For this week, the assignments to be accomplish are:

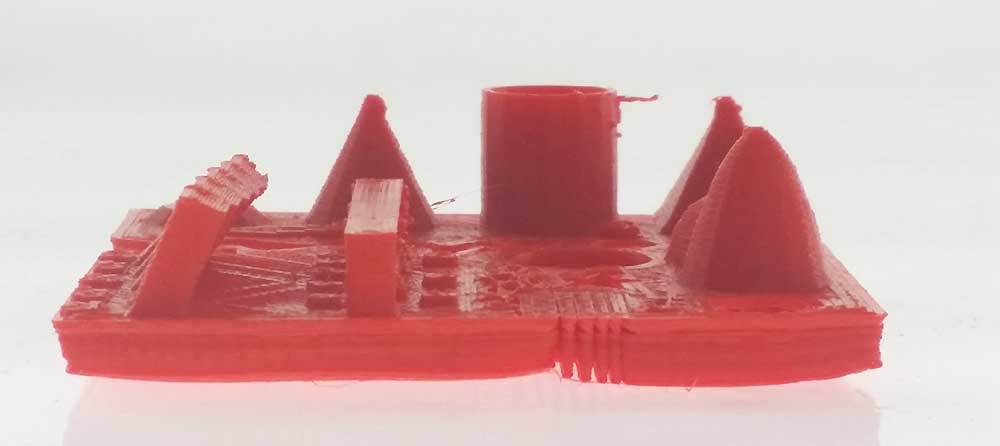

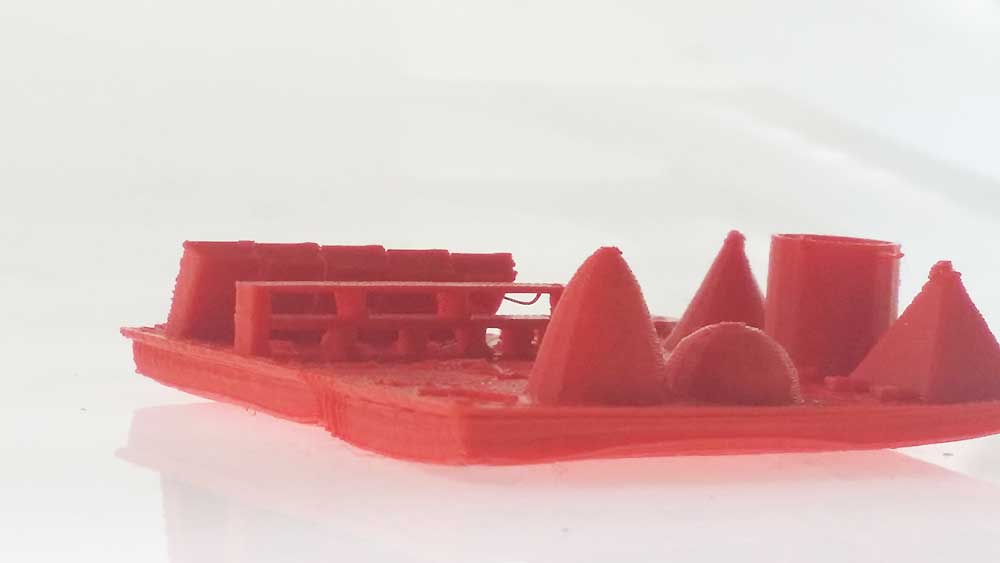

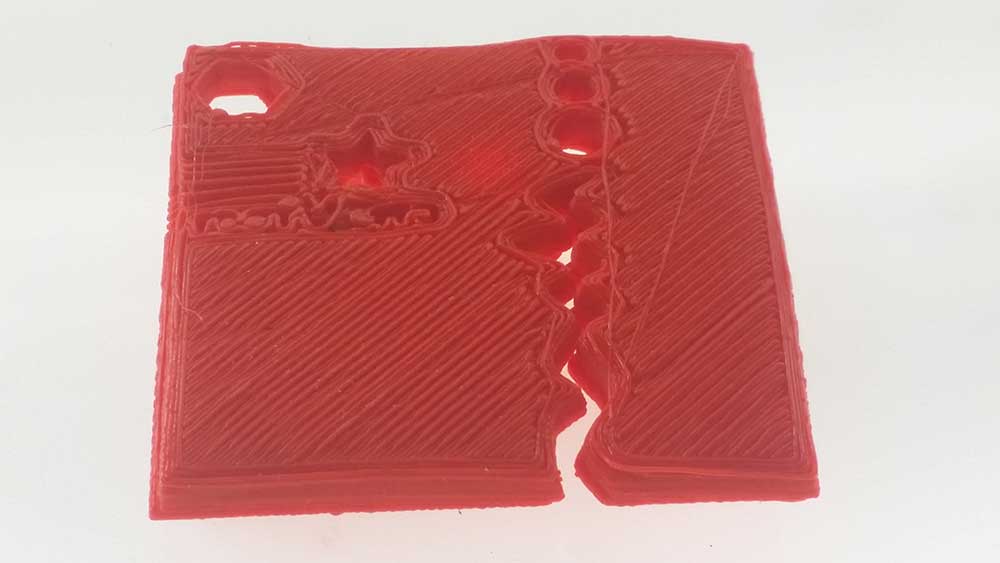

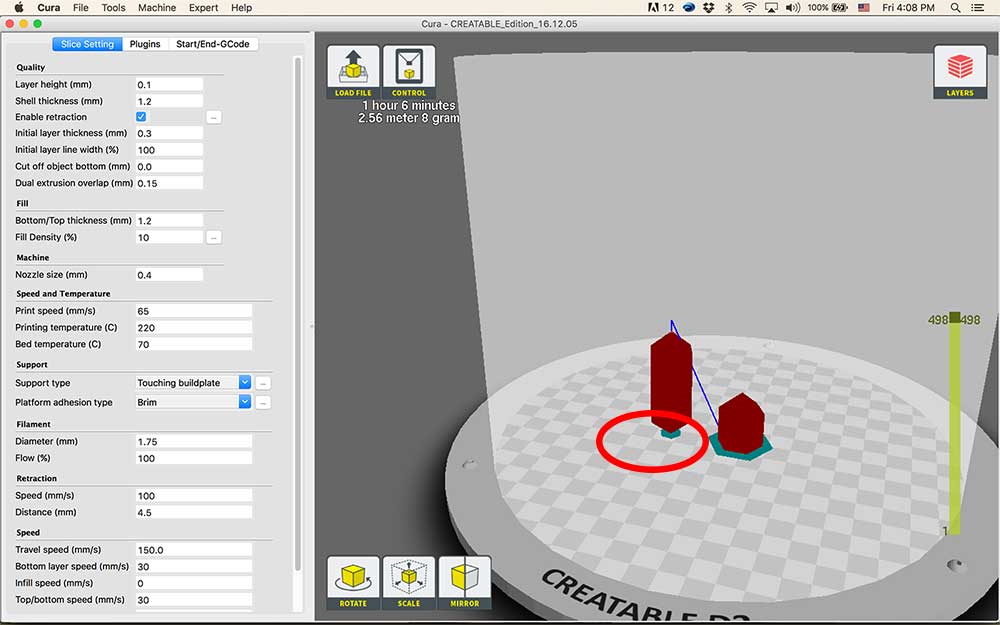

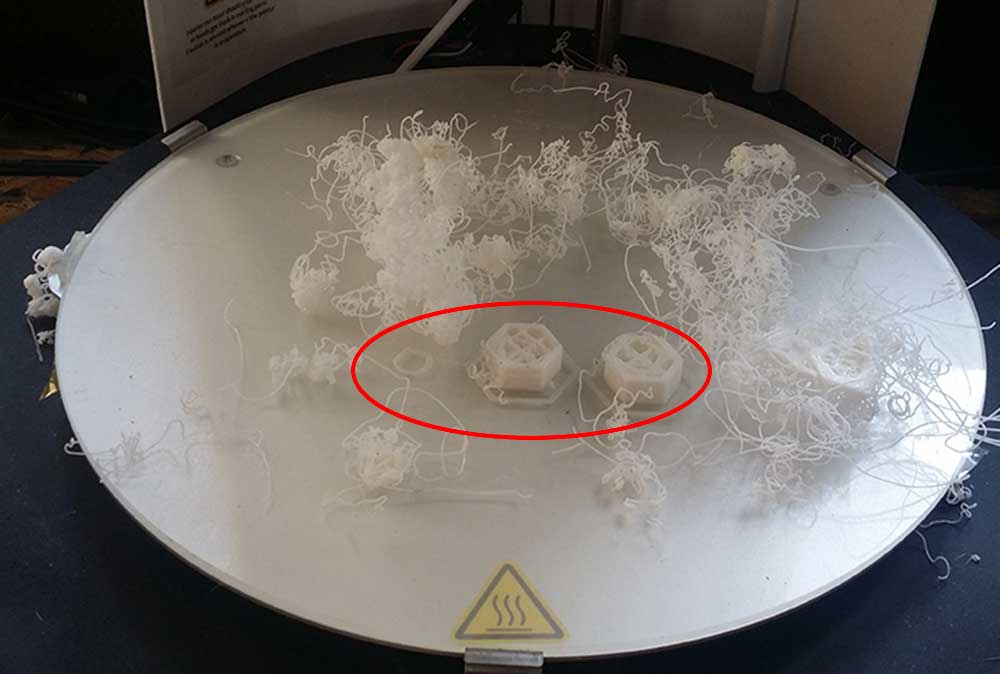

First, The 3D printer used for this week is a Korean brand Creatable D3 Delta bowden extruder with a maximun temperature of 240 (dont recommend ABS on it), using a CURA slicer (another important thing about this week is temperature fluctuations very high due to the old building and winter conditions) .I printed PLA using no support neither adhesion type, layer height 0.1mm shell/top/bottom thickness as 0.8mm and speed at 80 and temperature of 225 for the nozzle and 75 for the bed( before any comments our lab is located in a very old building where the difference in temperature during the day and night are very high)

The file above was borrow from thingverse.com and as you see was a disarter. so maybe I need to create a file that will give me a simple and faster feedback regarding one characteristics of the printer.

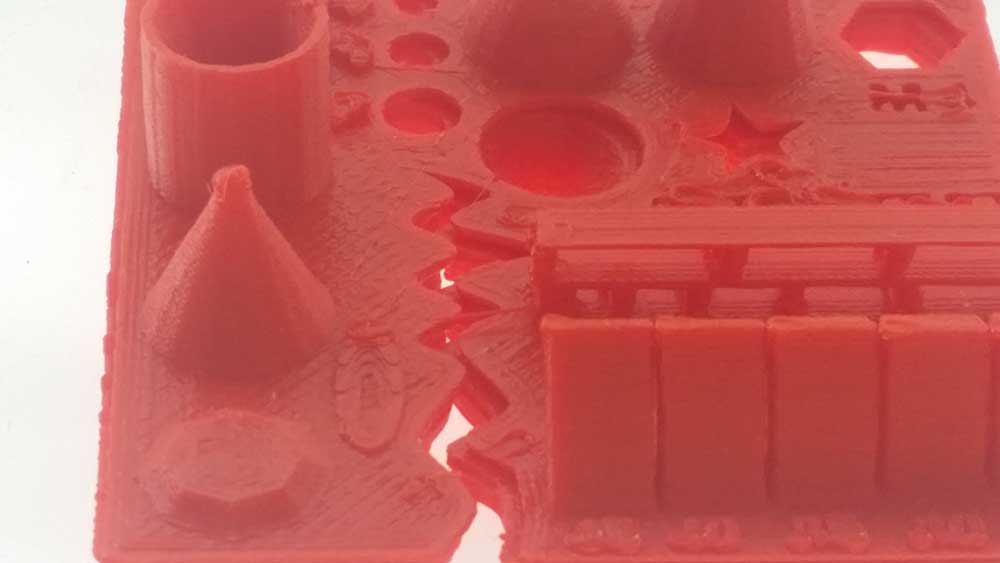

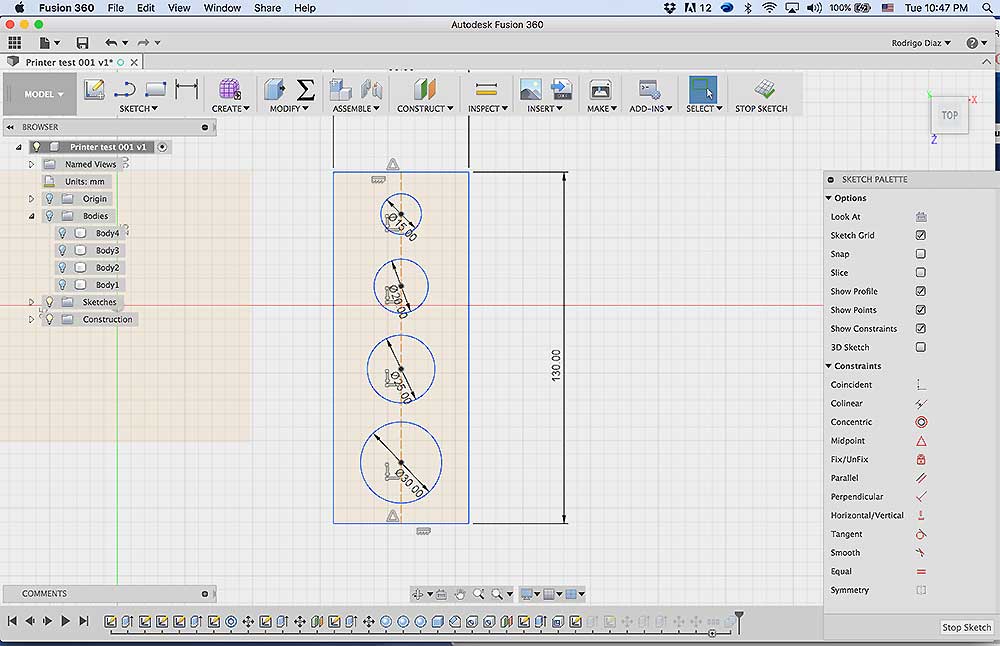

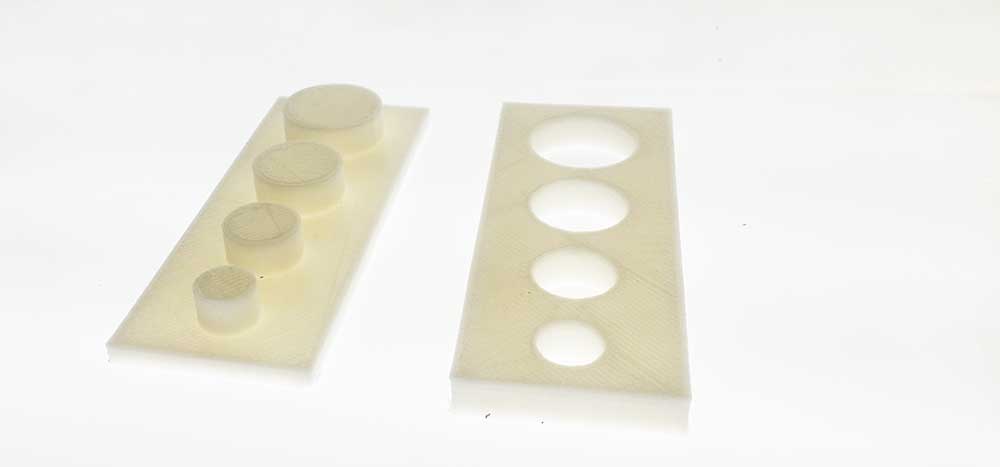

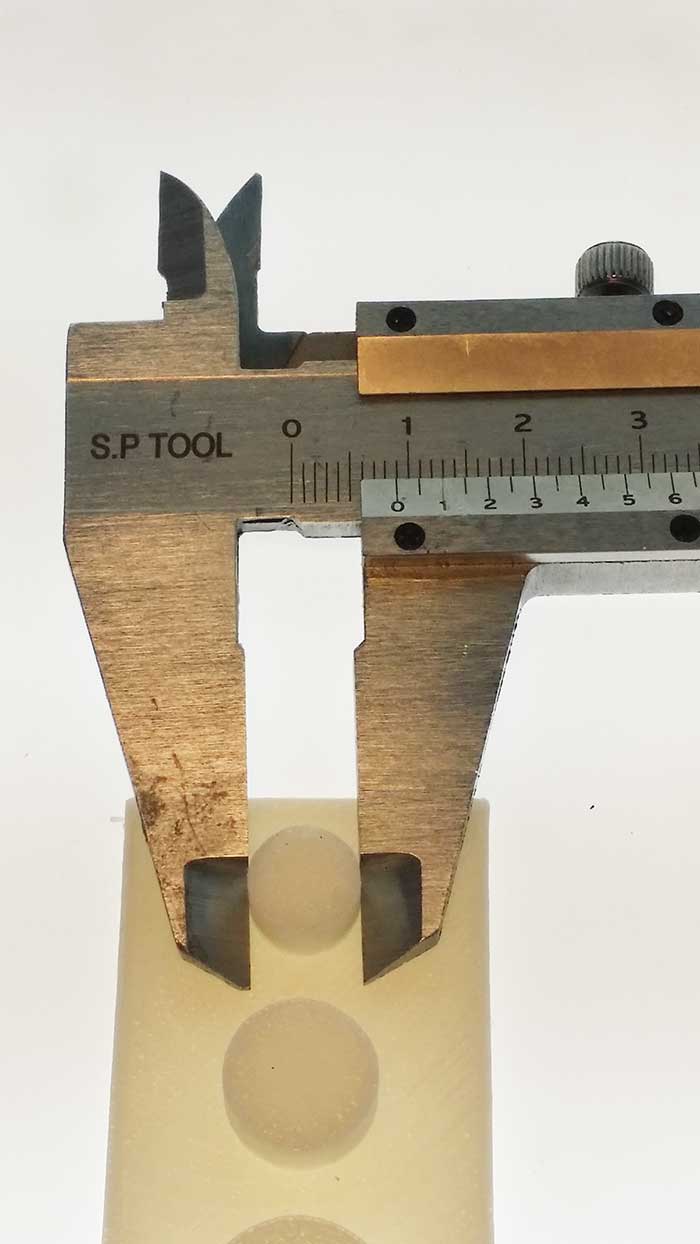

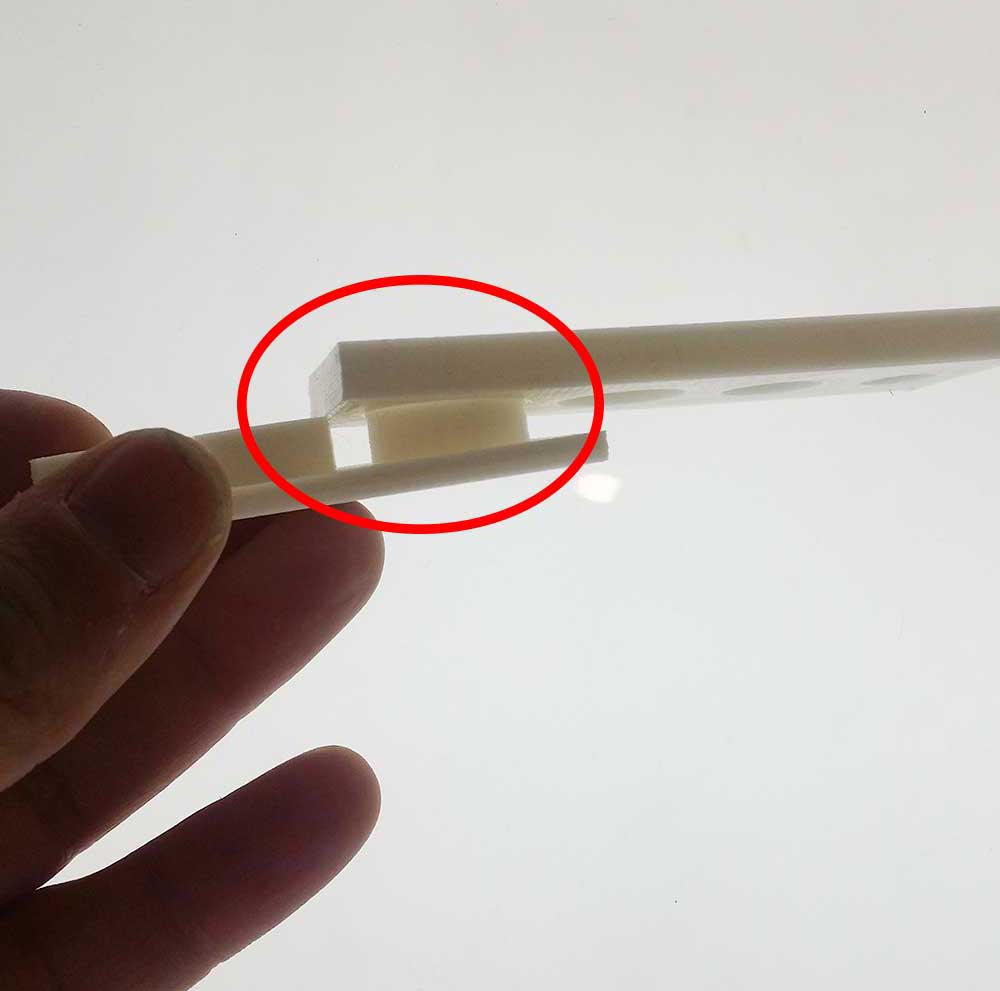

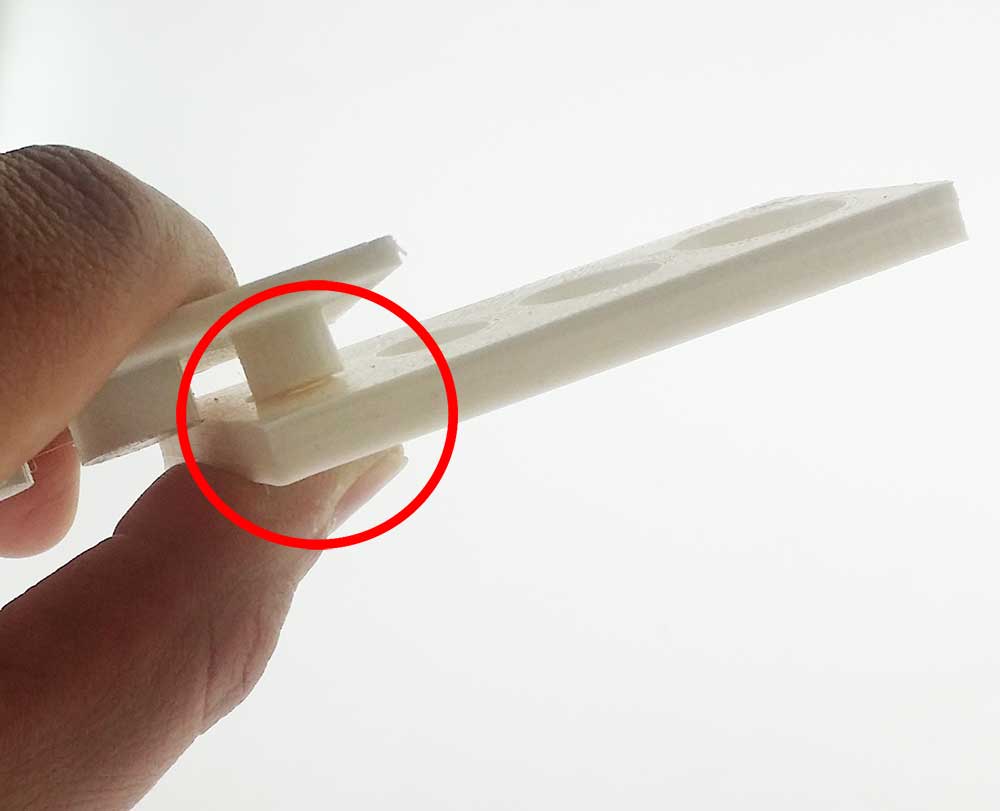

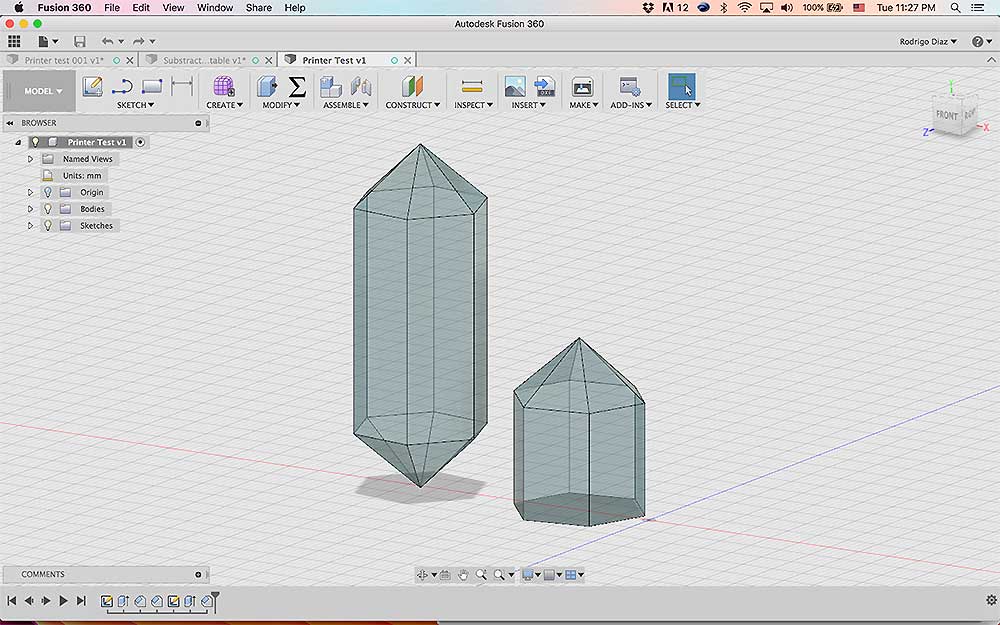

therefore, I end up doing is a file that can measure the constraction after the print is done.

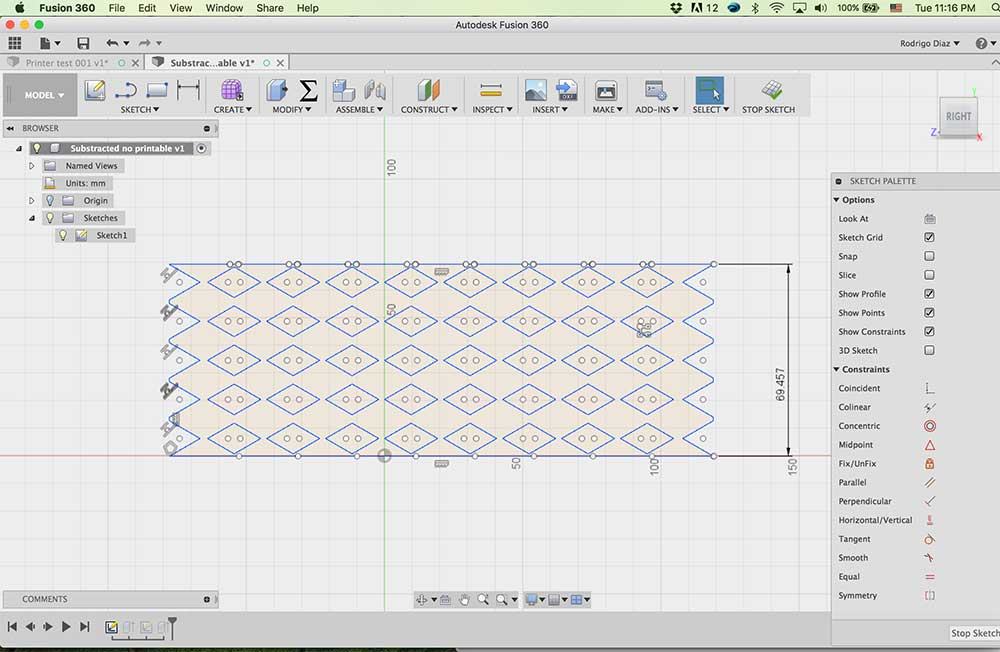

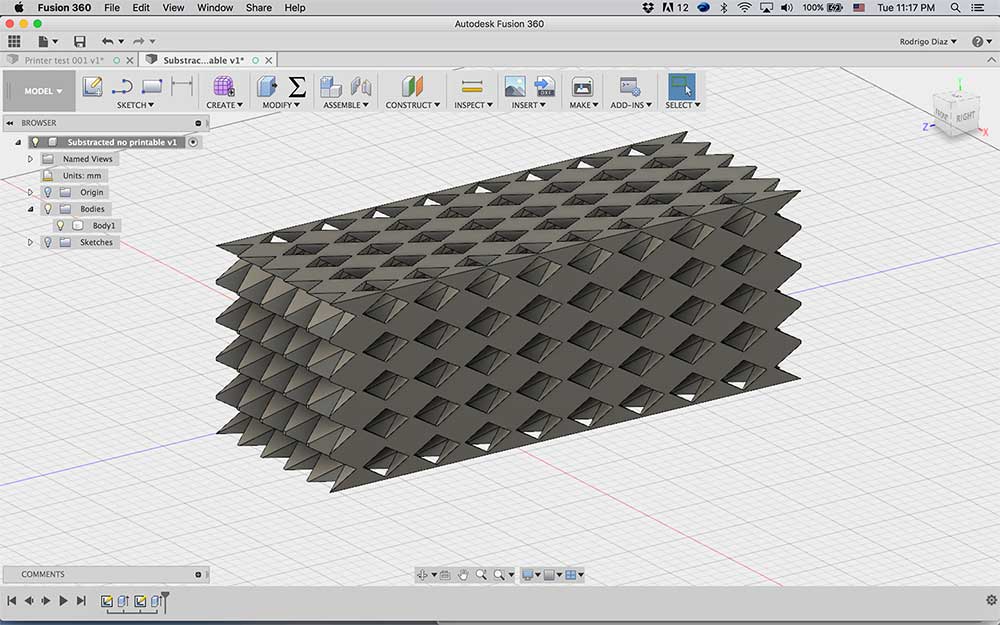

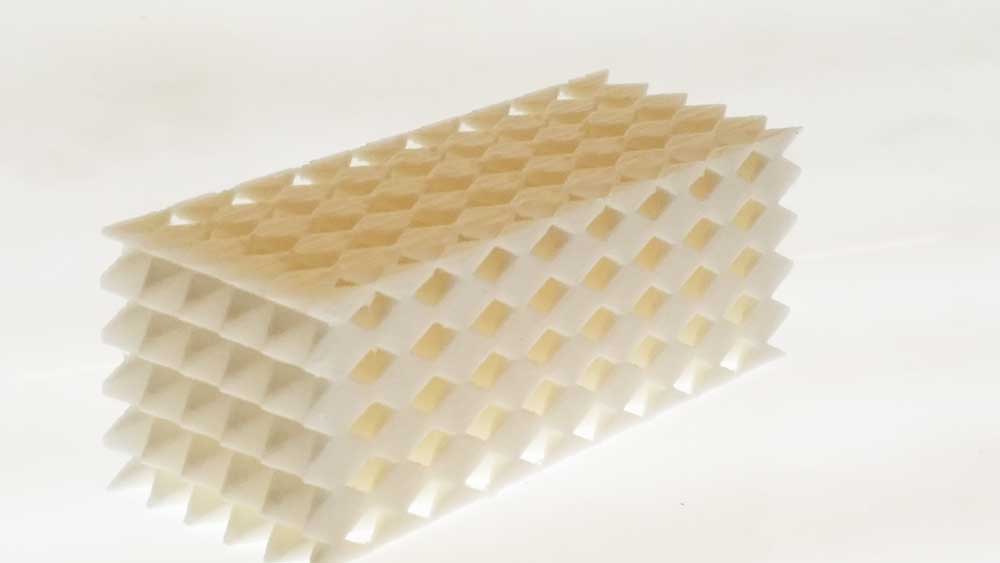

I wanted to take advantage of the 3D printing since If this model would have been made in a CNC it need to be rotate 6 time top/bottom wich has hangging part that are and 4 sides, this can only be made rotating too manny times and probably lose the orientation and failed. another solution is buy an 6axis CNC that cost at least 2 FabLabs (hahahaha)

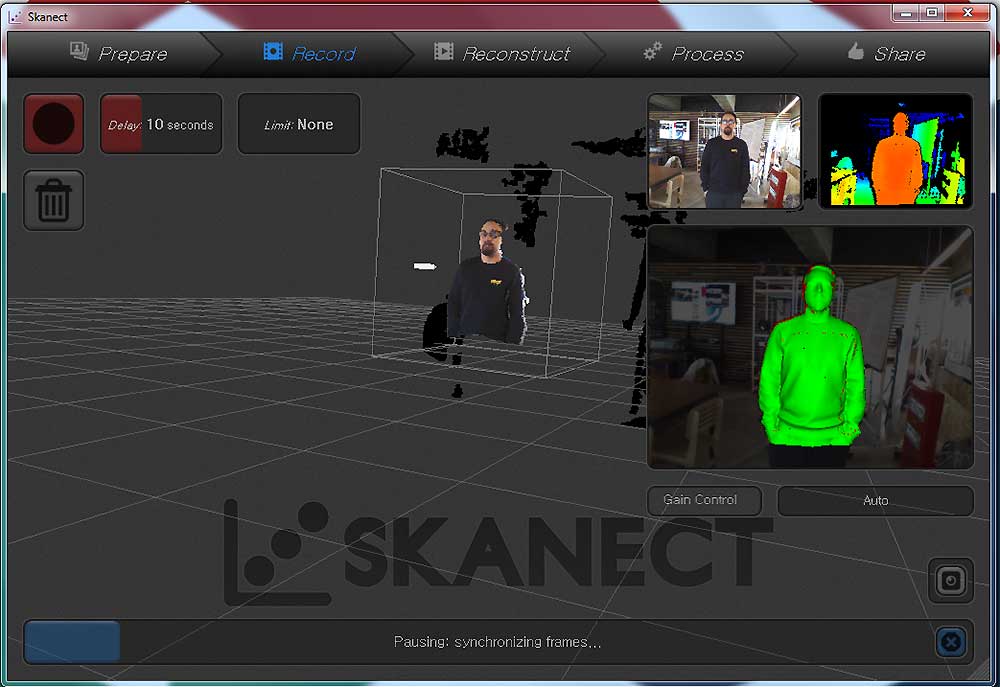

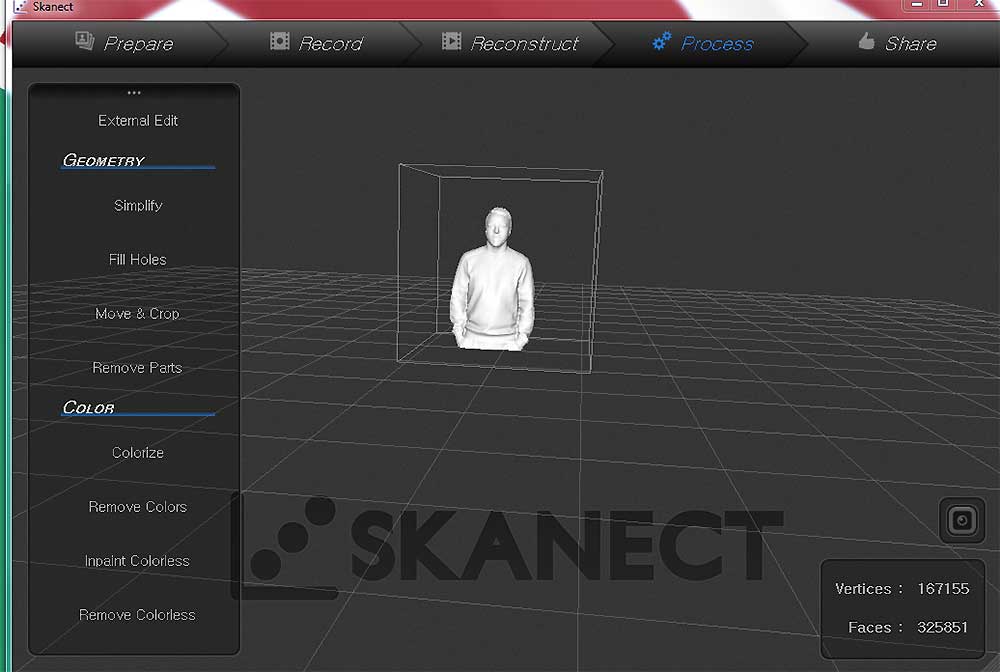

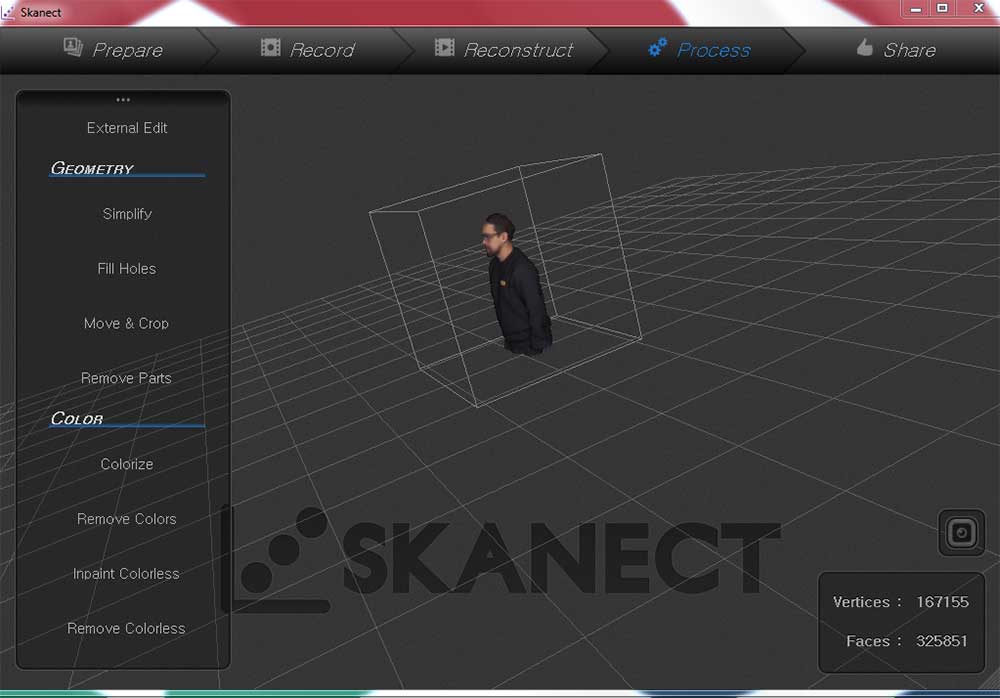

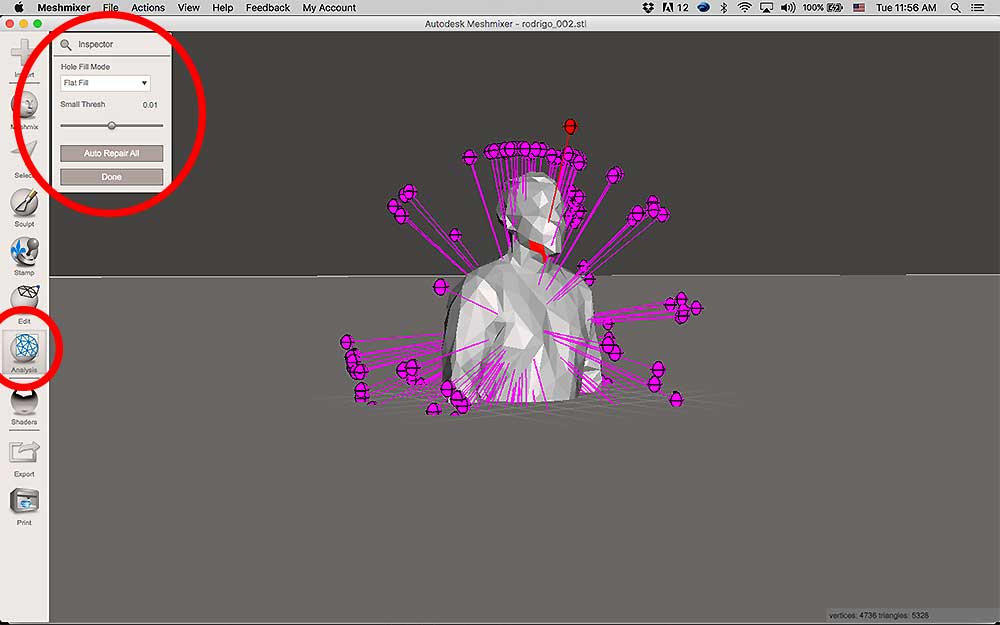

For the scanning assigment I used the KINECT that uses an RGB camera with depth sensor and infrared projector with a monochrome CMOS sensor which sees the environment not as a flat image, but as dots arranged in a 3D environment, the video below help me to understand more.

What I was not able to do this week:

What I did but need to get better at: