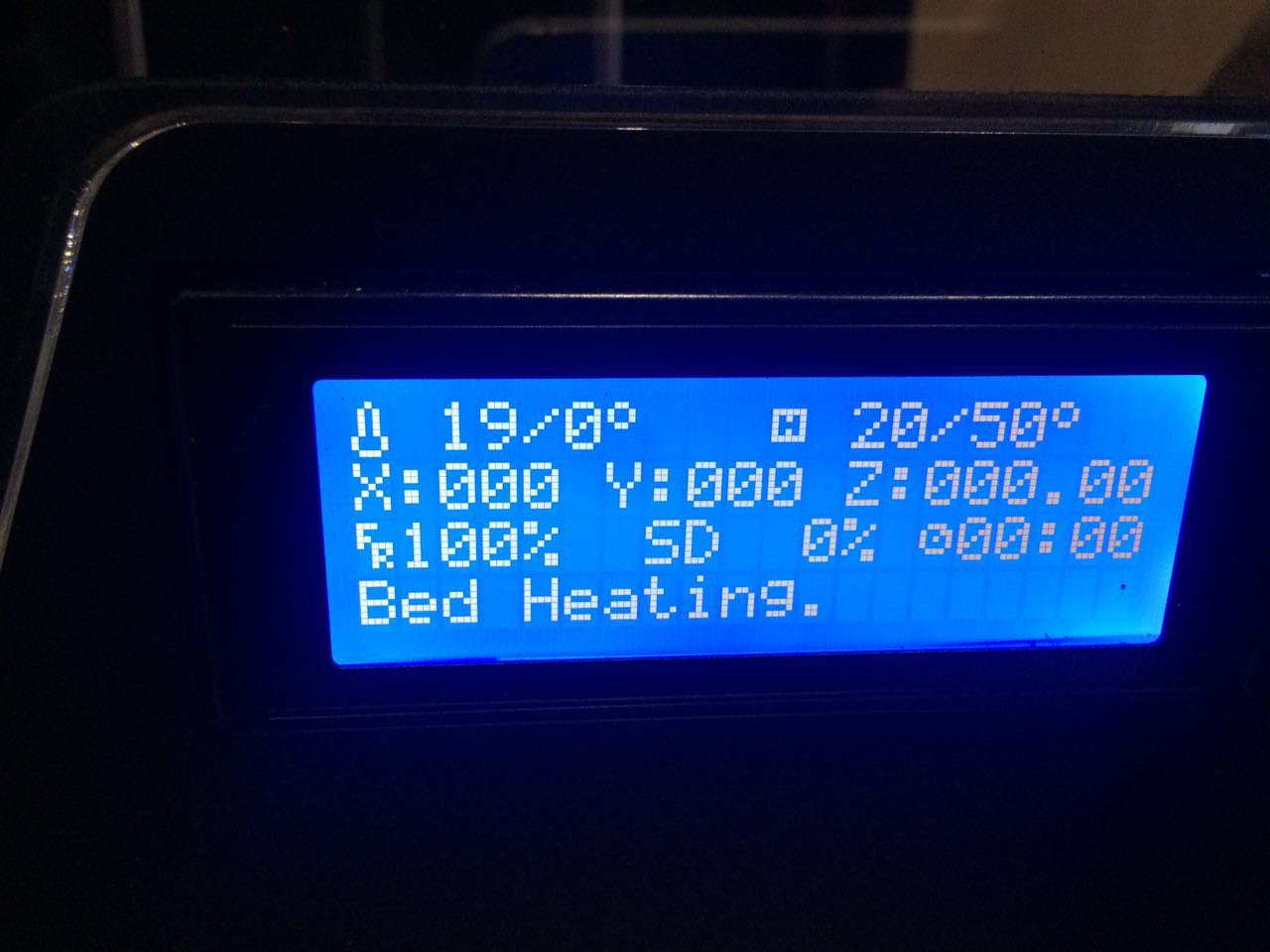

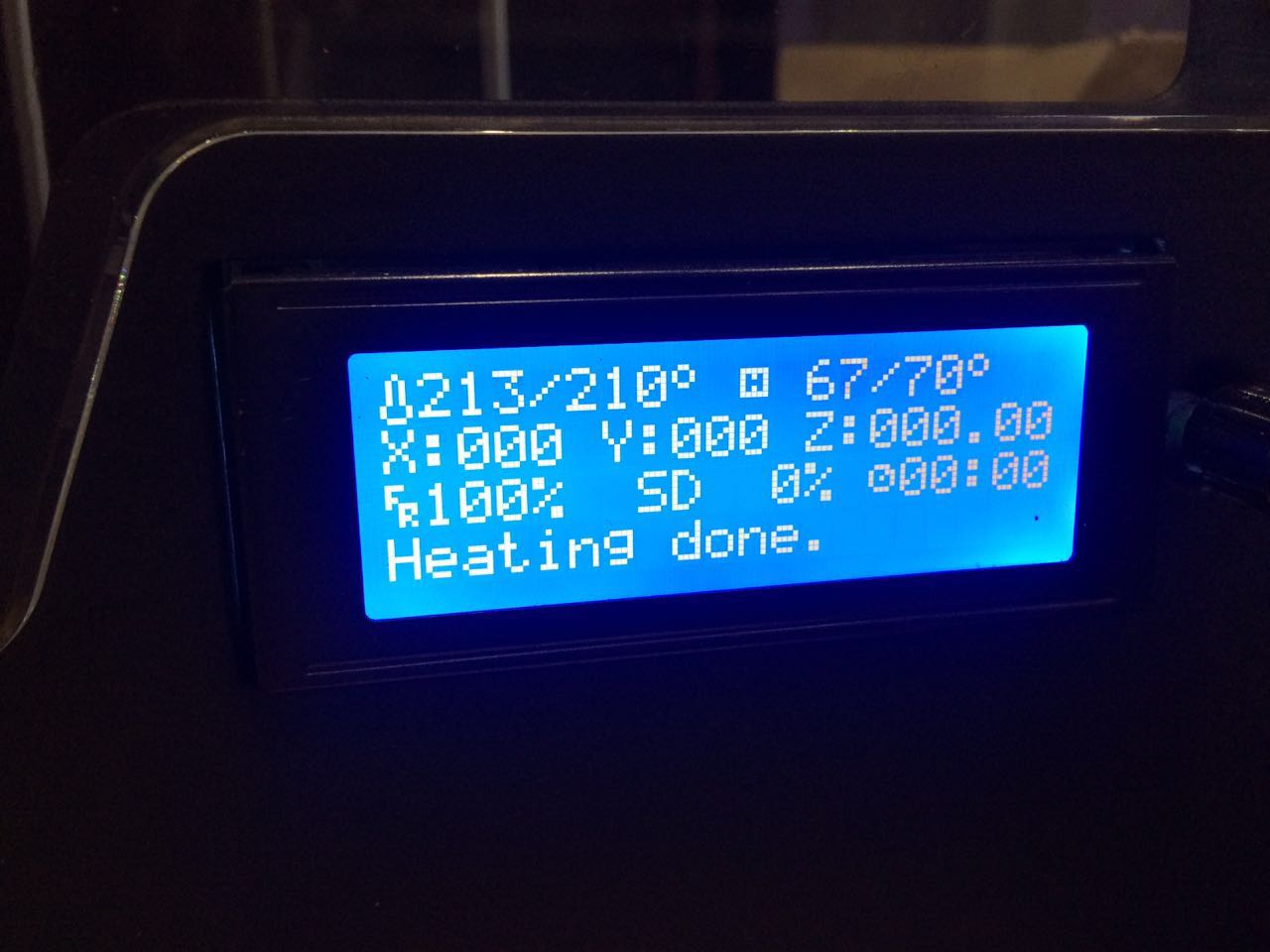

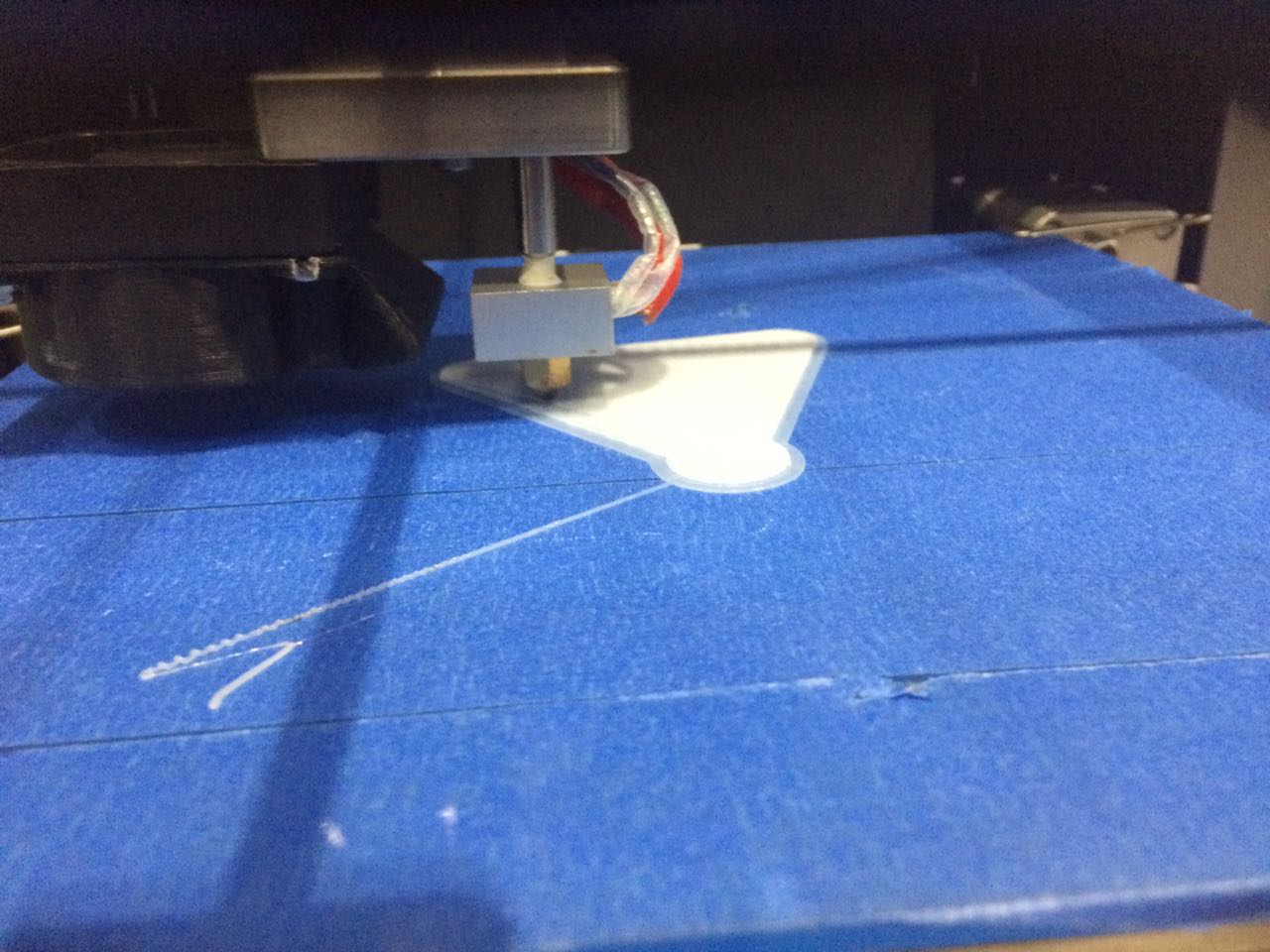

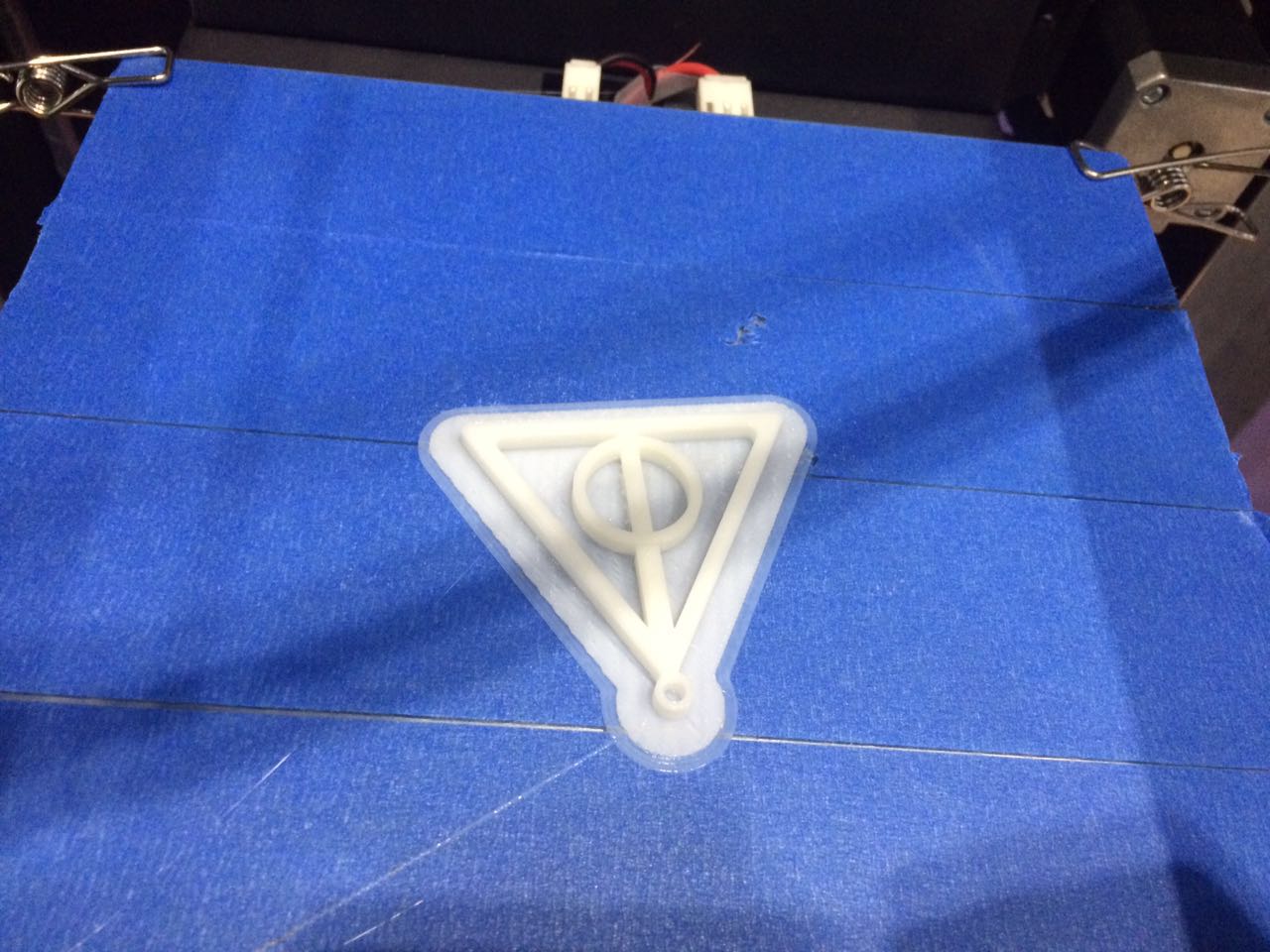

click on and wait for printing:

It will build the bed:

Finish:

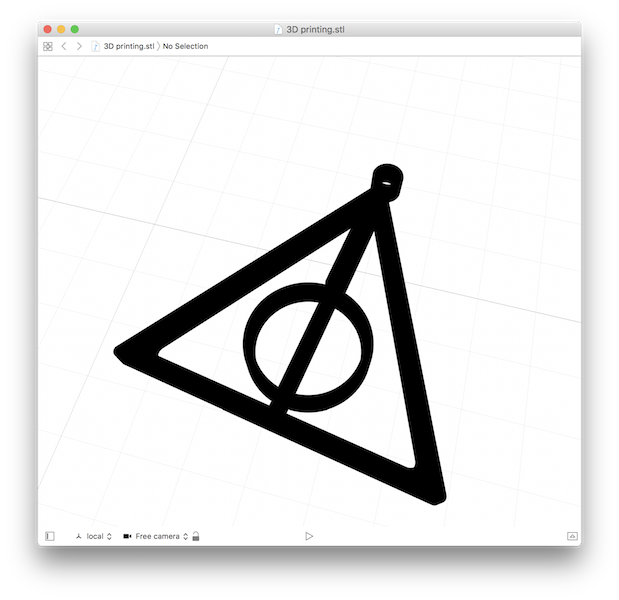

1.this model can't be downloaded from the web (I design it)

2.this model can't use the mill machine to build: there is a axis inside the model: