Assignment

-

Test the design rules for your printer(s) (group project)

-

Design and 3D print an object (small, few cm) that could not be made subtractively

-

3D scan an object (and optionally print it)

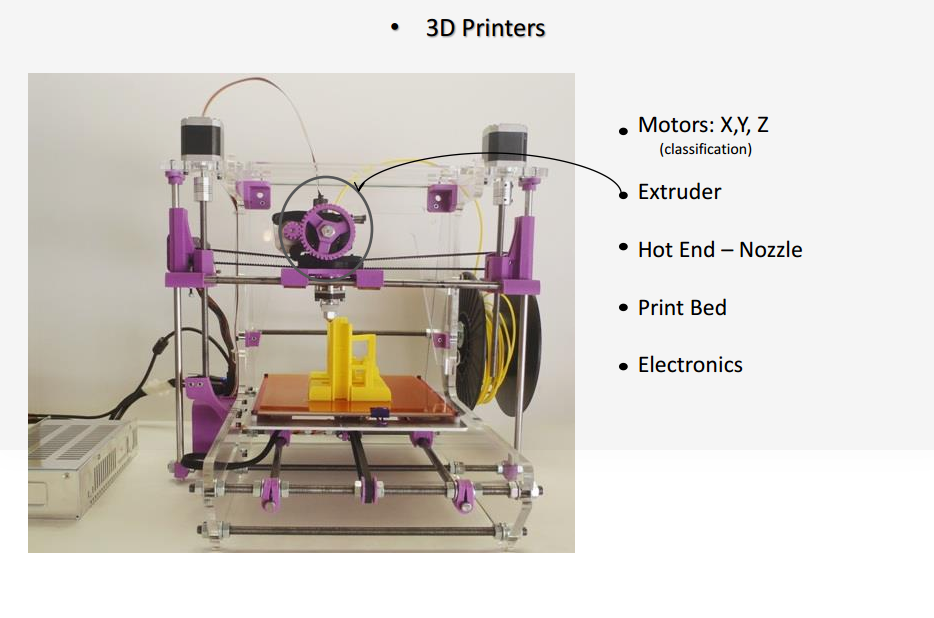

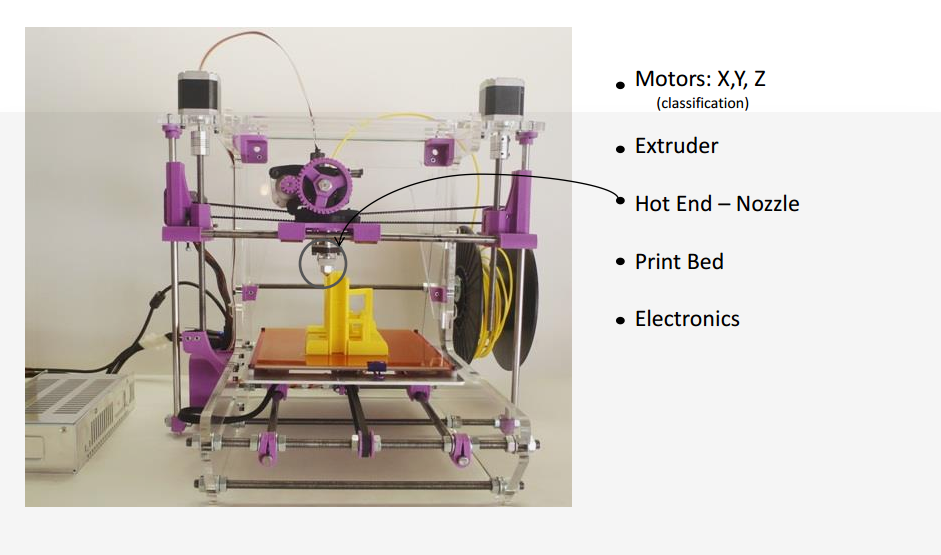

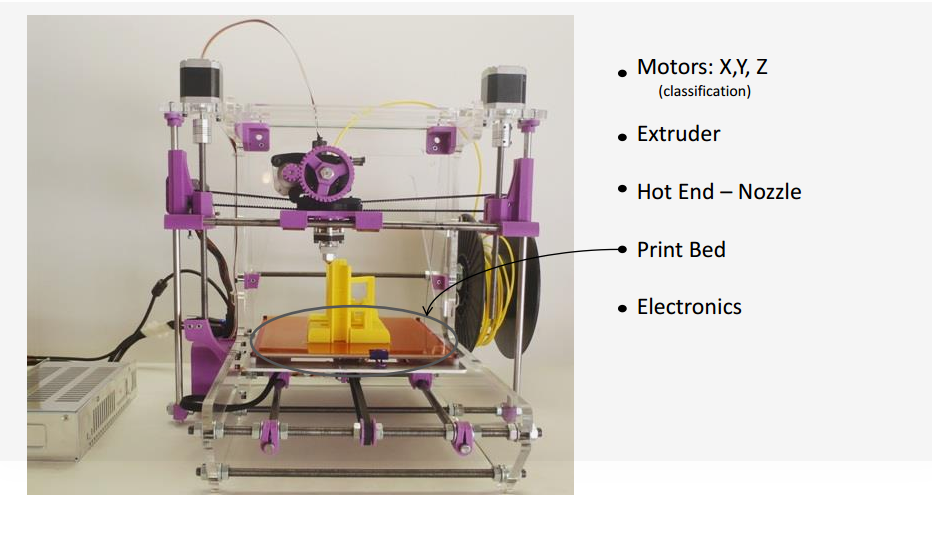

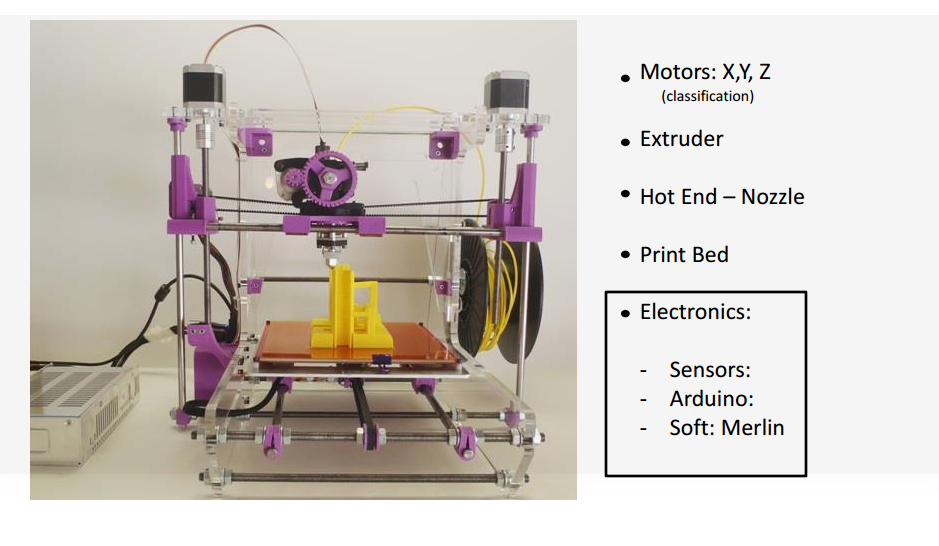

Introduccion 3D Printer

A 3D printer itself is a robot, there are different configurations of robots, most common in a 3D printer is the Cartesian configuration, this configuration is present in printers like the prusa i2 / i3, makerbot and others.

There are other configurations like the delta or scara, a printer model with delta configuration is the Kossel printer, and a model with Scara configuration is the Morgan.

Cartisian vs Delta

The molten deposition model uses an additive technique, depositing the material in layers, to form the piece. A plastic or metal filament initially stored in rolls is introduced into a nozzle. The nozzle is above the melting temperature of the material and can be moved in three axes electronically controlled. The nozzle is usually driven by stepping motors or servomotors. The part is constructed of thin strands of material that solidify immediately after exiting the nozzle.

Here we can see which are the advantages and disadvantages between the delta and Cartesian configuration.

Advantage

Disadvantage

Parts of 3D Printer

Model to Stl to g-code

Gcode web visualizer

I have created a gcode viewer using the js (ThreeJS) library, in this way we can see how to see the model by using a web browser, the model that is loaded is part of the extruder of a Prusa I2 printer.

https://github.com/nanusefue/ThreeJS-Visualizer-gcode

Test the design rules for your printer(s) (group project)

(group project)

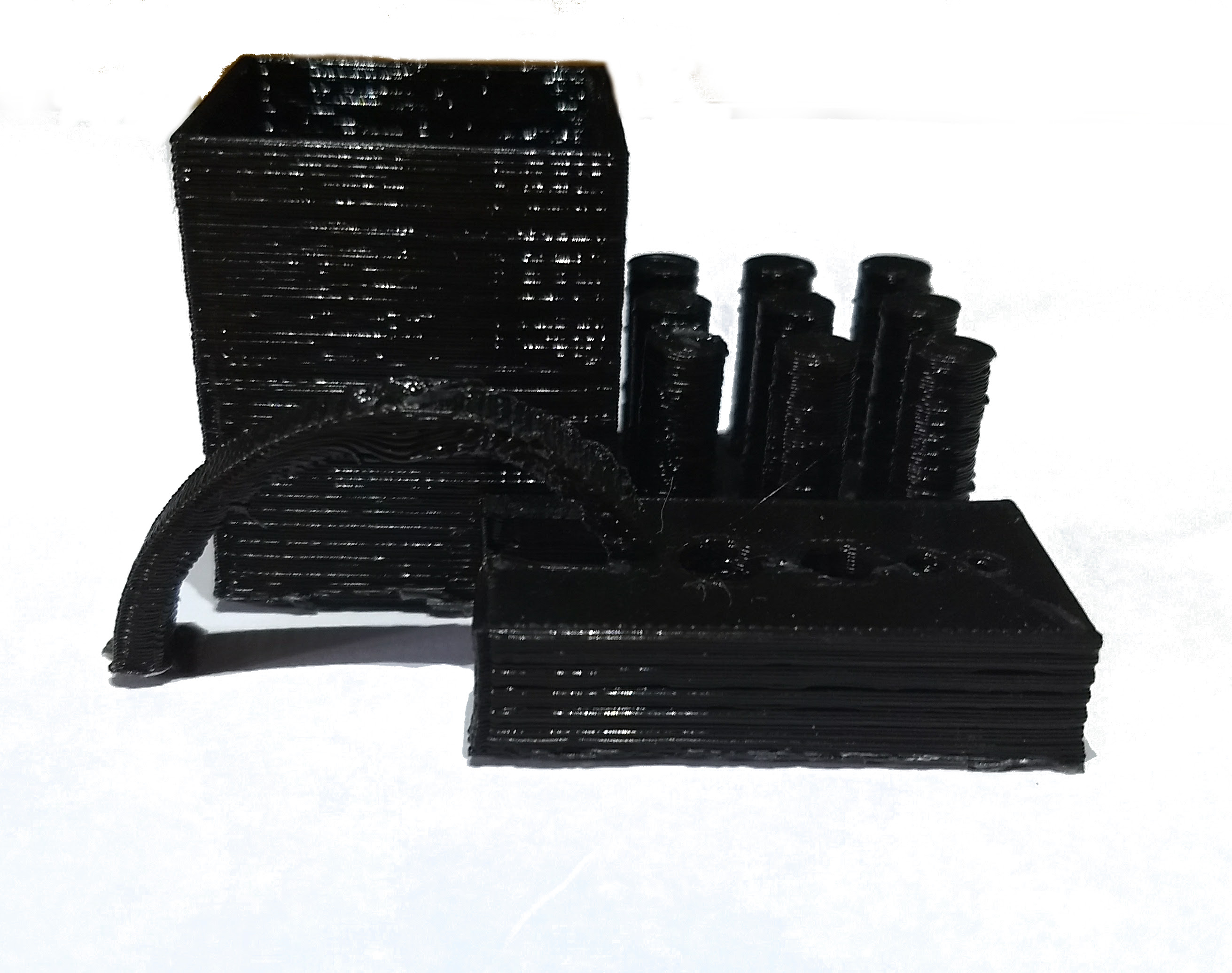

For the design test for the 3D printers I decided to use thingivers and look for a test that I found complete enough to see what resolution I could get from my printer.

I have used a model called "Torture Test", since it tests the quality, calibration, configuration parameters, etc. of our printer.

the characteristics to make this impression are the following:

- Print Setting

- Nozzel: 0.4mm

- Layer height: 0.3mm

- Perimeters: 3

- Solid Layers: 3

- Infill: 25%

- Fill Pattern: Rectilinear

- Filament Setting

- Diameter: 1.75mm

- Temperature

- Extruder:

- First layer: 205

- Other layer:180

- Bed:

- First layer:60

- Other layer:60

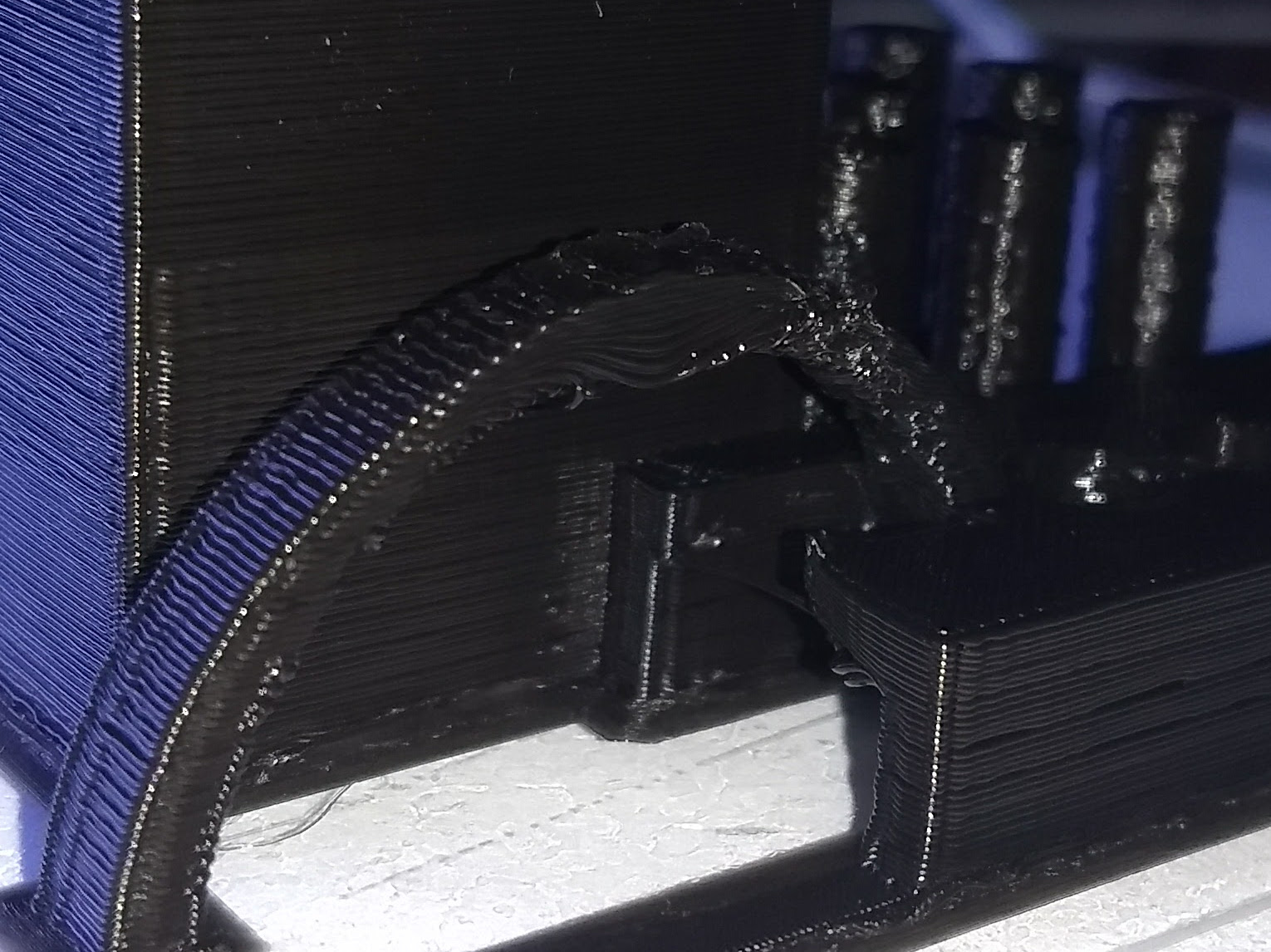

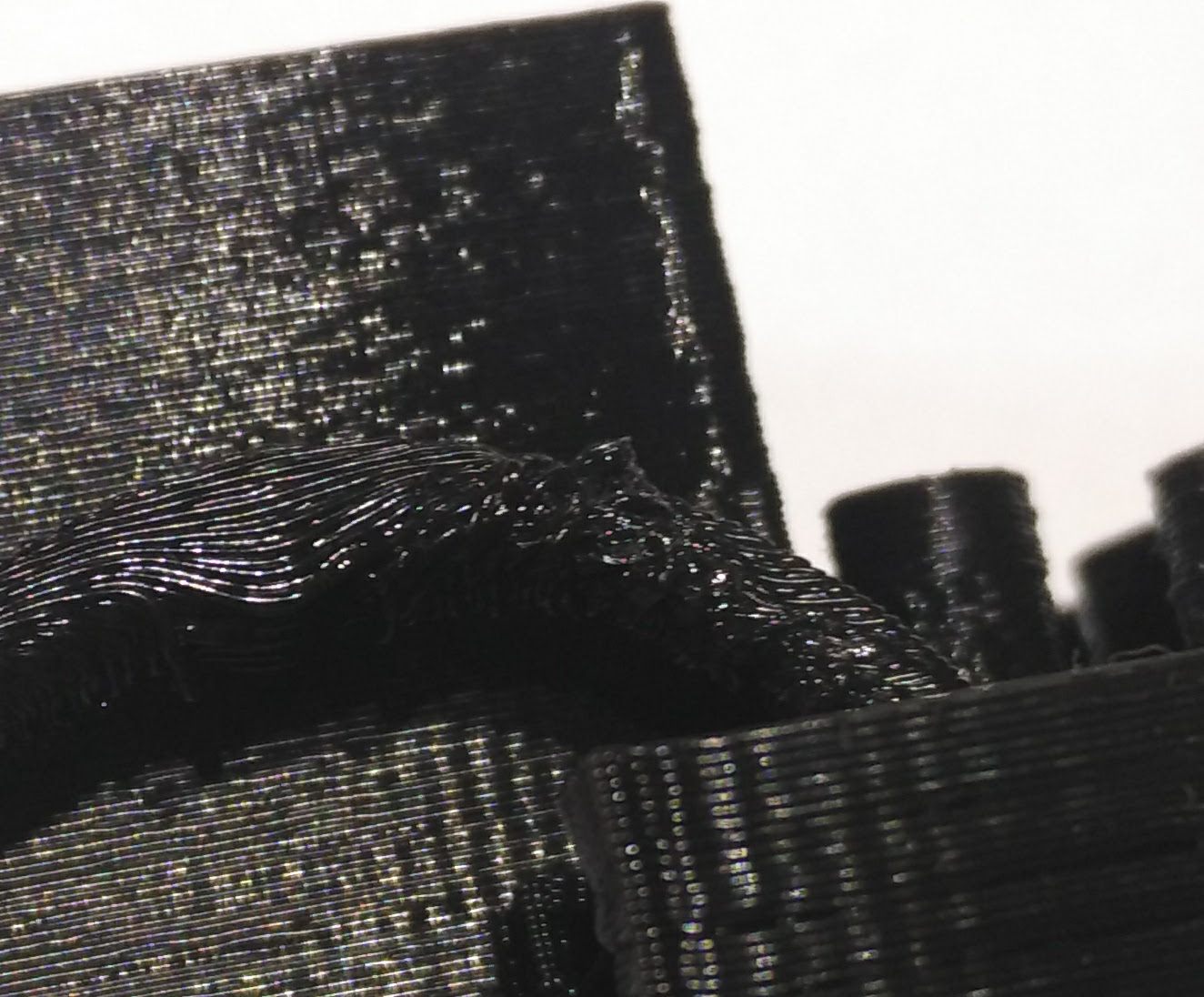

Here we can see that when you make the bridge, it does not finish correctly, this could be solved if we add a fan that cools the plastic in a faster way.

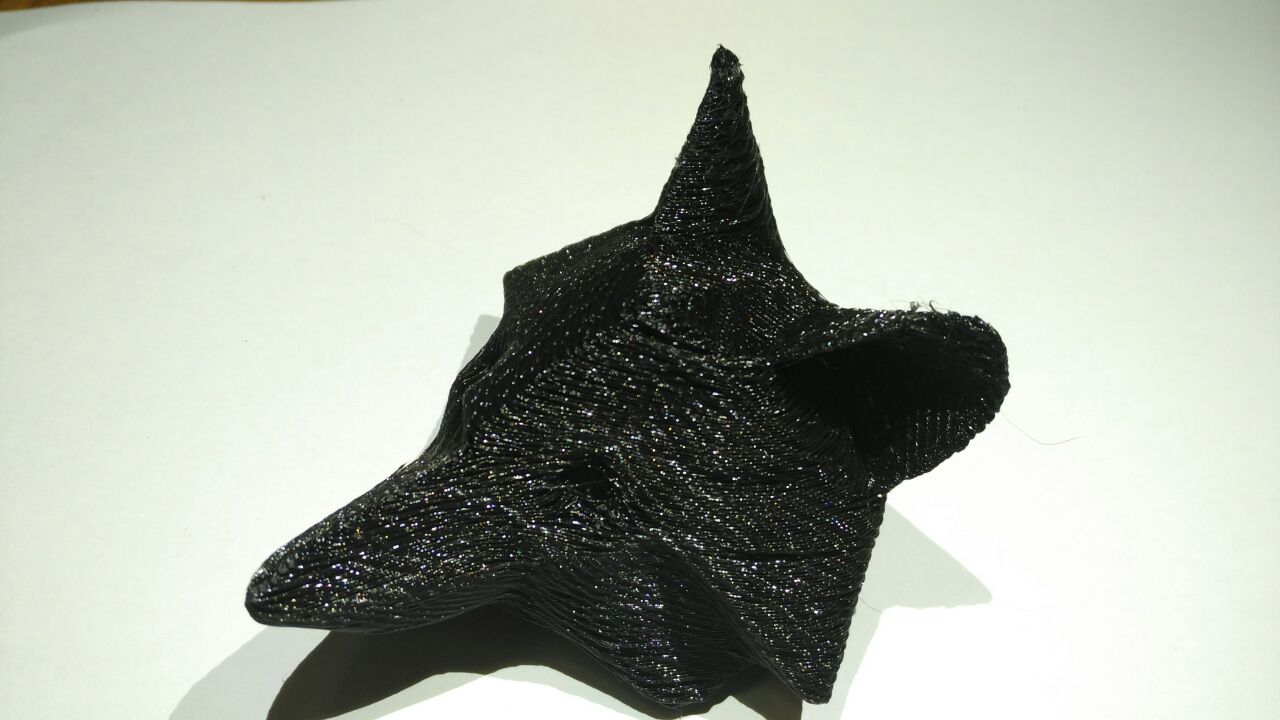

Design and 3D print an object.

(small, few cm) that could not be made subtractively

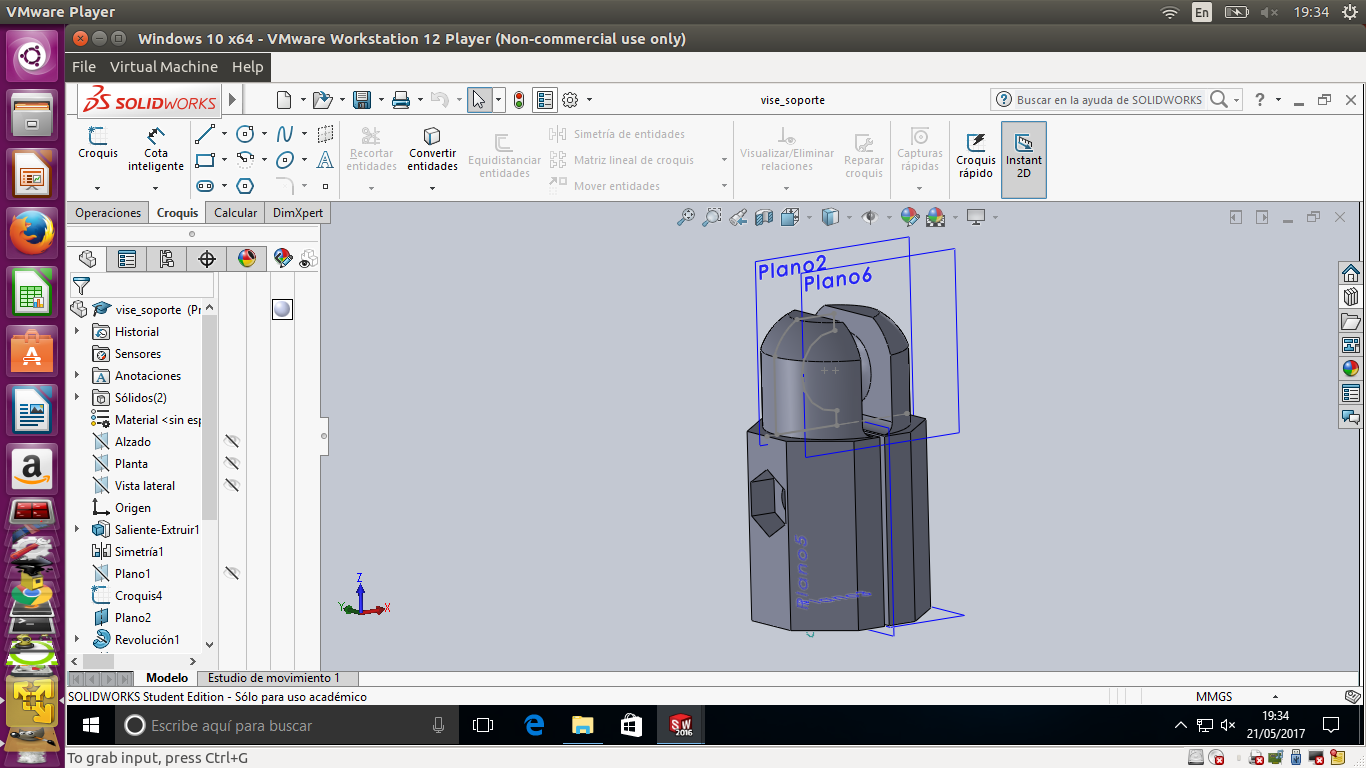

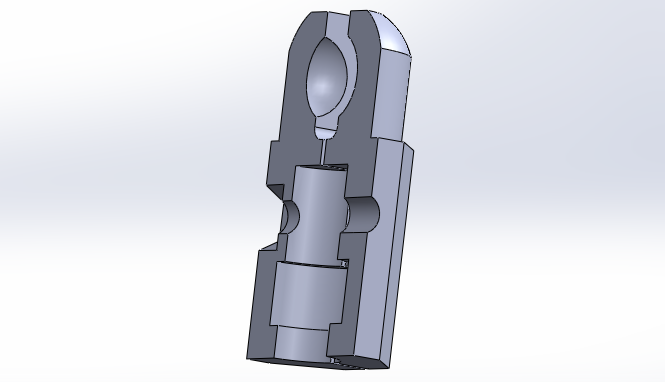

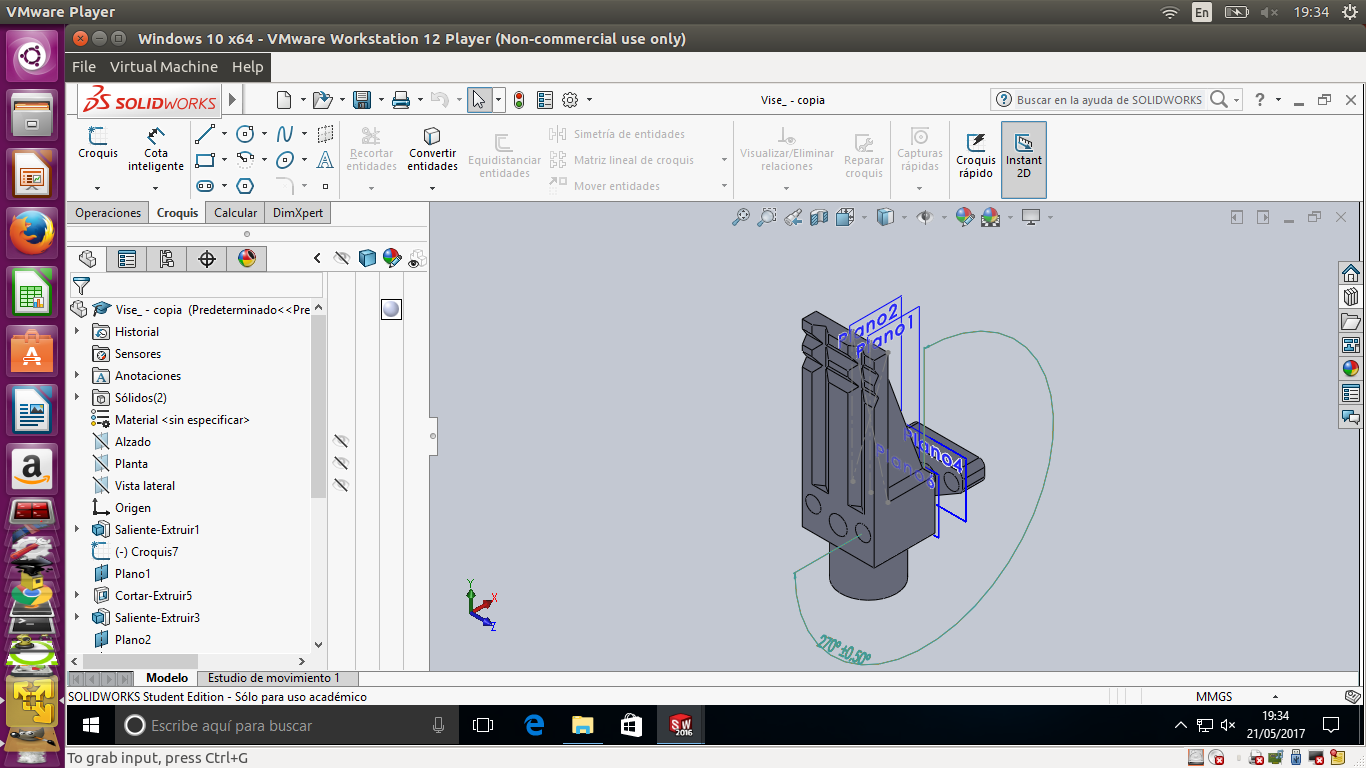

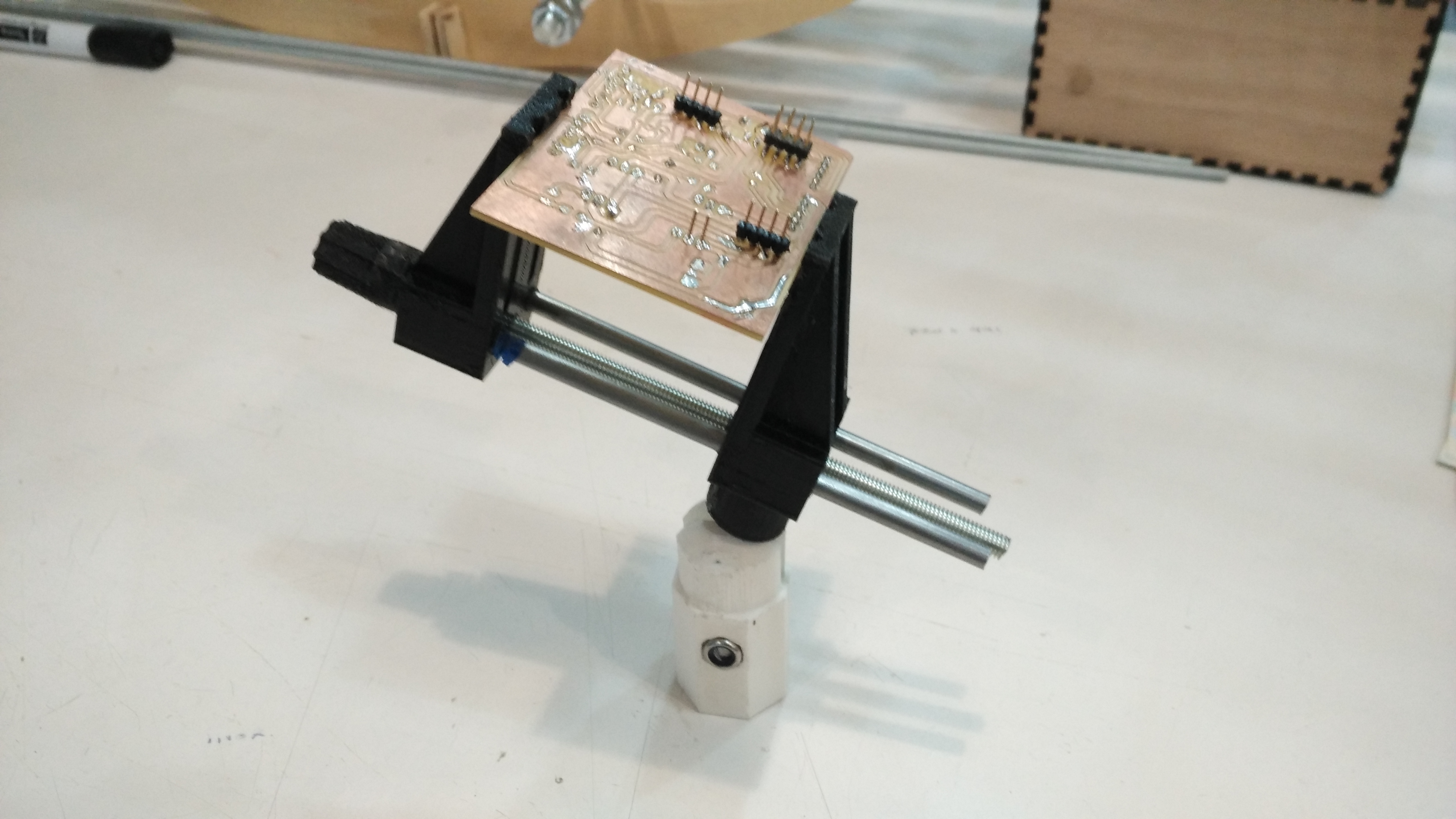

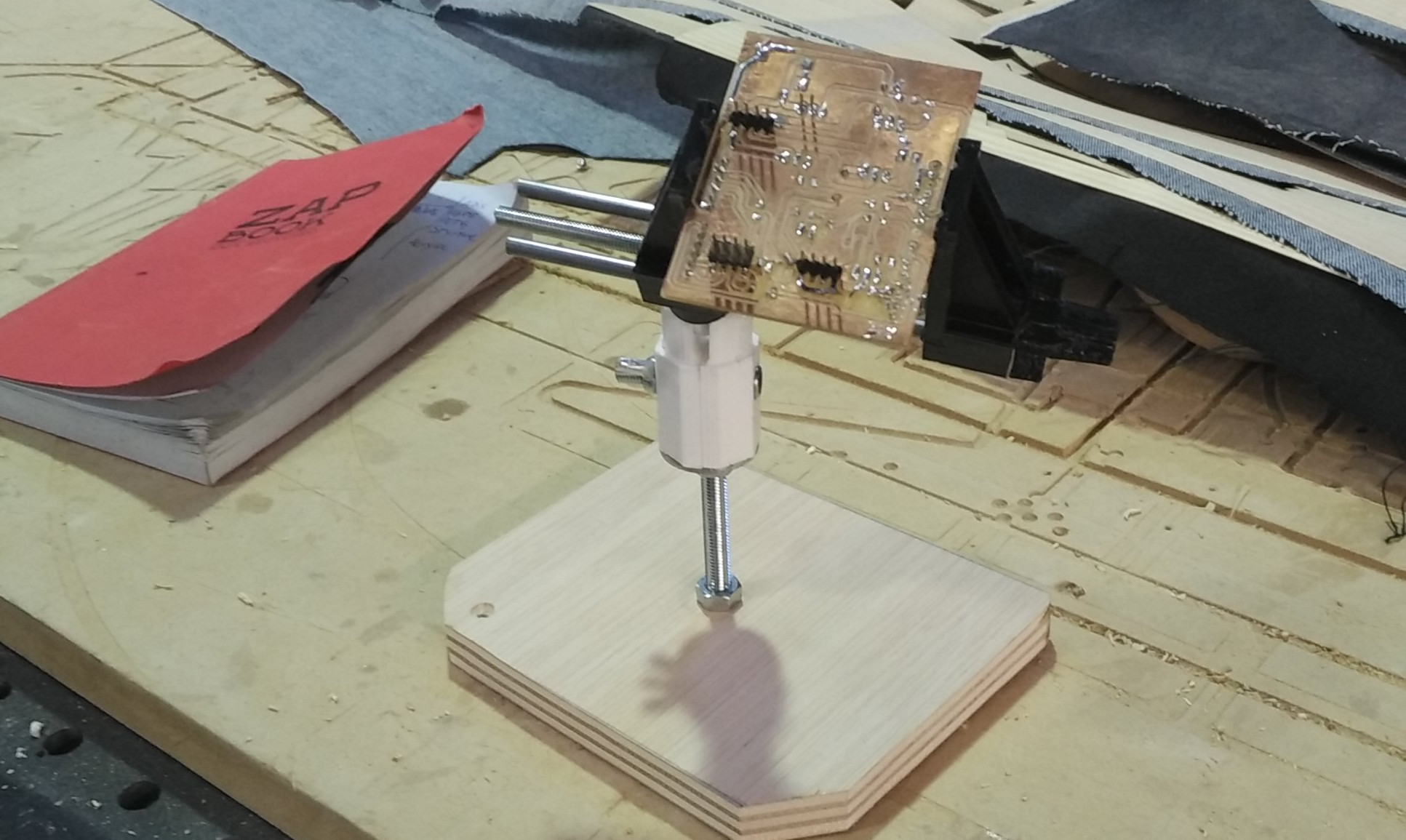

I decided to design a 3D printer version of a plate holder using solidworks, some of the piezad are simple and could be done using the material subtraction system, but I decided that I could create a small project creating almost all the parts for a 3D printer.

Model to replicate

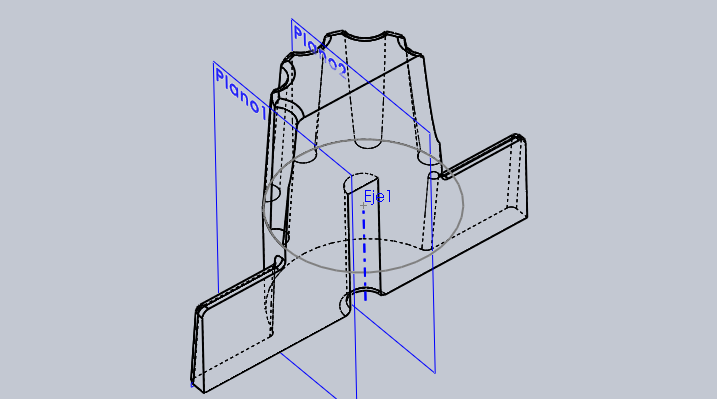

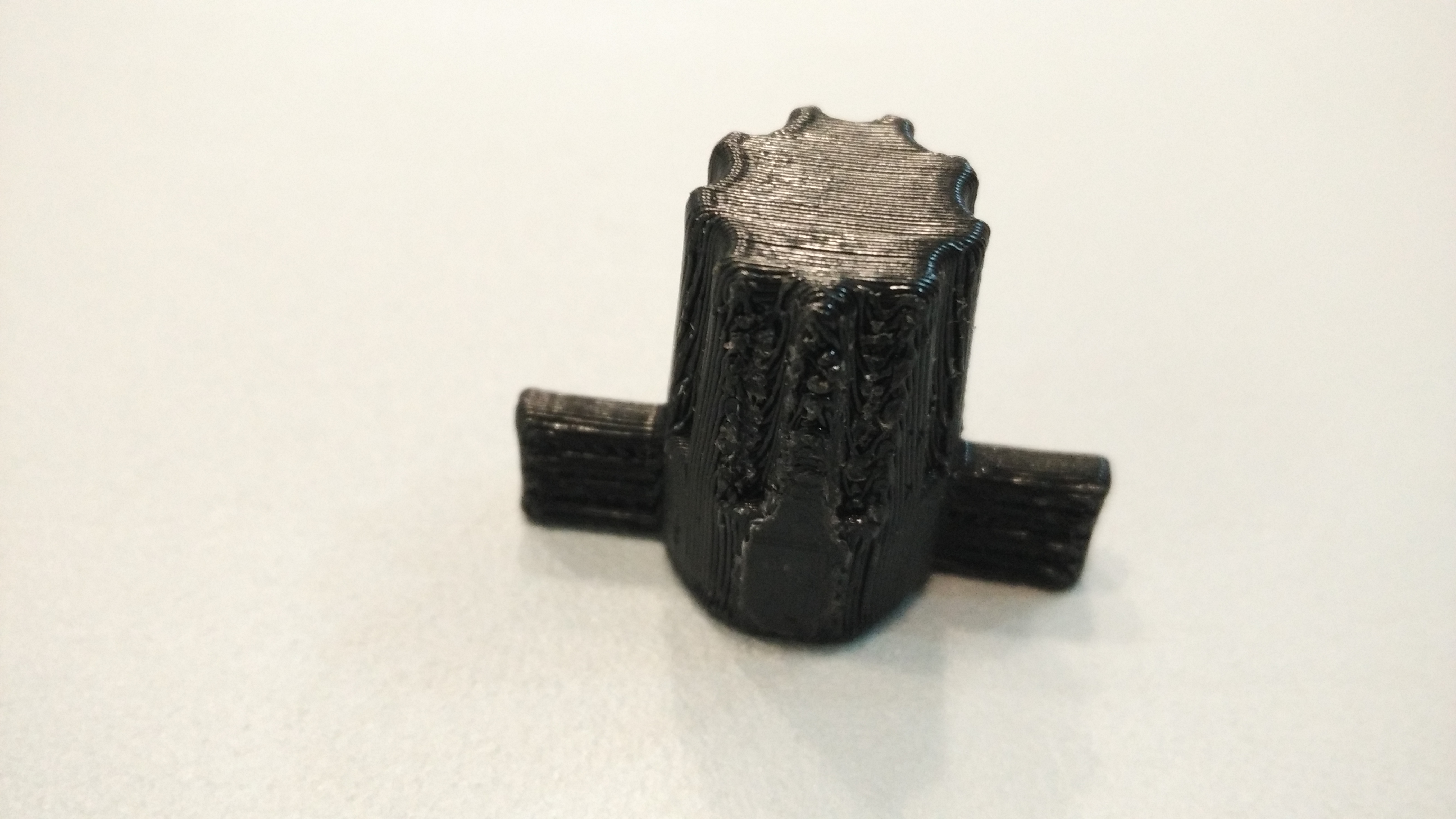

I decided to replicate this model since once finished it would be something that could give one used in lab, exiten several pieces that could not be made subtractively since it has several cavities in different planes of the piece, there is the possibility of performing it by parts and finish joining the parts to get the final piece, below we can see two pieces that could not be done subtractively, because of the complexity of the same in different planes and like this, we can see a cut in solidworks to see the internal complexity.

Details for 3d pieces

Final printer

3D scan an object

(and optionally print it)

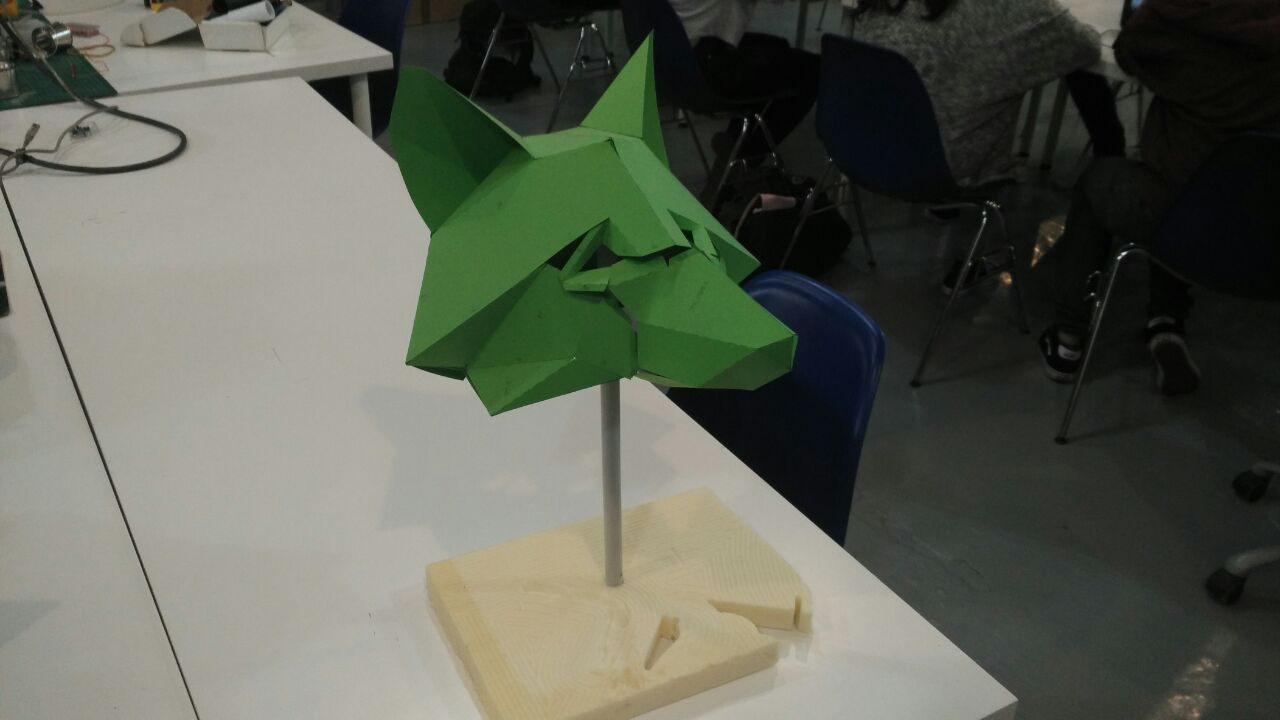

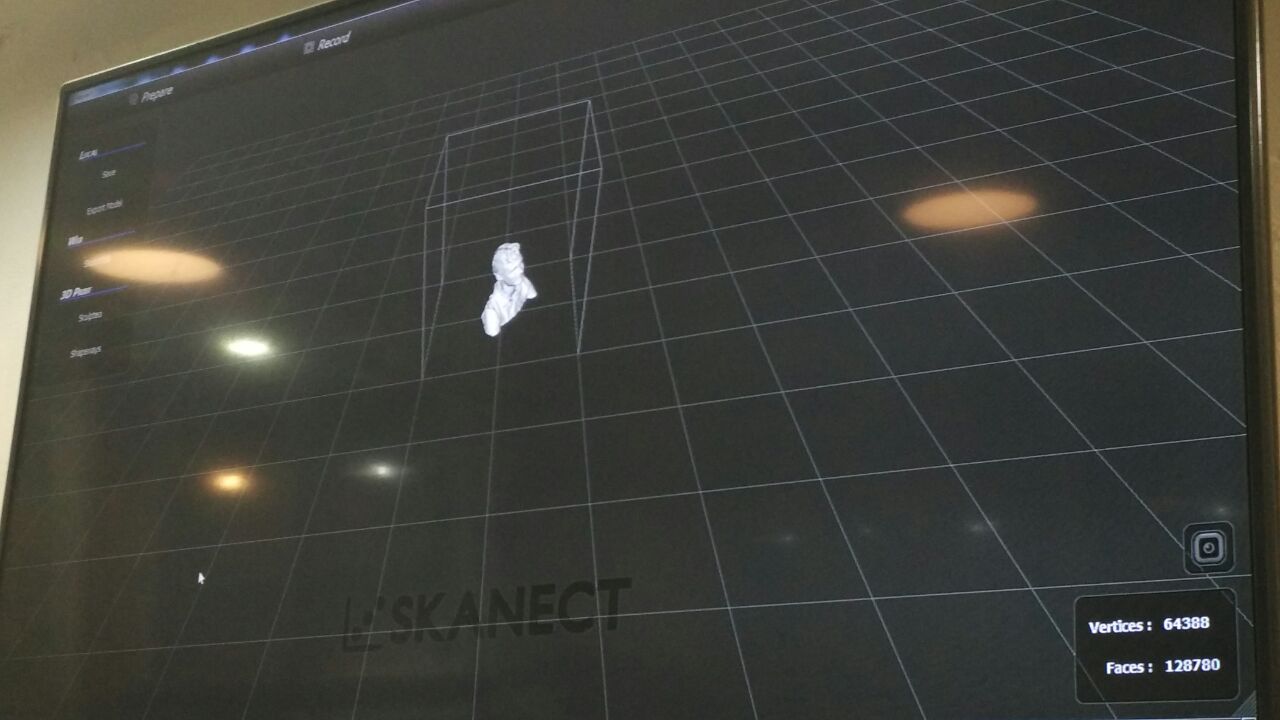

For the 3D scan I decided to choose a mask of fox, so that the hiding works better I have placed it on a stage, and thus to be able to scan it better. There are several methods for scanning objects in 3D such as:

- Laser and webcam

- Kinectis

Prepare objeto to Scan

Objeto before Scan

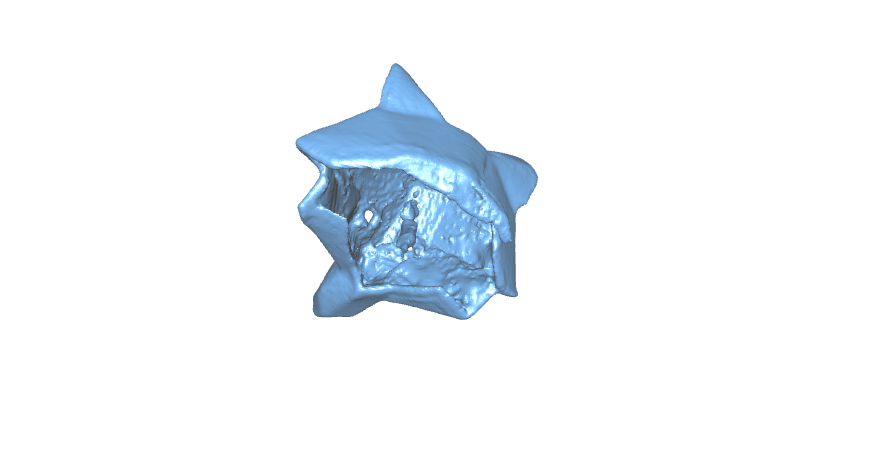

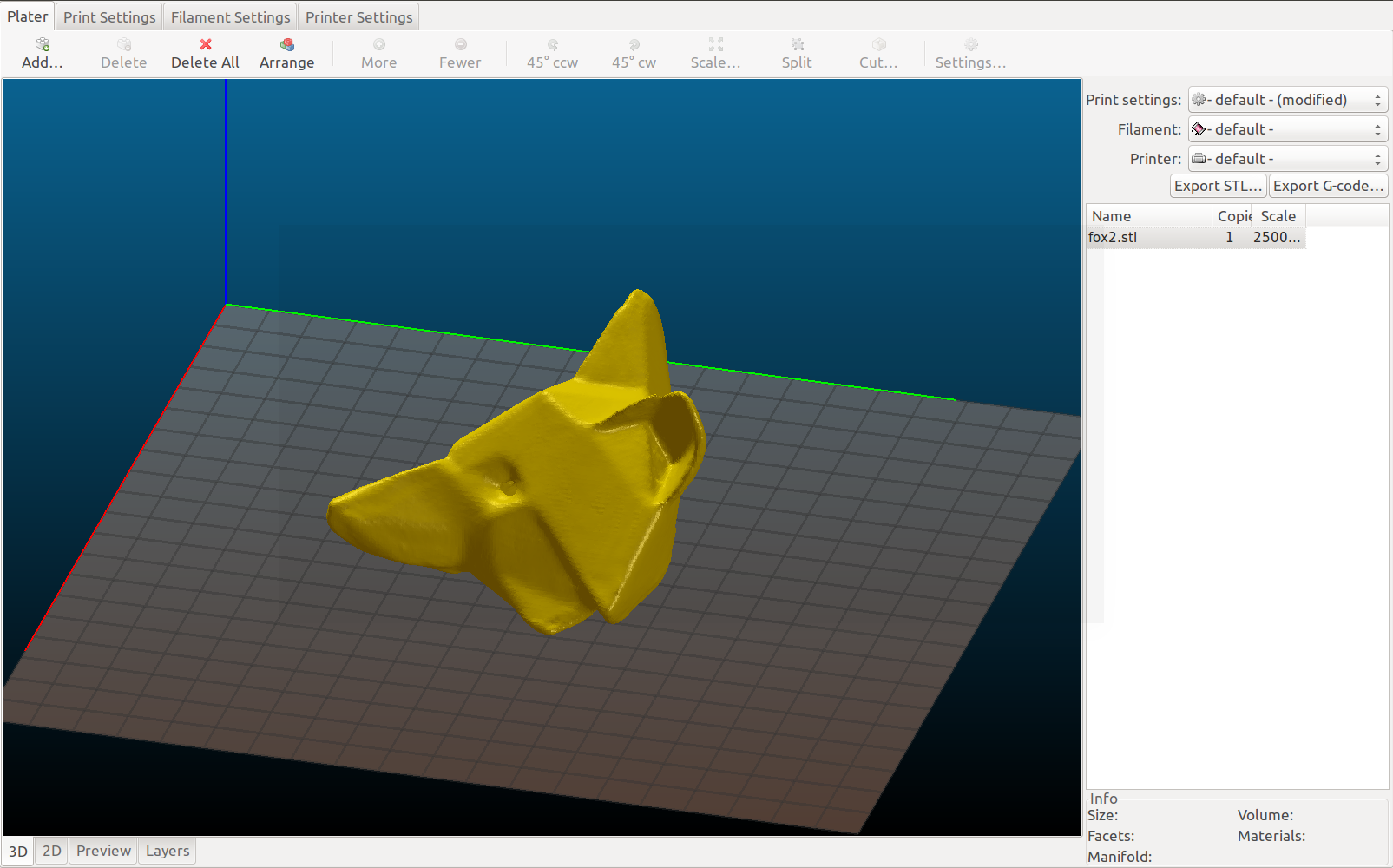

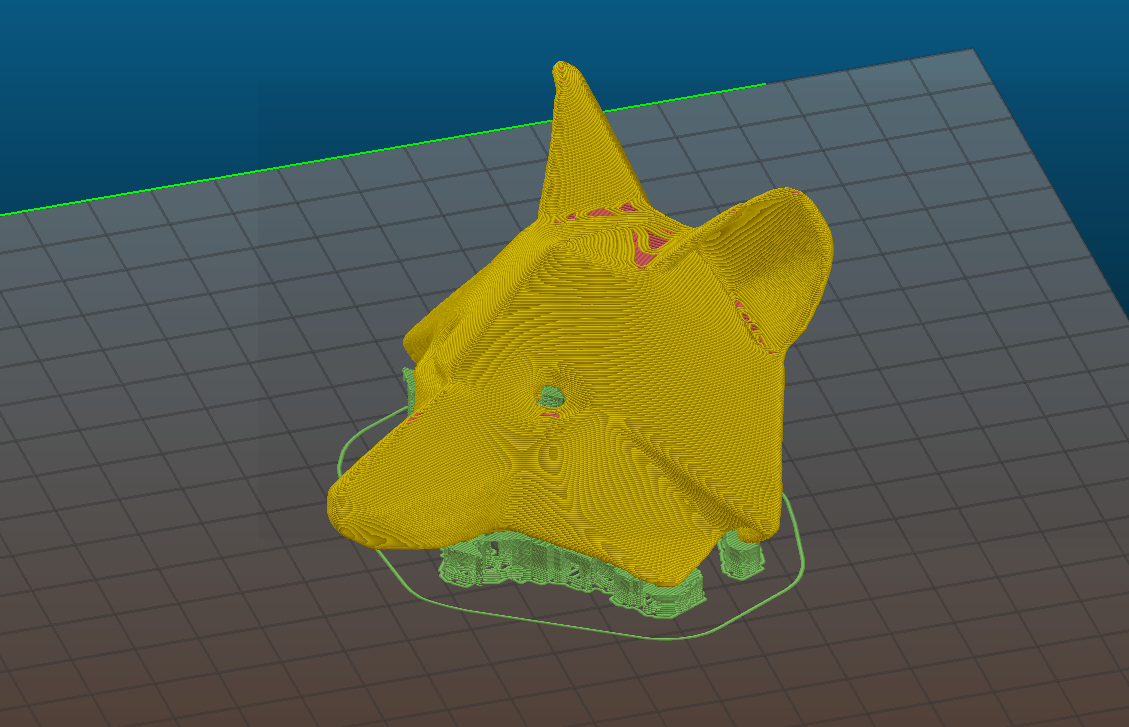

Slic3r for 3D object

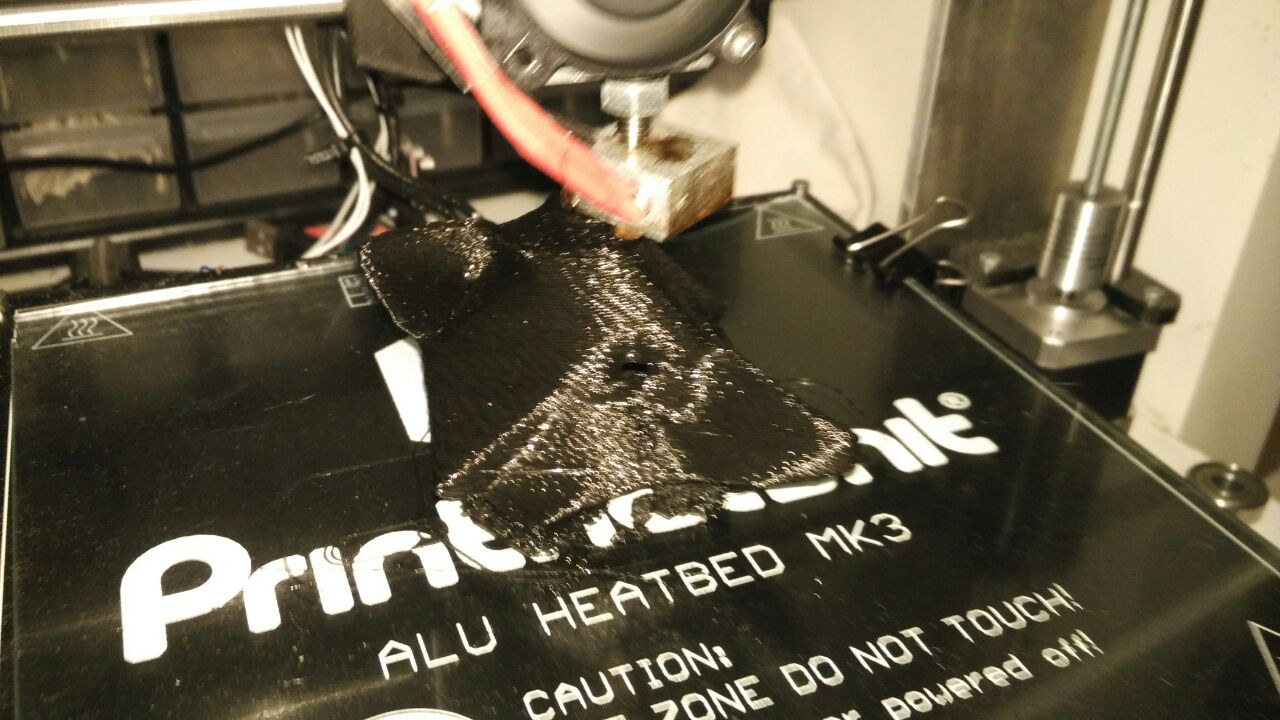

Printer 3D scan object (Prusa I3) and support material after printer

Final result