12. Molding and Casting

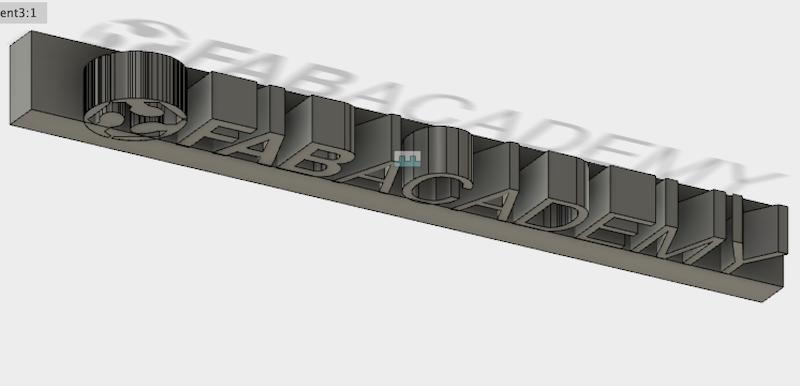

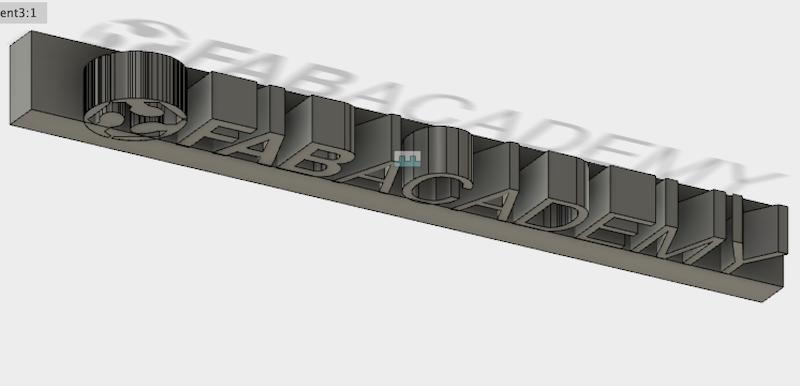

design the 3d mold

I used the Fusion360 to design my mold:

There is no undercut if place it in the proper way to cut.

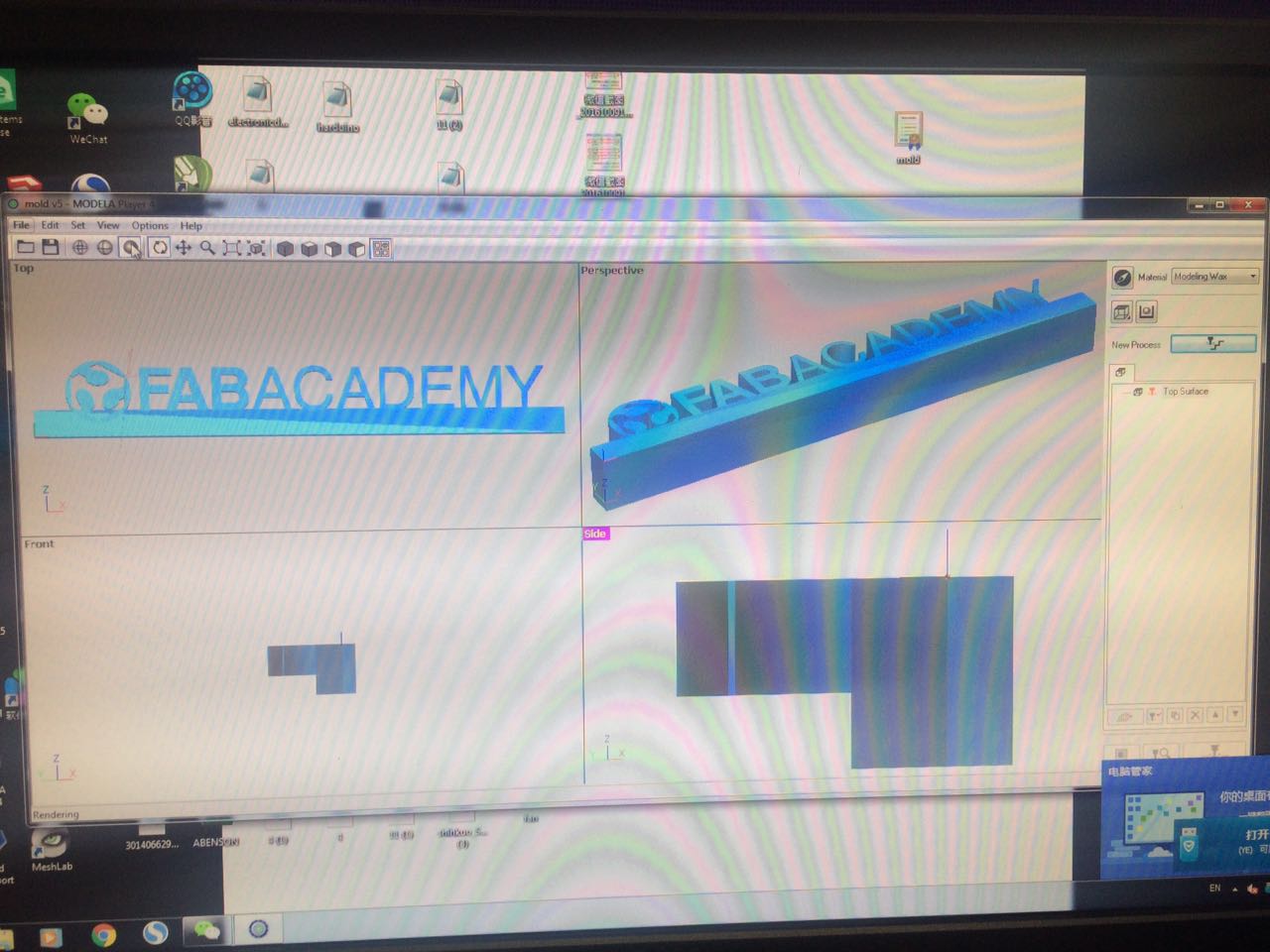

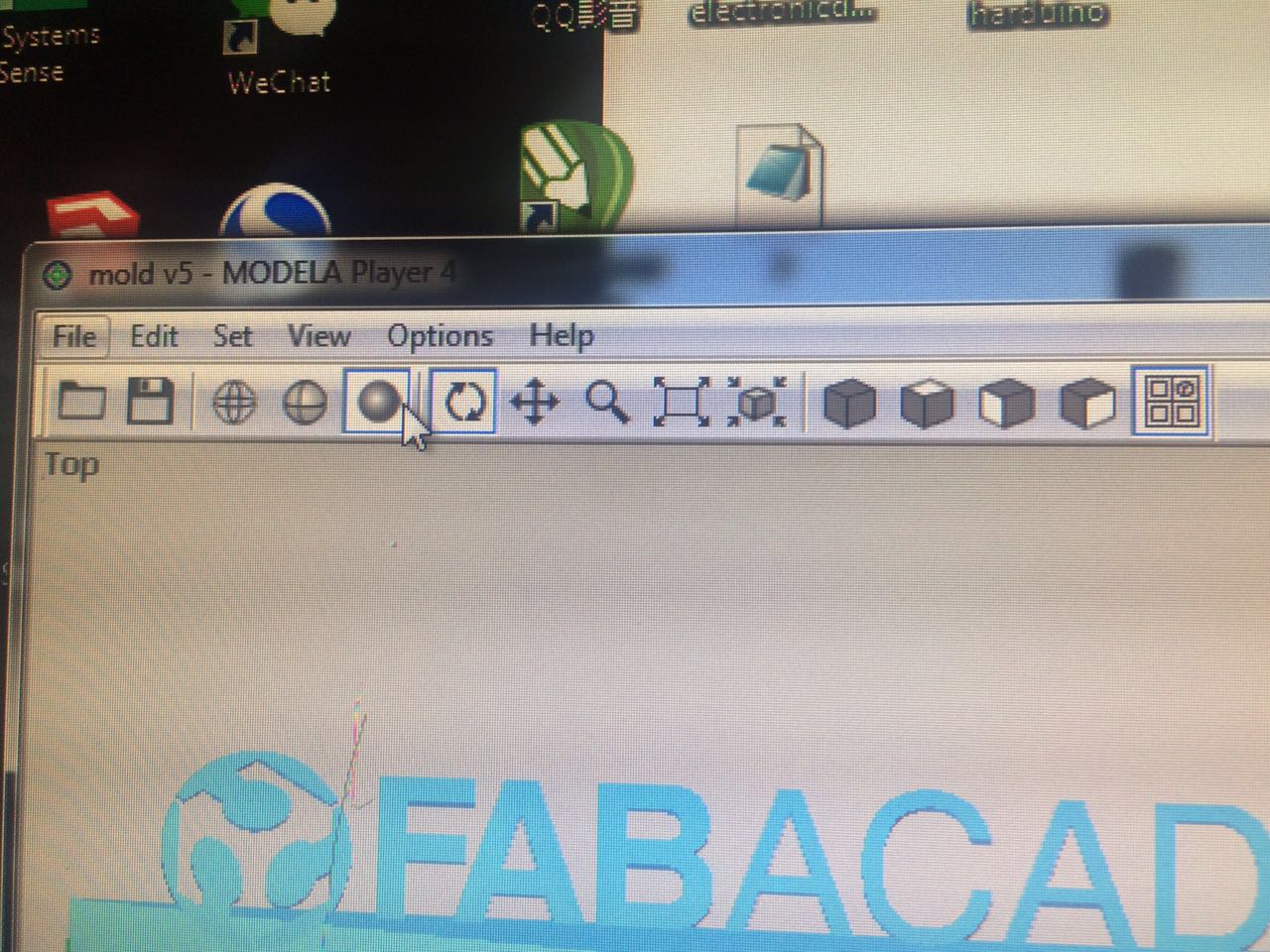

use the modela player to calculate

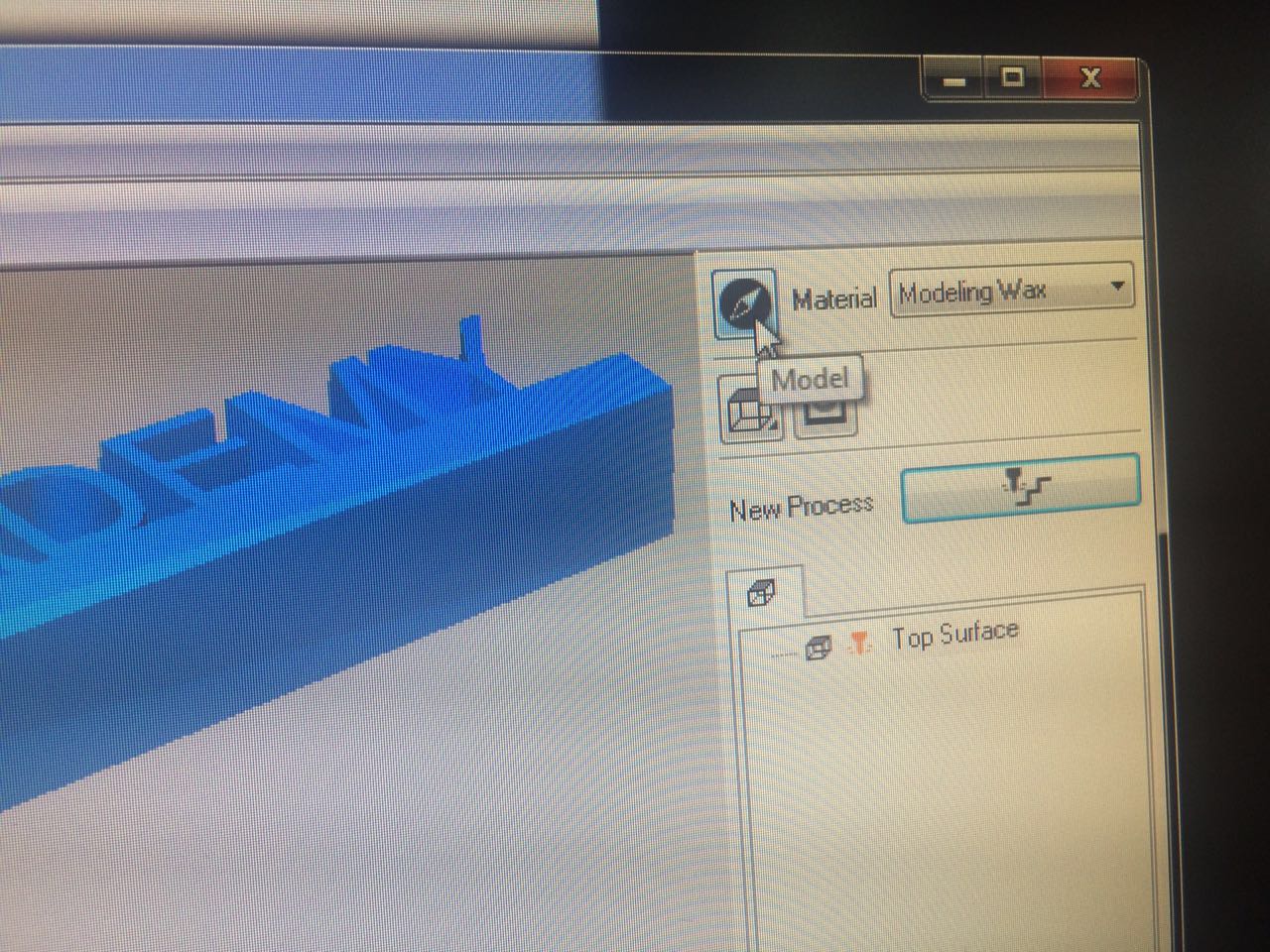

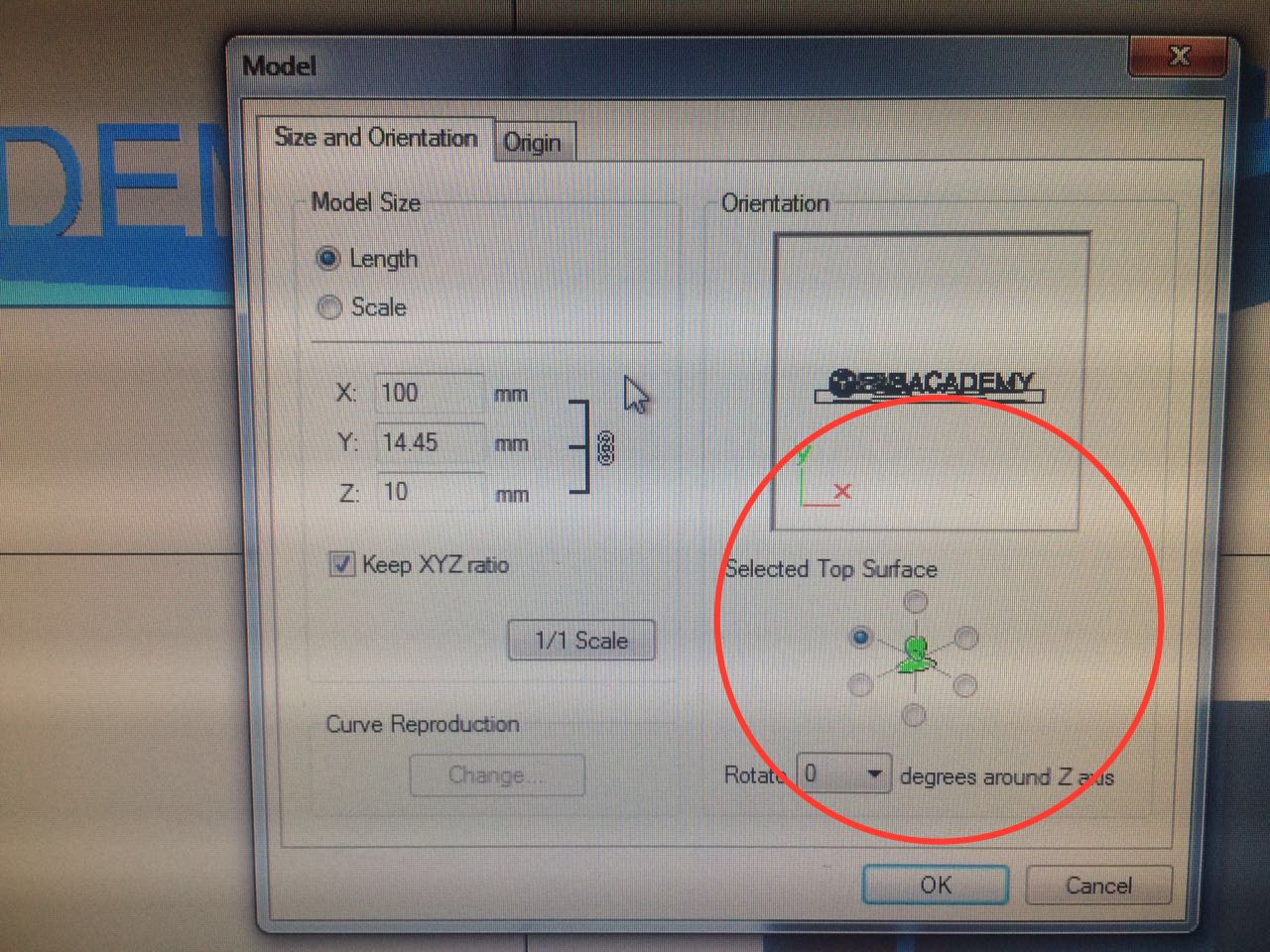

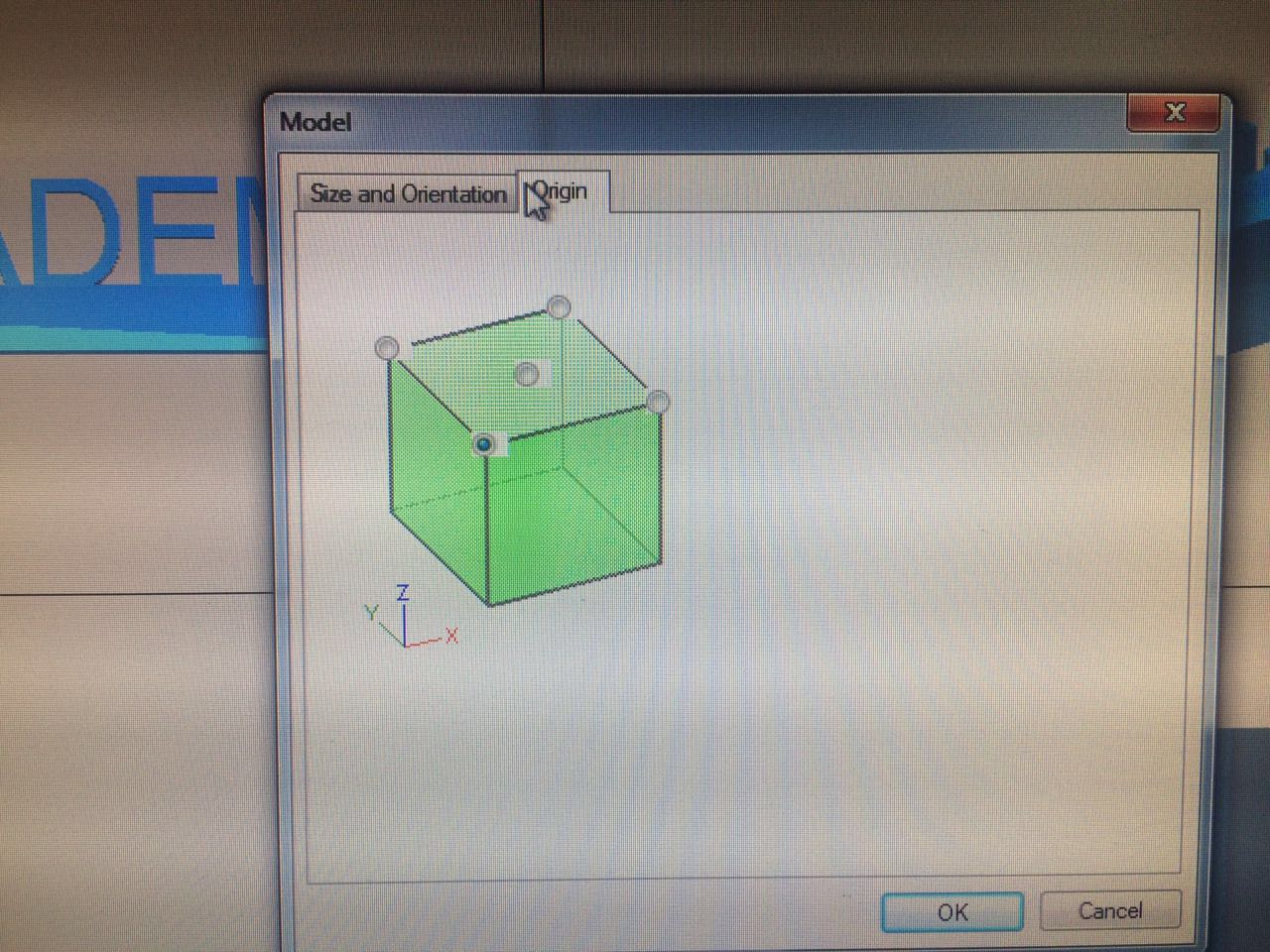

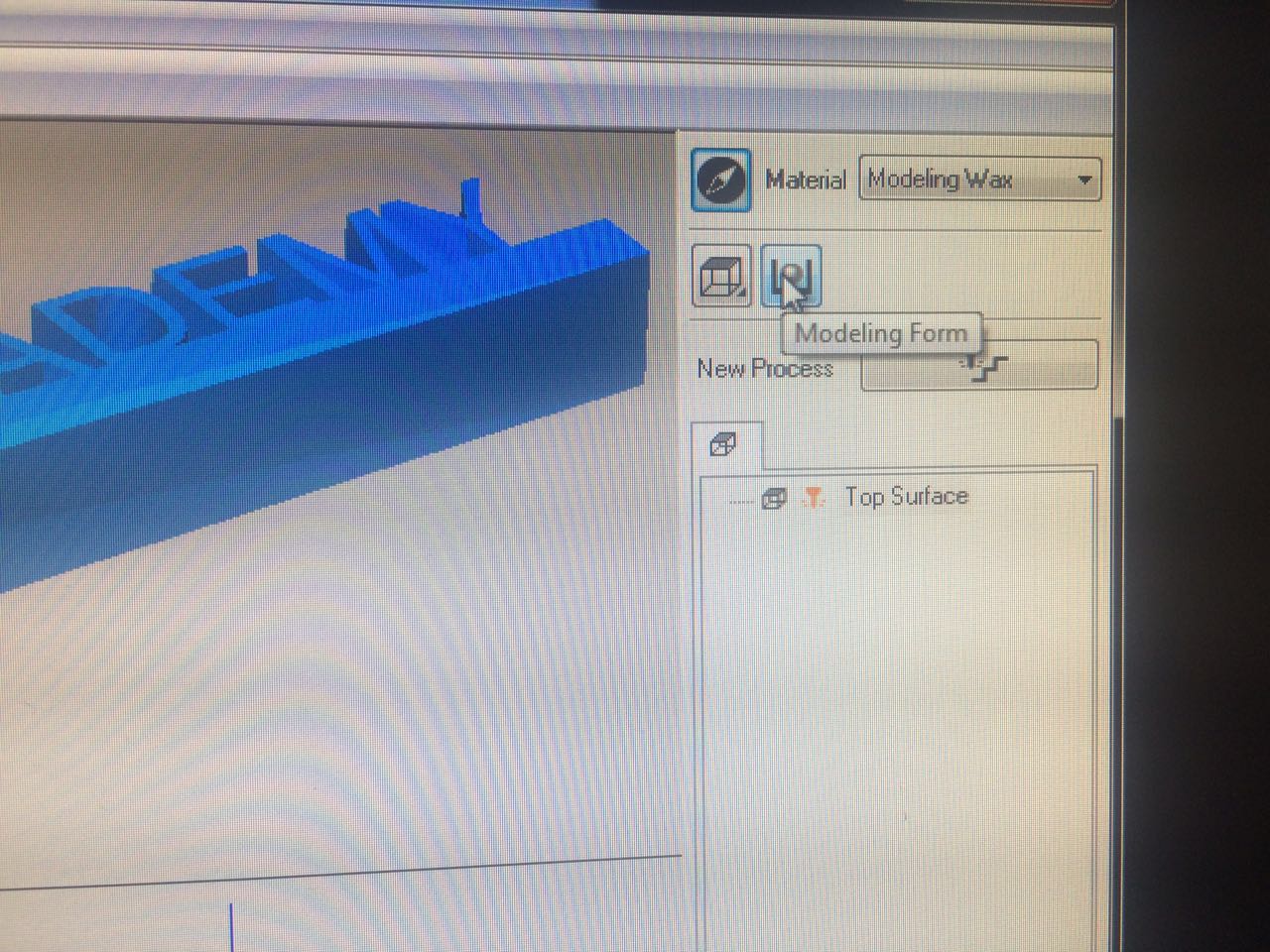

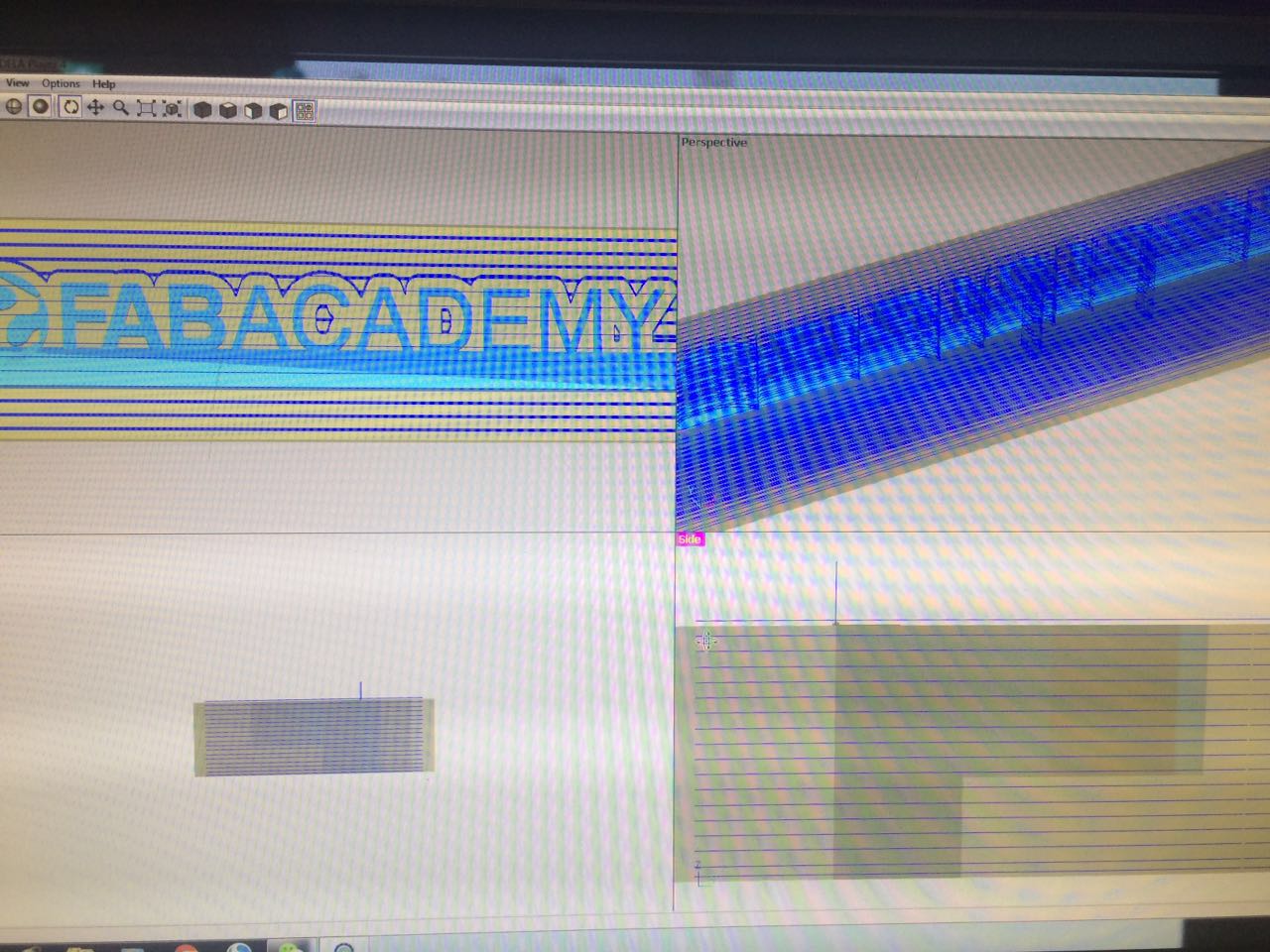

I used the MODELA Player4 to calculate my mold and use cnc to cut it out:

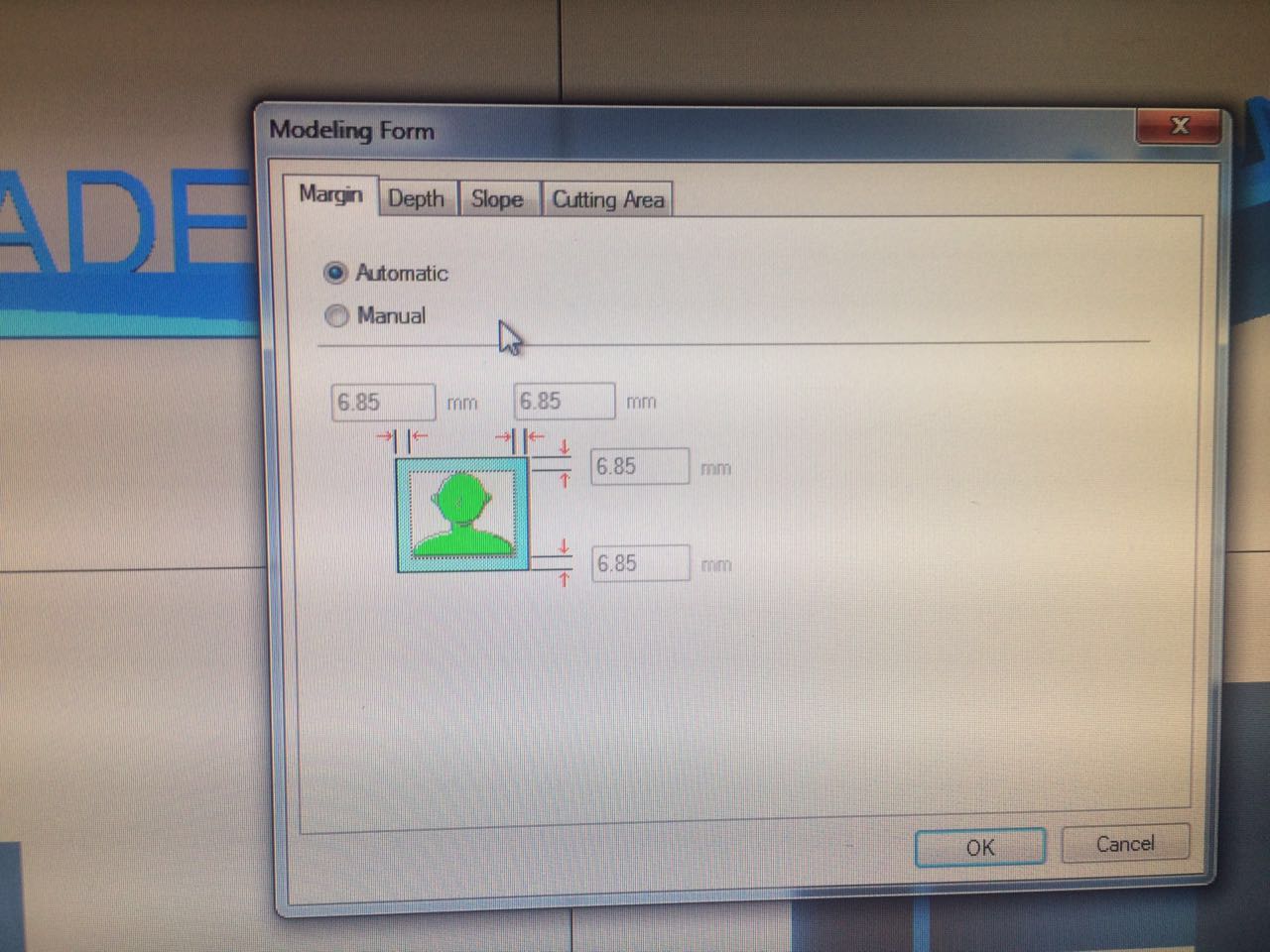

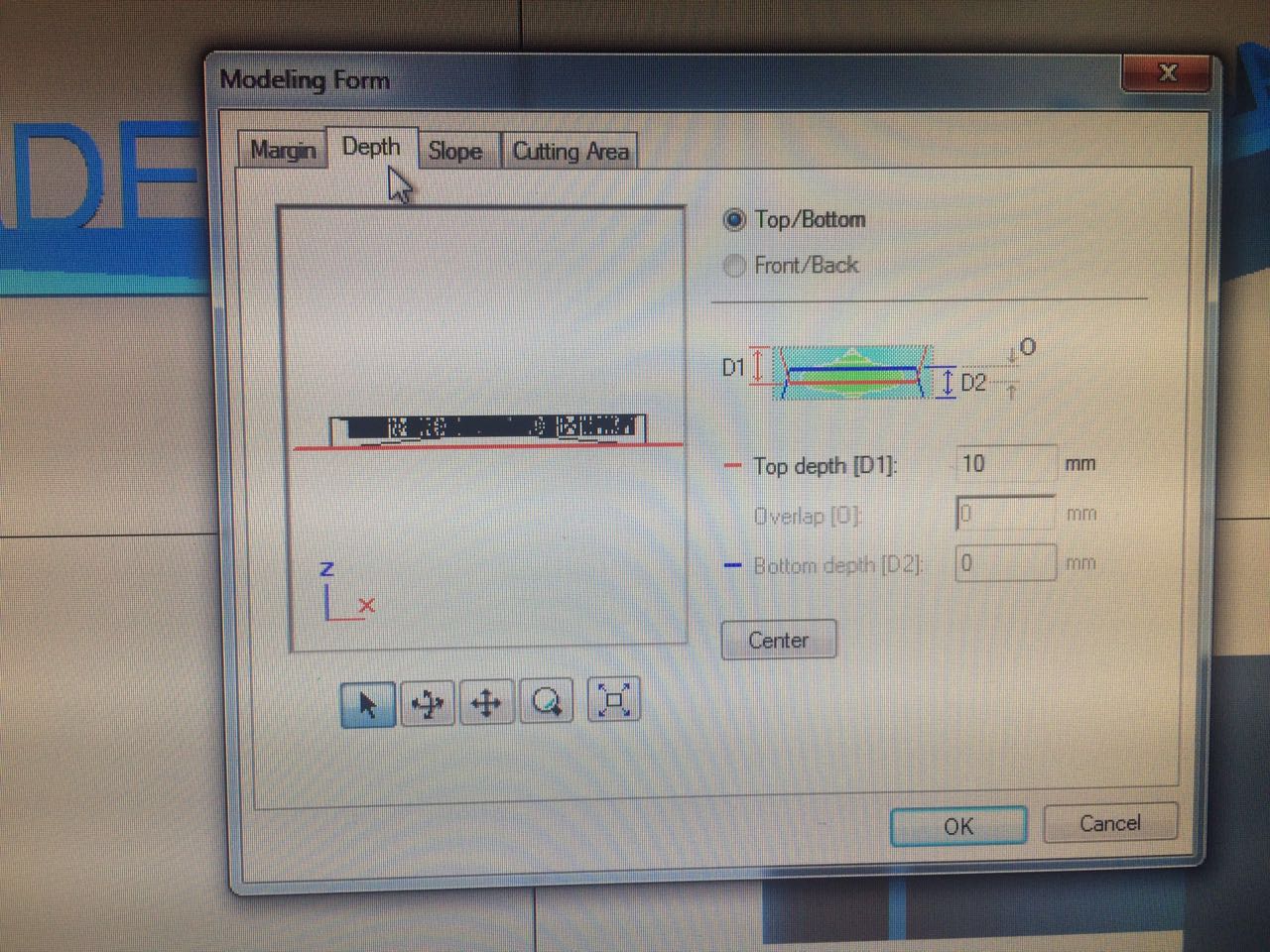

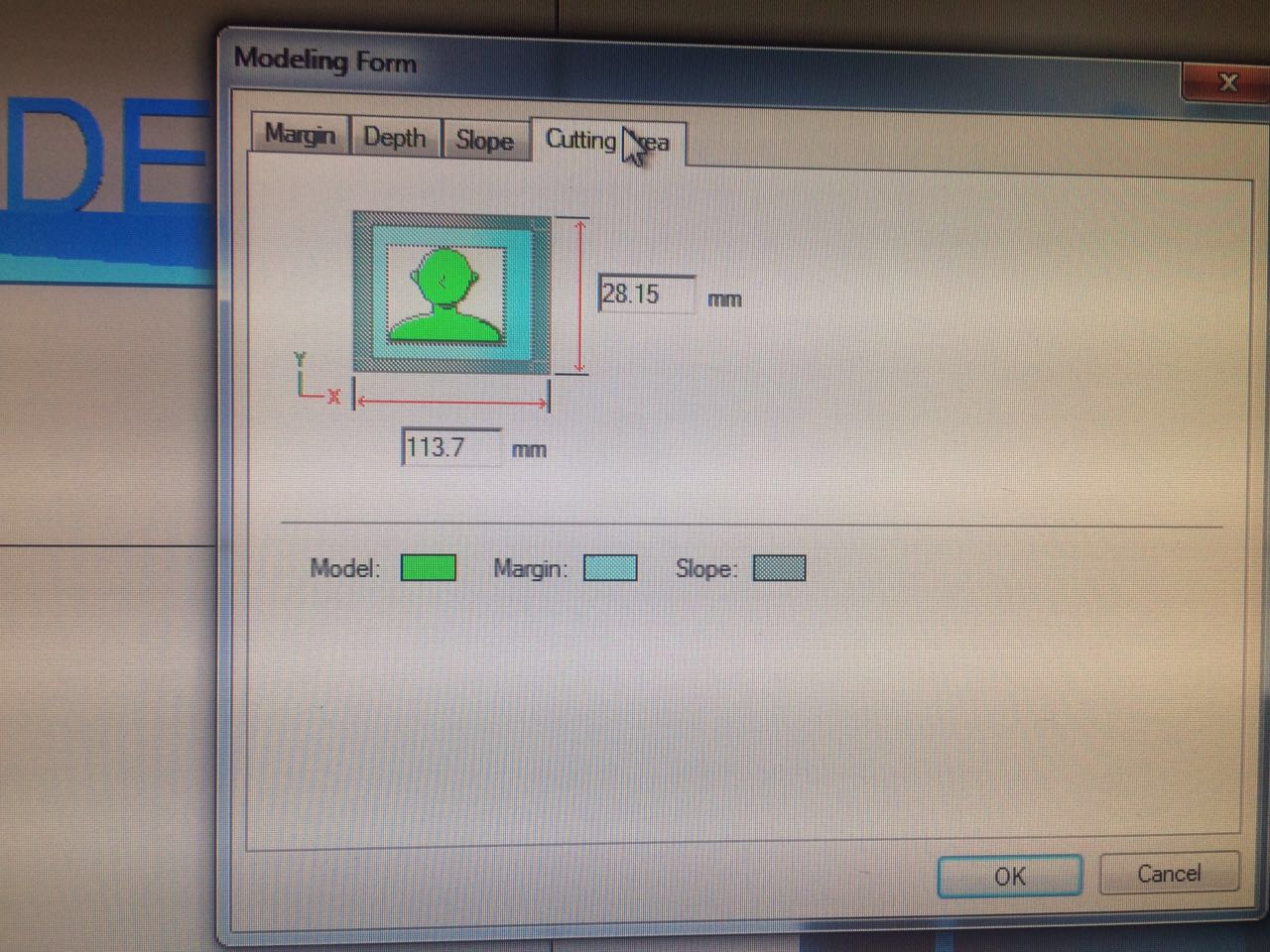

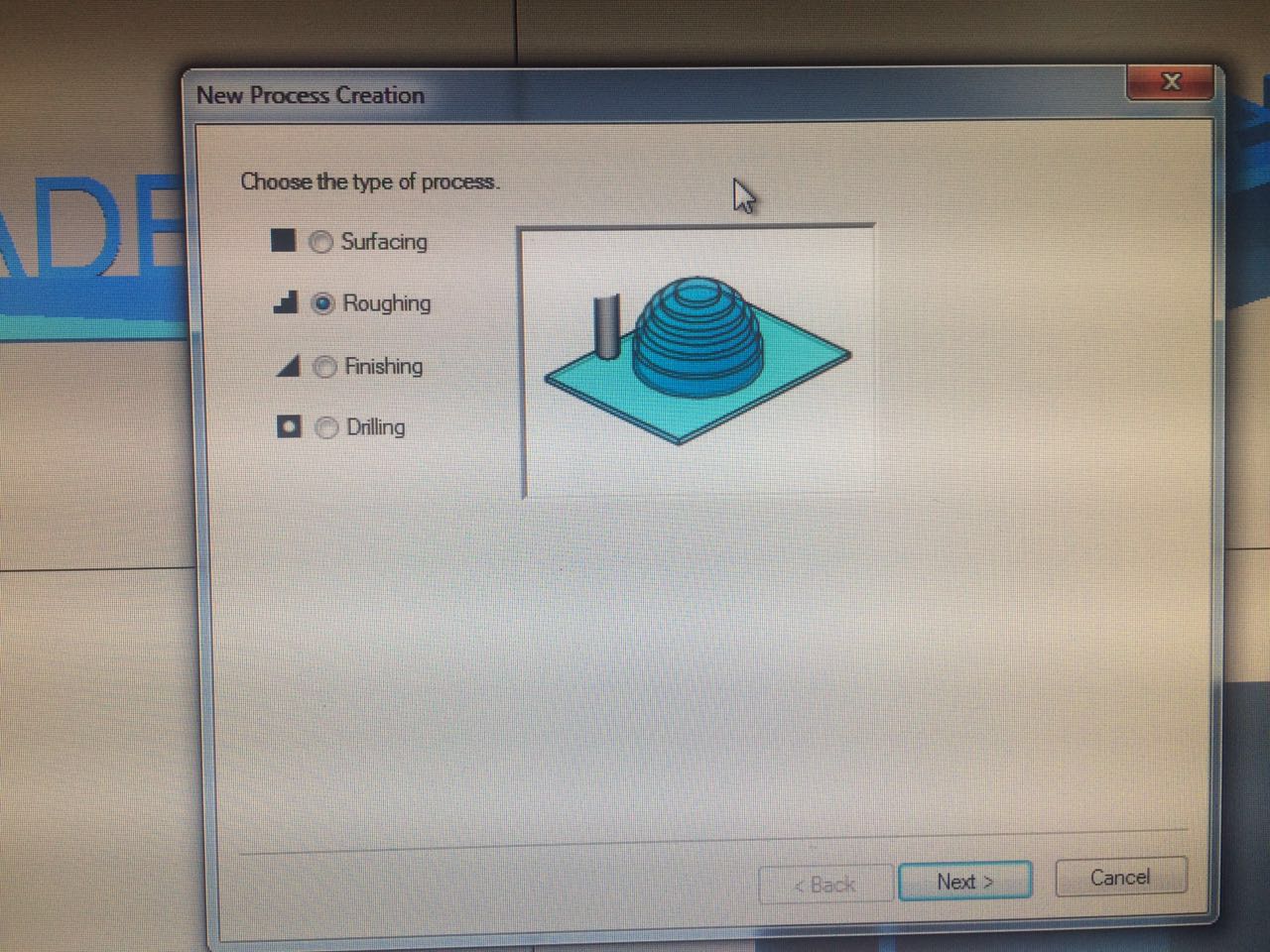

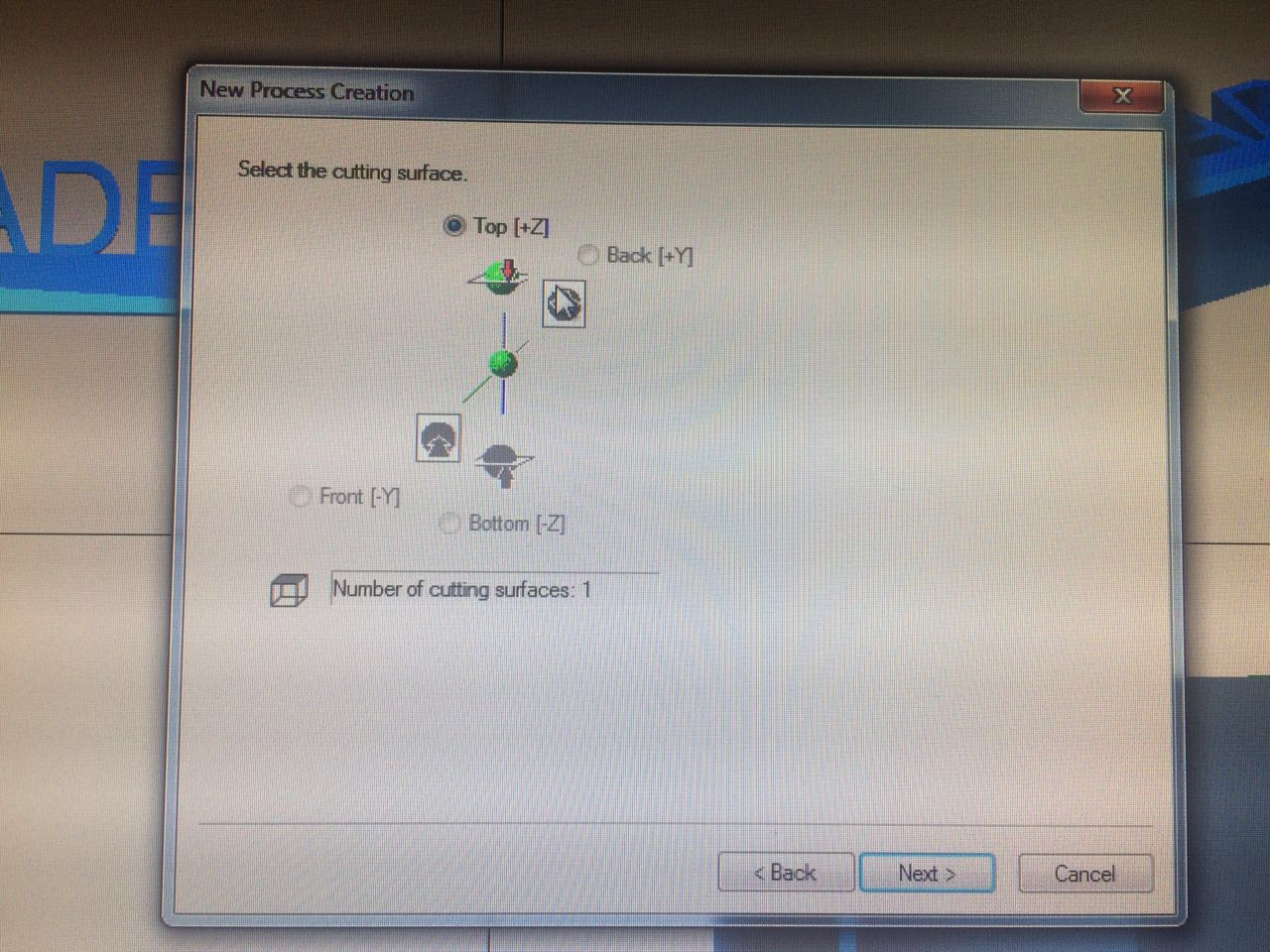

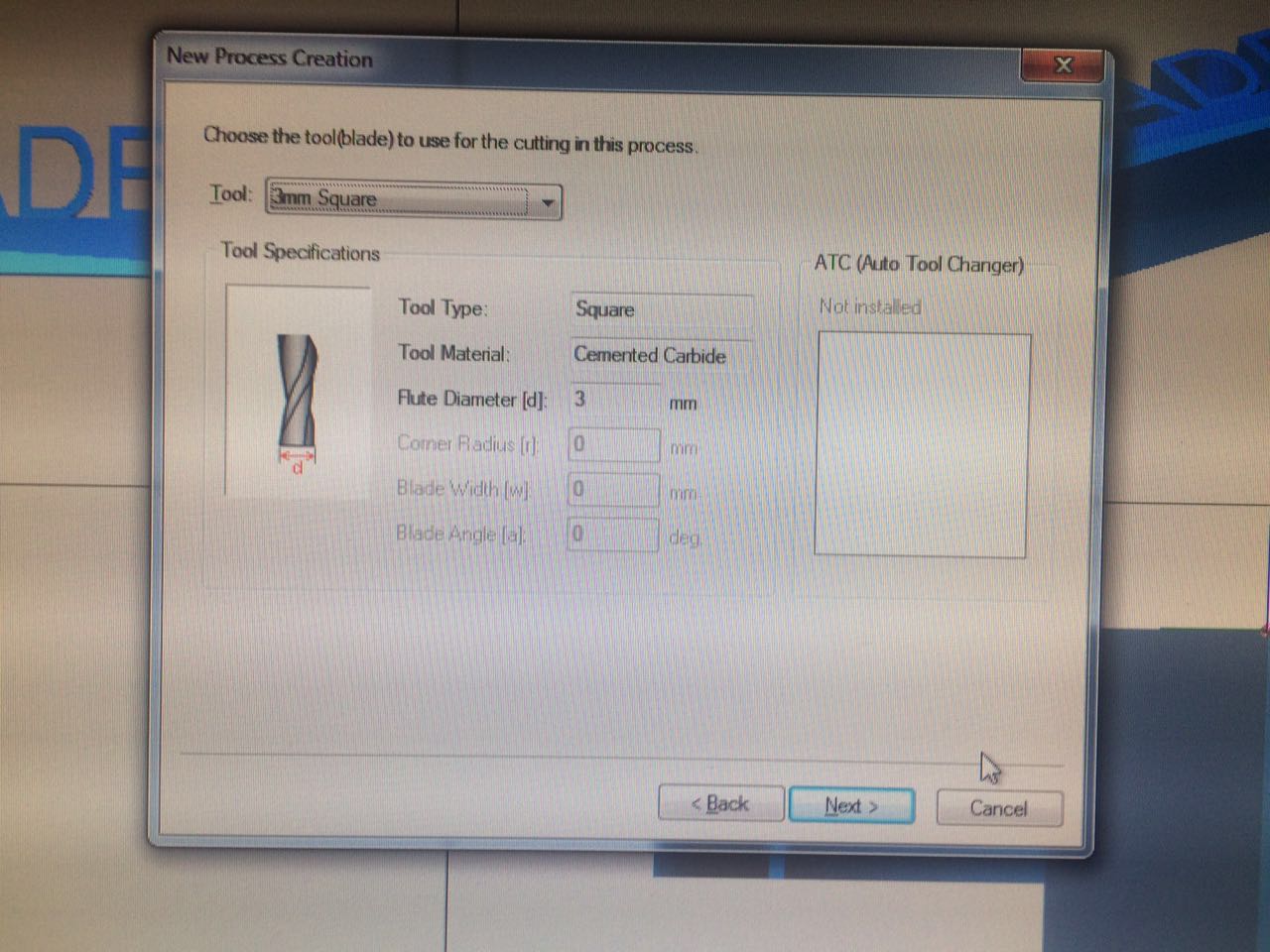

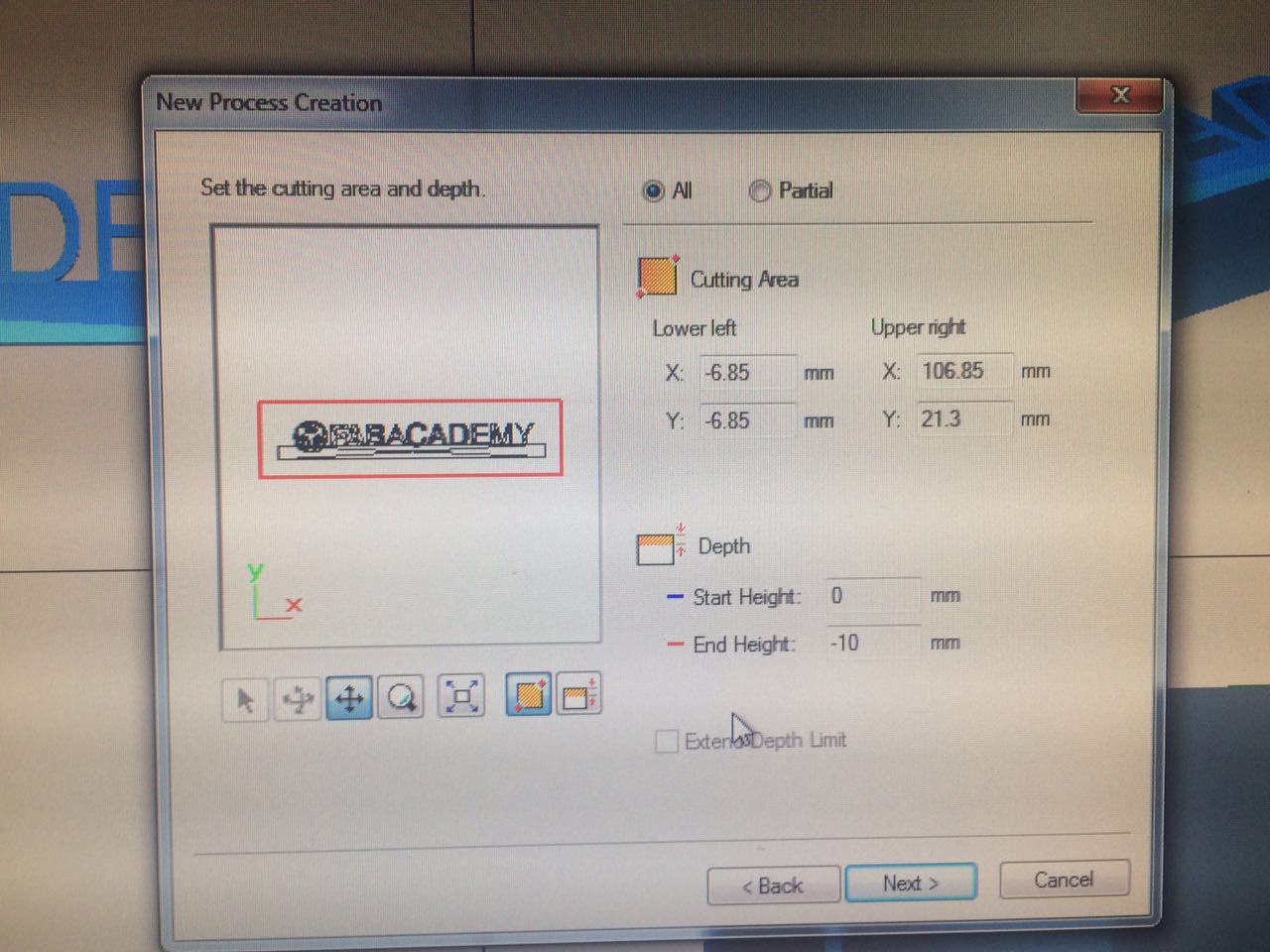

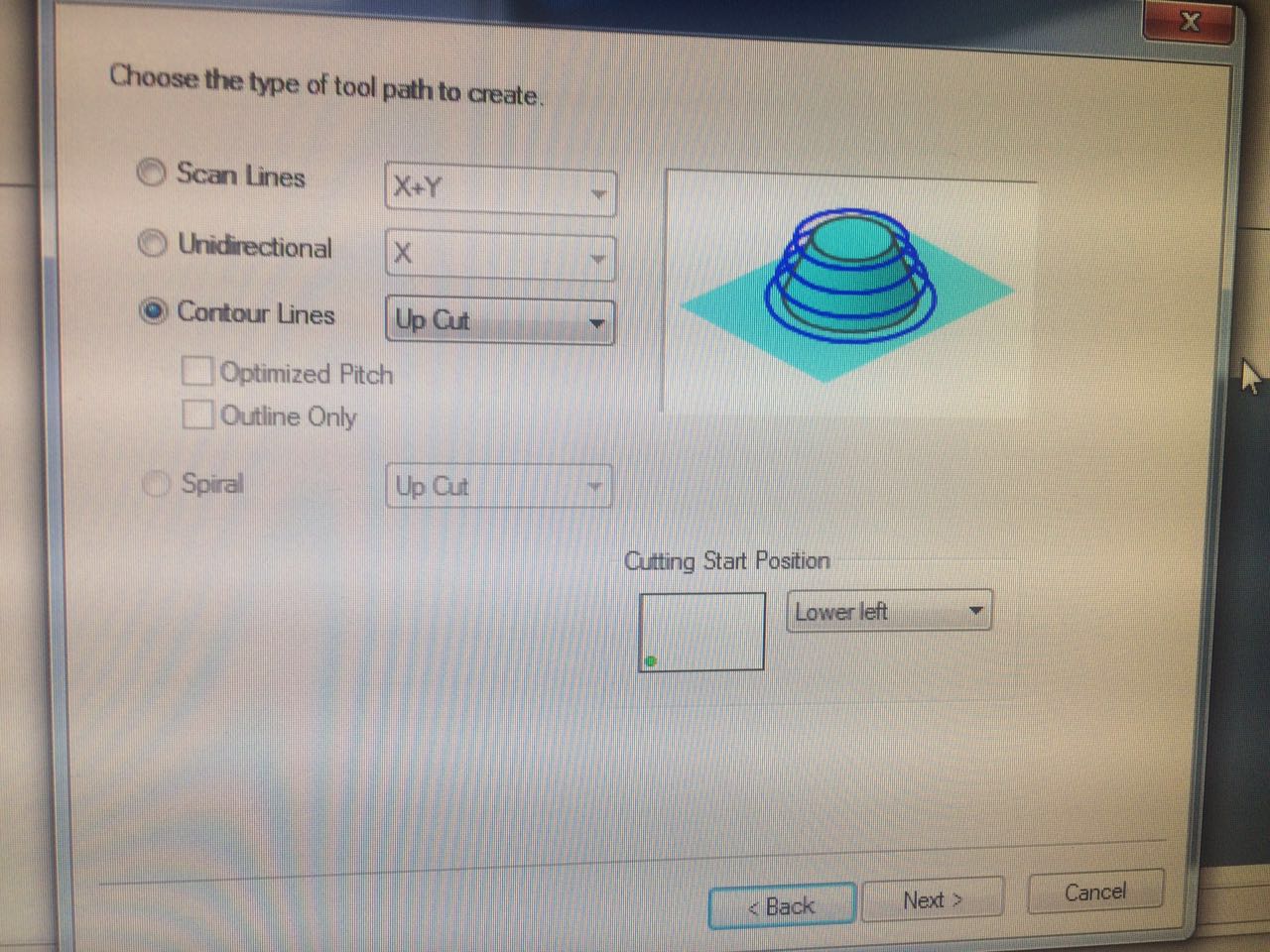

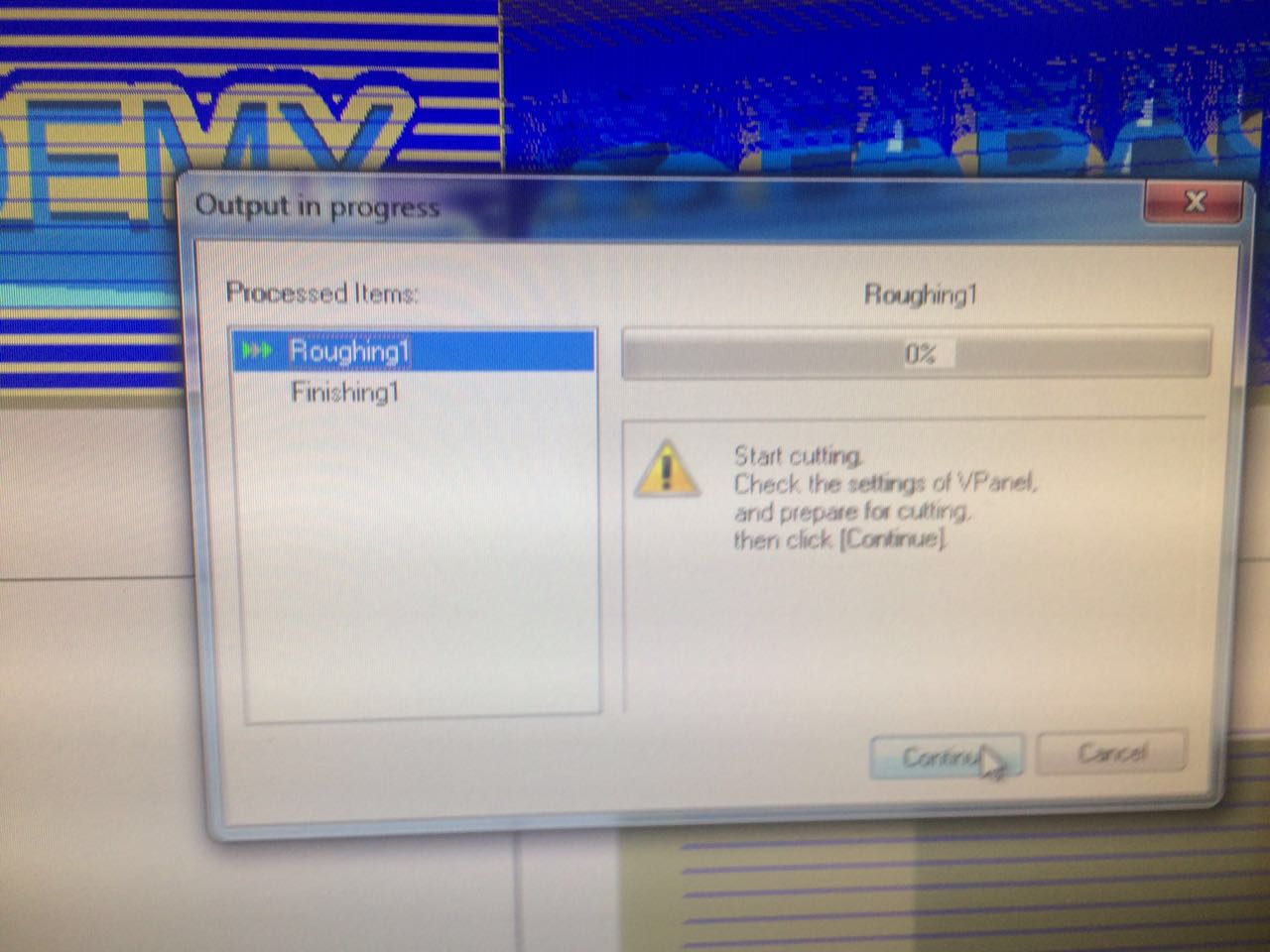

1. open the files(stl file is fine) in MODELA Player4:above you can change the way to preview your files 2. change the material that you will use to mill and click on the Model:3. you will see the information of the file (scale) and you can change which direction the machine will cut:Remember: the design of your project should not exist the undercut components. 4. set the origin:5. after finishing in the Model, click on Molding Form to change the setting:In the Molding Form, you can change the Margin, the Depth, the Slope and Cutting Area,Here are my settings on it:6. Click on the New Process and create a Roughing first:7. Click on next and next and change the tool diameter to 3mm Square (1/8 inches)8. Then again next and next and change the tool path to Contour Line (You may use others but remember to change it to X+Y - axis)9. Continue to click on next and finish and recreate a new Process and create a finishing (other settings are the same as the Roughing) Here I got and sent it to the mill machine( set the original point first! )

problem

my design is too small so 3mm tools is too large for it to cut - many things haven't cut out

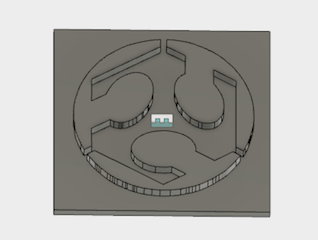

So I redesigned one in a larger scale(80mm*80mm - total in 100mm*100mm):

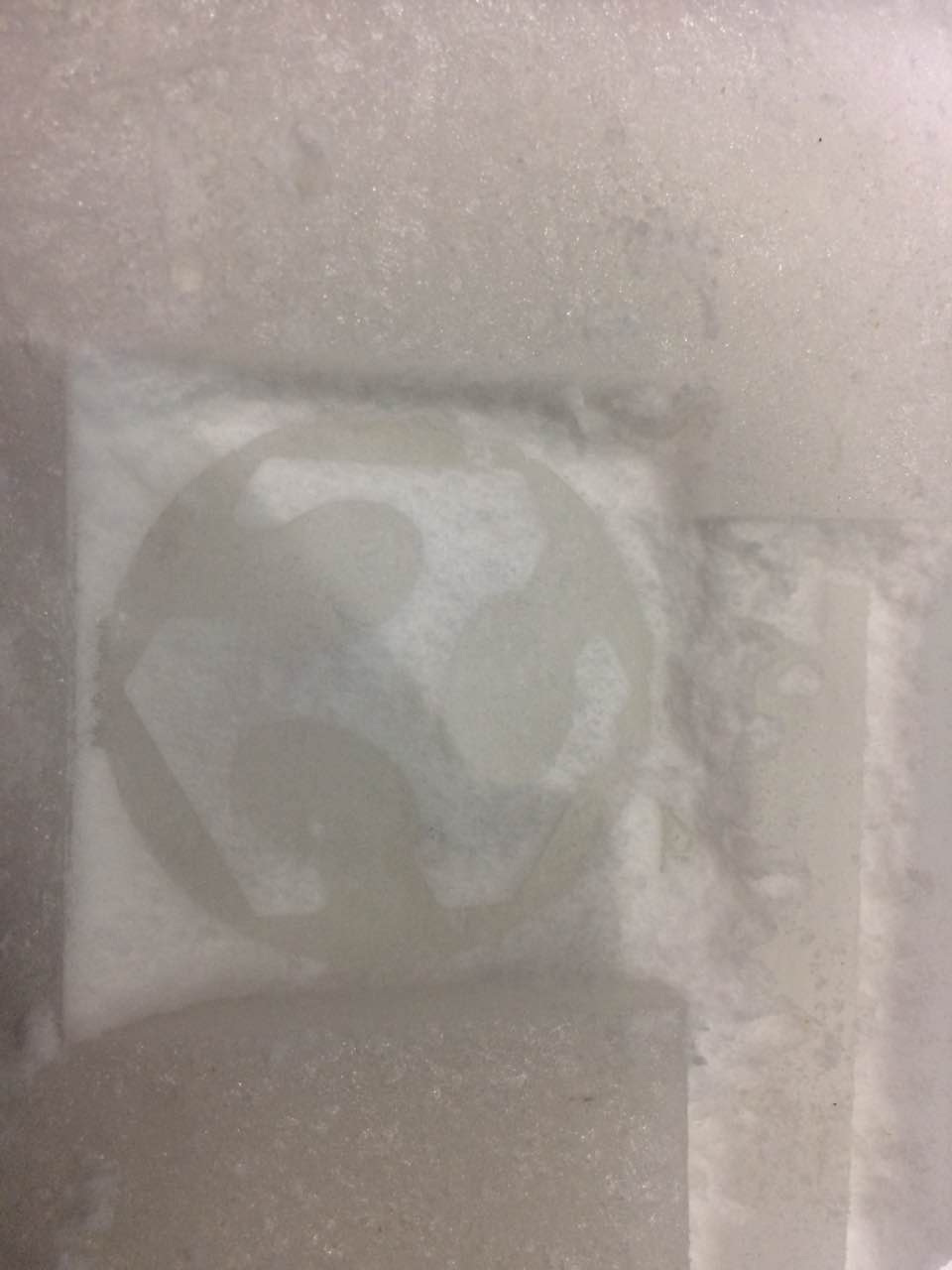

And Here is what i cut out:

And I used a cleaner and a knife to get some remained wax out.

casting

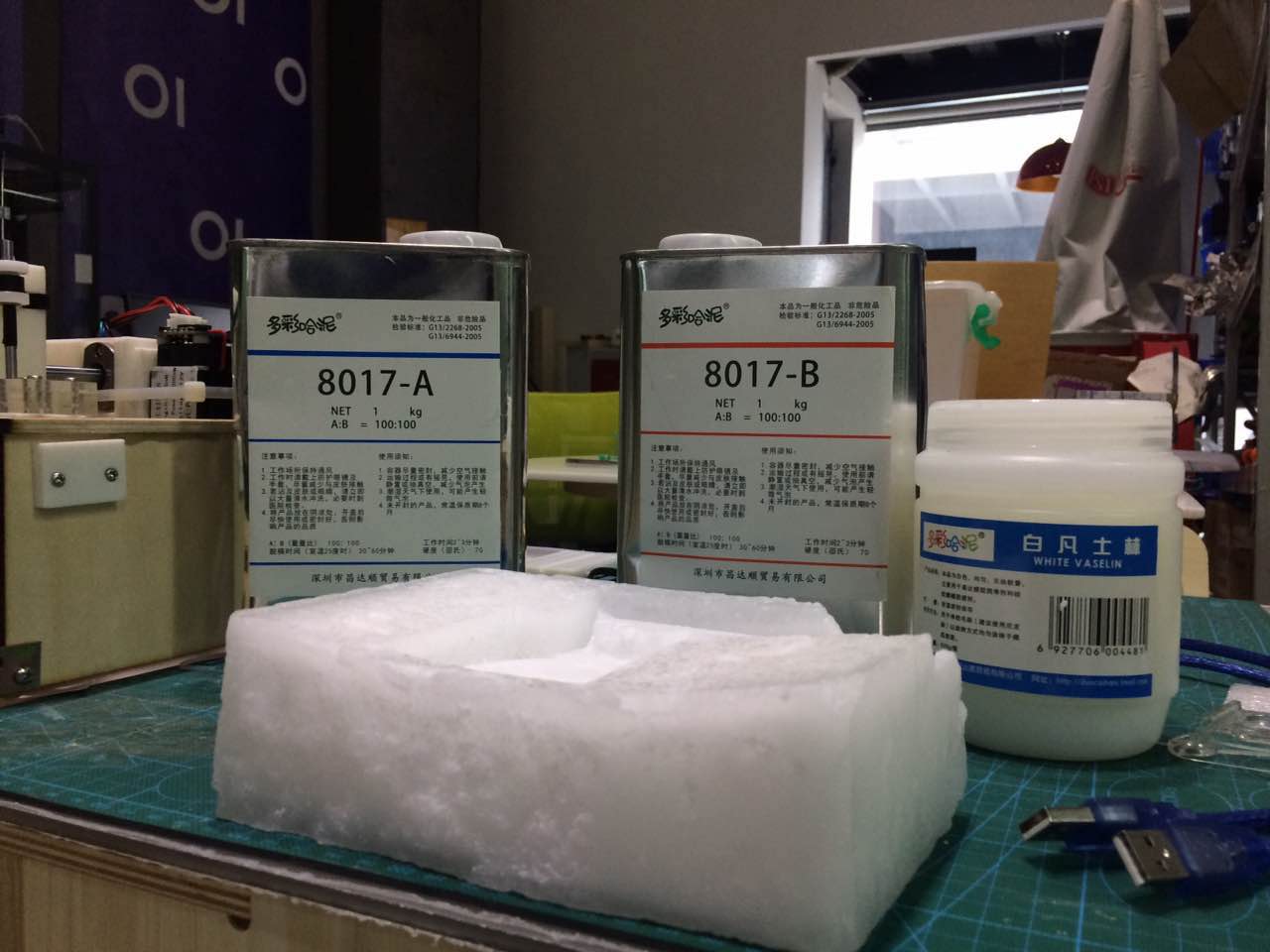

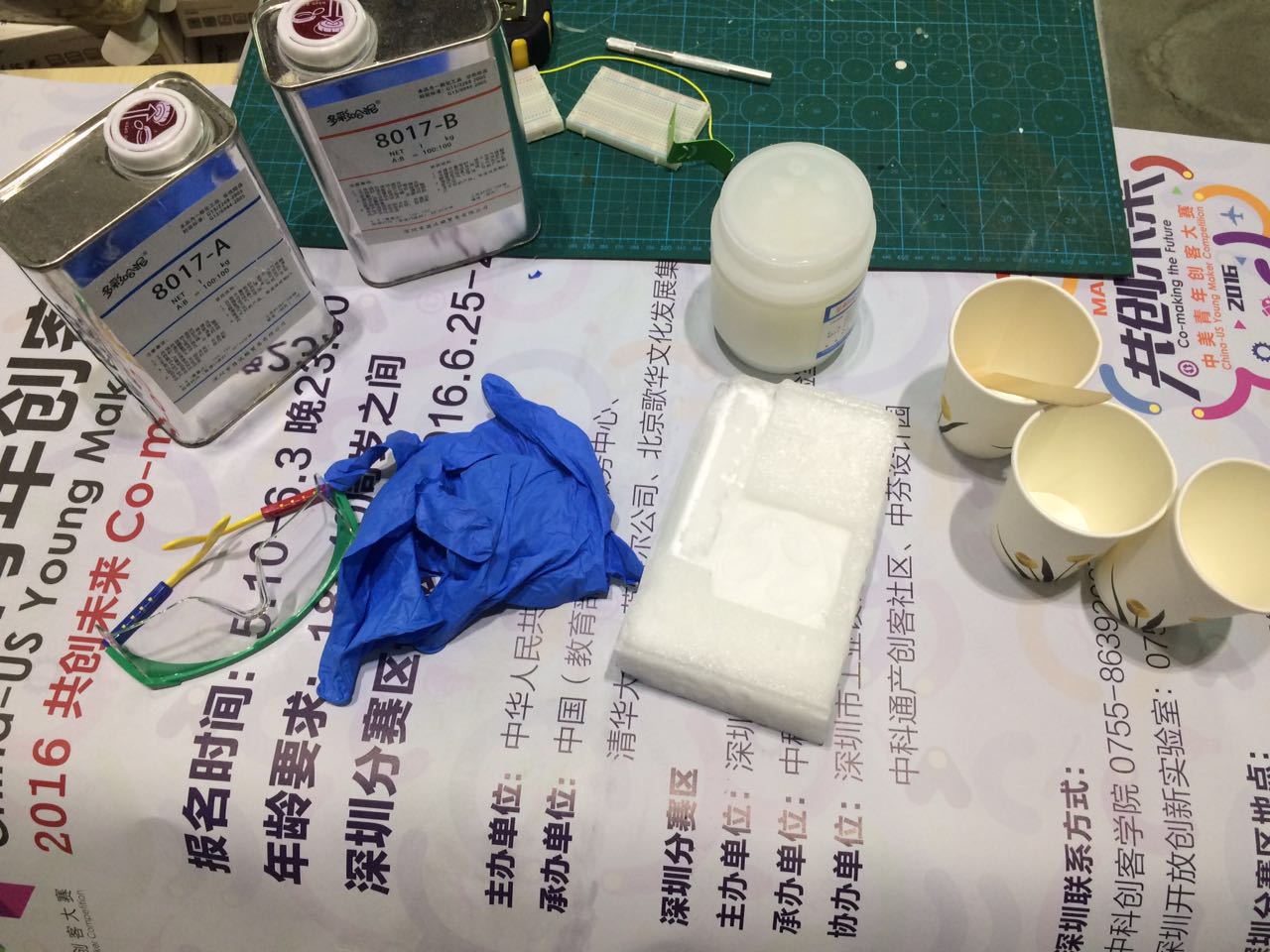

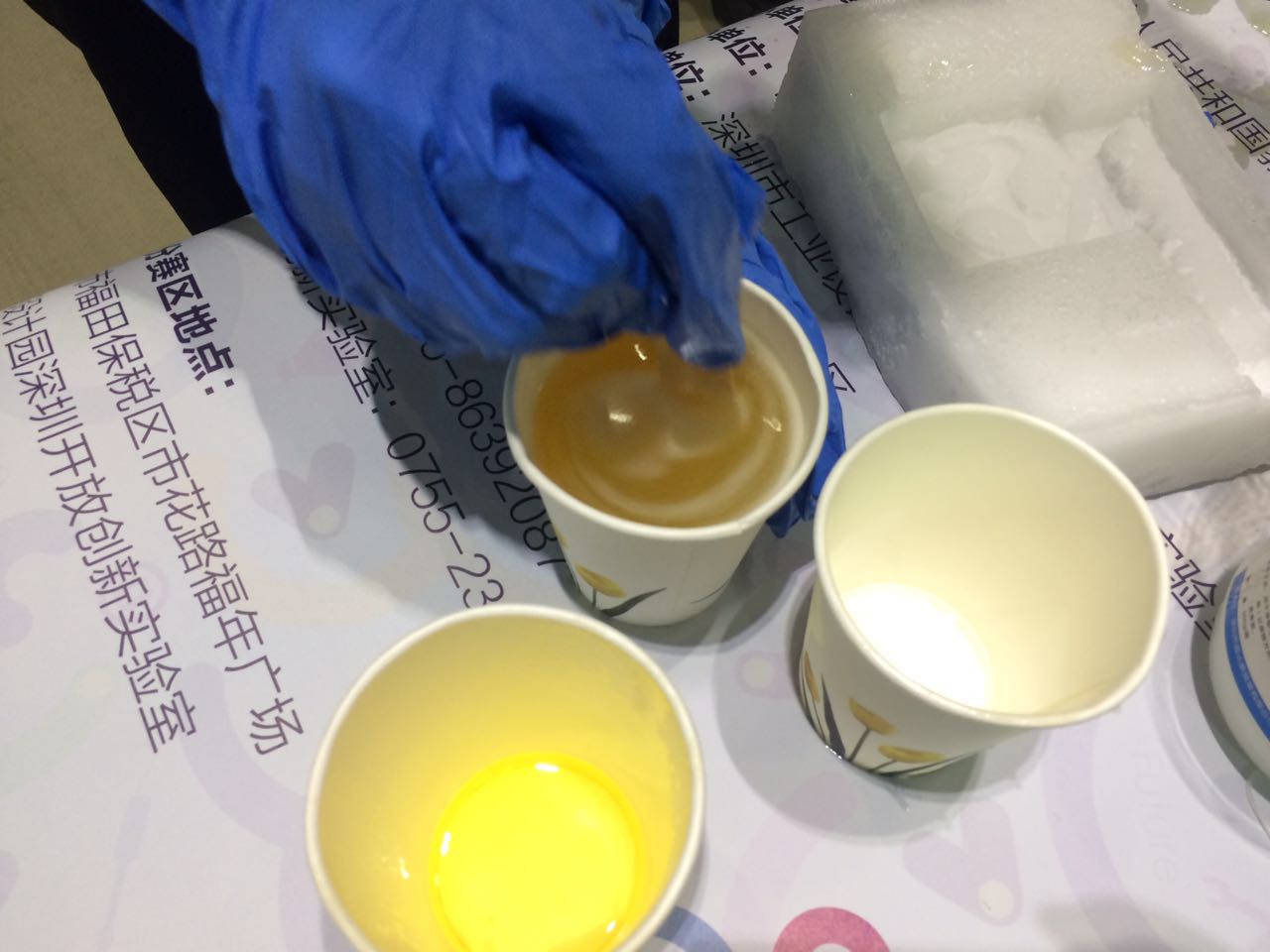

Prepare the materials that are needed:

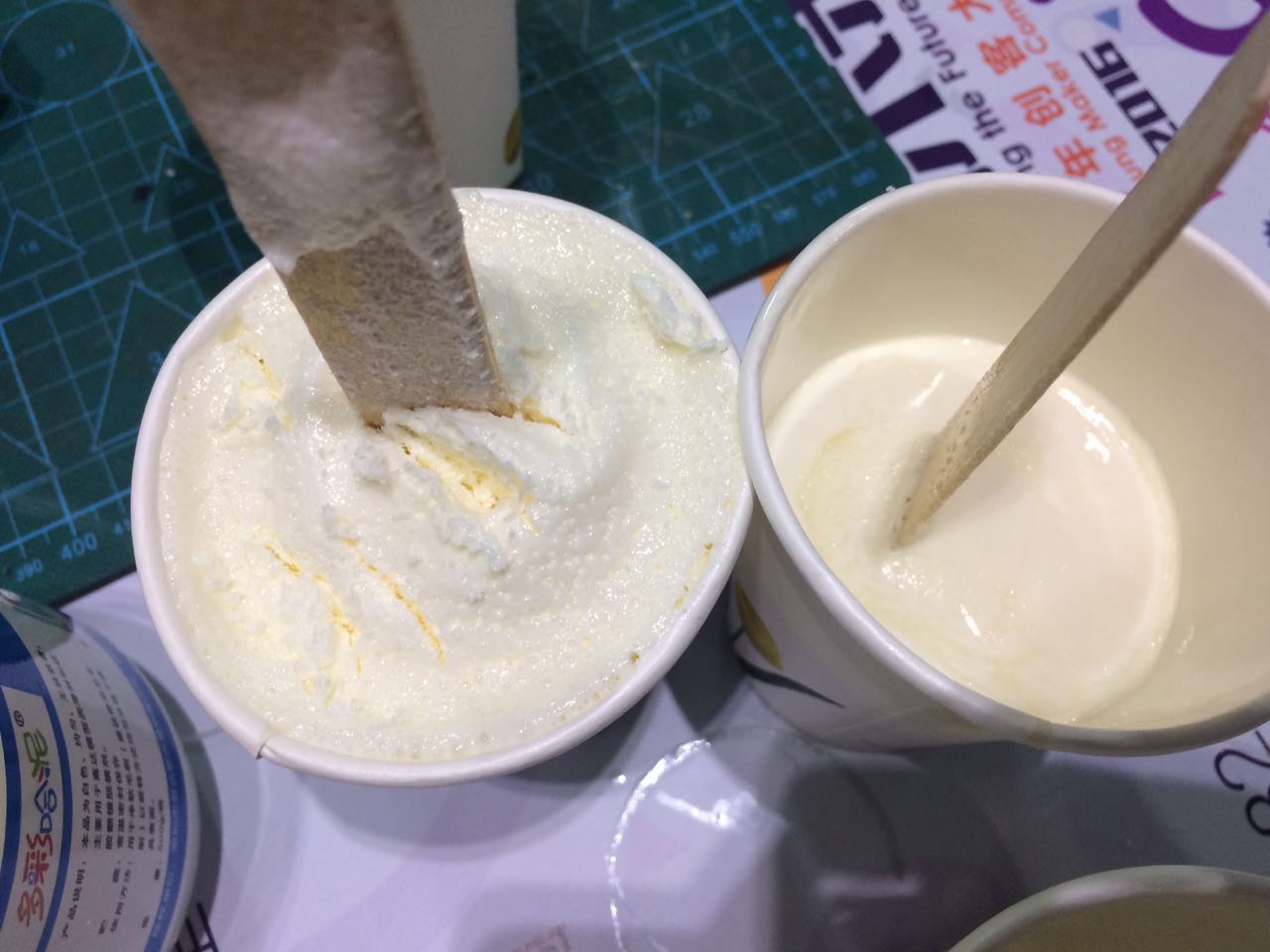

1.What I used are:8017-A and 8017-B - it said to mixed in weight of 1:12.make sure safety is the priority and mixed 8017-A and 8017-B together3.after a while, put the mixture to the mold.

I met some problems : the introductions said it will take 20-30 mins to solid their mixture, but I found it only take less than a minute to solid them. It was really fast, and the first time I failed - after 30 seconds or so, it heated really fast!

So I did it again and finished:

After about half an hour, my instructor Ma Yufei said he gave me the wrong meterial, so I needed to remake a wax mold and did them again:

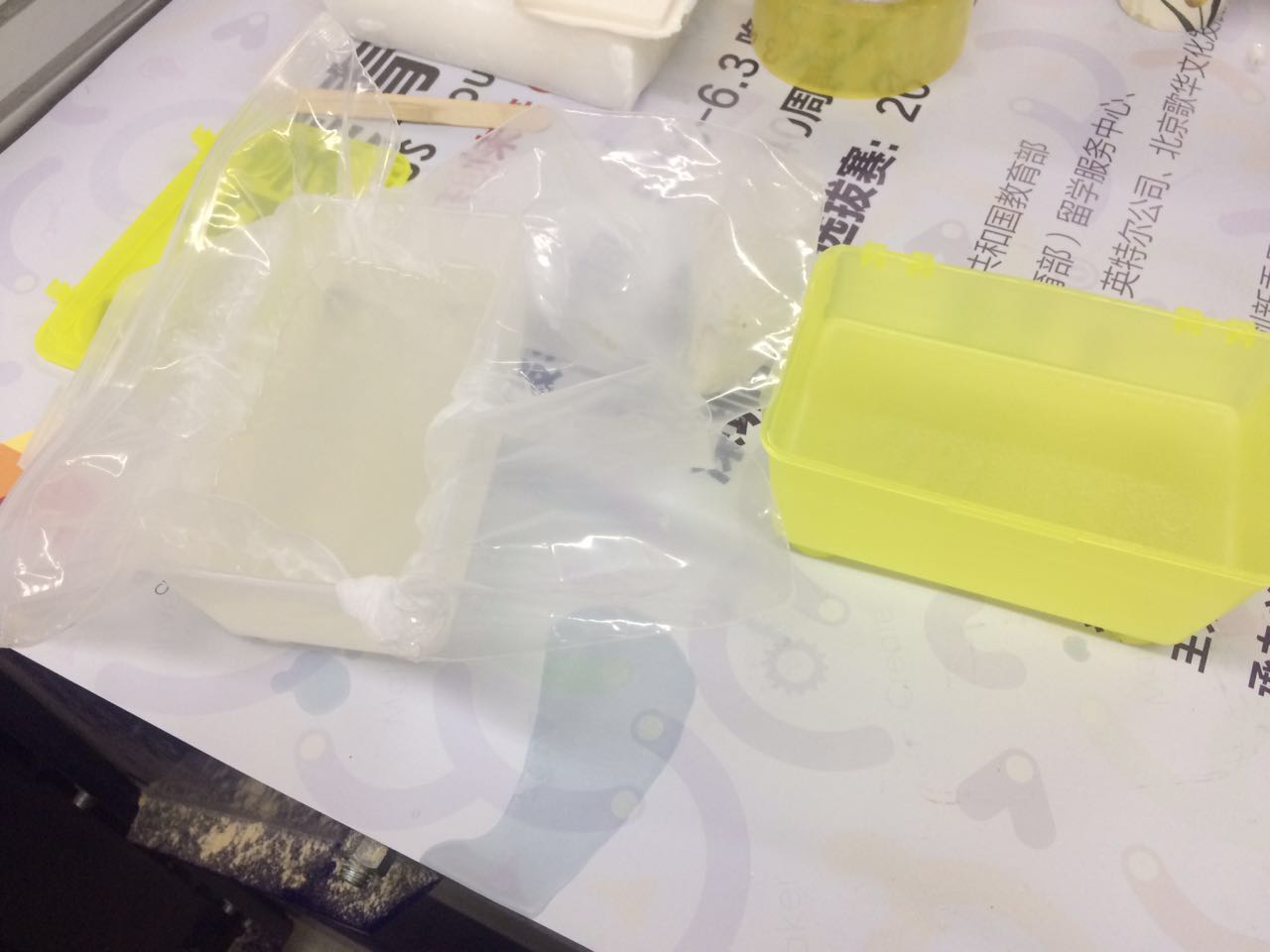

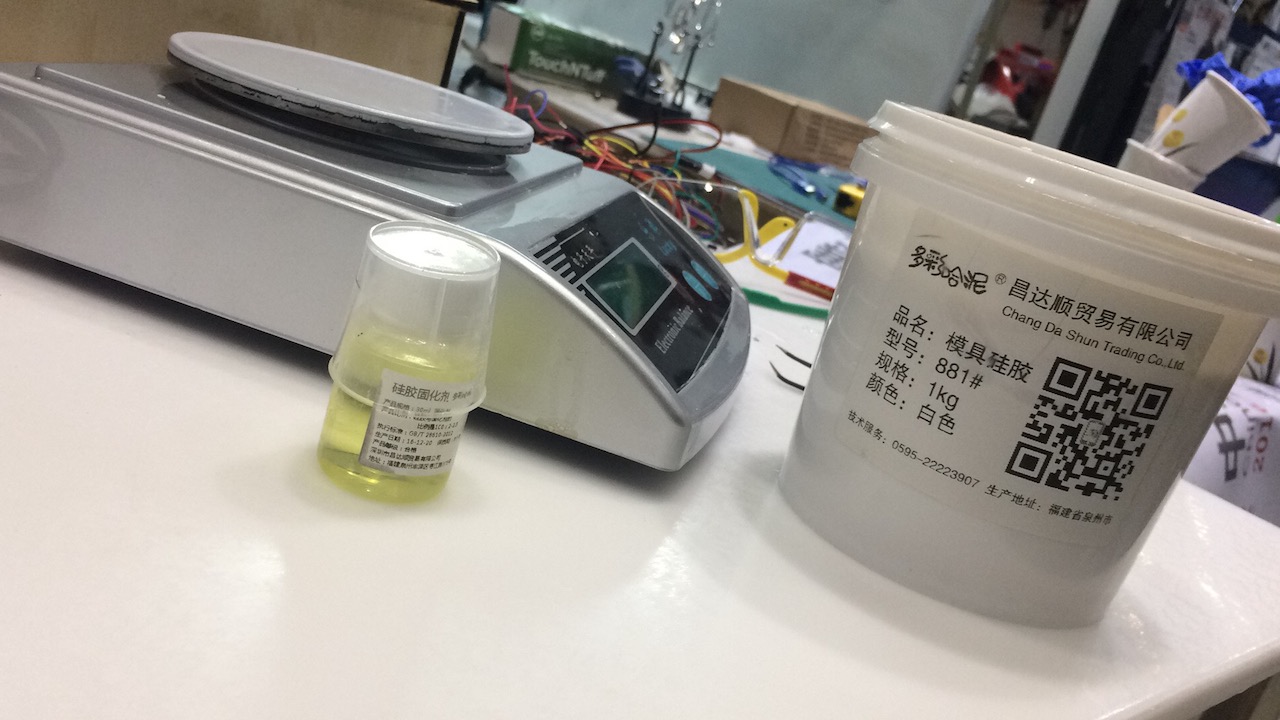

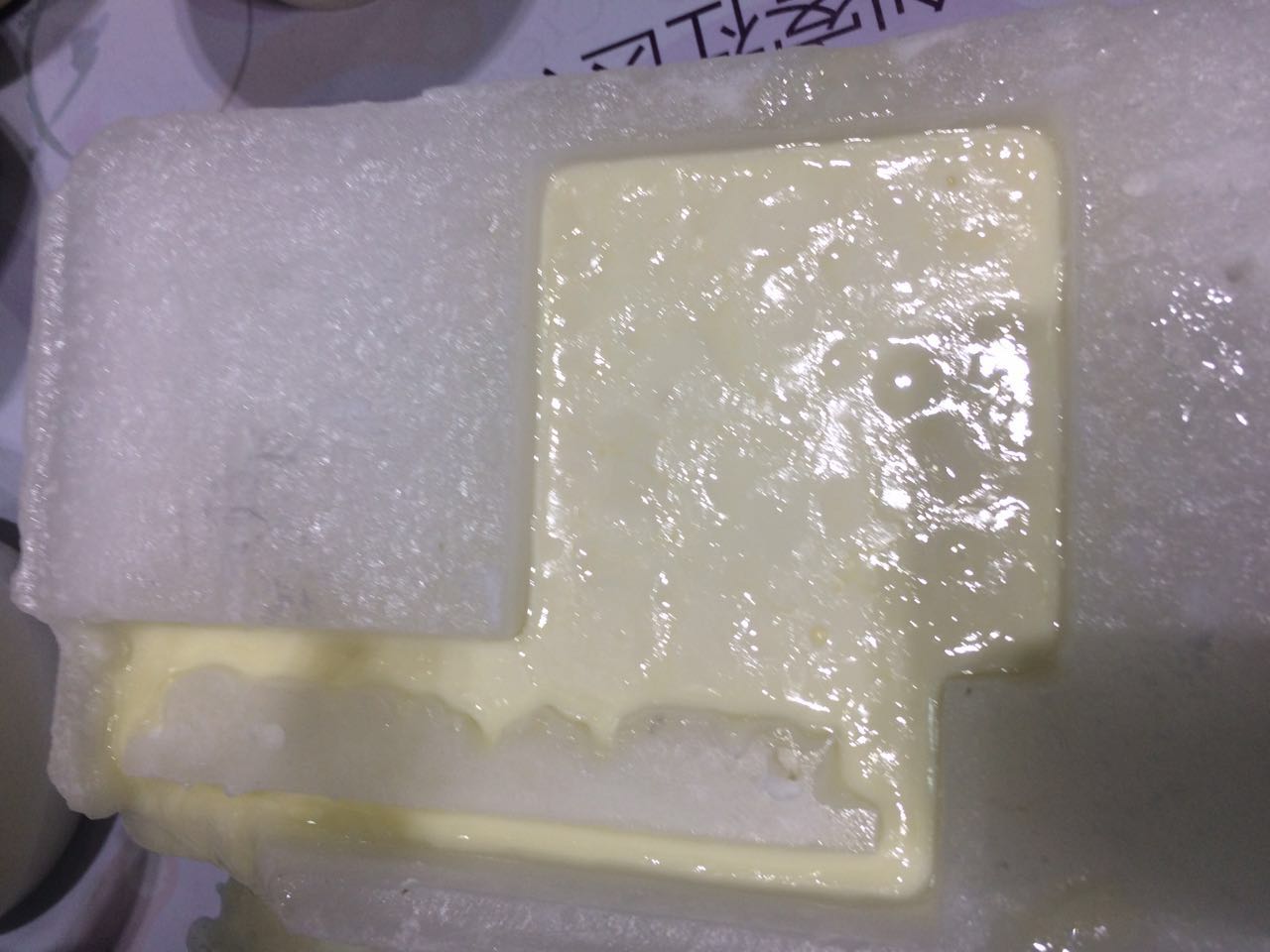

1.What I used then:(silica gel)2.mix them and put the mixture to the wax: (It said to mix the solid liquid to the881# in proportions of 100:2-2.5 in weight, so I used the electronic balance to weight them)

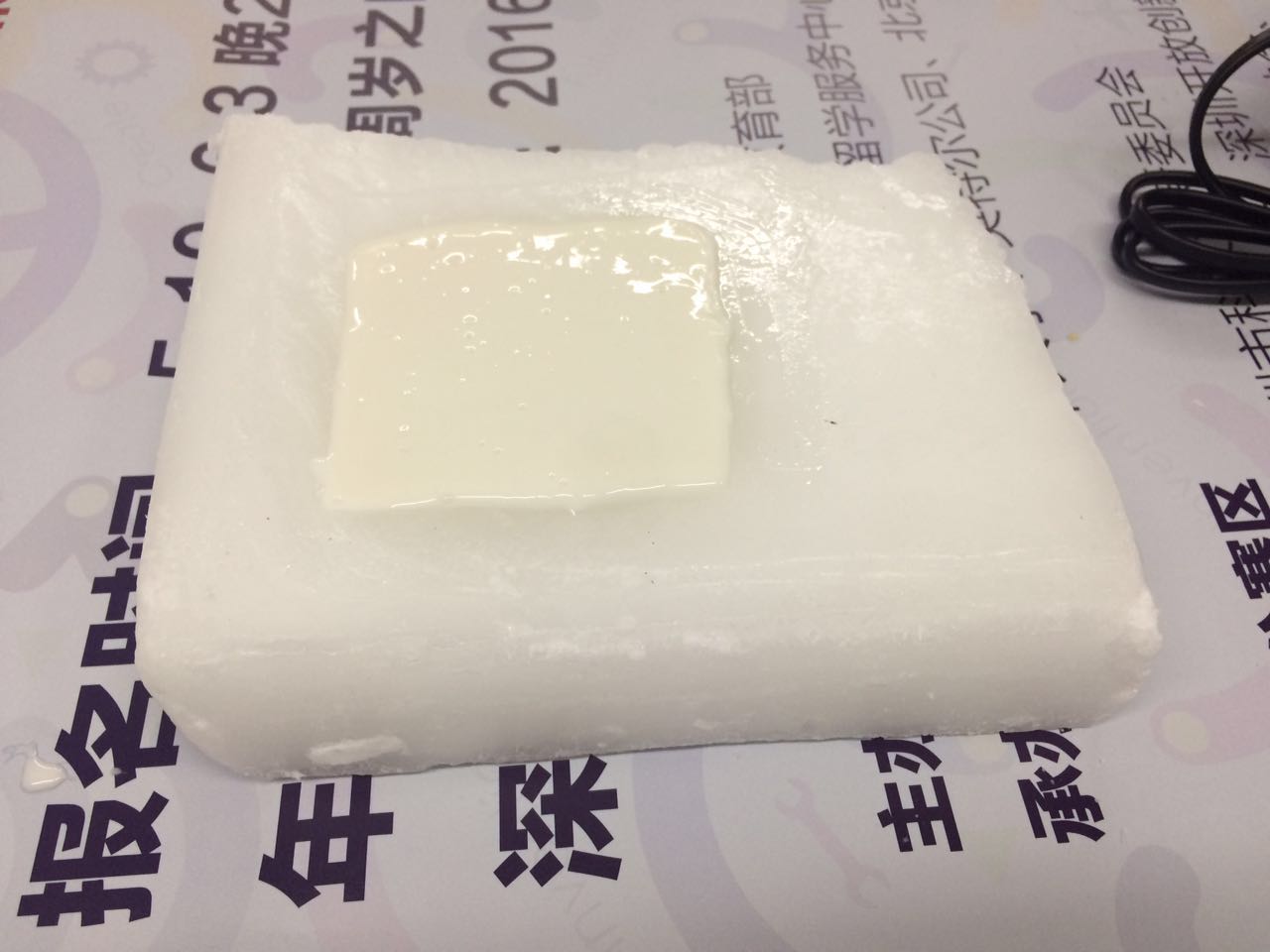

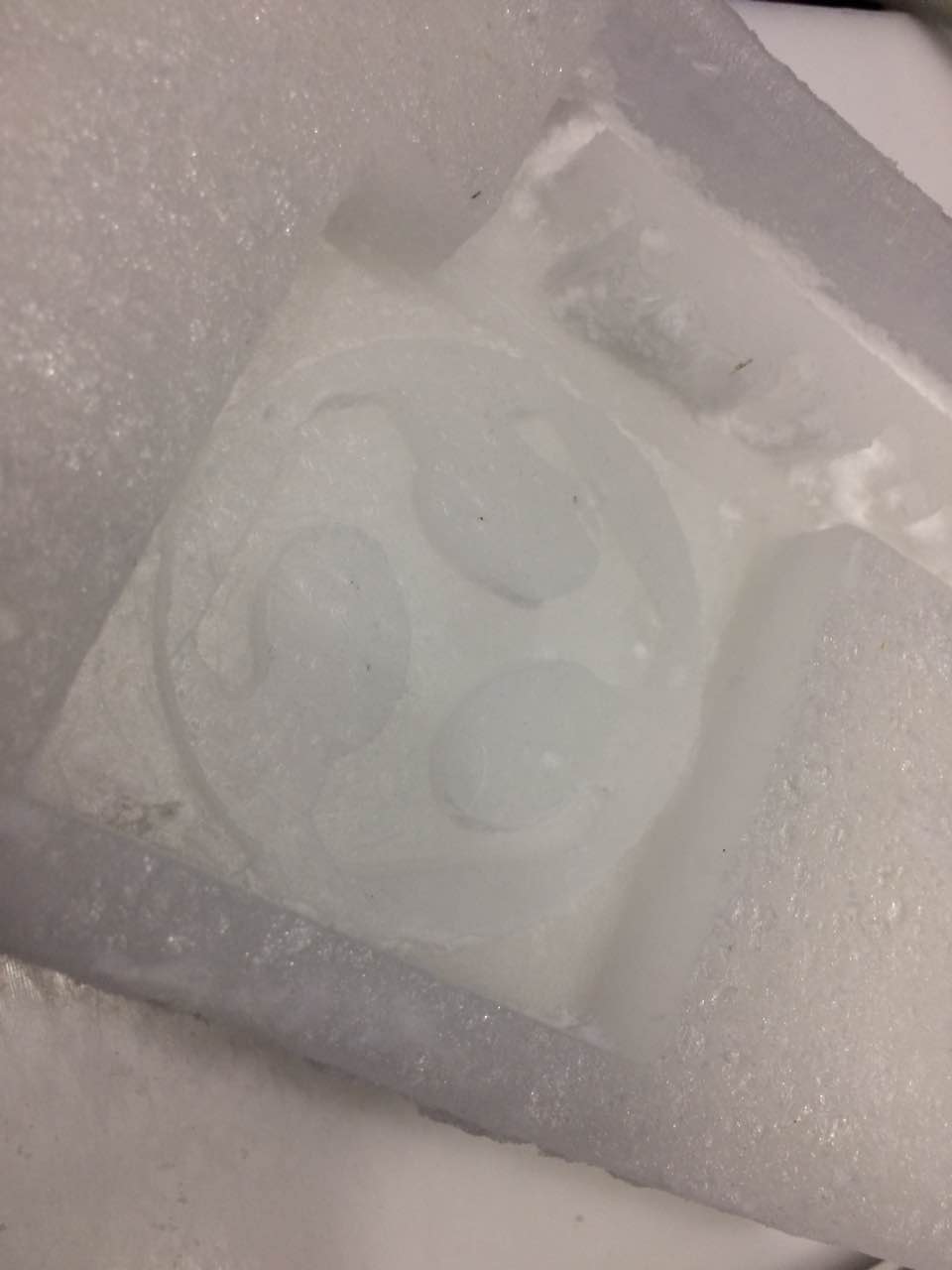

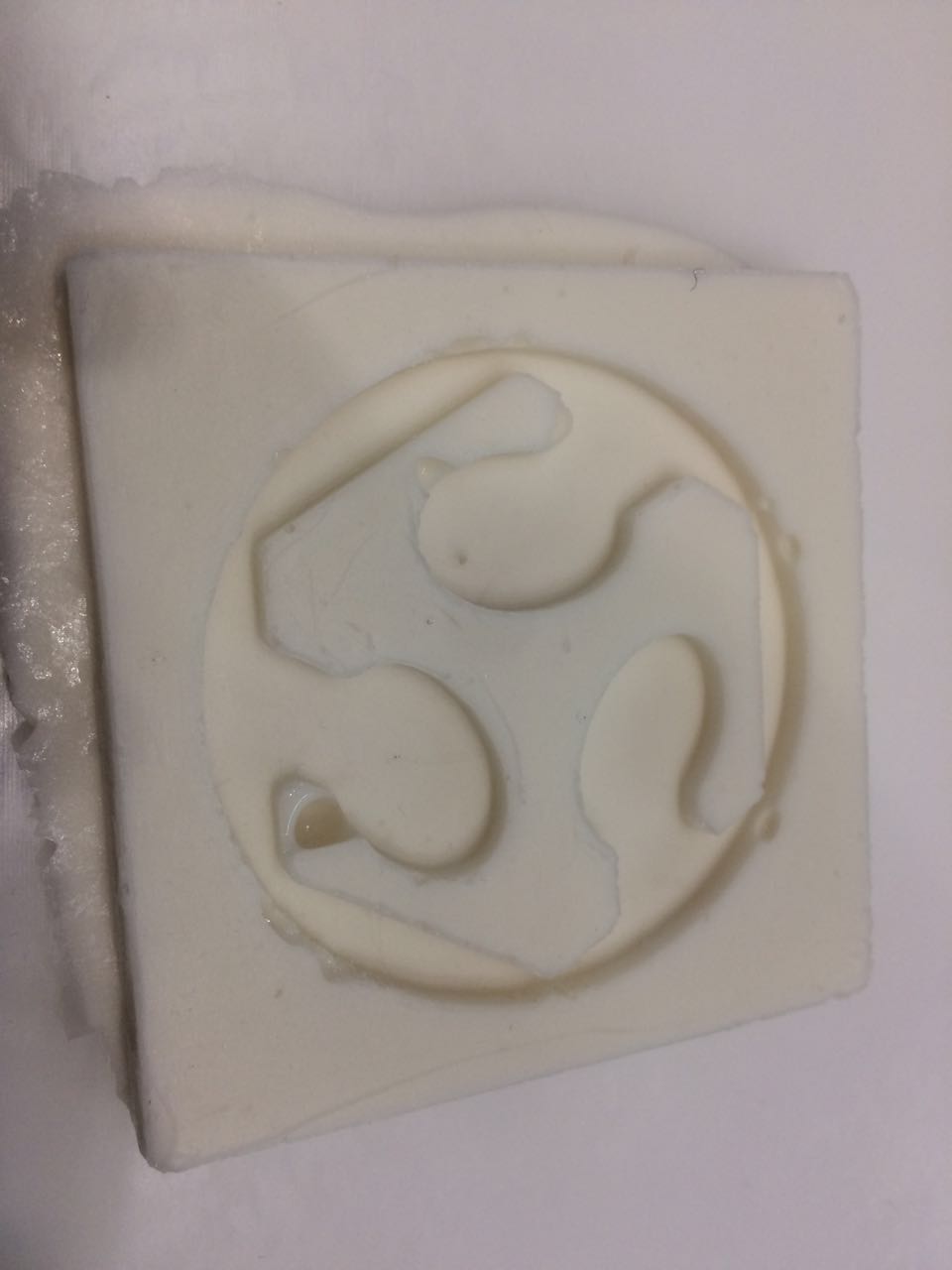

Here is what I made after 8 hours:

Here you see there must have some bulb inside the mold when it cool down.

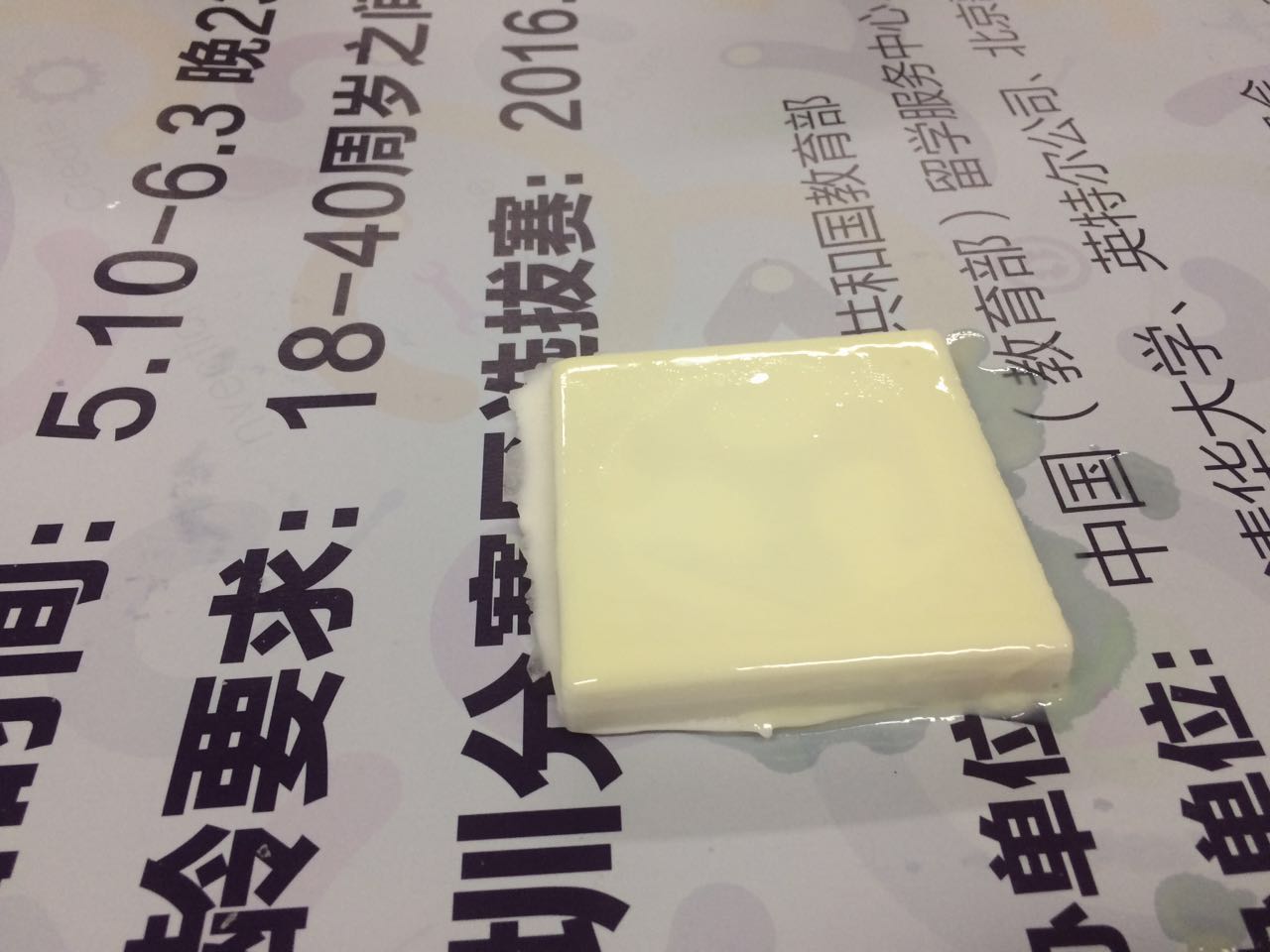

Then I used the 1:1 mixture of 8017-A and 8017-B for casting

Finish:

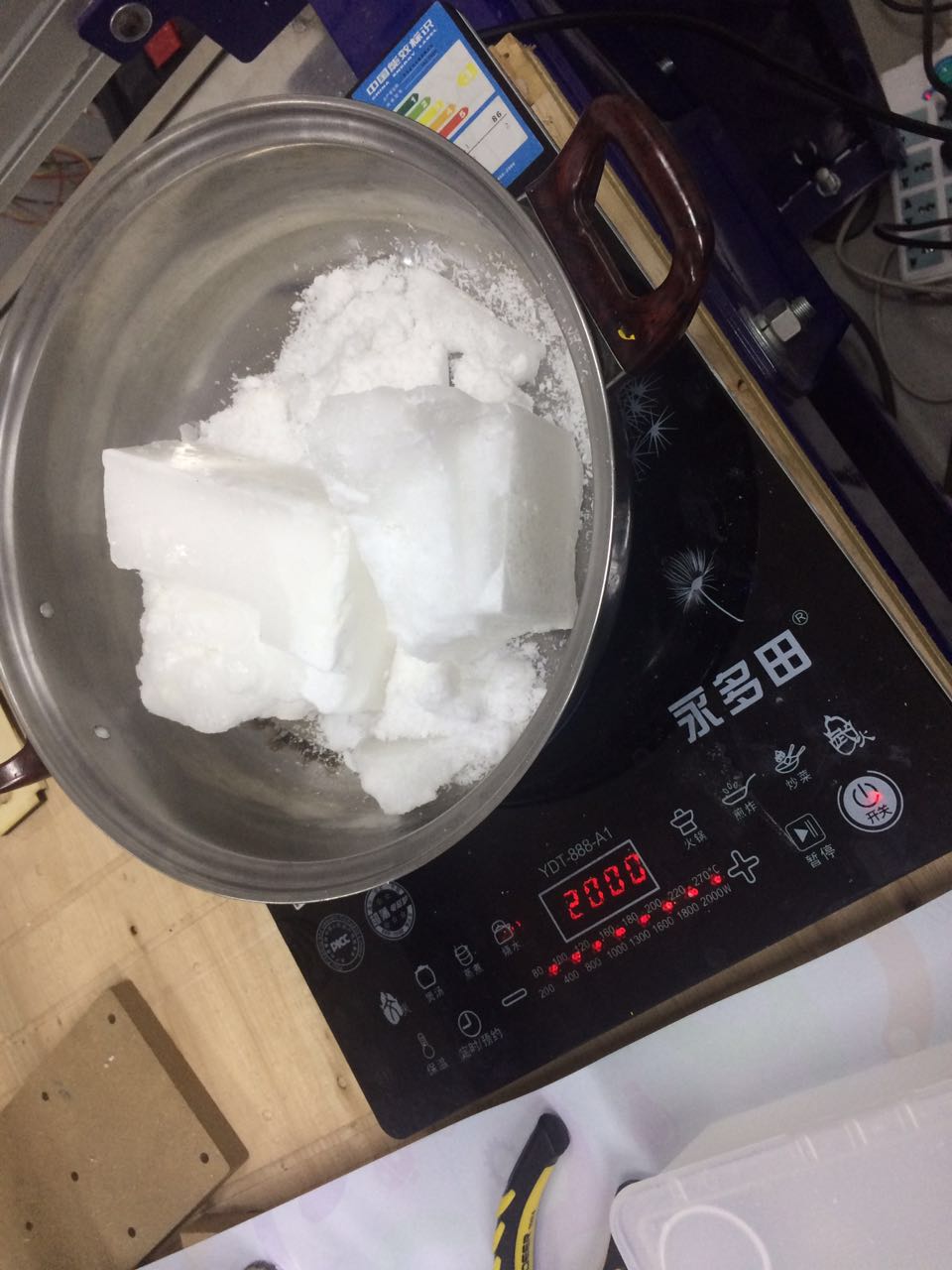

fun thing: remake the wax

We recollect the wax that used and heated them and remake the wax by cooling down: