Assignment 9

mechanical design

This week assignment is a group work and our group is me, Yrjö and Jari. Task is that we need to design a machine (and its mechanics) which is made from standard cardboard parts and it need to do something. More about our group project is explained in our group project sites.

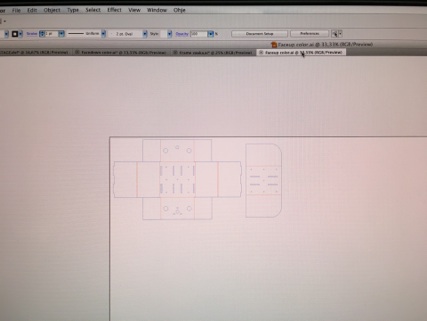

My task is to make cardboard bodies to our group project. I started by downloading ready DXF -files from Fabacademy sites. There were multiple problems with original cutting files from FabAcademy sites. Scale was totally wrong and our laser won´t cut it as a original file. Then I need to scale it to correct size because it was in inches so our design softwares scale it down to 1:25,4 from original size. I opened it on Illustrator and import window ask scaling so I change it 1 unit = 25,4 mm.

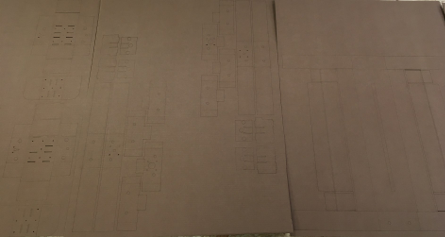

After scaling it opened to correct scale so I divided it three individual files (Frame, Faceup, Facedown) because all of them won´t fit to our laser table at once.

All files in one file and scaled to correct size

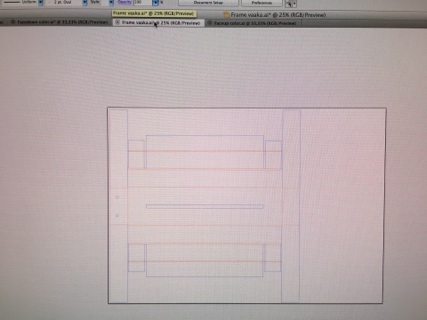

Frame on its own file and fitted to laser table

Facedown on its own file and fitted to laser table

Faceup on its own file and fitted to laser table

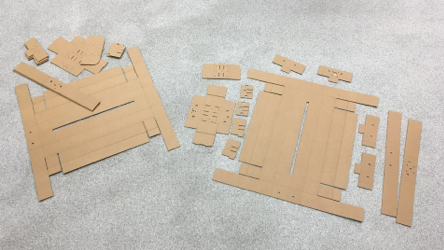

Cutting

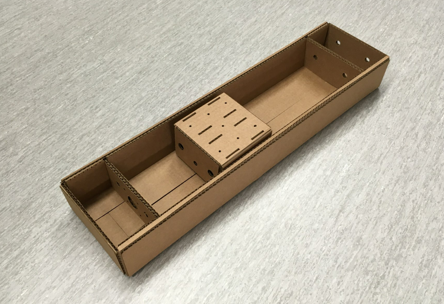

Cut boards

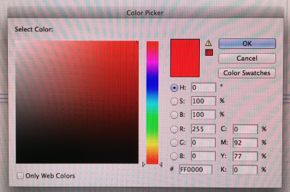

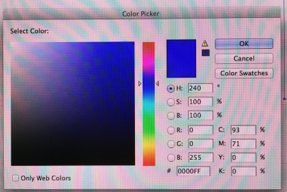

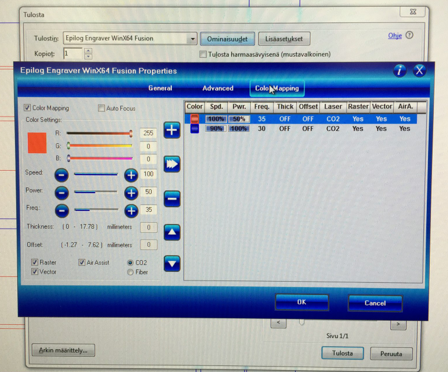

When files were ready I started cutting. I use cutting speed 90%, power 100% and frequency 35% for cutting through (blue lines) and speed 100%, power 50% and frequency 30% for ”scored” lines (red lines) as a cutting parameters (our lab Epilog 75W CO2).

Test assembly

Cut boards

Values for color mapping

Color mapping and used parameters

FILES:

FACEDOWN.ai, FACEUP.ai, FRAME.ai, Facedown.dxf, Faceup.dxf, Frame.dxf

I spend quite much time to figure out how to get cuttable (and working) files from original .dxf files. I also made this cutting file modification to our group to make cardboard bodies.