FabLab Cept

CASTING

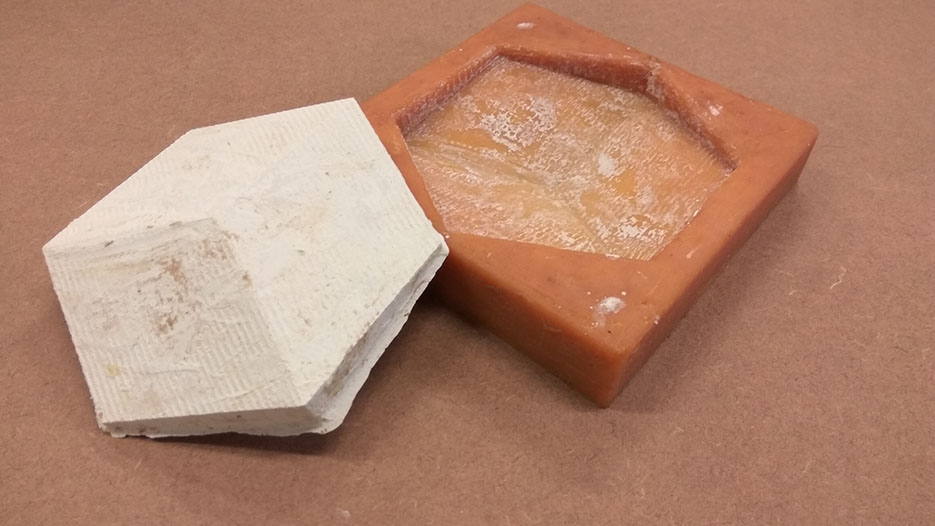

The second part of the assignment was to create a cast. For me, I created a negative cast from the mold that I prepared using CNC milling. And then I used this piece as a mold for casting my final tile.

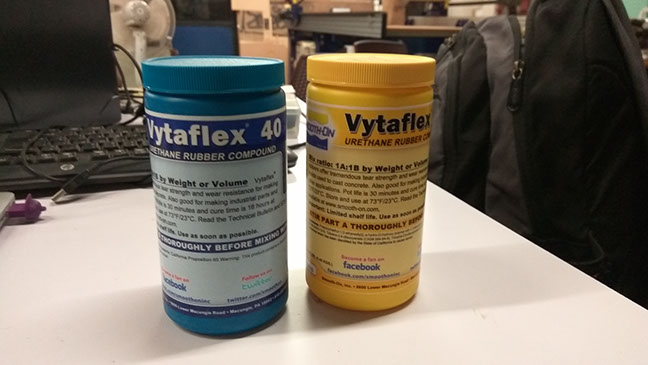

I used Vytaflex 40 liquid rubber and hardener for preparing this cast.

Both of them will go in 1:1 ratio.

.jpg)

-crop-u8694.jpg)

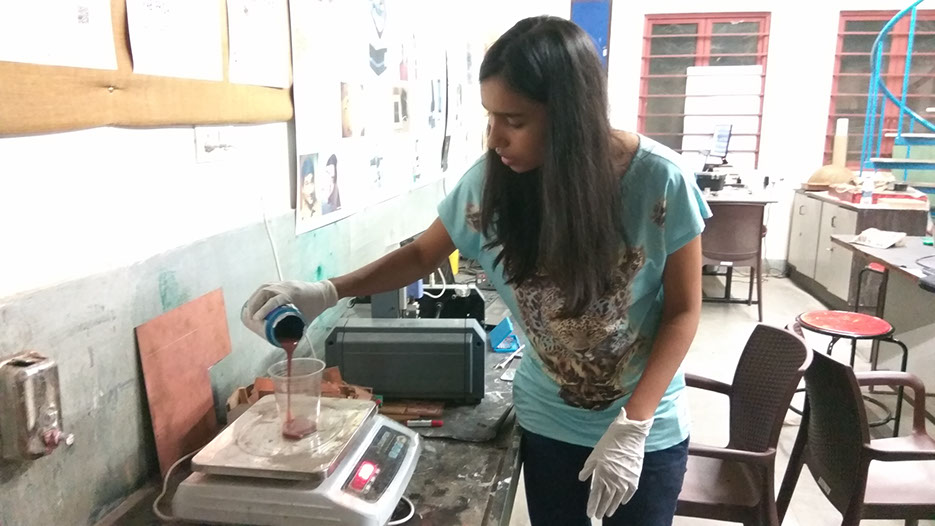

The first step was to apply a mixture of Grease-oil-soap water to prevent the casting material sticking on the mold.

First I poured Liquid Rubber in a glass and used weighing machine to keep a check on the weight.

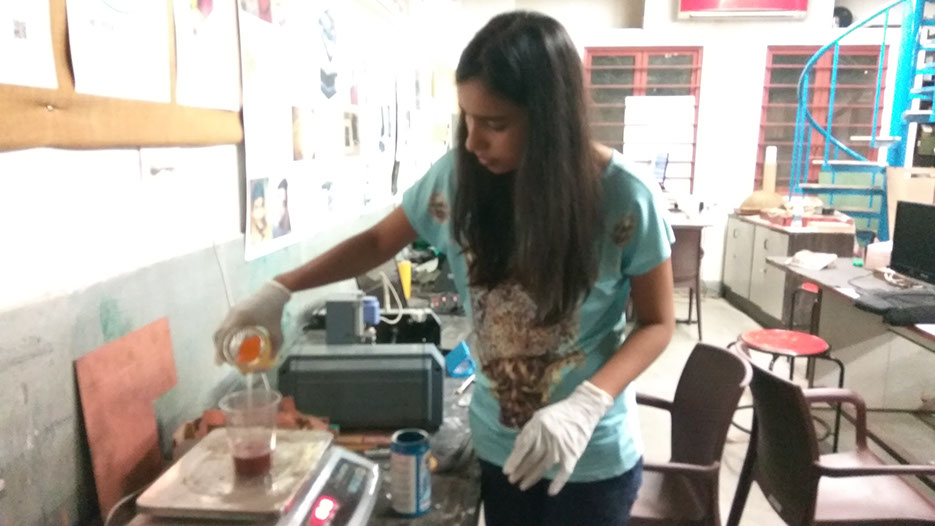

Next I poured equal amount of Hardener.

Mix the mixture thoroughly and pour on the mold.

I had to prepare another mixture quickly since I ran out of my mix.

Thus, a colour difference is seen in the cast.

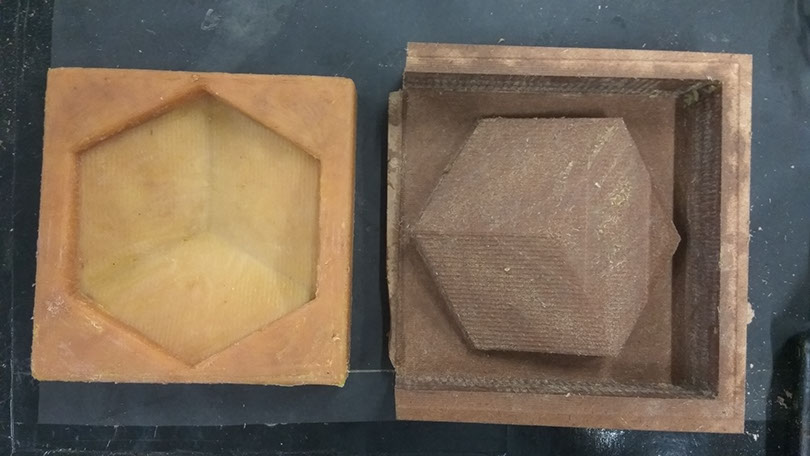

Once this was done, I let the mixture dry for 16hours as prescribed in the manual.

I had to sand one of the edge of the mdf mold to pull out the liquid rubber cast the next day.

9 - 9

<

>

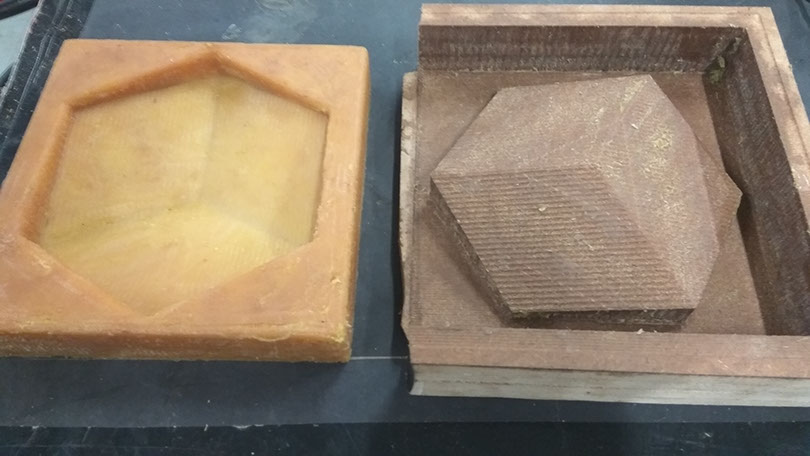

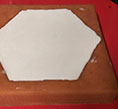

These are images of my Rubber mold.

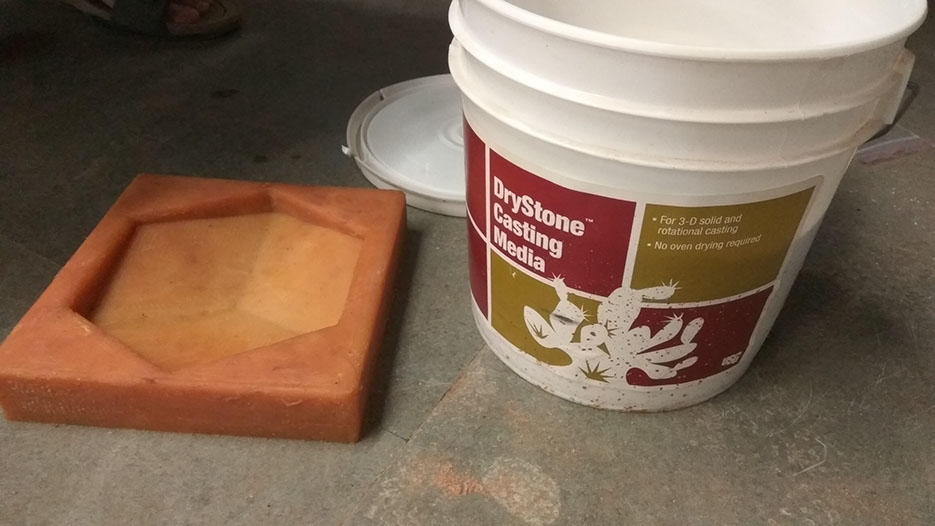

Next step is to prepare Plaster of Paris solution for the tile. Following pictures show the process followed.

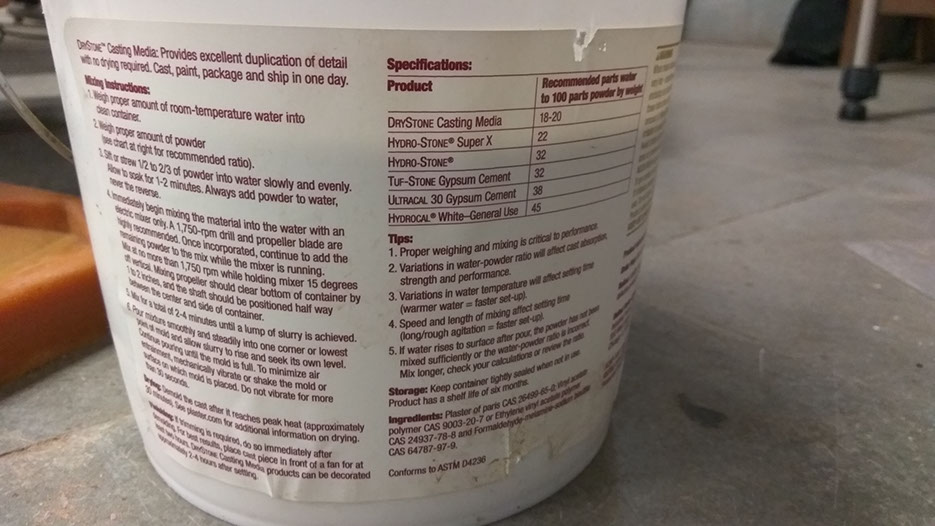

Our lab provided "DryStone Casting Media" which is mainly composed of Gypsum

I read the instructions and followed step by step process.

I u sed the red measure spoon to measure the powder. I need the powder and water in 2:1 proportion.

I added water to the powder.

Next was to mix it thoroughly, so that no bubbles are left in the mixture.

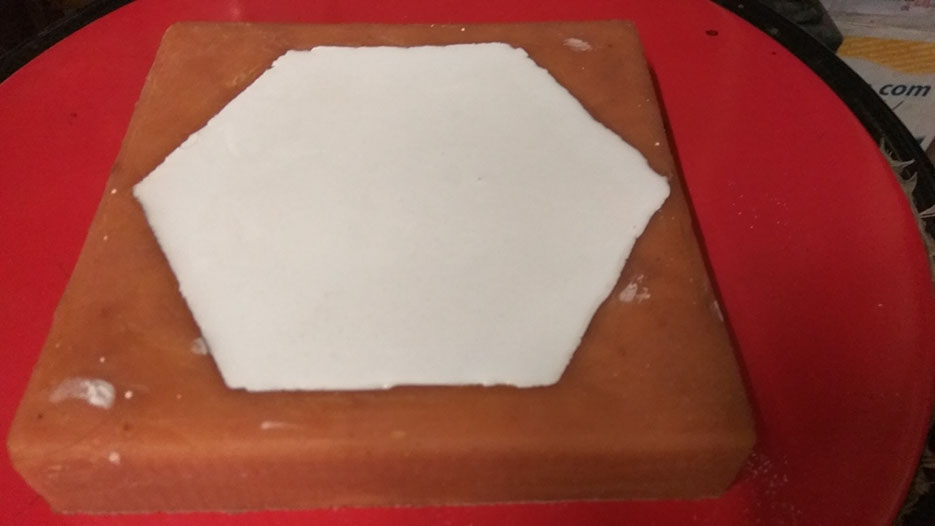

Pouring the mixture on the rubber cast.

Allowing it to set for 30mins as given in the instructions.

In 30mins my Tile was ready.

8 - 8

<

>