Fab Academy 2017 at Fab Lab Barcelona By Trinidad Gomez Machuca

Design appropriate objects within the limitations of 3 axis machining

Demonstrate workflows used in mould design, construction and casting

For my final project I'm planning to do a soft robotcs, so for this assignment I want to start experimenting with this type of robots because I've never done one of those. So I did the research and I found that there is lot of examples on the internet, and i found the idea of this Ears that move when they are inflate with air, as you can see in the begining of the video.

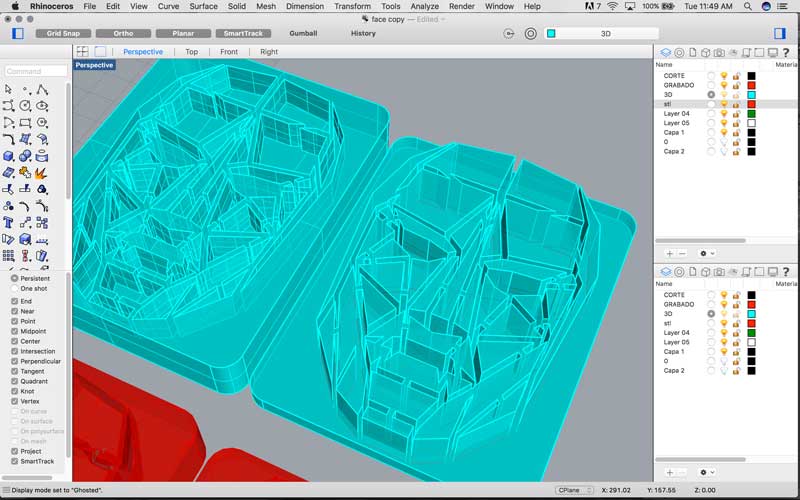

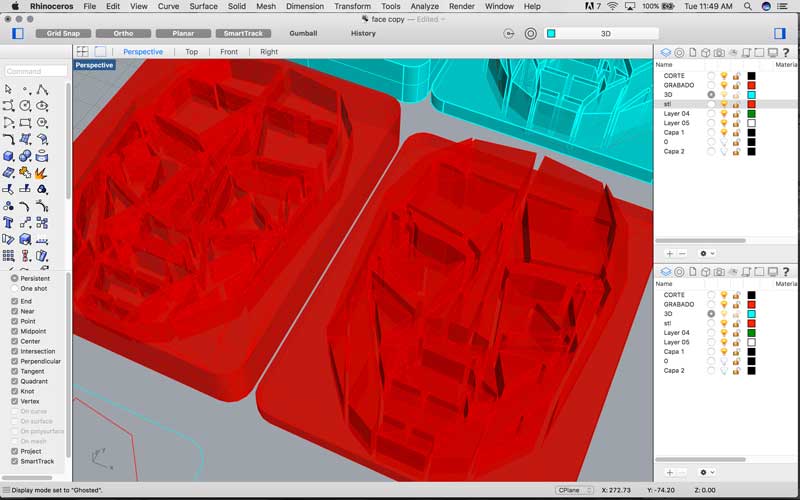

I started analyzing how the soft robotics works, the measurments, the materials, the patterns and everything that can allow to move the material in the way you need, so I designed my own mold considering the limitations of the size of the wax.

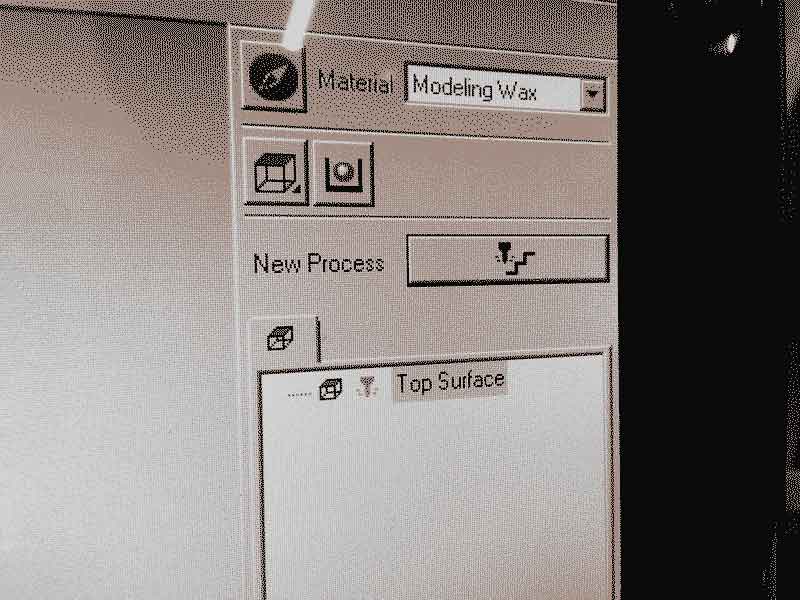

Open the Software and go to the option new process

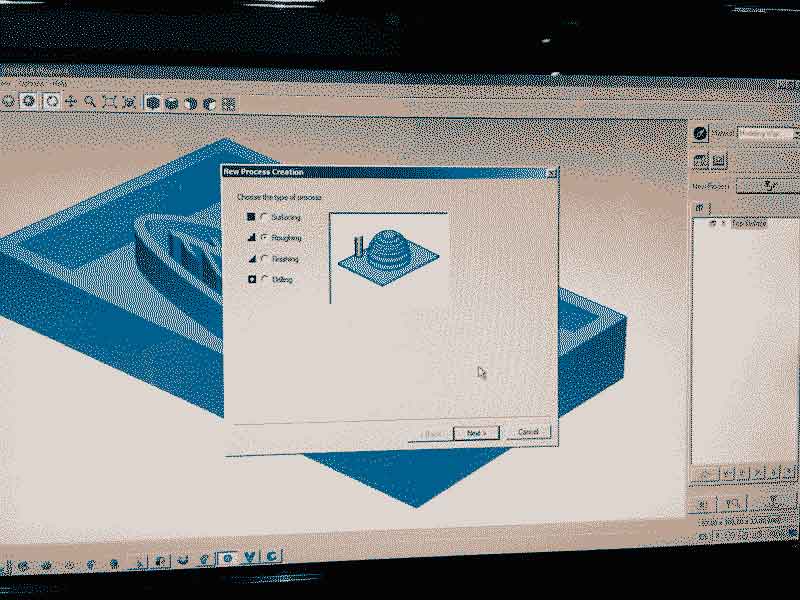

You have to select Roughing option

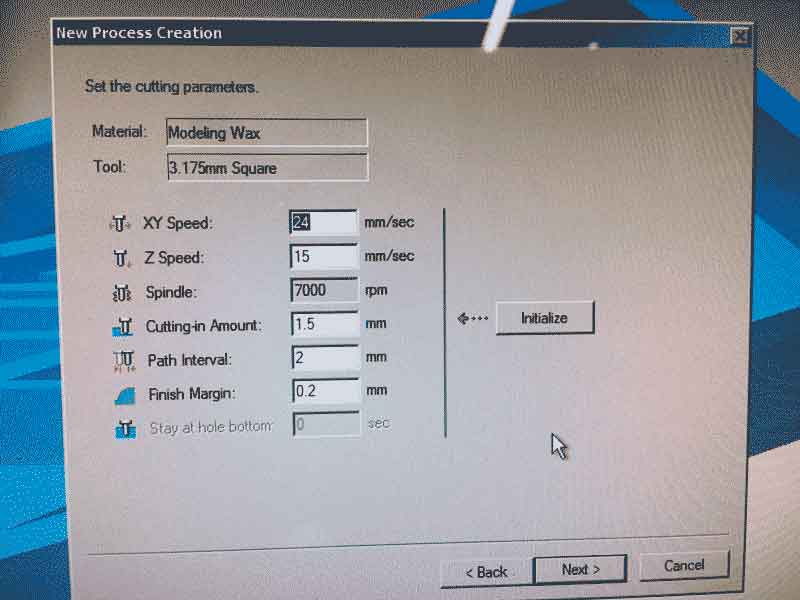

Select the tool that you are going to use, 3.17 mm

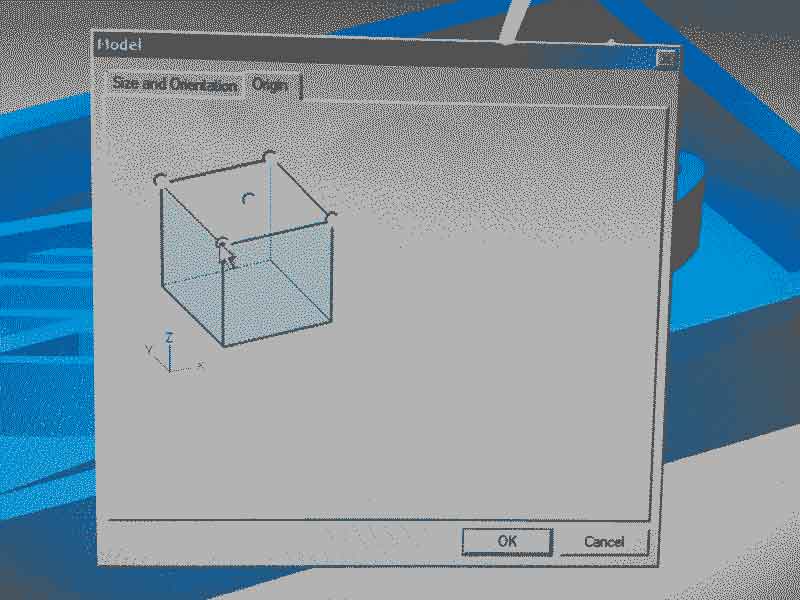

Then change the origin of the file that has the be in one corner not in the middle

Make sure all the measures are ok, almost all the time this information is by default

Here you can see what your tool is going to do first, it doesn't said if there is some error, so you have to be very careful

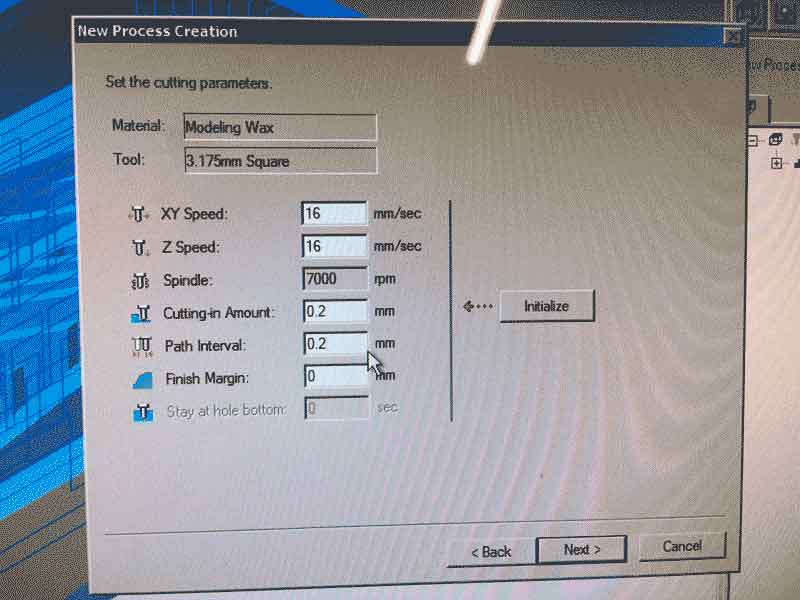

Second you have to do the finishing part, where you can make the litle details, so you have to select the option finishing

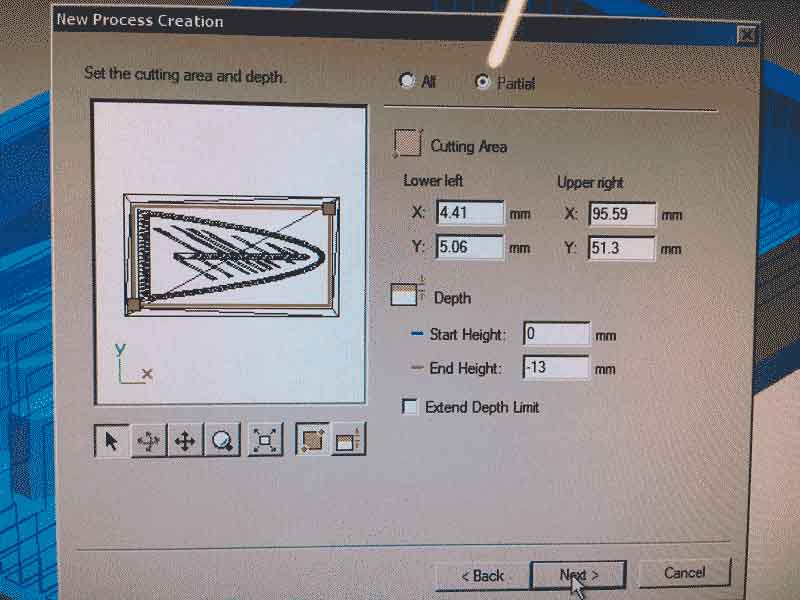

Here you have to select the area of the details are

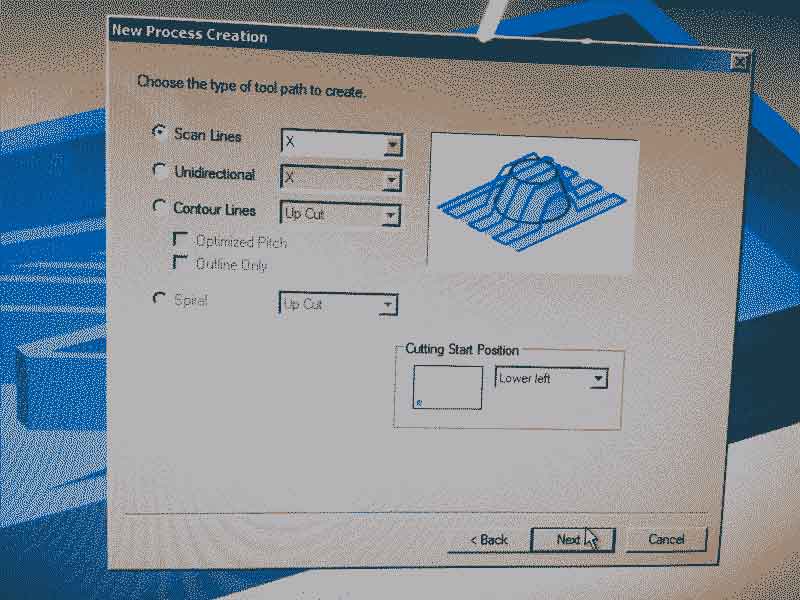

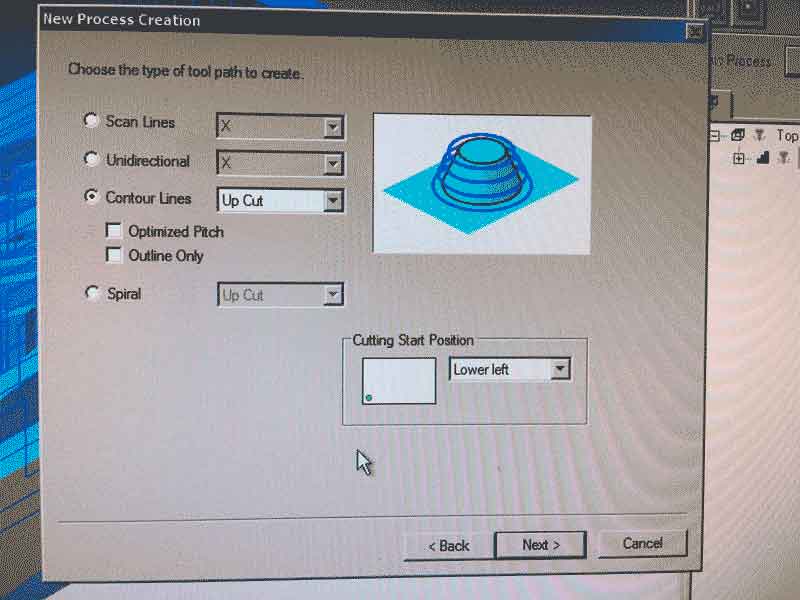

In my case the best strategy was to do the Contour lines

Select the detail area

Make sure again of the measures are correct

Here you can see the path that the finishing part is going to follow

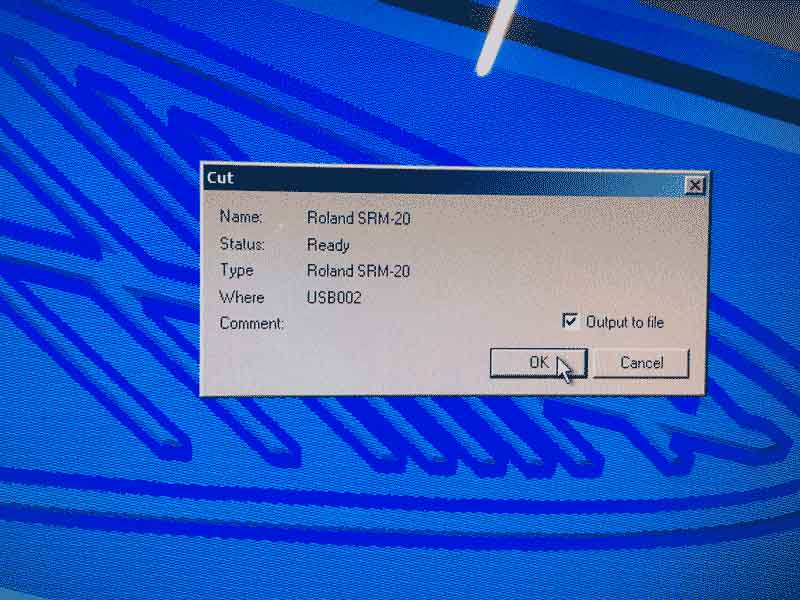

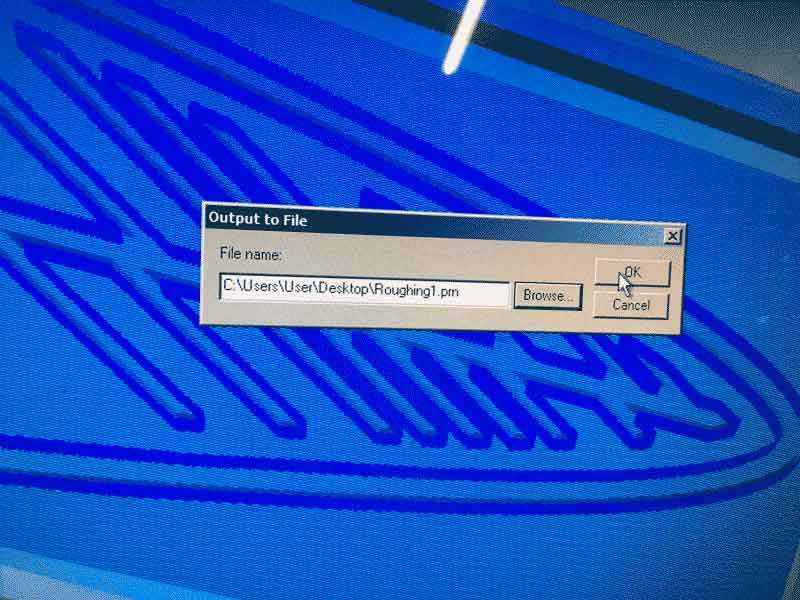

Save the Files

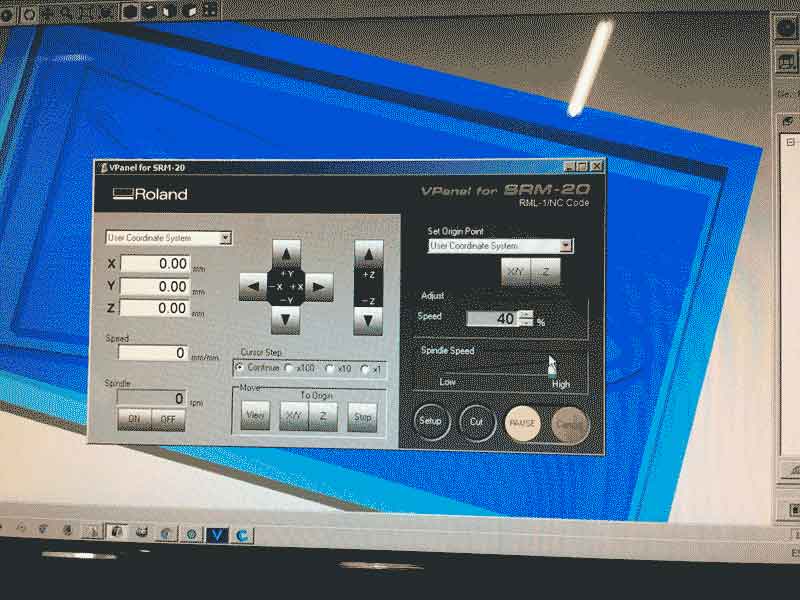

After finishing, you have to and open the file in the Modela Software, set X, Y and Z and start your milling. Make sure you paste the double tape in the wax and after the machine start you have to clean it and see if everything is going ok.

Pick the material that you are going to use, in my case I choosed use the EcoFlex 00-30 wich is the best for doing soft robotics. Before to start you have to read the instructions otherwise your mix could never work and in the worst case it could be dangerous. The proportion of this material are 50/50.

When you combine the 2 materials, by default it start appear some bubbles in the liquid and this could be bad for your mold. To fix this step you have to vacuum repetitive times the material. Here the bubles tend to go up and then dissapear.

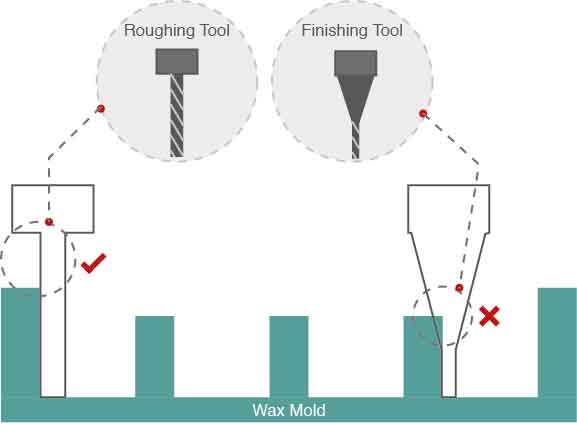

I had some problems with my measures of my mold, because I didn't consider the size of the finishing tool, when this tool tried to mill the bottom, it destroyed a little bit of my wax mold. For fix this I change the measure of all my design. This happend to me because I studied other mold but all of them were made in the 3d print, so this things would never happened in thi machine.

As final result I discovered a lot of things. First I didn't do the cober of my mold, so when i tried to fix the lid, I realized that i didn't control this side, when i put some air, some of the areas stretched more than others, for the next time i have to make sure that the other part should be with an other mold.

I haven't programed it with a air pomp yet but works with Syringe hahahahahaha :P

Yes, I did two examples for this assignment, I did this casein plastics because I thought it will work with my composite assignment , but at end I discovered that it wasn't about to do a hard piece, It was about to combine materials and mix it with quimicals to make it strong with a structural purpose. I hope this exercise help. For my final project I want to do a soft robotic, So, I started with molds made in 3d print and with the Modela, but as you can see both materials are totaly comertial, besides, i took the bootcam academy of Fab textiles and i learnt a litle bit about bio plastics. I saw that for this assignment we should use very toxic material that being honest my migrain is not as Excited as me for doing this project. So I decided to create two diferetens kinds of bioplastic for my final project, the most important is the bioplastic that is going to replace the ecoflex, a very very flexible material and the second one that i want to create for this assignment is the one that is going to replace the plastic for the mold, a hard bio plastic that i can milled in the modela or any CNC machine. Finally i found that the Casein PLastic could be a good option, in the next video you can see that when you finish to cook it is very hard and stable and it could be a option to use in the milling in a CNC.

The recipe that i follow is one that i found in Instructables Milk plastic

Milk

White Vinegar

Liquid measuring cup

Measuring spoons

Coffee filters to absorb the liquid

Fine weave strainer

Spoon

Plate

Pan

Cookie cutters

Skewer not shown

Wax paper not shown, line the plate with wax paper.

When you combined this two materials, the vinager separate the properties of the milk, leting only the caseine. You can use any kind of caseine the only thing you have to consider is to use one that has at least 5% of acid.

Then the milk, in this case, it has to be hot, so let it in the oven like 20 min and before boiling you can mix it with the vinegar. The proportion is 500 ml of milk and 3 normal spoons of vinegar.

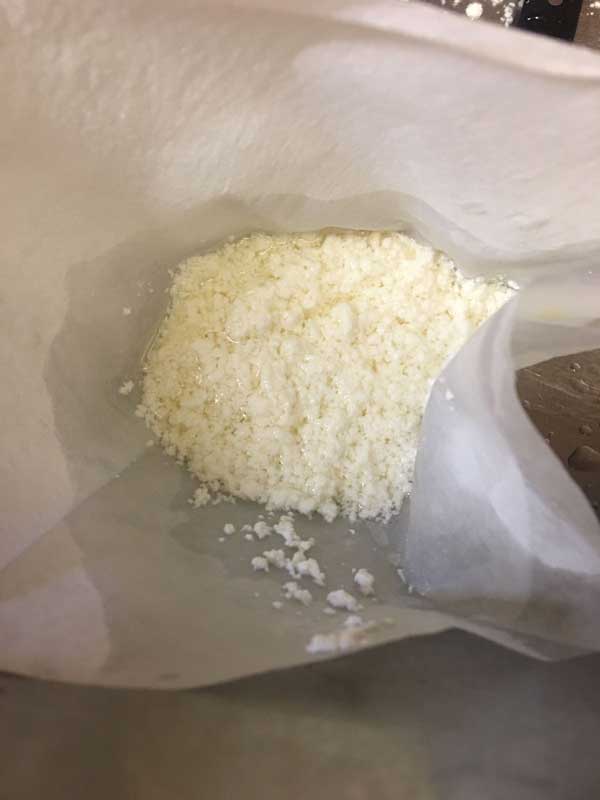

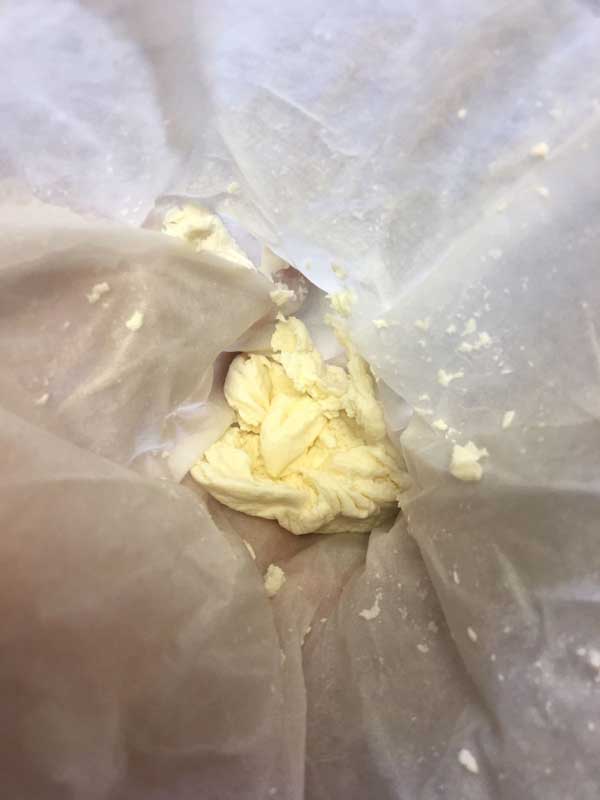

When you mix it, the properties of the Milk start separate inmidiatly. After this you have to filter it with some fabric or in my case i used coffe filters.

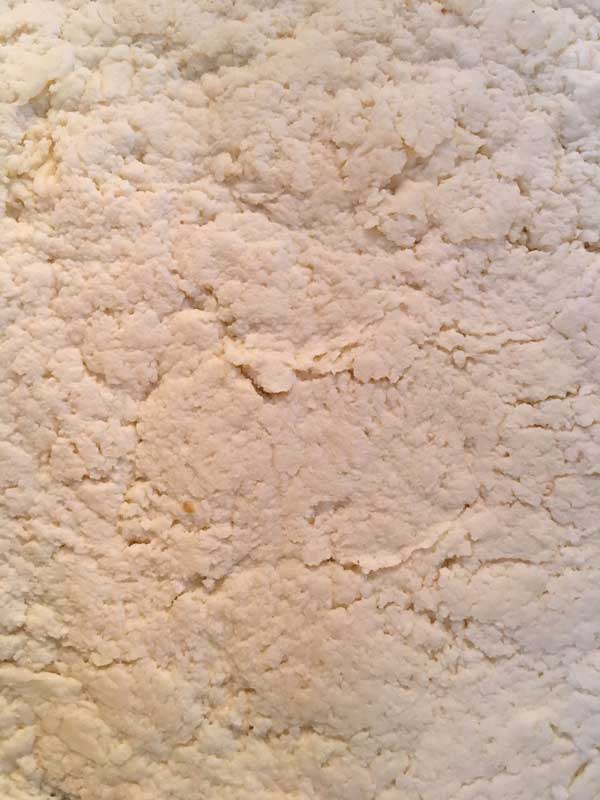

Here you can see the result after filtering, but in this case I think this step of the process it will be very helpfull to use a profetional press, because if you do it manually the material has a lot of imperfections that makes a very weak material.

The final result is not good, but is very hard, but not as good so milled in the CNC Machine, also it's not rigid and thik enough.

With the same design I did a mold for the molding.

It works! After 3 weeks I separated the result and it is hard and very good result, the only thing is that it has to be in a control environment otherwise it will be rotten like this, but it is resistant as a plastic object and well done.

.jpg)

.jpg)

Special thanks to Superficie Fermentada for the amazing help about your research of Bio plastics from México. Thanks you very much!

//Rhinoceros

//Modela

//Rolland

Molding and Casting Assignments and Assessment

Soft Robotic's Instrutable

Ear Video

| Fab Academy 2017 | Fab Lab Barcelona | Trinidad A. Gomez Machuca |

| IAAC | trinidad.gomez@iaac.net | |