Week 10

Output Devices

The tenth lecture on Wednesday March 29th was about Output Devices: LEDs (basics, RGB, arrays), video, speaker, motors (DC, servo, brushless, stepper), relays. Assignment given by Neil for this tenth week was:

- Add an output device to a microcontroller board you've designed and program it to do something

Designing a microcontroller board including a servo motor control

Between the various output types described by Neil during Week 10 lecture, I decided to focus on the control of a Turnigy TGY-MG90S servo motor (13.4g weight - 1.8-2.2kg torque - 0.10sec/60° speed), thinking it could also maybe useful as an output for my Mailplus Final Project (e.g. to raise and tear down a possible mailflag, but on this point I'm still in doubt, since mailflags are used in U.S. to communicate presence of outgoing mail, not incoming mail as in my purpose). A rotary servomotor is an actuator that allows for precise control of angular position, velocity and acceleration; in general it consists of a motor coupled to a sensor for position feedback.

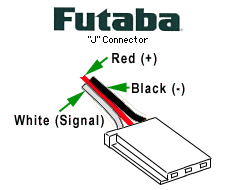

Servo Pinout

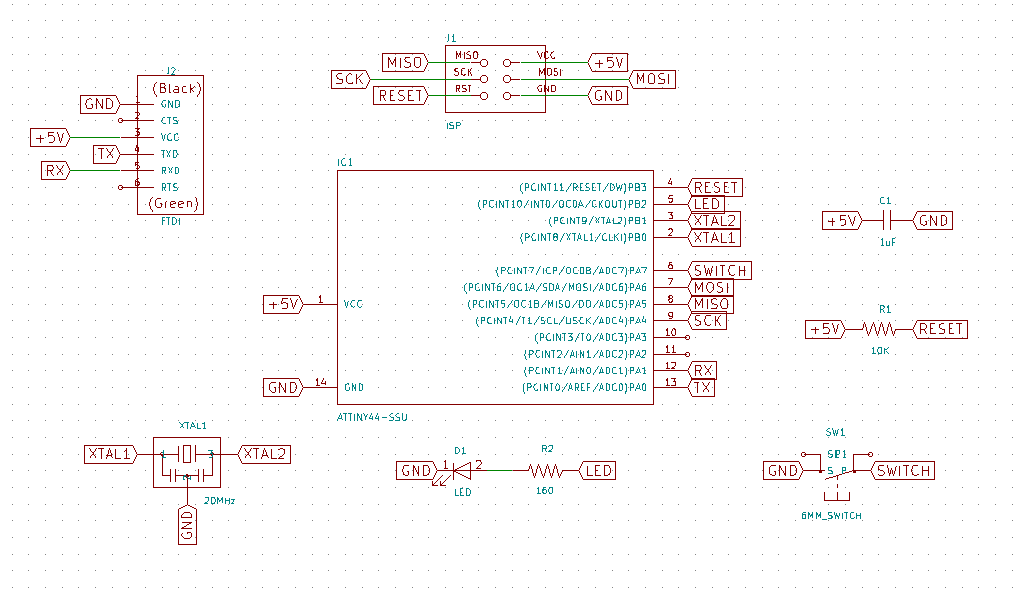

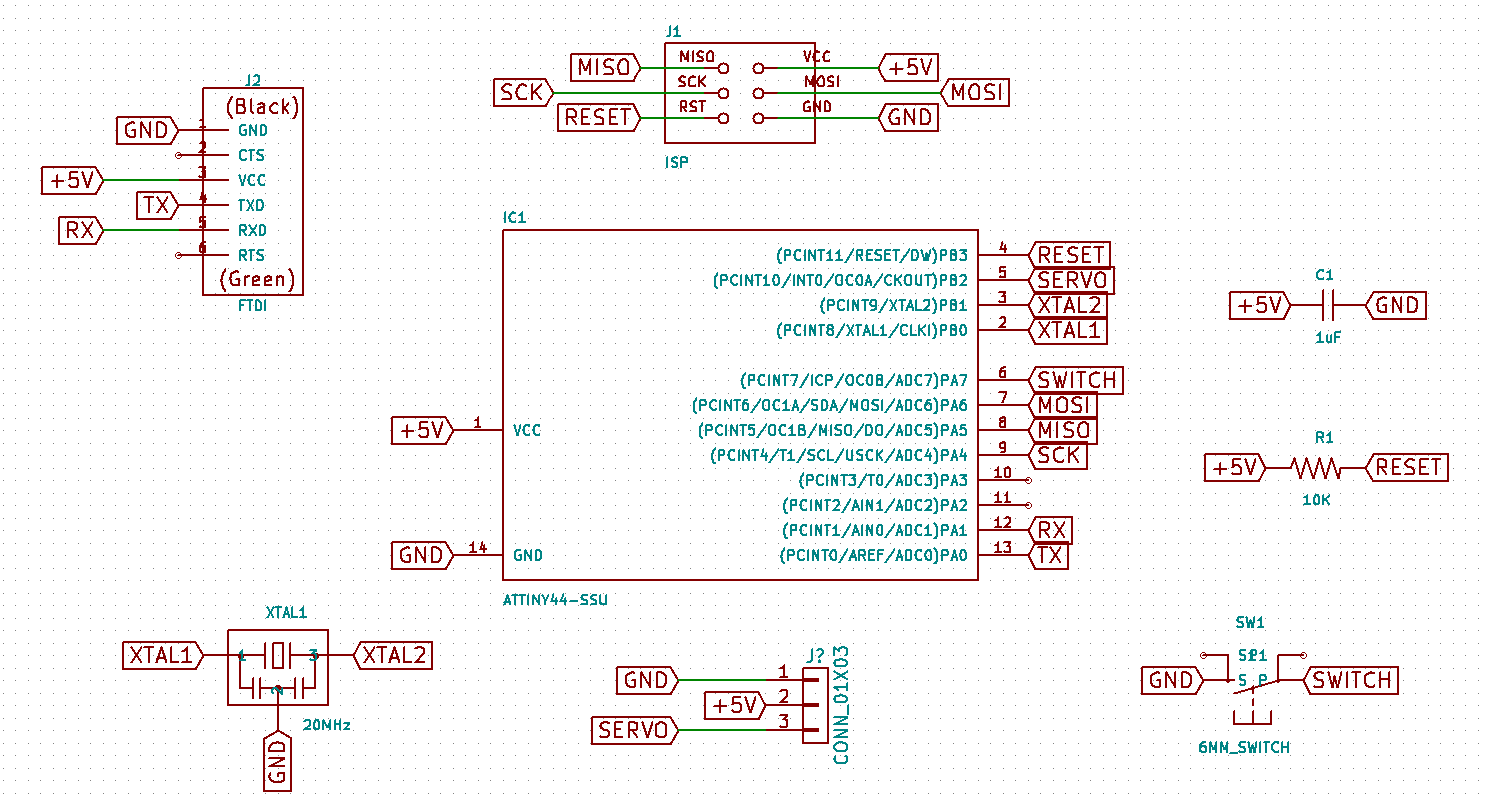

Starting point for this assignment was the previous built echo hello-world board; used KiCAD EDA, opened Eeschema Module

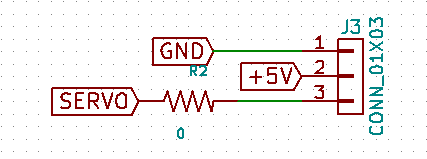

Since servo motor control is based on PWM (Pulse-Width Modulation, a technique for getting analog results with digital means), I went on checking ATTiny 84A datasheet, and finding Ports with PWM capabilities: Port PA5 (OC1B, Pin#8, already used by MISO), Port PA6 (OC1A, Pin#7, already used by MOSI), Port PA7 (OC0B, Pin#6, already used by Switch); Port PB2 (OCOA, Pin#5, already used by LED on the hello-world board). I decided to use Port PB2, Pin#5 to put the servo header control (I used a 01x03 connector) instead of the LED output: starting from the central one, I connected the Pin headers to +5V, GND and Port PB2, Pin#5 (renaming it "SERVO")

Since it would be very difficult (not to say IMPOSSIBLE) to route the tracks with a single sided SMD board like this without crossing the routes, and as in my previous Fab Academy assignment I wanted to route it manually through the KiCAD PcbNew Module, I was looking for an easy method to cross routes and the result turned out to be to add a Zero Ohm Resistor to the header schema:

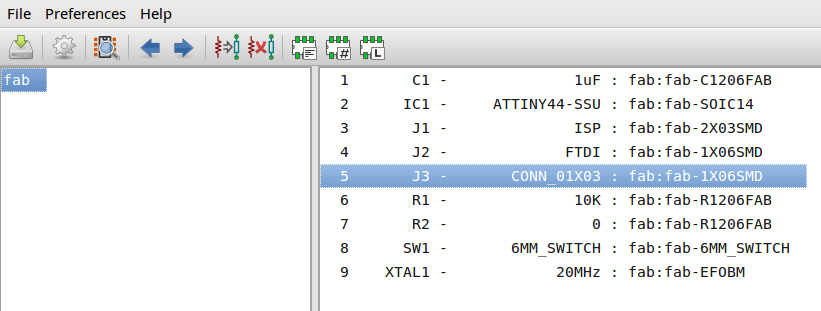

Then as usual, I went successfully through automatic schema Annotation, Electrical Rules Check (ERC) and, before exporting the NETlist, I associated components and footprints from libraries using KiCAD cvPCB Module; since in fab library, the only one I imported and used, I could not find a 01x03 connector header I associated it to the 1x06SMD footprint:

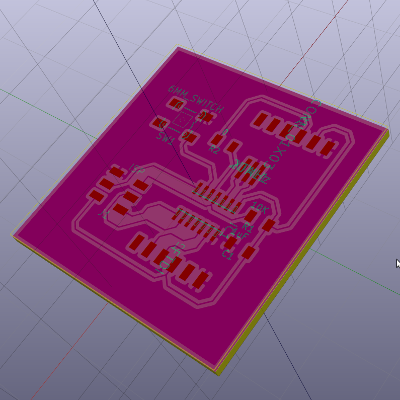

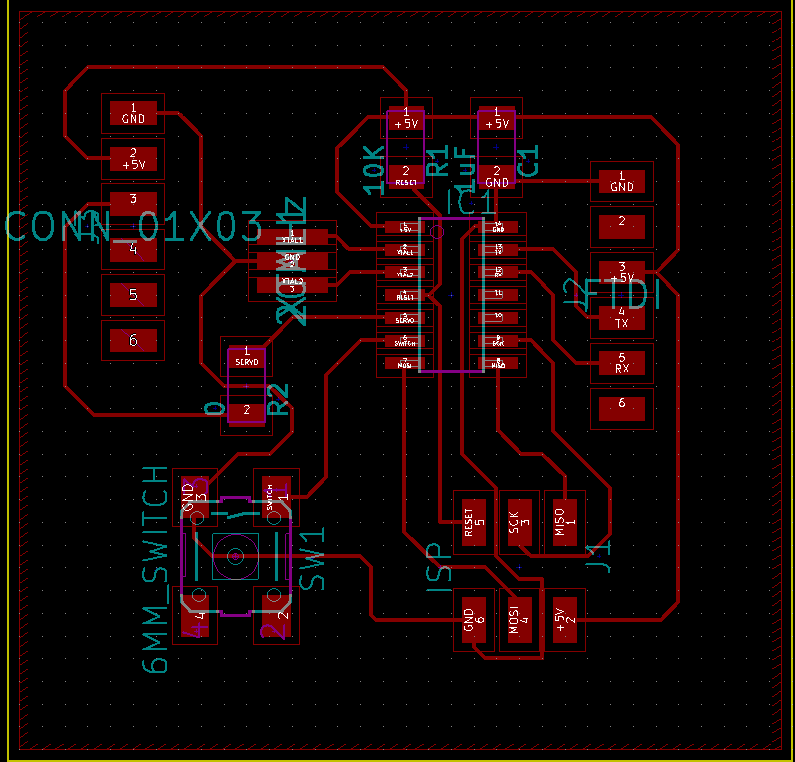

Here's the manual route result:

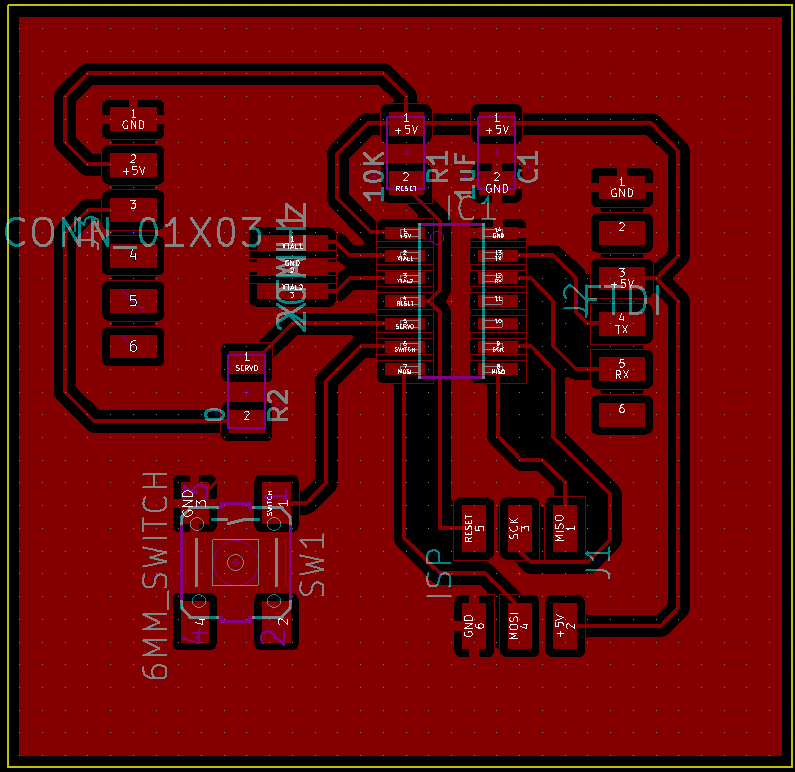

Here's with the filled zone, before SVG export

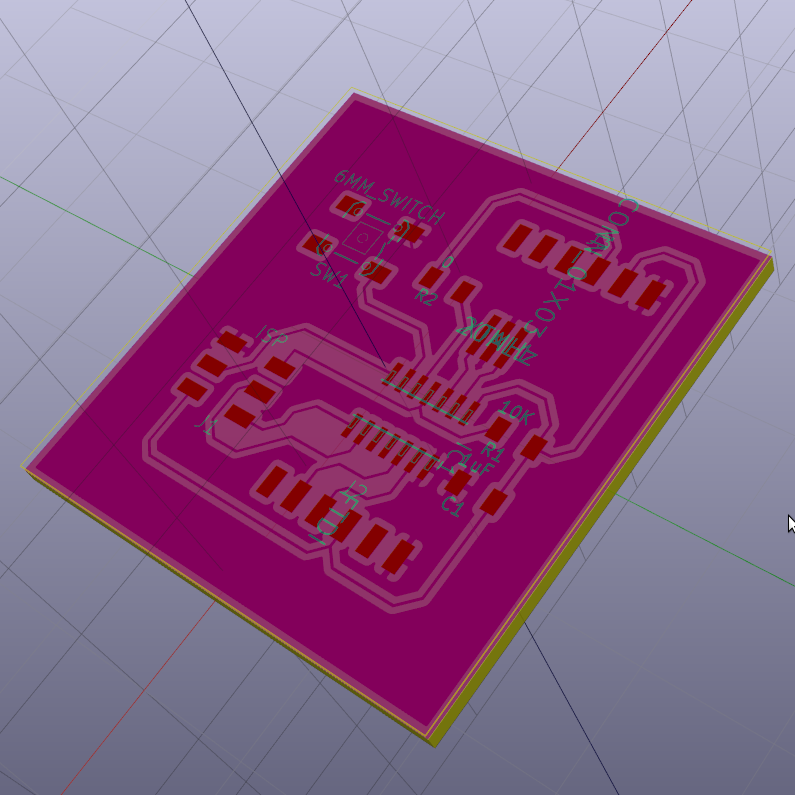

Here's is the KiCAD 3D render output

About the firmware I took inspiration from Arduino Sweep tutorial, then wrote the following code with Arduino IDE. I slightly modified sketch readapting PINs to ATTiny pinout, then I programmed the button to execute one single sweep when pressed.

/*

* Based on Servo Sweep example code

* by BARRAGAN <http://barraganstudio.com>

*/

#include <Servo.h>

#include <SoftwareSerial.h>

const int buttonPin = 7;

Servo myservo; // create servo object to control a servo

SoftwareSerial mySerial(1, 0);

int pos = 0; // variable to store the servo position

int buttonState = 0;

void setup() {

// initialize the pushbutton pin as an input:

pinMode(buttonPin, INPUT);

digitalWrite(buttonPin, HIGH);

// attaches the servo on pin 5 to the servo object

myservo.attach(5);

myservo.write(pos);

// initialize serial interface

mySerial.begin(9600);

mySerial.println("Output device: servo");

}

void loop() {

// read the state of the pushbutton value:

buttonState = digitalRead(buttonPin);

// check if the pushbutton is pressed.

// if it is, the buttonState is LOW:

if (buttonState == LOW) {

mySerial.println("Button pressed, executing servo sweep!");

for (pos = 0; pos <= 180; pos += 1) { // goes from 0 degrees to 180 degrees

// in steps of 1 degree

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(25); // waits 15ms for the servo to reach the position

}

for (pos = 180; pos >= 0; pos -= 1) { // goes from 180 degrees to 0 degrees

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(25); // waits 15ms for the servo to reach the position

}

}

}

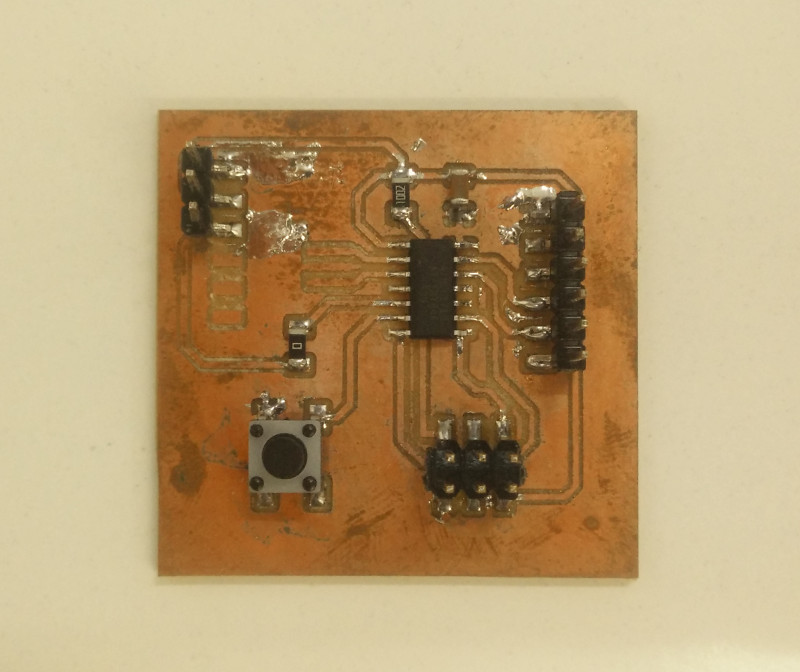

Here's the "Hero Shot" of the actual final servo board result: milled, stuffed with components and programmed (for details see Week 04)

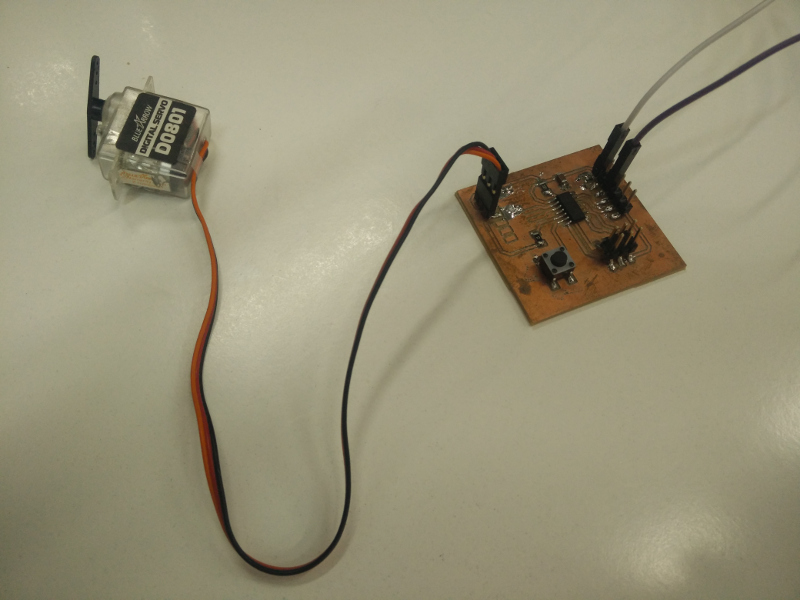

and here with servo actuator attached

Source files

- servo.sch -KiCAD Eeschema output SCH File

- servo.net -KiCAD Eeschema output NET File (Netlist)

- servo.kicad_pcb -KiCAD PcbNew output KICAD_PCB File

- servo-F.Cu.svg -KiCAD PcbNew output SVG File (Traces)

- servo-F.Cu.png -Inkscape output PNG File (Traces)

- servo-F.Cu.rml -Fabmodules output RML File (Traces)

- servo-Edge.Cuts.svg -KiCAD PcbNew output SVG File (Edge)

- servo-Edge.Cuts.png -Inkscape output PNG File (Edge)

- servo-Edge.Cuts.rml -Fabmodules output RML File (Edge)

- servo.ino -Arduino IDE output INO File