FabLab Cept

COMPRESSION

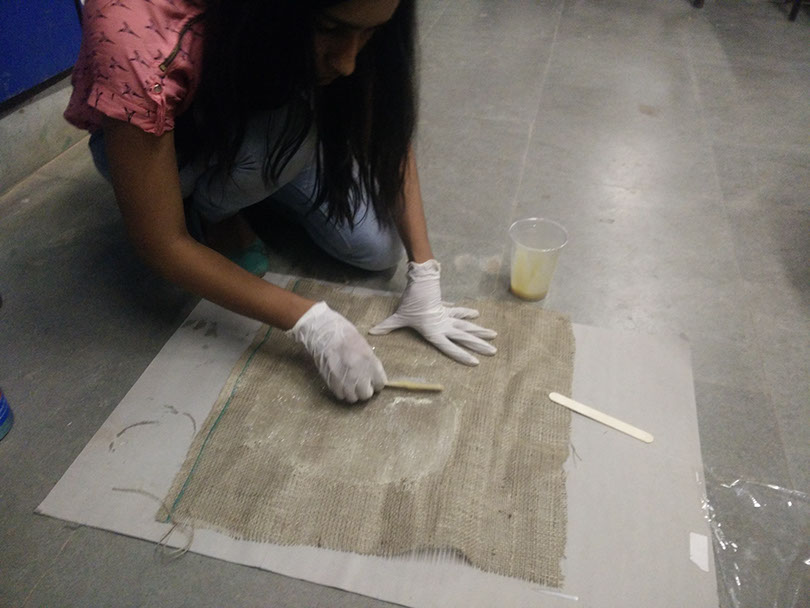

For compression process, I used vaccum bags. Again. I kept my tensile material as burlap and used Epoxy resin and Hardener.

1. The first step secure the mold using a cling-wrap, so that the base does ont get destroyed.

2. Next use equal proportion of resin and hardener to form a mixture and mix it throughly till it changes its colour to uniform light yellow.

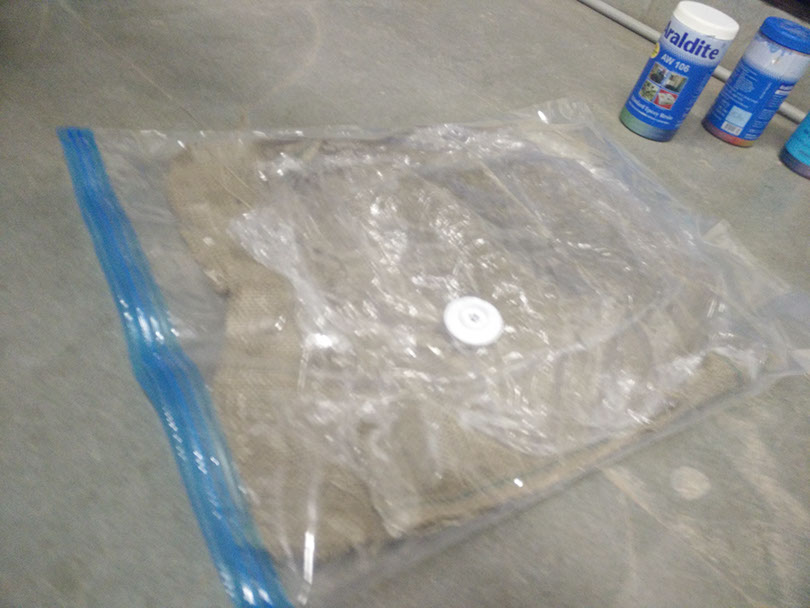

Left image shows transparent Epoxy-resin, Araldite AW 106

Right image shows addition of hardener, brownish colour, HV 953 IN.

This mixture needs to be mixed throughly

3. The next step is to apply a thin but adequate layer of this mixture on a piece of burlap. The rest the burlap piece on the CNC mold.

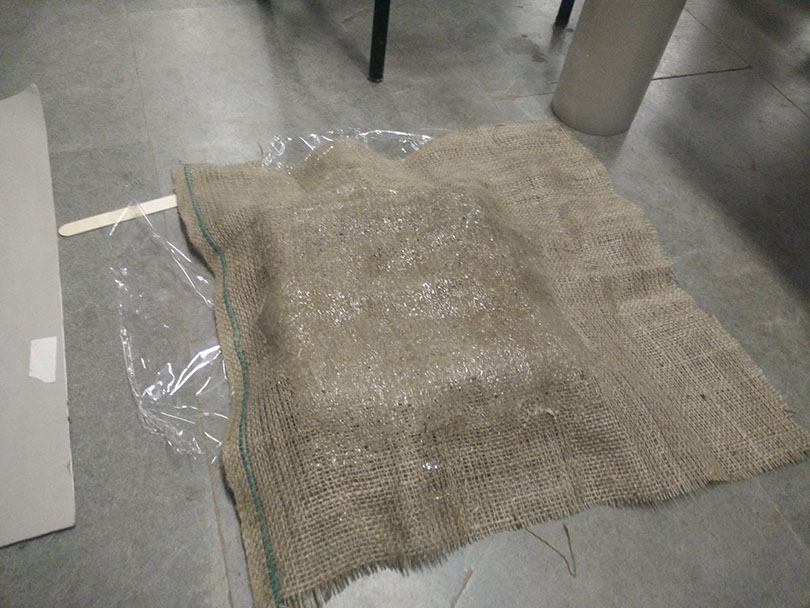

I repeated the process using 3 pieces of Burlap and then covered it with a cling wrap sheet on top of it.

1 - 9

<

>

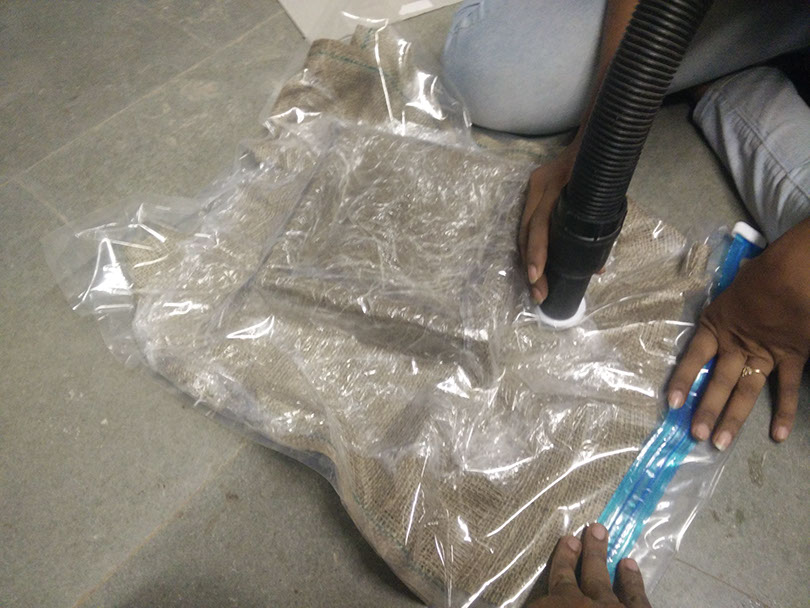

4. The CNC mold with burlap is passed into a Vaccum bag. The zip is secured tight and then air is sucked out using a Vaccum-cleaner. It is left overnight to harden.

4 - 4

<

>

I removed it from the vacuum bag after 3-4 hrs. It had gained strength and had become very hard.

This is how the form looks like finally.