FabLab Cept

3D PRINTING

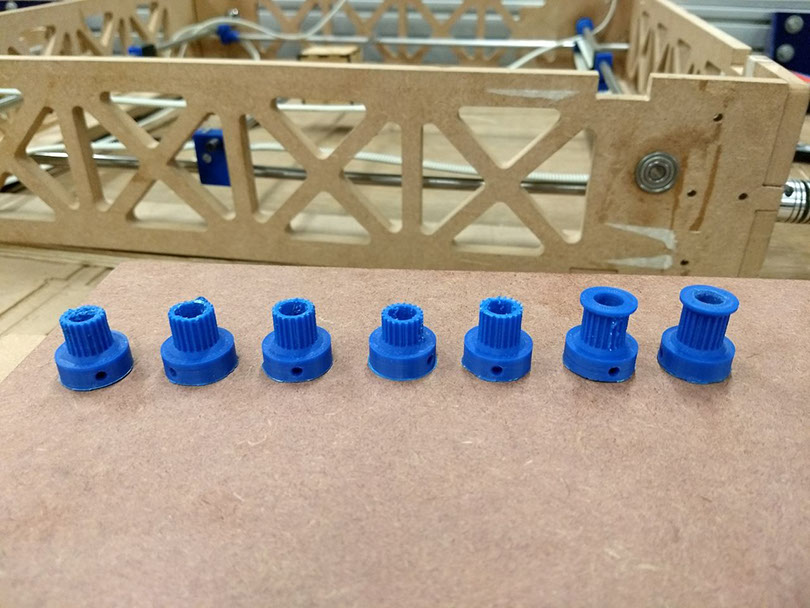

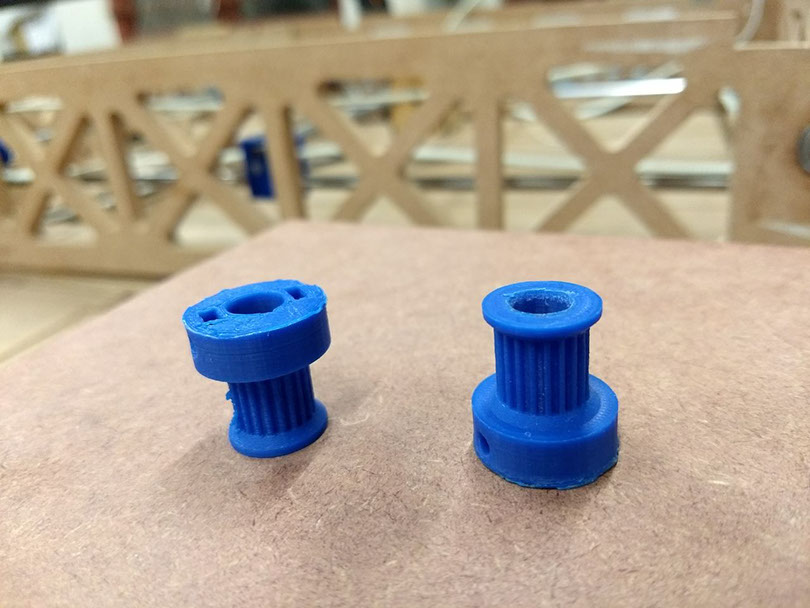

We decided to design our own pulleys instead of buying them from the market. We had to go through quite a few tests before we could finally get the correct pulley.

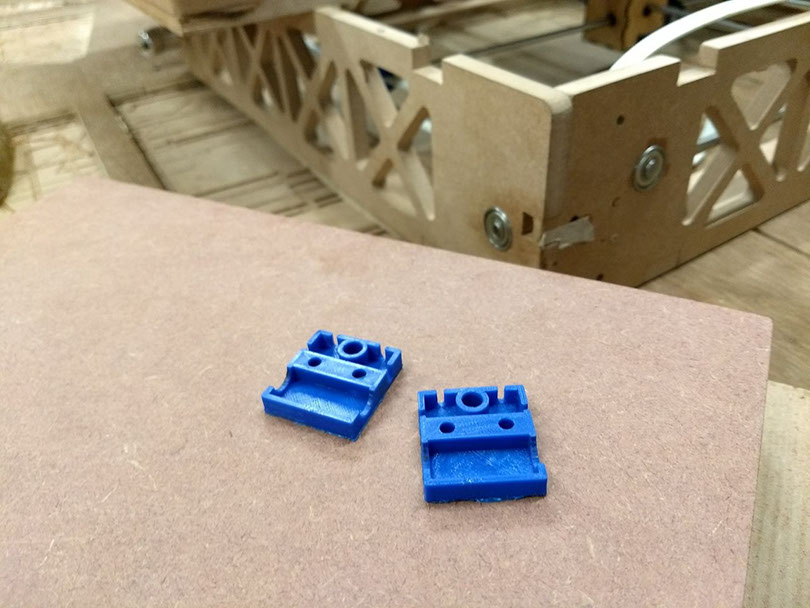

1. The first step was to design 3D file in rhino for pulley

The left one shows the first 3D and the right one was the final 3D which gave us a proper pulley for our machine. We explored different parameters like changing the height of the belt area, the diameter for the rod and also addition of the holes at side for screwing it. G-code was prepared using Cura.

.jpg)

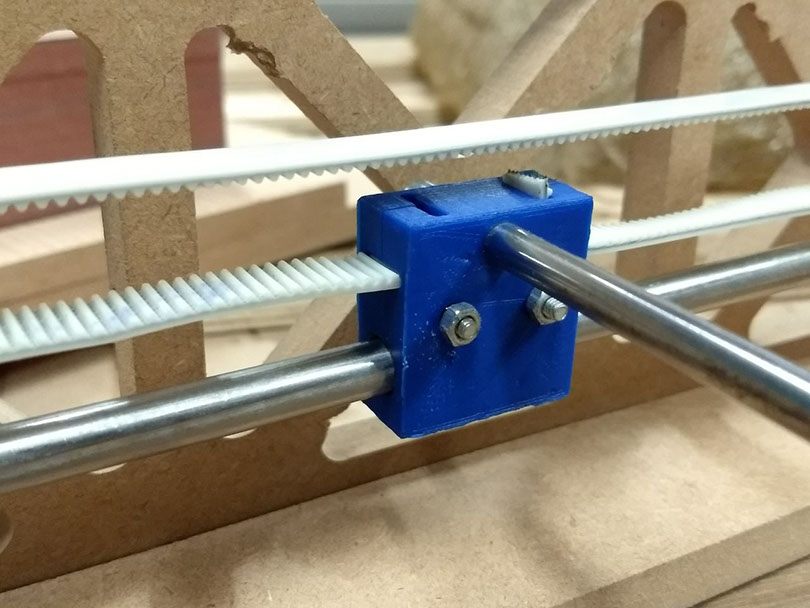

2. Next step was to prepare a box for sliding on the belt holding the rod.

So we only needed to design half part of the box and printing 2 of them gave us 1 complete box. Printing in 2 parts was necessary to pass the belt and also to pass the rod through it. After few attempts, we could achieve a perfectly fitting belt-box for our machine. Again, G-code was prepared using Cura

.jpg)

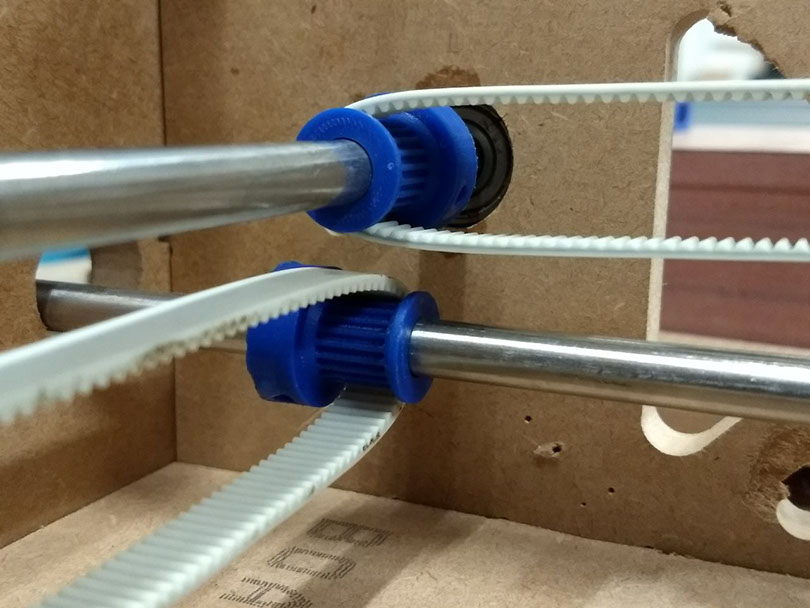

Here are some pictures of belt box and pulleys.

5 - 5

<

>

Final design files can be found here.