Week no. 14

Composites :

- read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it

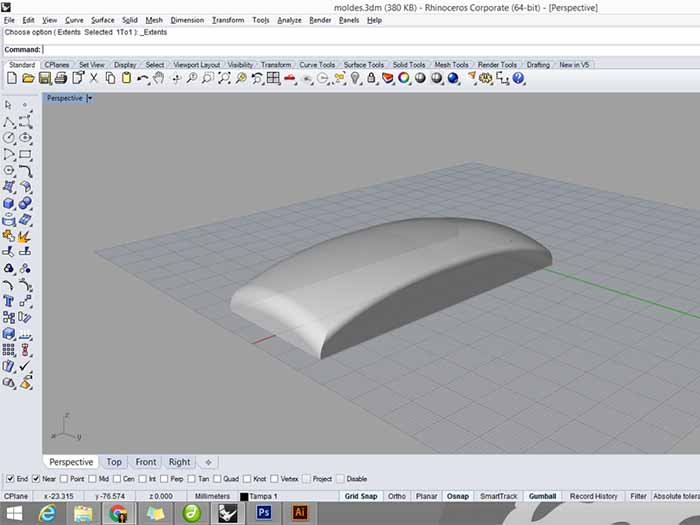

Design a 3D Mold

This week I thought I might would make and alternative for my previous cover for my brake light, but this time

with resin and fiberglass:

Started by designing the mold, for that I used Rhino:

Fabricate the 3D Mold

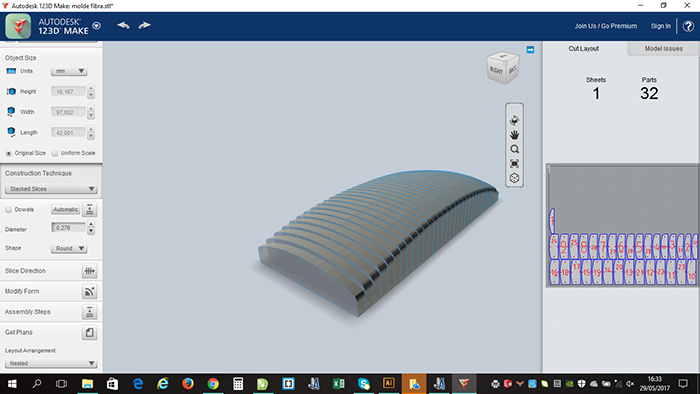

Then I exported the Rhino model to an stl file and imported the stl to Autodesk 123D Make.

In this program you can choose different construction techniques for each object.

First you choose a manufacturing technique where you can defin your work units, material size and thickness (3mm plywood).

Next you need to define your object size and construction technique, in this case I choosed the stacked slices technique,

and choosed the slice direction that I thought was better. You can see in real time the preview in the cut layout

and how many sheets will you spent and

how many parts will you need to build your model.

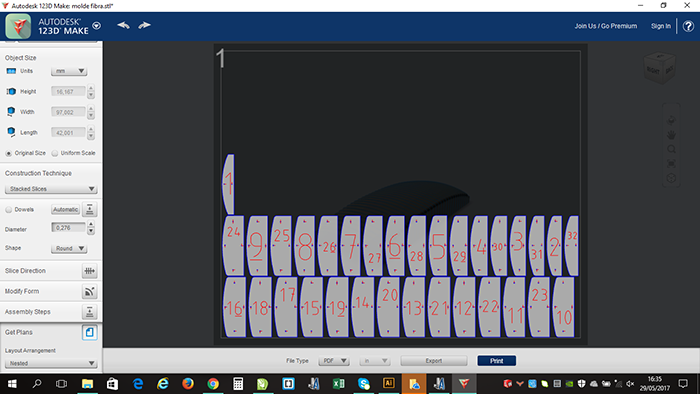

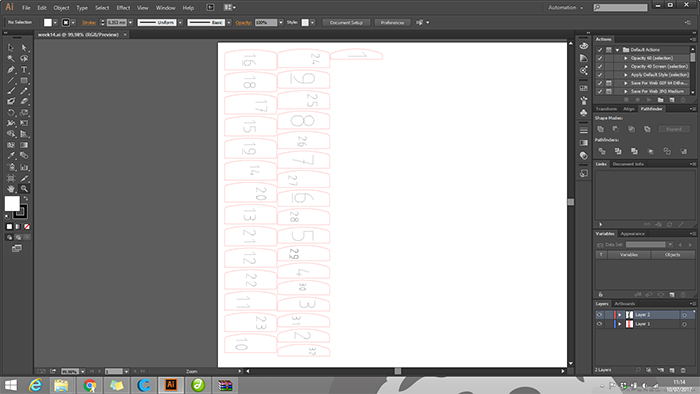

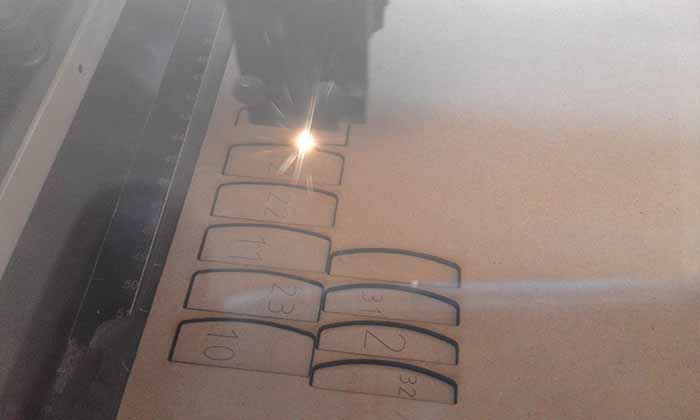

After this pushed the get plans button and exported a pdf file with the model plans (with the numbers) to guide me

trough the construction, opened the file in illustrator, set the parameters to cut and engrave the 3mm plywood on the laser cutter machine.

Next, and following the numbers engraved on the pieces, I did the assembly and fixed the pieces

with two mdf blocks and a clip.

To fix all the pieces together I brushed a generous layer of wood glue all around the piece.White glue becomes transparent

after drying.The glue allows the pieces to be all together and creates a uniform layer around the piece!

I let it dry for like an hour or less. And my mold is ready!

Produce the Fiber Composite Part

Materials Used:

-

I used the CLR Epoxy Resin with the CLF Hardener, Resin and Hardner in 100:47 ratio.(Guide);

-

Peel ply and release film;

-

2 fiberglass layers;

-

Plywood mold;

-

Scale;

-

Vaccum bag.

First I started with a layer of release film and peel ply, next 2 layer of fiberglass and resin and another

layer of release film and peel ply. After all the layers are piled, I used the vaccum bag with the vacuum pump:

I took the vacuum off after 24 hours, and this was the final result:

You can download my files here.