small.bmp)

- MACHINE DESIGN (week 2 of 2)

- Automate your machine. Document the group project and your individual contribution.

Class material: Machine Design

Insper FabLab's operational manual here.

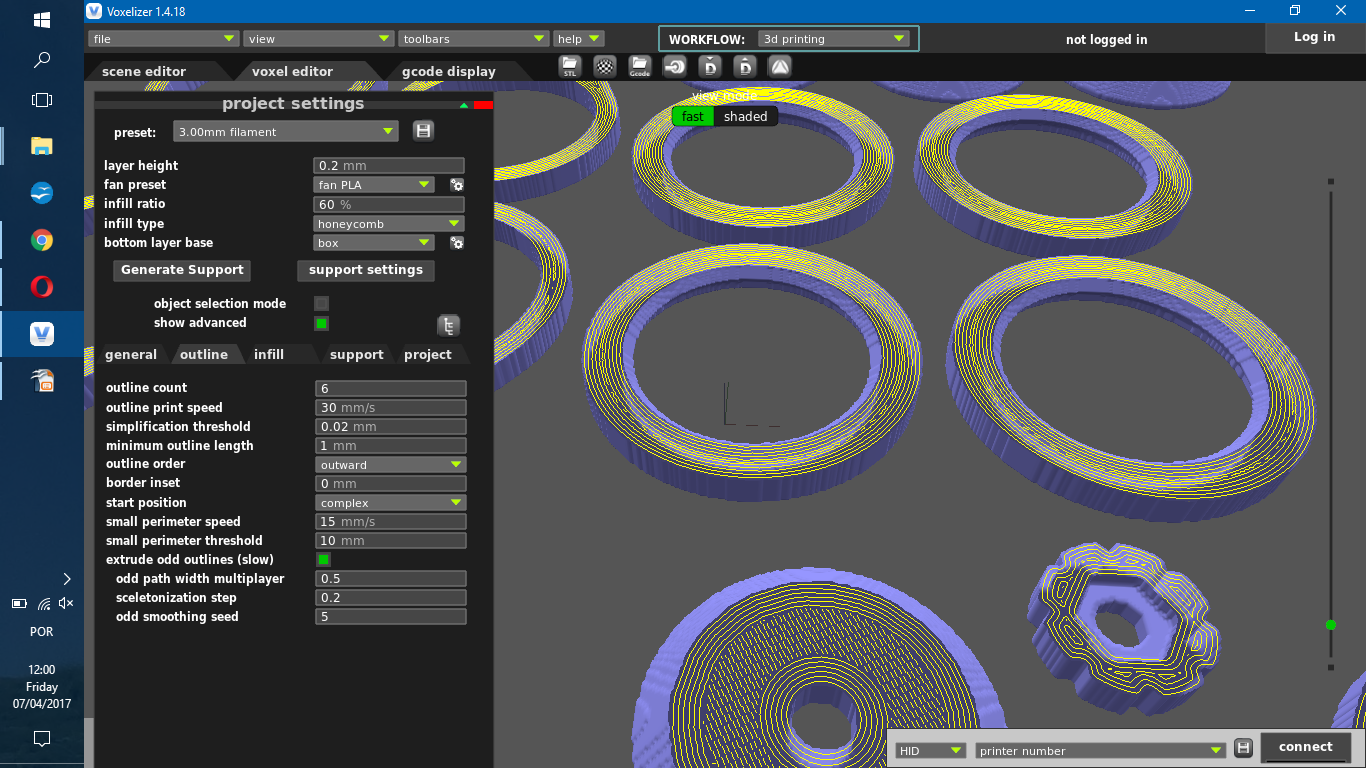

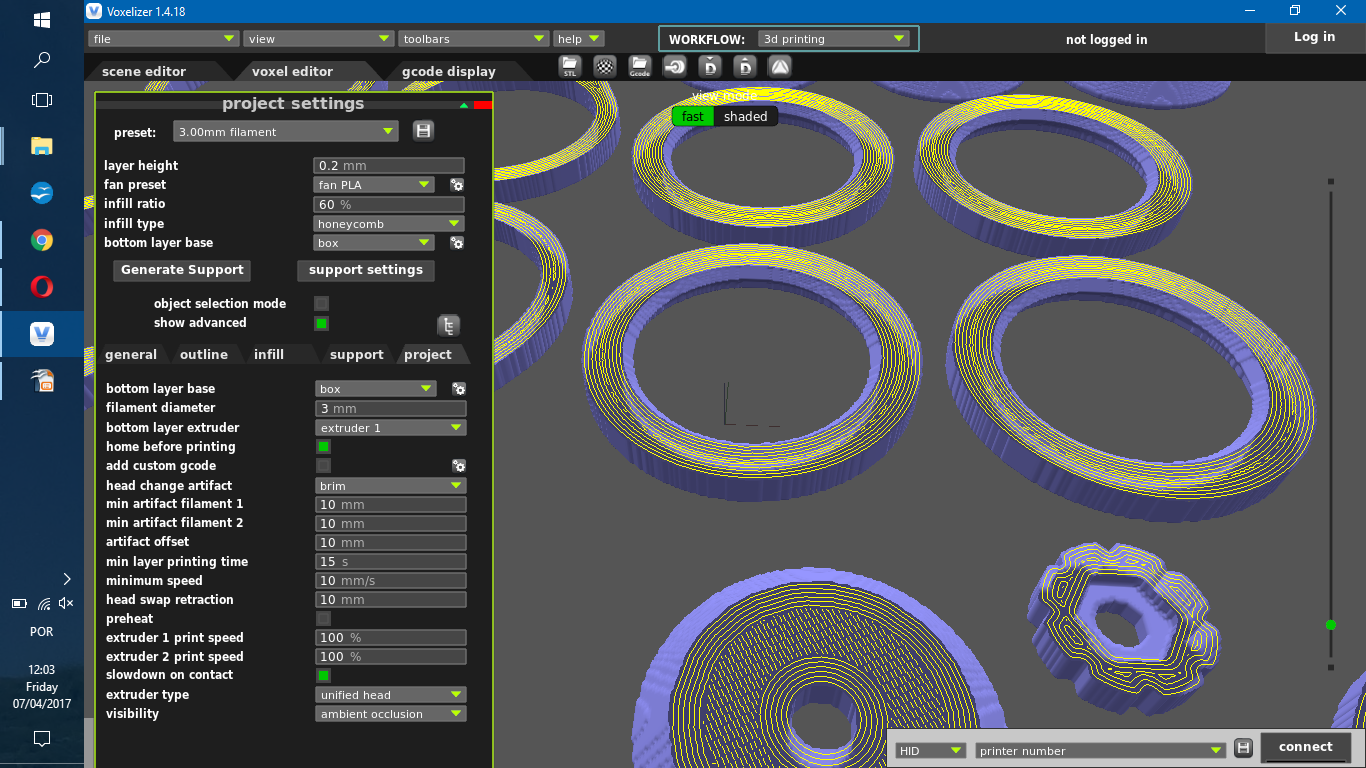

Zmorph 2.0SX - extra information here and also there is this first print tutorial online. The slicer Zmorph recomends is called Voxelizer; for tutorials and download click this link.

3D print filament diameter 3.00 mm - that was proper to the toolhead I used. The access the ABS material available at Insper, click here; and for the PLA click here.

Hair spray was the glue used for this 3d print.

- Temperature - nozzle: 190°C - bed: 60°C.

- layer height: 0,1 mm

- printing speed: 30mm/s

- material: ABS 3.00 mm.

During the last weeks the group worked on the DrawBot project. I worked with the team for the last and final assemble and tests. We understood that it was successful. Below, there is a collection of my own documentation. Our tutor instructed us to build some description of our work in this group project at the personal website.

Again, there is some information on 3D printing and some information about robot structure development.

I really printed a lot of parts, till we get a set that worked together properly.

small.bmp)

small.bmp)

small.bmp)

small.bmp)

-----------

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.