Week #3: Computer-controlled cutting

The tasks for the third week were:

- Design, make and cut a parametric press-fit construction kit

- Cut something on the vinylcutter

Our

week began with a little incident: a colleague chose some wrong options

while using Git Bash and all our websites returned to their older

versions. To me, this was not a big deal, since I always keep an up to

date local copy of all my website files (thanks for the tip, Kenzo!).

Something curious, though. During the pull, I got this message:

But, after that, everything seemed ok.

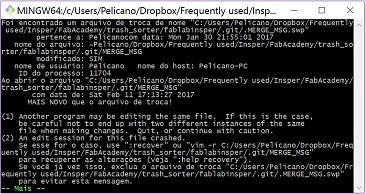

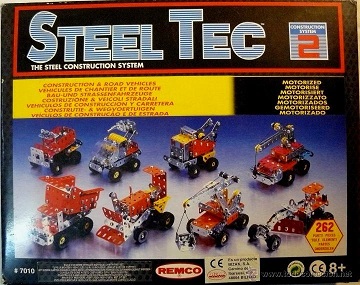

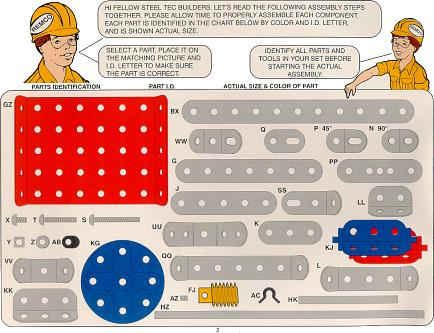

As for our task, after some thinking, I recalled an educational toy I used to play with when I was a kid: Steel Tec.

As our instructor Kenzo pointed out, there's a very similar toy called Meccano:

The

one I had, Steel Tec, was comprised of different sizes of plates

with holes, such that you could attach each other with nuts and bolts

and make different vehicles, like the bulldozer shown above. It also

came with some tools and an instruction manual:

My idea for this week's task was to mimic this toy with cardboard, using some kind of press-fit nut and bolt system.

Before

doing that, I had to learn how to produce a file that is compatible

with the laser cutter software. At Insper Fablab, our laser cutter

is an Epilog Laser Mini, which I already knew how to use; but, it broke down

just as our classes starded. So, after some phone calls (thanks again,

Kenzo!), some kind people from FabLab Educação lent us their laser

cutter, an ECNC L-560, as shown below.

This model of laser cutter uses UD5 files as source, and these files are generated by a

software called LaserCAD, which in turn is fed by .DXF files. I am used

to working with Inkscape, which is able to generate these files, but is

not able to do parametric modelling. So, I chose Creo Parametric for

the task.

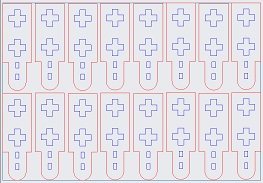

When it was our turn to use the laser cutter, we

started by the group work part of our assignment, which was

to create different types of press-fit joints in order to

understand how the machine works, e.g., how it deals with fractions of

milimiters and how wide is its kerf.

We used two softwares for

this task: Fusion360 and Creo Parametric 4.0. With the first one, we

designed pieces with small differences: chamfer, fillet etc. This is what we got:

By

doing that, we learned how to take the kerf into account and we also

learned that some cuts can greatly improve the assembly of the pieces

together.

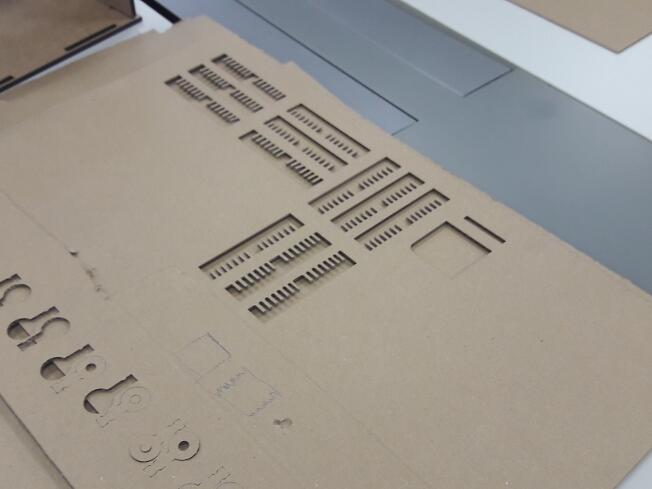

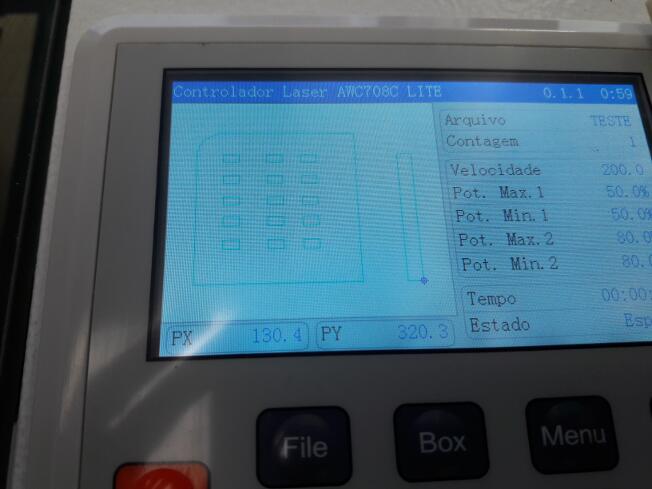

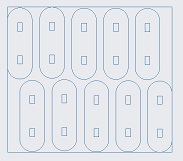

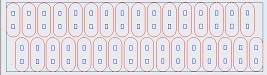

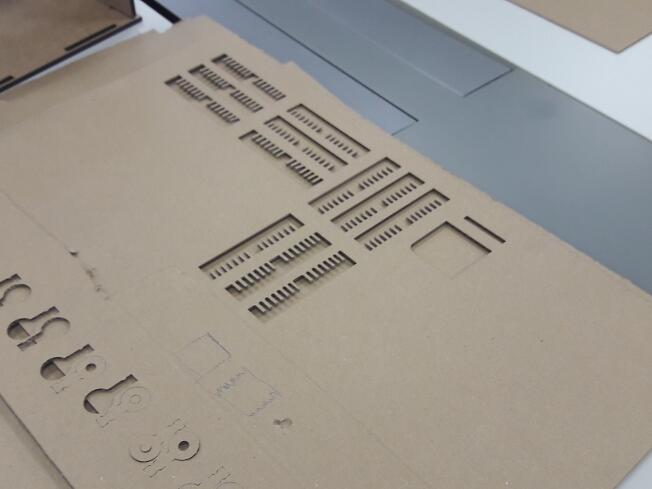

Then, with the help of Creo Parametric 4.0, we cut

rectangular holes with small differences in height and width (file here; password abc123). We drew

15 holes in 3 columns and 5 rows, as can be seen on the machine display:

In

the first row, all the rectangles have a height of 2.6 mm; in the

second, 2.7 mm, and so on, meaning that, in the last row, all the heights are of 3.0 mm. In the first column, the width is 4.9 mm; in the second, 5.0 mm and, in the third, 5.1 mm.

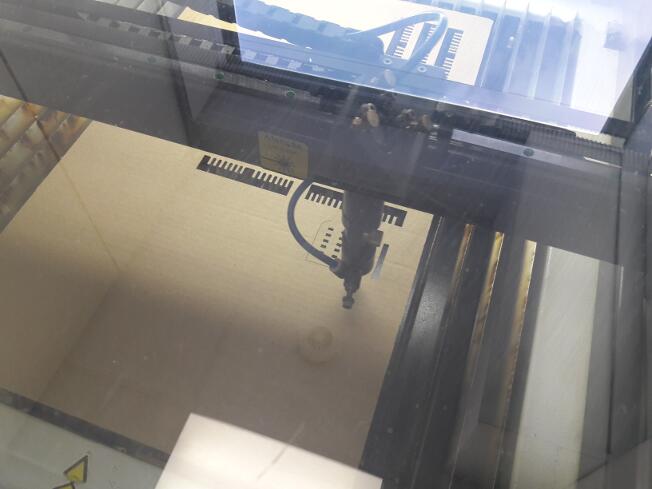

This is the cutting itself:

The

reason why we did this second test was to answer a simple question: if

the male piece is x mm wide, should the female piece also be x mm wide?

The answer we got was: no!

When we tried to fit together two 5

mm wide parts, the assembly was quite loose. On the other hand, when

trying to fit a 5 mm wide part into a 4.8 mm wide part, the fit was

perfect. That was an important lesson: don't forget to take 0.2 mm out

of every female part.

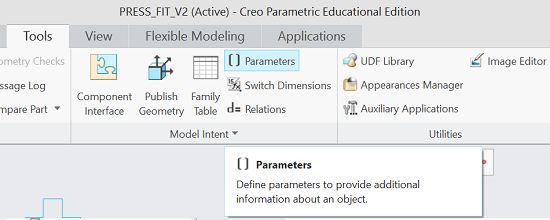

After the tests, I proceeded to the

individual part of the assignment. Since the carboard thickness could

vary, I had to design the parts parametrically, which is quite

straightforward to do in Creo Parametric 4.0. To do that, we first create the parameters by clicking on Tools -> Parameters.

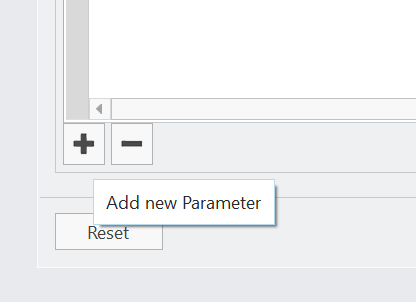

Then, click on "Add new Parameter":

After that, we have to give the new parameter a name and a value:

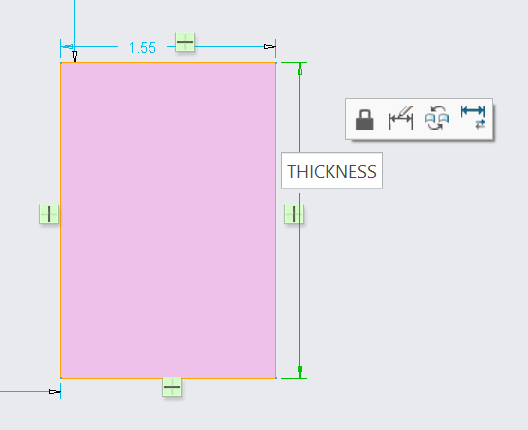

Then,

we proceed to the design. For example, if you want do draw a rectangle

with, say, height THICKNESS, first you draw the rectangle without

specifying them. After that, you double-click each dimension and

replace the value by the desired formula:

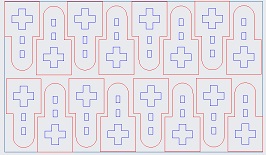

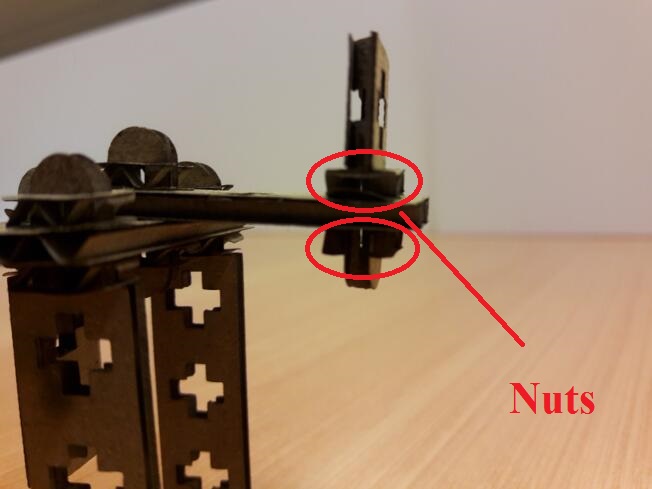

At first, I designed two

types (first two figures below) of bolts and the nuts (the last figure

below). The first bolt can hold together 2 layers of cardboard; while

the second one can hold 3 layers.

As

soon as I finished designing those bolts, I realized the cutting could

go terribly wrong: what if the contour of the bolt is cut before the

hole? If this were to happen, maybe the bolt would detach from the

board and the holes wouldn't be cut (and the laser would be activated

for nothing during those cuts).

So, after talking to Kenzo, I

confirmed that the laser cutter could be instructed to cut lines of

specific colors in a certain order. Then, I went back to my designs and

chose the color blue for the first batch of cuts and the color red for the second batch, as can be seen below. I designed 9 kinds of pieces (not counting the nuts), which can be seen below.

As

expected with computers, things did not work out quite right from the

beginning. The first problem was that the .DXF file generated by Creo

Parametric was not compatible with LaserCAD, freezing the program

instantly.

So, I tried opening this .DXF file with Inkscape and

saving as another .DXF file. This time, LaserCAD was ok with the file,

but there was some misconfiguration regarding the units and the drawing

was interpreted by LaserCAD as really, really small. Then, I tried

tweaking the configurations, but to no avail. I just could not seem to

get LaserCAD to interpret the dimensions correctly.

After some

thinking, I tried saving the drawing in Creo Parametric as a .PDF file.

Then, when I opened it with Inkscape and saved it as a .DXF file,

everything worked out just fine.

This

step also helped with something else: when you copy multiple instances

of a parametrized object in Creo Parametric, the software gets

exponentially slower. So, if I open one instance of the object in

Inkscape, I can copy it as .PDF, which is much faster.

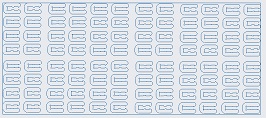

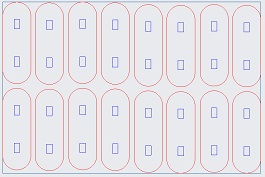

Then, I proceeded to the cutting. The pieces are show below (files here, password abc123).

As

can be seen, some pieces were burned. That happened because the machine

was being shared and, in between files, someone changed the laser

power. But, that's ok, as I still got lots of pieces to play. This is

an example of assembly, just to see if the pieces did, in fact, fit

together:

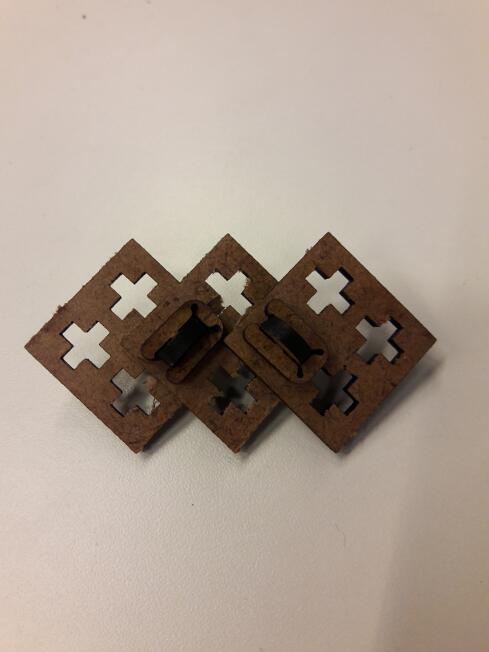

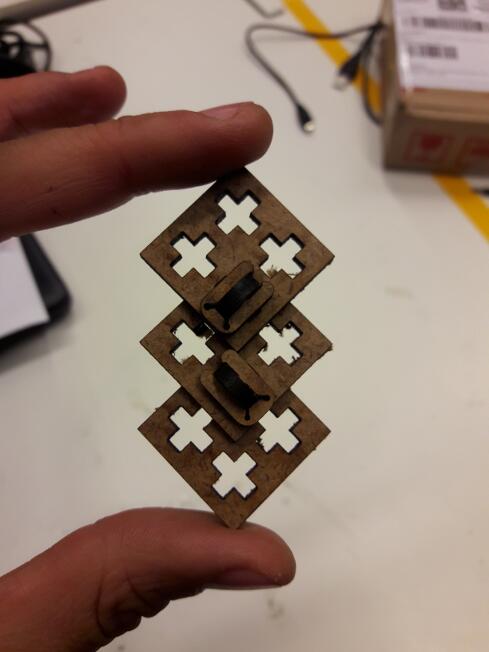

Here you can see another example, using the pieces properly:

As

expected, my toy did not work quite so well. I forgot to take into

account that de corrugated cardboard is not solid and, because of that,

the pieces were extremely weak. So, after the first assembly, the

pieces weren't of much use for a second assembly.

I was

going to try again with wood, but our laser cutter was not working at the moment, so

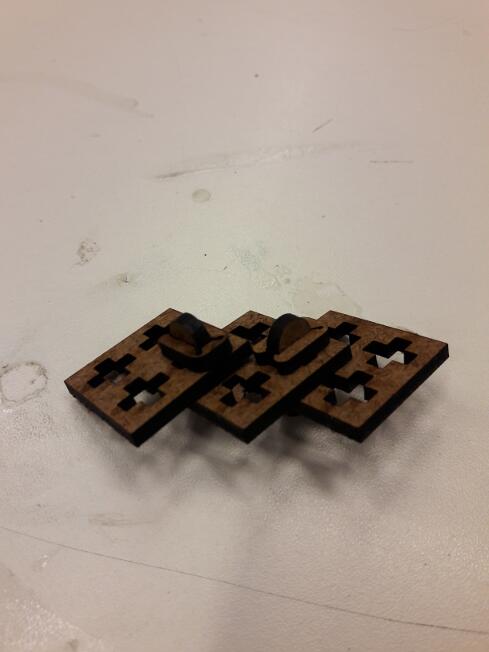

this idea had to be put on hold for a while. After the machine was fixed, I tried againd and the results were much, much better:

As

for the vinyl cutter, our instructor Kenzo showed us how to operate the

machine, which can be seen on the three images below, and then asked us

to cut a sticker.

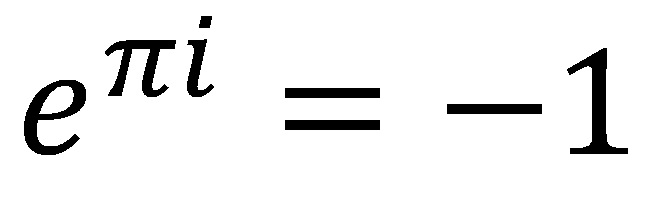

Since

I wasn't feeling particularly creative at the moment (all the

creativity was spent on the press-fit project), I decided to cut an

equation, instead of a figure. The equation I chose is a direct

application of Euler's formula (for complex numbers) and is considered

one of the most beautiful in Mathematics, since it shows two popular

irrational constants, the imaginary unit, the equal sign, the minus

sign and the number 1:

To design it, I simply typed it on Word Equation Editor, chose a really big (100) font size and exported the file as a PDF:

Then,

to generate the .EPS file which can be interpreted by the vinyl cutter,

I imported the file into Gimp and exported it as a .EPS.

You acand find both the .PDF and the .EPS files here (password abc123).

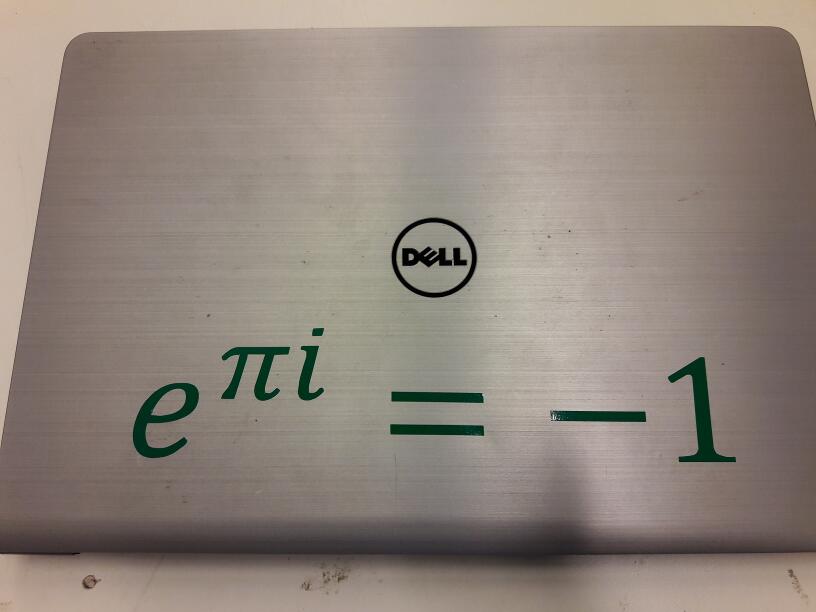

This is what I got for the final result:

And that's my progress for the third week! Next step: electronics production!

All the files that were mentioned in this week progress can be found here.