Week no. 12

Molding and Casting:

- design a 3D mold, machine it, and use it to cast parts

Designing the 3D Mold

This week I did somenthing that I've never tryed before, carving a block of wax, molding and casting.

To do this i first begun by designing a piece, in this case it would be a cover for my brake ligh,

i thought i'd better make something for my final project.

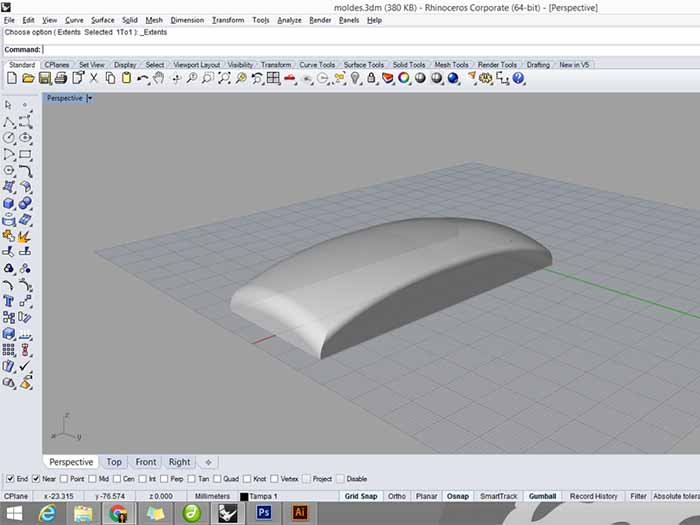

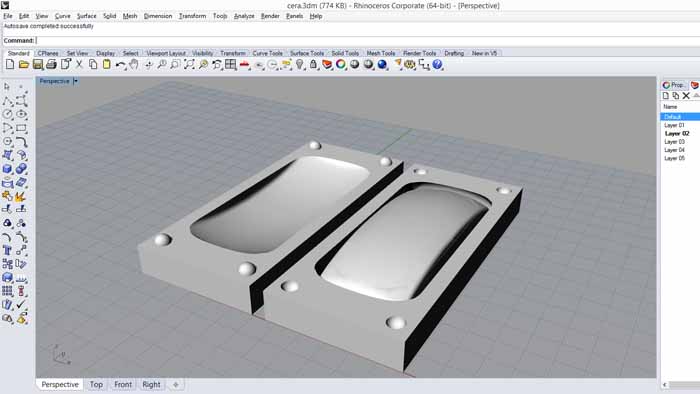

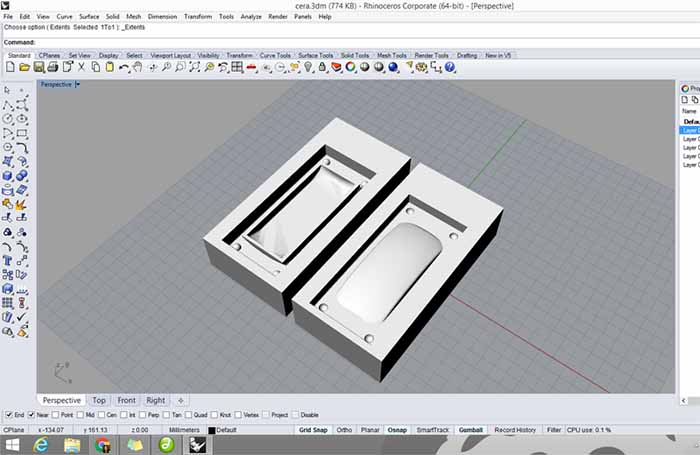

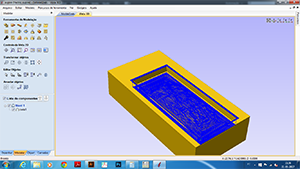

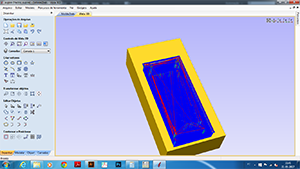

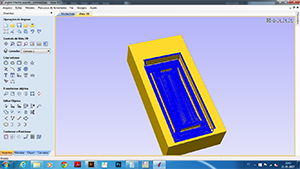

Started by designing the mold, for that I used Rhino:

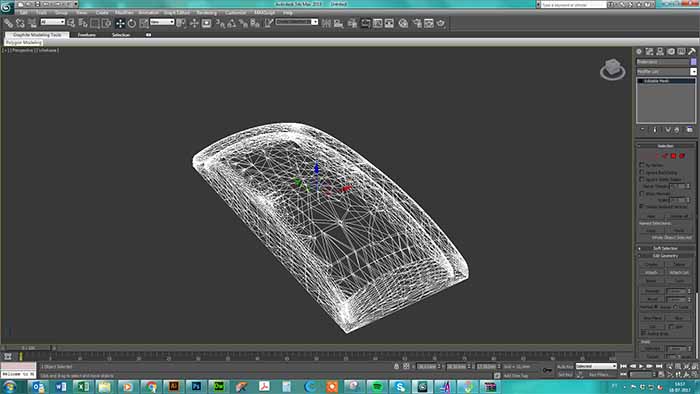

For de mold part I exported my model in stl. and opened it in 3D Studio Max.

First I did a weld command to have sure that my mesh wasn't broken, with holes or something like that.

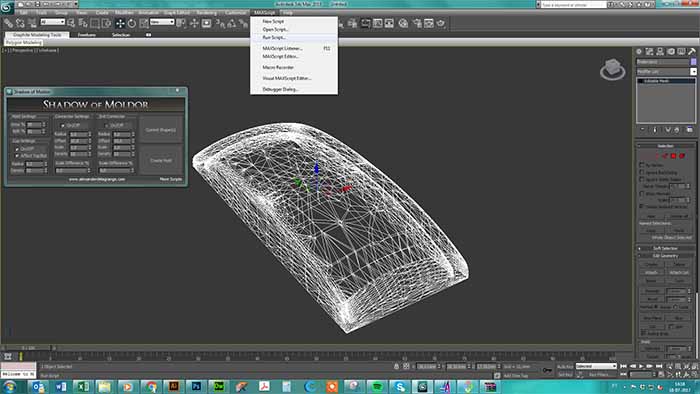

And then I runned a script called Shadow of Moldor the quickly creates a mold from a piece.

You just to click on Convert shape and Create mold.

This scrip creates in just a few seconds the mold of our pieces with connectors so each part can fit perfectly

whith each other if you print it or in my case if you cast it, you can choose also to

create a filling channel.

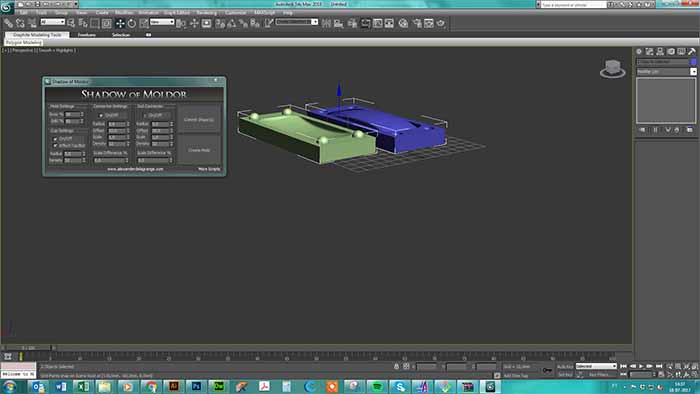

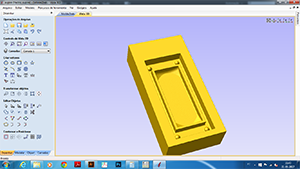

After my mold was done I export the two pieces in stl. And opened again on rhino.

Here I designed two blocks with the wax dimensions and fit my mold into the blocks.

In way to have the right dimensions to the milling process.

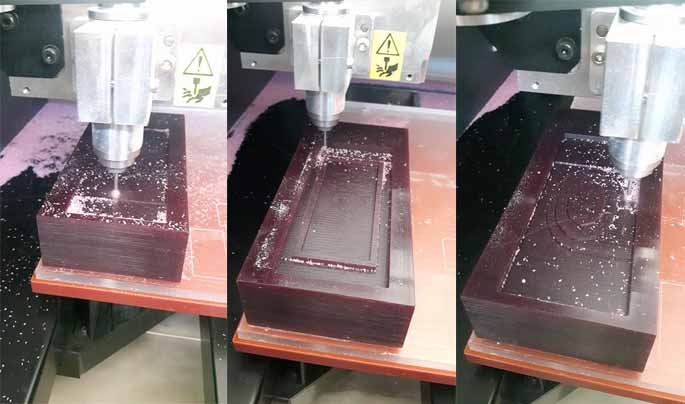

Machining the Mold:

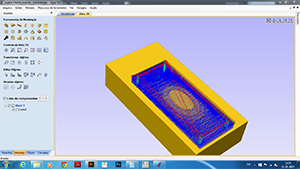

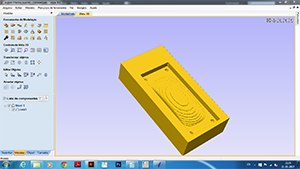

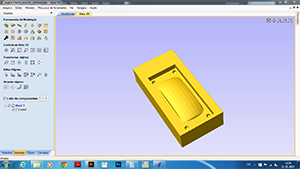

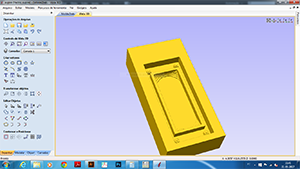

With the negative blocks i went into Aspire to print directly to the machine with the parameters i thought were best.

Just needed to set the Z on the modela V-Panel (zero out the Z axis to the top of the wax).

The paths that were generated as you can be seen in the images below.

The milling...

It was my first time doing this and i was really surprised with the finish cut result!

Casting

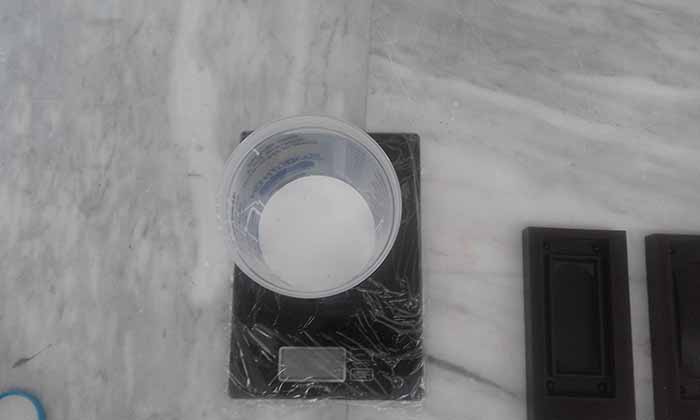

For the casting we used Mold Max 30 from Smooth-On :

First problem : Open the bucket! Needed to see this first : https://www.smooth-on.com/support/faq/115/

The Mold Max is a tin-cured silicone rubber compound, its a 10A to 1B mix (to weight):

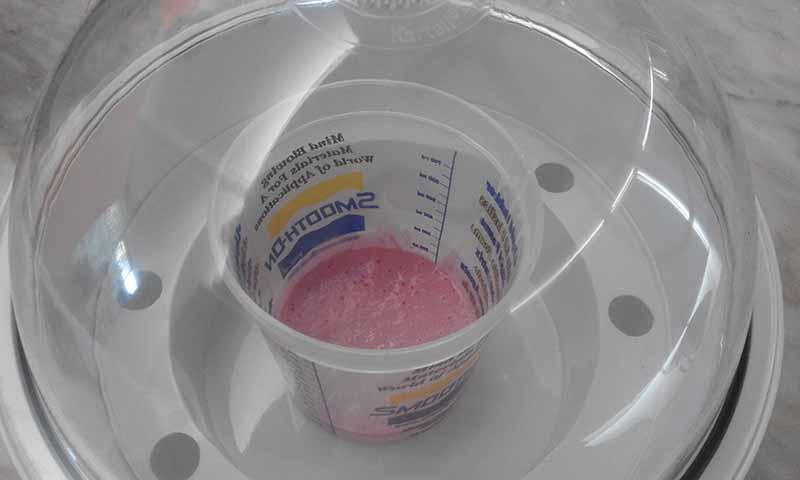

After all was well mixed i put the cup into the Vacuum degassing chamber.

After mix the silicone and pour into the wax mold - this will form a NEGATIVE mold with POSITIVE space:

After waiting overnight, I removed the rubber mold from the wax mold.

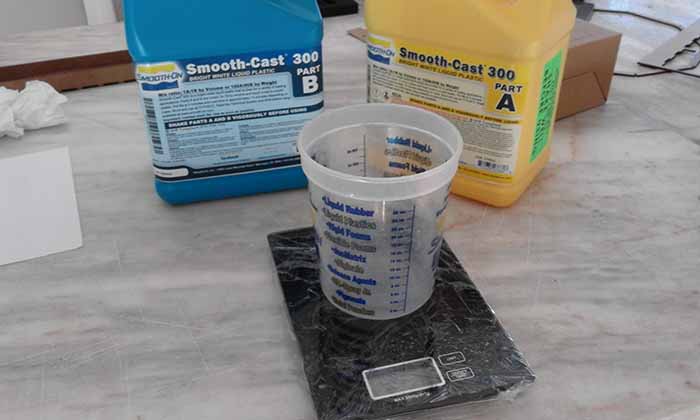

For the cast I used the Smooth-Cast 300 that are bright white and virtually bubble free.

Vacuum degassing is not necessary, 1:1 mix ratio by volume.

This plastic cures really fast in 7 - 10 minutes!

And the final result:

I think it went really well for the first time:

You can have all my files here.