Week 9 March 22th: Mechanical Design

Making machines that make: Group Assignment Machine Page

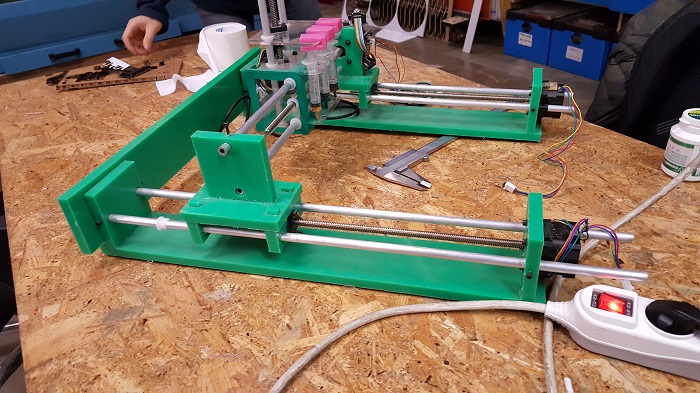

Initially I proposed we make an actuator that has the ability to raise, lets say, an useful beautiful functional cool table up and down so you can use it standing up and sitting down. However our instructor said we can only make machines that make. I countered that making this would make me happy as it would promote my custom table build I had going on. Alas no dice. So we decided on making an improved version of the past CNC dye machine that the previous FabLab Academy students made. We wanted to upgrade it by having it be more stronger and be able to use a router to make it awesome.

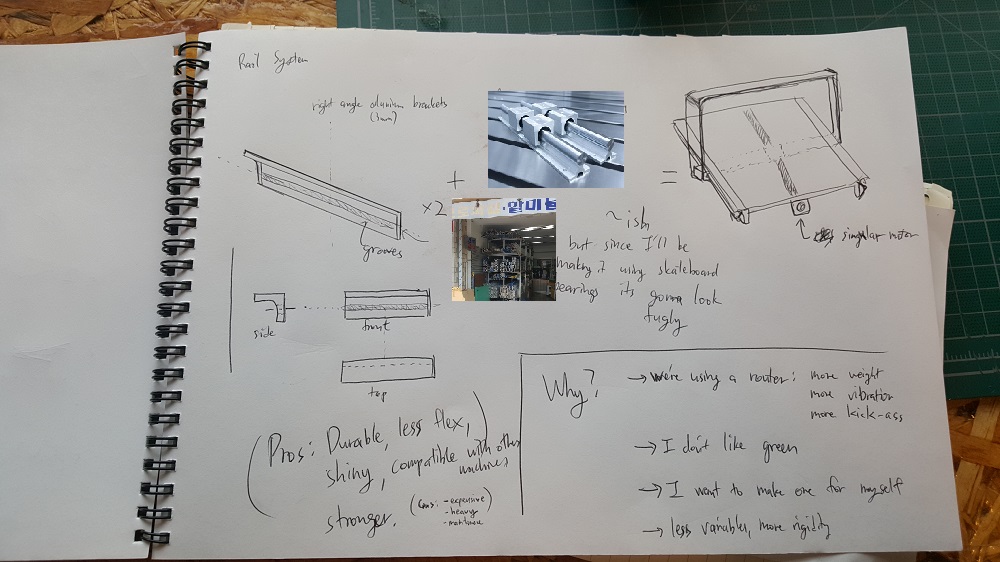

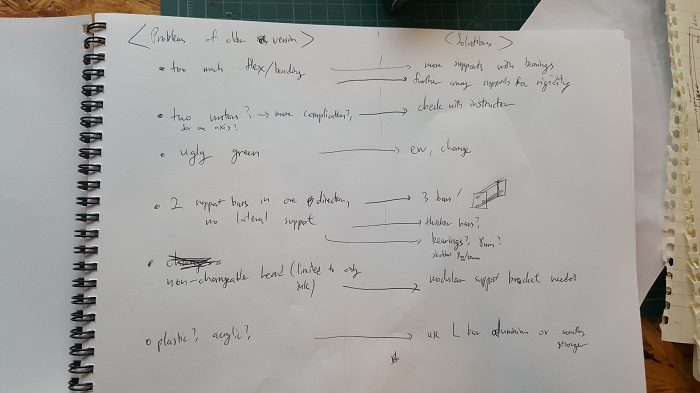

We first started by individually thinking of the best way to improve the design, and then were to compile them together to make a consensus on the best design possible. I had two designs(one with 1 less motor for the y axis and centered in the middle underneath the platform & another where the Z axis which had the router would suffer the most force would be run by 2 stepper motors while the X and Y axis each would be powered by only one) that used an alumnium profile with bearings that would allow a strong structure yet smooth motion with the stepper motions albiet being more harder to make and expensive. However we decided on sticking with HDPE as it is much more manageable and cheaper and its strength is incredible compared to its cost-weight. Not to mention we had to make our designs modular, so basically we were forced to scrap our 3d designs and make a new one. We tasked our group assignment and I got the short stick of software since I didn't show up to the one of the meetings. I plan to be much more diligent start now.

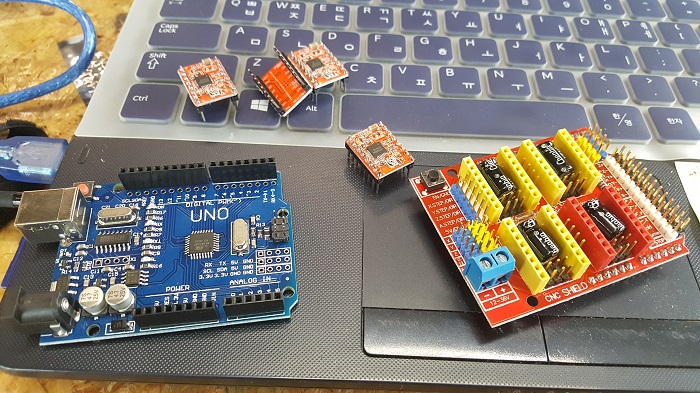

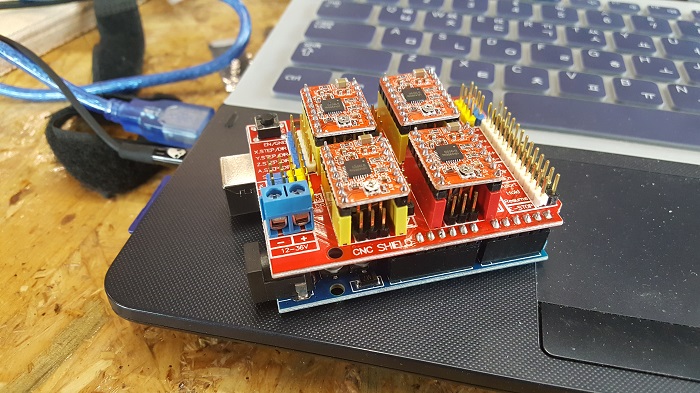

So first I opened the package we got overseas(kudos to Fab Foundation, we got everything in nice safe package) which contained our components. I specifically use the term components, as I had no idea specifically what they were. Sure thats a motor and that's an Arduino Uno, but the rest was 'wow I sure do hope I don't break anything here since I have no idea what they do'. It turns out these particular feats of engineering were something called GRBL which is an amazing simple to use CNC software with included help on hardware. They provide very clear and informative instructions on how to bootload the arduino and hex file, how each board is made, how the CNC shield and UNO and the stepper drivers all connect, and further more how to code and operate the motors. Also NYC CNC(the amazing guys who teach Fusion Friday lessons) on Youtube have a great visual aid video on how to do it as well. I used avgdude on Git Bash to flash the .hex file and Universal Gcode Sender to operate and test the motors. Since we had 2 motors for the Y-axis, I use the clone function available on the shield by just soldering two pins in a female header(I think this is what its supposed to do? Will need to check). Checked using the volt meter as for the other parts and seems like it was okay? Anywho everything went unexpectedly fine and got the motors to move on my first try. However it turns out that I could only get all the motors to move at the same time, and not each individually for each axis... Our instructor said, "This is interesting". I concur. In fact this intrigues me and baffles me; does anybody know why this is that way it is? Anyways I plan to find out soon enough but scouring the Internet, as there seems to be a plethora of people who have made the same attempt.