Final Project

DIY Digital Clock Lesson

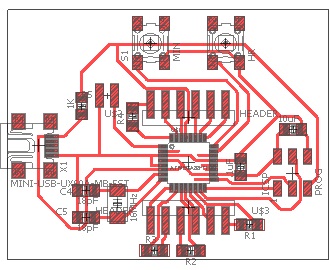

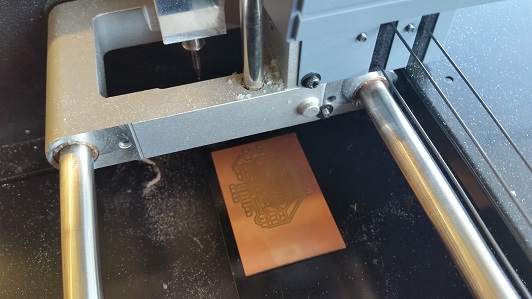

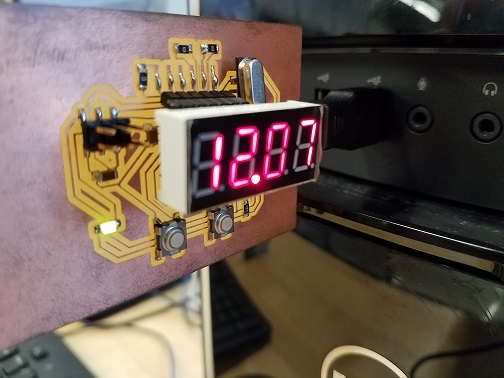

The idea is to adapt what I’ve been learning in Fab Academy to create a project that can be used as an advance high school lesson. This project is to design and program a copper-traced board that is cut from our milling machines. Once the circuit is done, a casing will then be designed and created from one of many fabrication processes we offer in our Fab Lab program.

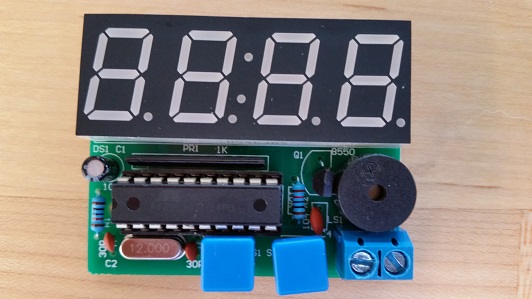

I started this project by designing a enclosure for the circuit. I looked around for a through-hole kit that was already designed to base my schematic off of for surface mounting.

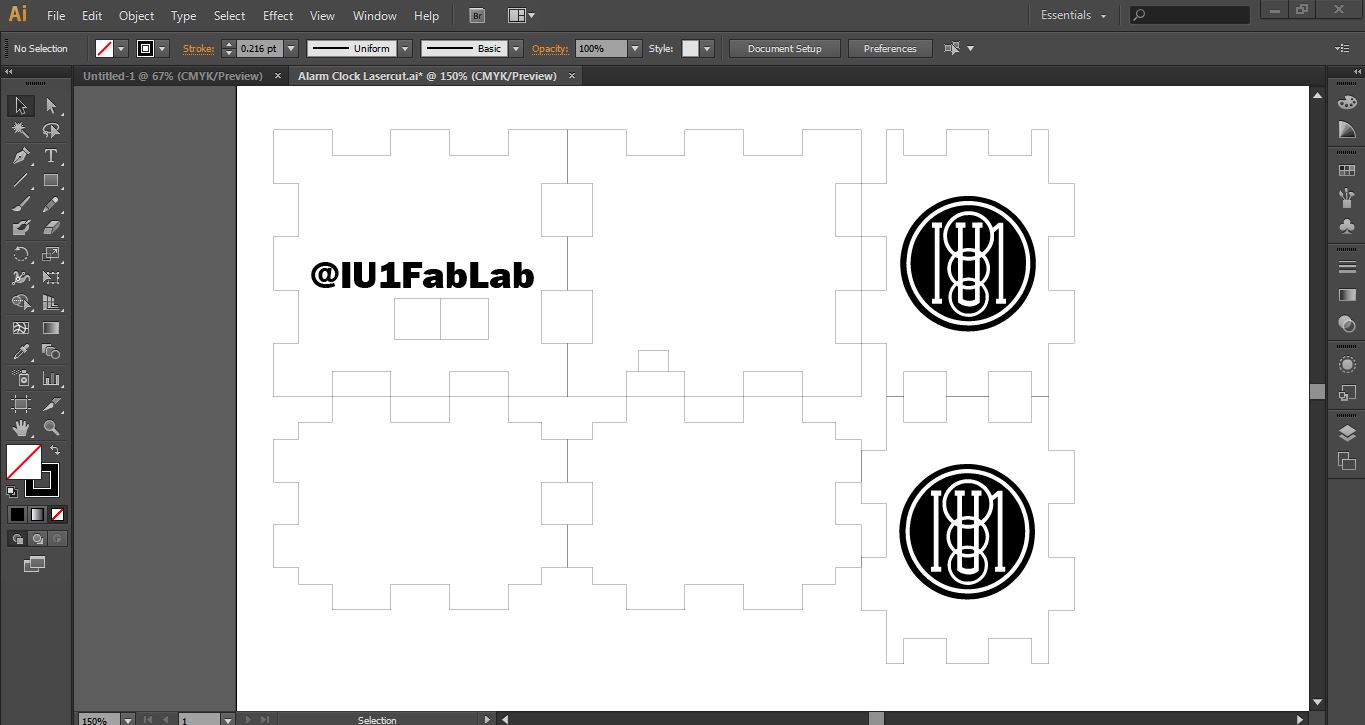

Designing a Casing Through Vectors (Adobe Illustrator)

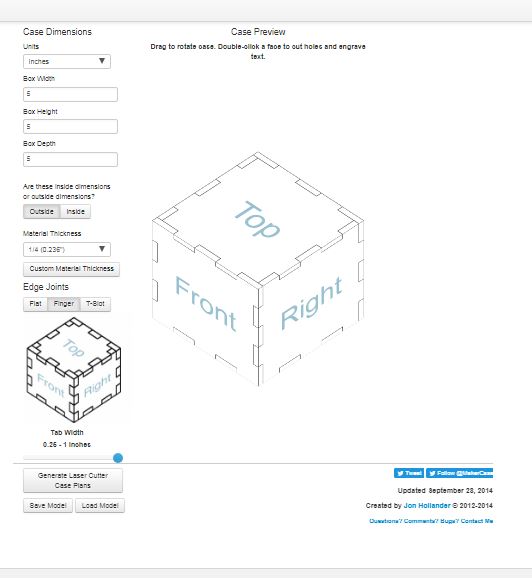

I started by utilizing www.makercase.com which is a simple sketch generator to design a basic box shape with a percise finger joint layout. I chose this program because of it all being parametric, and good for projects with joinery. Once I plugged in the few parameter questions, it generated a .SVG file which can then be pulled into other vectoring software. I decided to experiment with Adobe Illustrator by importing, designing, and manipulating the file that will somday be either lasercut or CNC milled.

Using Adobe Illustrator:

To make this kind of design, I knew I would need a software that is great with node editing features that is also better than Inkscape. I’ve personally only used CorelDRAW in my lab during my time here as manager so I wanted to see the difference in this software. Obviously, the 2 liscenses are more alike than different. The only major differences is the tool layouts and labels for those tool features.

Features Used:

Type Tool (With Features)

Various Line Segment Tools

Direct Select Tool (Node Editing)

Image Trace (Pixels into Vectors)

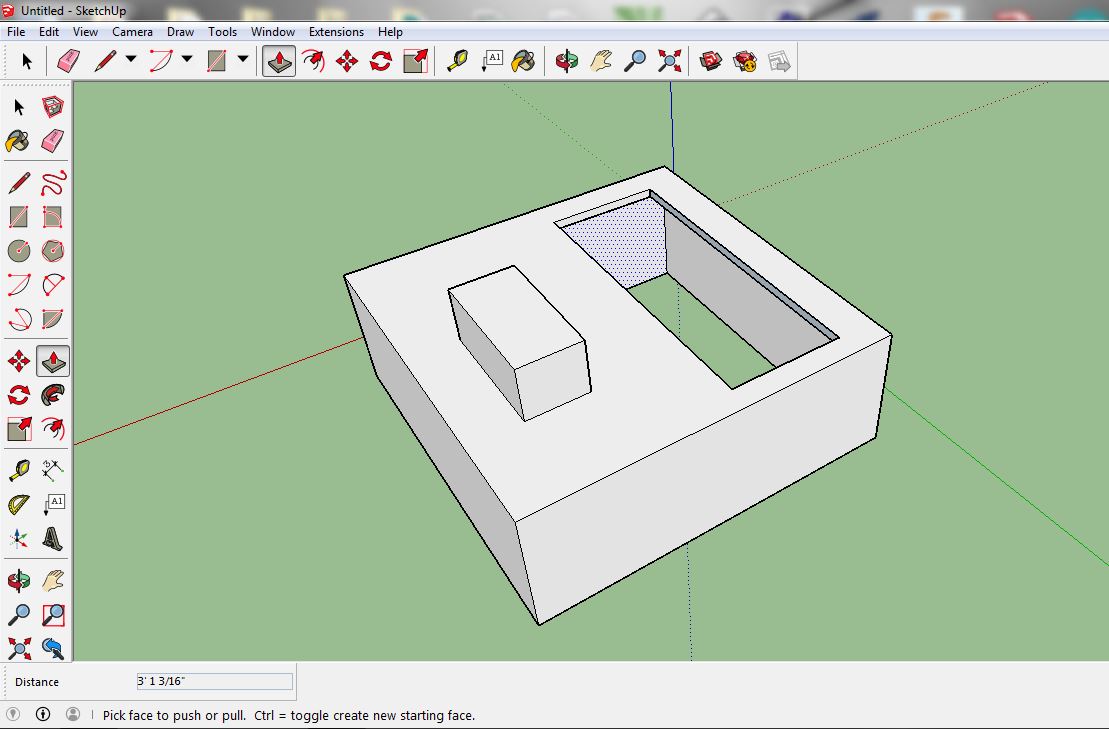

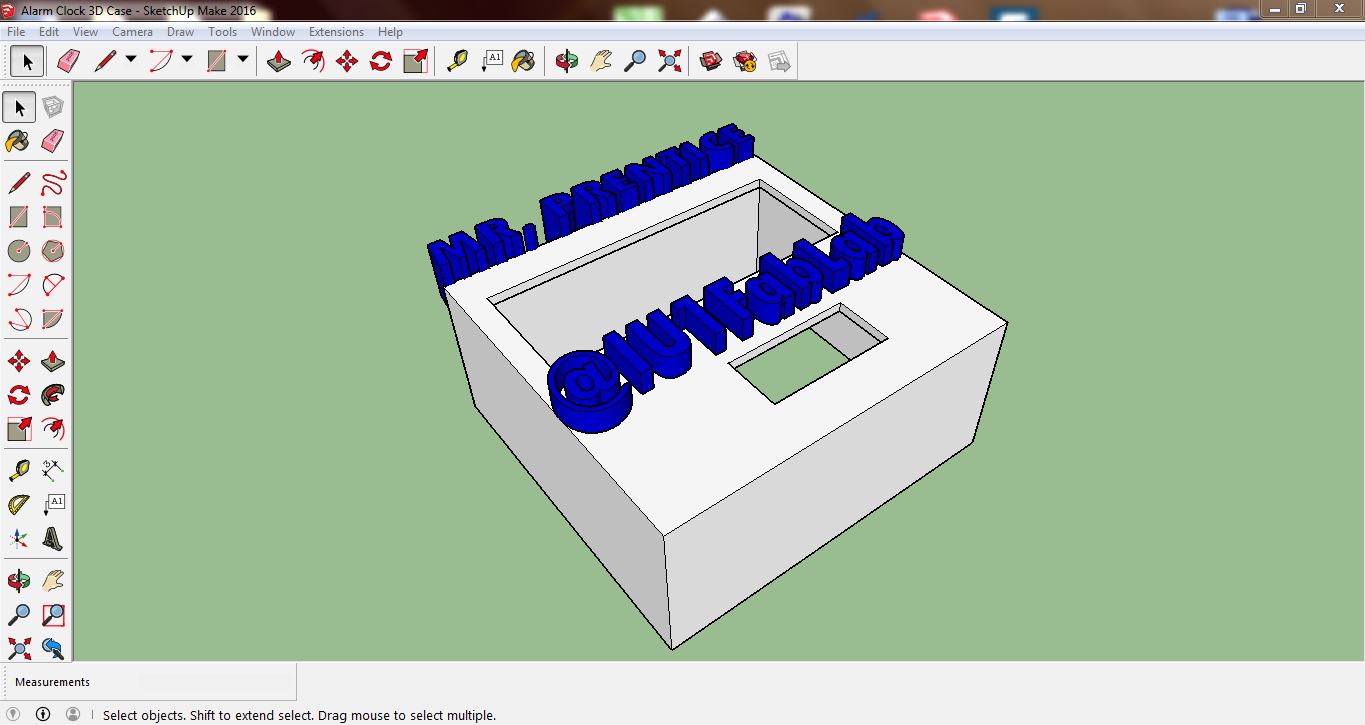

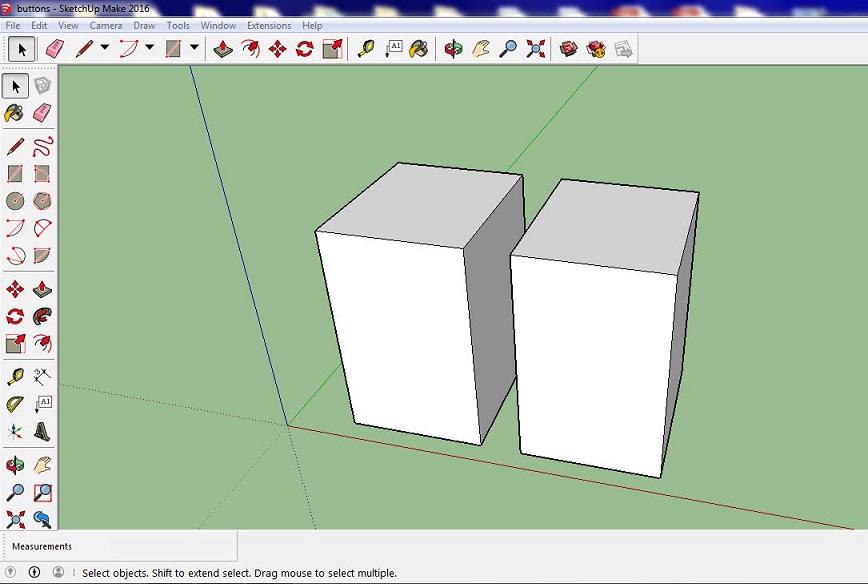

Designing a Casing Through 3D Modeling (Google SketchUp)

As a option for our students, I am considering 3D printing as a viable option to create their casing. Below is a version I made that took just around 1-2 hours to print, which is considerable time for me to instruct a small class from my mobile lab.

Using Google SketchUp:

To incorporate the 3D modeling aspect for my project, I thought of using SketchUp as my primary learning tool. I’ve taught in Elem/Middle school areas when it comes to this kind of 3D printing where it can be simple, fun, and very accessable to the students. Other software that I have used for this kind of application include Tinkercad & 123D Design. I always found those two programs very similar on how they manipulate shapes and wanted to go a slightly different way. SketchUp is free like the others so I found this appealing to adapt in these same sort of classes I teach, where even younger students can load this program on their own personal computer.

I started with a simple cube shape where I subtracted away all of the hollow areas that you see in the pictures below. Once I made my guesses on where to put the openings for the buttons & 7-segment display, I “pushed” the 2D shapes inward to subtrate the material away. My last step was to add the 3D text on top, extruding it in such a way that I can switch colors of filiment during prints to bring out more contrast.

Features Used:

Rectangle

3D Text

Push/Pull

Navagation Tools (Move, Rotate, Offset, Orbit, etc.)

Tape Measure Tool

Paint Bucket

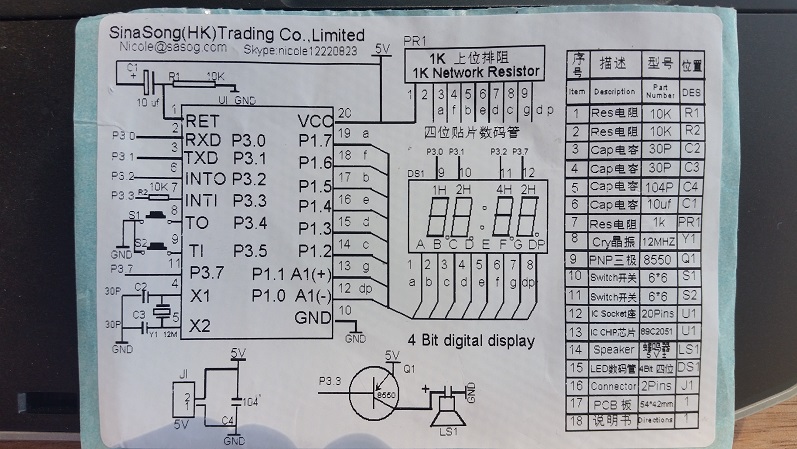

Making the 1st Schematic Attempt

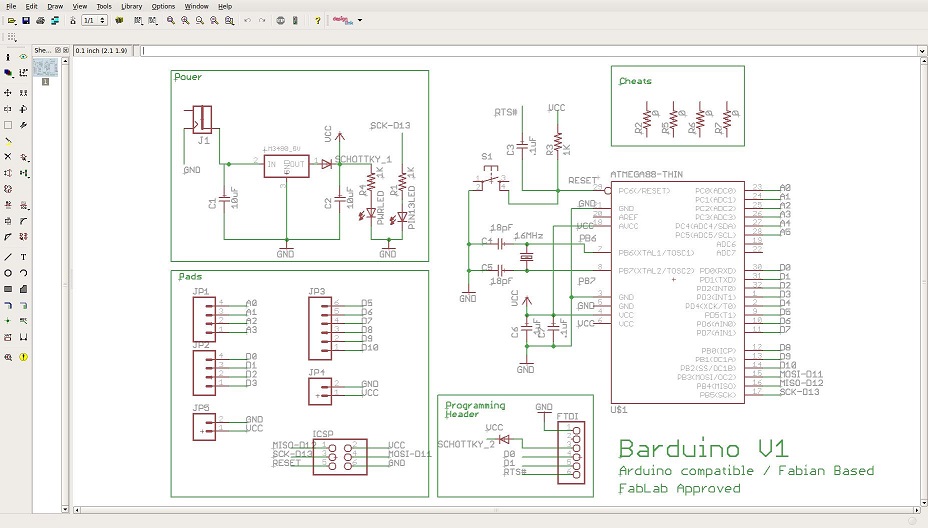

I starting this process by studying the schematic/parts list for the orginal circuit I bought from China. Once I understood all of the parts, I went to our class archives to pull the Barduino board design to start from.

Official Barduino Schematic:

From reviewing our Fab Lab inventory again with our SMDs in particular, I drafted a Google sheet organizing parts that our lab has already along with parts I need attached to specific vendors I found selling them cheap.

Both Original and Surface Mounted Materials Chart

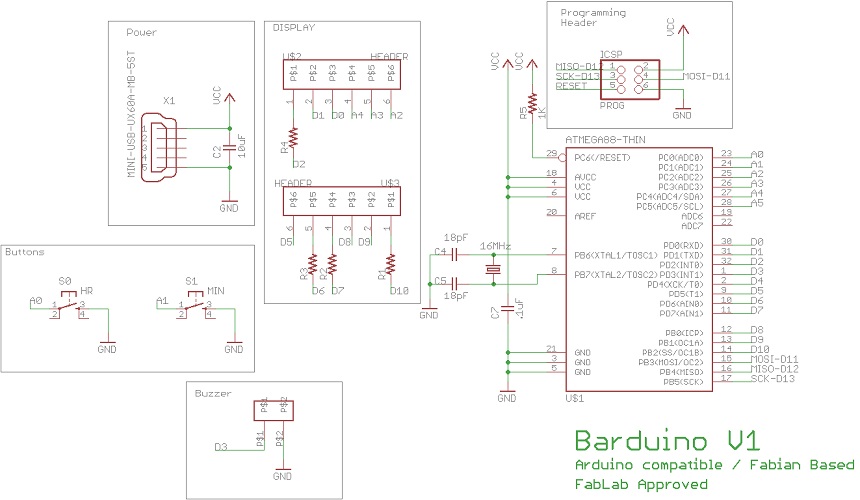

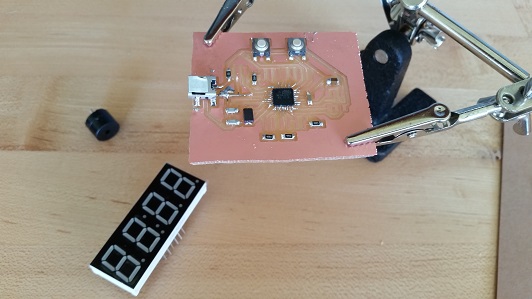

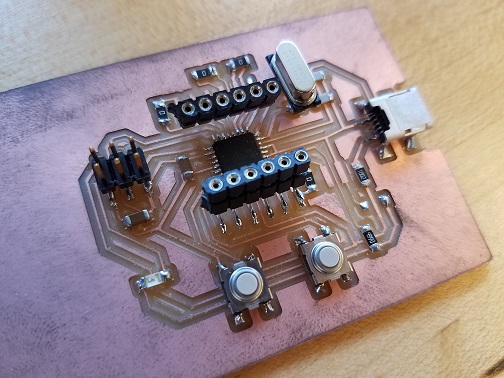

Using Eagle, I drafted the first schematic from the barduino by adding the buzzer, USB power supply, 7 segment display, and the buttons. Once completed, I traced everything appropriately, having the 7 segment display hovering over the entire board from extra legnth prongs that will still be soldered onto with surface mounts.

Reflecting on 1st Schematic Attempt

Improvements to consider:

- Eliminating the x4 (499ohm) resistors going into the display (doing this does not burn out LEDs)

- Slightly moving over the 6 pin programming header so display doesn’t have to be unplugged to upload program.

- Create a larger footprint for the (16mHz) crystal for easier soldering.

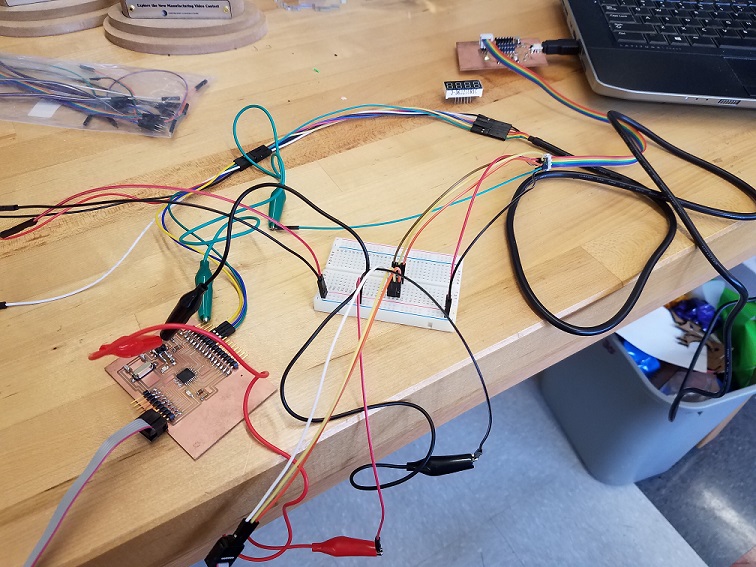

Connecting to the “Satshakit” (Arduino Uno Clone)

Using my Arduino Clone that I’ve re-traced in earlier assignments, I was now able to program with Arduino IDE to set up the code shown further below. The reason for all of the excess wires/breadboard usage was due to having no female plugs for the header pins.

After the connections were made, I preceded by first uploading the “TimerOne” library onto the IDE and then sending the file over with the command “Upload Using Programmer” under the Sketch tab.

Setting Up the Program:

The first task involved with writing the program was getting the display to work. I used the 7 segment display datasheetto determine the function of each pin. I wrote code to set the segment pins correctly to display a digit. The display is multiplexed so only one digit can actually be displayed at a time but uses the ATMega’s speed to display each digit sequentially many times a second. This speed tricks the eye into thinking that all of the digits are displayed simultaneously.

The next task was using the ATMega’s timer to accurately count in one second intervals. I used the TimerOne library to abstract away the technical details so I only had to write the time handling code that occurs every second. Since this clock uses 12 hour time, I also added an AM and PM LED which are set depending on the time of day.

I added button control code which treats the buttons as interrupts and debounces their switching. This results in quick button detection and smooth switching. I used the tone() function to send a little beep to the buzzer so the user knows when the button is pressed. This buzzer is also used to sound an hourly chime and play the alarm when it goes off.

The last task was adding the software control to mimic the original clock’s functionality. The left button cycles through setting the hour and minute, turning the hourly chime on or off, setting the hour and minute of the alarm, and turning that alarm on or off. When the clock is in normal operation, pressing the right button switches between HH:MM display and MM:SS for keeping accurate track of time.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296

297

298

299

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

333

334

335

336

337

338

339

340

341

342

343

344

345

346

347

348

349

350

351

352

353

354

355

356

357

358

359

360

361

362

363

364

365

366

367

368

369

370

371

372

373

374

375

376

377

378

379

380

381

382

383

384

385

386

387

388

389

390

391

392

393

394

395

396

397

398

399

400

401

402

403

404

405

406

407

408

409

410

411

412

413

414

415

416

417

418

419

420

421

422

423

424

425

426

427

428

429

430

431

432

433

434

435

436

437

438

439

440

441

442

443

444

445

446

447

448

449

450

451

452

453

454

455

456

457

458

459

460

461

462

463

464

465

466

467

468

469

470

471

472

473

474

475

476

477

478

479

480

481

482

483

484

485

486

487

488

489

490

491

492

493

494

495

496

497

498

499

500

501

502

503

504

505

506

507

508

509

510

511

512

513

514

515

516

517

518

519

520

521

522

523

524

525

526

527

528

529

530

531

532

533

534

535

536

537

538

539

540

541

542

543

544

545

546

547

548

549

550

551

552

553

554

555

556

557

558

559

560

561

562

563

564

565

566

567

568

569

570

571

572

573

574

575

576

577

578

579

#include <TimerOne.h>

// letter n for displaying "on"

#define N 16

// special parameters to handle decimal point

#define DP_ON 17

// this is a general parameter to turn any segment off

#define BLANK 18

// pinouts for common cathode 7 segment LED display:

// segment is active high

// segment | display | header | mcu

// A 11 D9 PB1

// B 7 D5 PD5

// C 4 D0 PD0

// D 2 A3 PC3

// E 1 A2 PC2

// F 10 D8 PB0

// G 5 D1 PD1

// DP 3 A4 PC4

// digit is active low

// digit | display | header | mcu

// 1 12 D10 PB2

// 2 9 D7 PD7

// 3 8 D6 PD6

// 4 6 D2 PD2

// settings state

// these values make the code easier

#define DISPLAY 9

#define SET_HR 0xA

#define SET_MIN 0xB

#define SET_CHIME 0xC

#define SET_ALARM 0xD

#define SET_ALARM_HR 0xE

#define SET_ALARM_MIN 0xF

void ledSetup(void);

void ledAm(void);

void ledPm(void);

void buttonsSetup(void);

void buttonsS1(void);

void buttonsS2(void);

void nextSettingState(void);

void increaseSecond(void);

void increaseHour(void);

void displaySetup(void);

void displayDigits(int dig1, int dig2, int dp, int dig3, int dig4);

void setDigit(int digit, int number);

void setSegment(int number);

// displaying time

int sec = 0;

int min_1 = 0;

int min_10 = 0;

int hr = 12;

// decimal point

int dp = 0;

// switch between HH:MM and MM:SS

int hr_display = 1;

// differentiate between AM and PM

// 0 = AM // 1 = PM

int time_of_day = 1;

// default to display mode

int settings_mode = DISPLAY;

// hourly chime on or off

int hr_chime_enabled = 1;

// alarm on or off

int alarm_enabled = 1;

// alarm time

int alarm_hr = 12;

int alarm_min = 0;

// capture only 1 button press (kinda like debouncing)

int buttonBlockA0 = 0;

int buttonBlockA1 = 0;

void setup() {

// set display pins to outputs

displaySetup();

// set LED pin to output

ledSetup();

// set button pins to interrupt-enabled inputs

buttonsSetup();

// setup timer for 1 second tick

Timer1.initialize(1000000);

Timer1.attachInterrupt(increaseSecond);

}

void loop() {

// displayDigits in loop so they keep updating

// default display mode

if (settings_mode == DISPLAY)

{

// HH:MM

if(hr_display)

{

displayDigits(hr/10, hr%10, dp, min_10, min_1);

}

// MM:SS

else

{

displayDigits(min_10, min_1, dp, sec/10, sec%10);

}

}

else if (settings_mode == SET_HR)

{

displayDigits(SET_HR, BLANK, BLANK, hr/10, hr%10);

}

else if (settings_mode == SET_MIN)

{

displayDigits(SET_MIN, BLANK, BLANK, min_10, min_1);

}

else if (settings_mode == SET_CHIME)

{

// on

if (hr_chime_enabled)

{

displayDigits(SET_CHIME, BLANK, BLANK, 0, N);

}

// off

else

{

displayDigits(SET_CHIME, 0, BLANK, 0xF, 0xF);

}

}

else if (settings_mode == SET_ALARM)

{

// on

if (alarm_enabled)

{

displayDigits(SET_ALARM, BLANK, BLANK, 0, N);

}

// off

else

{

displayDigits(SET_ALARM, 0, BLANK, 0xF, 0xF);

}

}

else if (settings_mode == SET_ALARM_HR)

{

displayDigits(SET_ALARM_HR, BLANK, BLANK, alarm_hr/10, alarm_hr%10);

}

else if (settings_mode == SET_ALARM_MIN)

{

displayDigits(SET_ALARM_MIN, BLANK, BLANK, alarm_min/10, alarm_min%10);

}

}

// correctly move through settings states

void nextSettingState(void)

{

// if you've turned alarm off, dont't set it, go back to display

if ((settings_mode == SET_ALARM) & (alarm_enabled == 0))

{

settings_mode = DISPLAY;

}

// last setting, go back to display

else if (settings_mode == SET_ALARM_MIN)

{

settings_mode = DISPLAY;

}

// else just go to next state

else{

settings_mode++;

}

// stop counting time when you're trying to set it

if (settings_mode == SET_HR)

{

// disable timer counter

Timer1.stop();

// also reset seconds for good measure

sec = 0;

}

// start counting after you've set the time

else if (settings_mode == SET_CHIME)

{

// restart timer counter

Timer1.restart();

}

}

// increase hour by 1 and handle AM/PM

void increaseHour(void)

{

// play chime on the hour if enabled

if (hr_chime_enabled)

{

// send 133 frequency tone for 70 ms to pin 3

tone(3, 133, 70);

}

if (++hr==13)

{

hr=1;

// flip between AM and PM

time_of_day ^= 1;

// change LED to match

if (time_of_day)

{

ledPm();

}

else{

ledAm();

}

}

}

// AM/PM LED is on D4 PD4

void ledSetup(void)

{

DDRD |= (1<<DDD4);

}

// low is AM

void ledAm(void)

{

PORTD |= (1<<PORTD4);

}

// high is PM

void ledPm(void)

{

PORTD &= ~(1<<PORTD4);

}

// Hack to get pin change interrupts on analog pins

// http://www.geertlangereis.nl/Electronics/Pin_Change_Interrupts/PinChange_en.html

void buttonsSetup()

{

// set button pins as inputs with internal pull-ups enabled

pinMode(A0, INPUT);

digitalWrite(A0, HIGH);

pinMode(A1, INPUT);

digitalWrite(A1, HIGH);

// switch interrupts off while messing with their settings

cli();

// Enable PCINT1 interrupt

PCICR =0x02;

PCMSK1 = 0b00000111;

// turn interrupts back on

sei();

}

// Interrupt service routine for every analog pin change

// A0, A1, A2, A3, A4, A5

ISR(PCINT1_vect) {

// press A0

if (digitalRead(A0)==0 && buttonBlockA0==0)

{

// set to 10

buttonBlockA0 = 10;

// send 133 frequency tone for 70 ms to pin 3

tone(3, 133, 70);

buttonS1();

}

// release A0

if (digitalRead(A0)==1)

{

// count down after releasing

if (buttonBlockA0 > 0)

{

buttonBlockA0--;

}

}

// press A1

if (digitalRead(A1)==0 && buttonBlockA1==0)

{

// set to 10

buttonBlockA1 = 10;

// send 133 frequency tone for 70 ms to pin 3

tone(3, 133, 70);

buttonS2();

}

// release A1

if (digitalRead(A1)==1)

{

// count down after releasing

if (buttonBlockA1 > 0)

{

buttonBlockA1--;

}

}

}

void buttonS1()

{

// go to next settings state

nextSettingState();

}

void buttonS2()

{

// need to be in display mode to change

if (settings_mode == DISPLAY)

{

// switch between HH:MM and MM:SS

hr_display ^= 1;

}

// else in some settings mode...

else if (settings_mode == SET_HR)

{

increaseHour();

}

else if (settings_mode == SET_MIN)

{

if (++min_1==10)

{

min_1=0;

if (++min_10==6)

{

min_10=0;

}

}

}

else if (settings_mode == SET_CHIME)

{

// switch between hourly chime enabled and disabled

hr_chime_enabled ^= 1;

}

else if (settings_mode == SET_ALARM)

{

// switch between alarm enabled and disabled

alarm_enabled ^= 1;

}

else if (settings_mode == SET_ALARM_HR)

{

if (++alarm_hr==13)

{

alarm_hr=1;

}

}

else if (settings_mode == SET_ALARM_MIN)

{

if (++alarm_min==60)

{

alarm_min=1;

}

}

}

// action to be done every 1 sec

void increaseSecond()

{

//keep track of time

// using 2 instead of 60 to make it faster

if (++sec==60)

{

sec=0;

// minutes

if (++min_1==10)

{

min_1=0;

if (++min_10==6)

{

min_10=0;

increaseHour();

}

}

}

// flip decimal point every second

dp ^= 1;

}

// set display pins to outputs

void displaySetup()

{

DDRB |= (1<<DDB1 | 1<<DDB0 | 1<<DDB2); // A F 1

DDRC |= (1<<DDC3 | 1<<DDC2 | 1<<DDC4); // D E DP

DDRD |= (1<<DDD5 | 1<<DDD0 | 1<<DDD1 | 1<<DDD7 | 1<<DDD6 | 1<<DDD2); // B C G 2 3 4

}

// cycle through and display each digit

// dp is for decimal point: 0 for off; 1 for on

// TODO: make dp a bool?

// TODO: put dp last so it doesn't affect dig2's brightness?

void displayDigits(int dig1, int dig2, int dp, int dig3, int dig4)

{

setDigit(1, dig1);

setDigit(2, dig2);

setDigit(3, dig3);

setDigit(4, dig4);

if (dp)

{

// display decimal point (special parameter)

setDigit(2, DP_ON);

}

else

{

// dont't display decimal point (special parameter)

setDigit(2, BLANK);

}

}

// display a number on the selected digit 1, 2, 3, or 4

// TODO: add range checks

void setDigit(int digit, int number)

{

// turn all digits off

PORTB |= (1<<PORTB2); // 1

PORTD |= (1<<PORTD7 | 1<<PORTD6 | 1<<PORTD2); // 2 3 4

// set up segments while digits off,

// so that the full digit comes up simultanously

// (although who is going to be able to detect a couple clk cycles?)

setSegment(number);

// then turn on specfic digit

switch(digit)

{

case 1:

// TODO: ONLY when display hours,

// don't display leading 0

//if (number != 0)

//{

PORTB &= ~(1<<PORTB2); // 1

//}

break;

// this case also handles decimal point

case 2:

PORTD &= ~(1<<PORTD7); // 2

break;

case 3:

PORTD &= ~(1<<PORTD6); // 3

break;

case 4:

PORTD &= ~(1<<PORTD2); // 4

break;

//default:

// bad - should't be here

}

}

// display a number or symbol using the 7 segments

// number can be between 0-9 or settings screen uses A-F

// TODO: add range checks

void setSegment(int number)

{

// first, reset all segments

PORTB &= ~(1<<PORTB1 | 1<<PORTB0); // A F

PORTC &= ~(1<<PORTC4 | 1<<PORTC3 | 1<<PORTC2); // DP D E

PORTD &= ~(1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

// then set the coorespoding segments

switch(number)

{

case 0:

// A B C D E F

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD5 | 1<<PORTD0); // B C

break;

case 1:

// B C

PORTD |= (1<<PORTD5 | 1<<PORTD0); // B C

break;

case 2:

// A B D E G

PORTB |= (1<<PORTB1); // A

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD5 | 1<<PORTD1); // B G

break;

case 3:

// A B C D G

PORTB |= (1<<PORTB1); // A

PORTC |= (1<<PORTC3); // D E

PORTD |= (1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

break;

case 4:

// B C F G

PORTB |= (1<<PORTB0); // F

PORTD |= (1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

break;

case 5:

// A C D F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3); // D

PORTD |= (1<<PORTD0 | 1<<PORTD1); // C G

break;

case 6:

// A C D E F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD0 | 1<<PORTD1); // C G

break;

case 7:

// A B C

PORTB |= (1<<PORTB1); // A

PORTD |= (1<<PORTD5 | 1<<PORTD0); // B C

break;

case 8:

// A B C D E F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

break;

case 9:

// A B C D F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3); // D

PORTD |= (1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

break;

// TODO: maybe use typedefs here instead?

case 0xA:

// A B C E F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC2); // E

PORTD |= (1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

break;

case 0xB:

// A B C D E F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD5 | 1<<PORTD0 | 1<<PORTD1); // B C G

break;

case 0xC:

// A D E F

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

break;

case 0xD:

// A B C D E F

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD5 | 1<<PORTD0); // B C

break;

case 0xE:

// A D E F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC3 | 1<<PORTC2); // D E

PORTD |= (1<<PORTD1); // G

break;

case 0xF:

// A E F G

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC2); // E

PORTD |= (1<<PORTD1); // G

break;

case N:

// A B C E F

PORTB |= (1<<PORTB1 | 1<<PORTB0); // A F

PORTC |= (1<<PORTC2); // E

PORTD |= (1<<PORTD5 | 1<<PORTD0); // B C

break;

case DP_ON:

// DP

PORTC |= (1<<PORTC4);

break;

//default:

// case BLANK falls through here

// just turns off the segment by initial "reset all segments" code

}

}

Operations:

Press left button to go into setup menus and then using

both buttons to change the folowing inputs:

A: Set Time Hours

B: Set Time Minutes

C: Set Hourly Chime (On/Off)

D: Activate Alarm (On/Off)

E: Set Alarm Hours

F: Set Alarm Minutes

Press right button to switch from displaying

Hours/Mins to Mins/Secs

Added Features

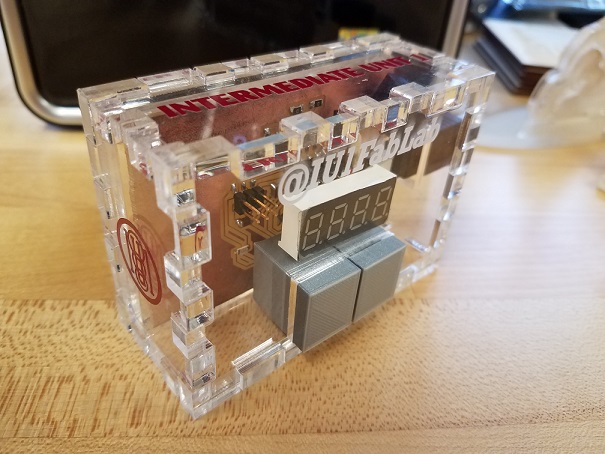

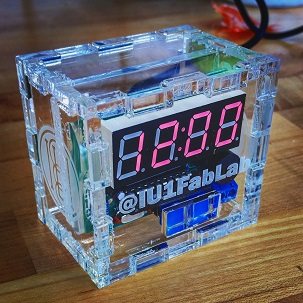

3D Printed Buttons:

The reason for this design being an afterthought was relizing that the copper PCB’s button controls are more difficult to use inside of the casing compared to the throughhole circuit. I elevated simple rectangle shapes to the specific size so they could fit snug inside the lasercut slot while gluing them to the SMD buttons.

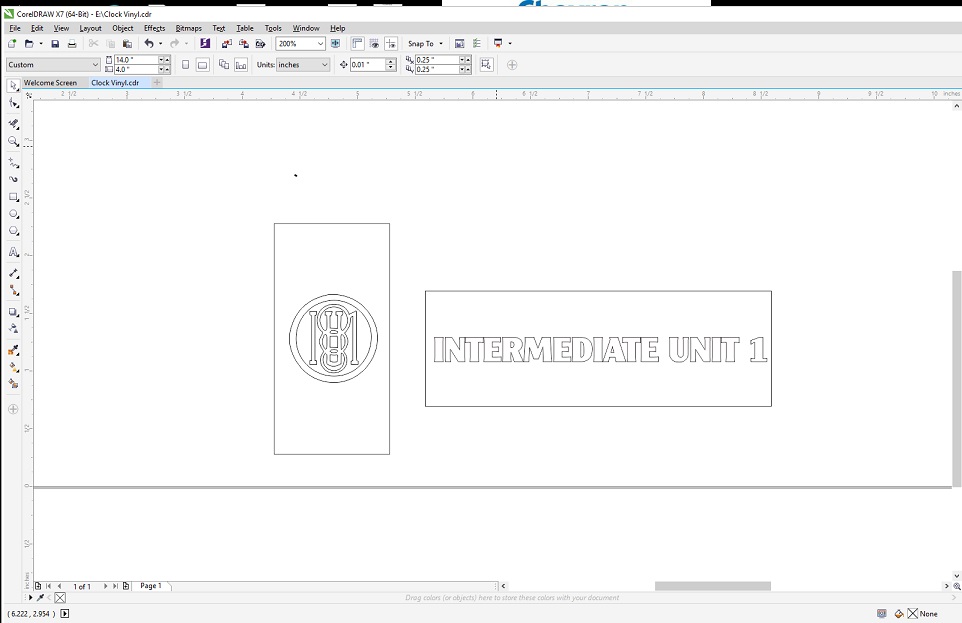

Vinyl Cut Labels

Adding the vinyl cutter was also a last minute decision to incorporate more processes into my design while getting it to stand out a little more. I used CorelDRAW to utilize its TEXT tool and manipulate it to have a hairline stroke with no fill, to then cut from vinyl material (Pen Force = 120 Gram-Force).

Finished Products:

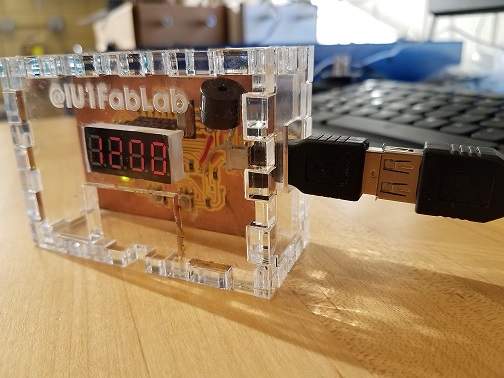

Original Through-Hole Design

Converted to Copper Milled Design + Added Features (3D Printed Buttons/Vinyl Labels)