This week we got the following tasks:

/*

Using a Pololu A4988 or StepStick Stepper Motor Driver with FabScan-Shield.

*/

#define MS_PIN A5 //HIGH for 16 microstepping, LOW for no microstepping

#define EN1_PIN 2

#define STEP1_PIN 3

#define DIR1_PIN 4

#define EN2_PIN 5

#define STEP2_PIN 6

#define DIR2_PIN 7

#define EN3_PIN 11

#define STEP3_PIN 12

#define DIR3_PIN 13

#define EN4_PIN A0

#define STEP4_PIN A1

#define DIR4_PIN A2

int x;

boolean done;

int curDIRx;

String forwards;

String backwards;

String left;

String right;

String down;

String up;

int pumpx;

void setup()

{

pinMode(EN1_PIN, OUTPUT);

pinMode(EN2_PIN, OUTPUT);

pinMode(EN3_PIN, OUTPUT);

pinMode(EN4_PIN, OUTPUT);

digitalWrite(EN1_PIN, HIGH); //deactivate driver (LOW active)

digitalWrite(EN2_PIN, HIGH); //deactivate driver (LOW active)

digitalWrite(EN3_PIN, HIGH); //deactivate driver (LOW active)

digitalWrite(EN4_PIN, HIGH); //deactivate driver (LOW active)

pinMode(DIR1_PIN, OUTPUT);

pinMode(DIR2_PIN, OUTPUT);

pinMode(DIR3_PIN, OUTPUT);

pinMode(DIR4_PIN, OUTPUT);

digitalWrite(DIR1_PIN, LOW); //LOW or HIGH

digitalWrite(DIR2_PIN, LOW); //LOW or HIGH

digitalWrite(DIR3_PIN, LOW); //LOW or HIGH

digitalWrite(DIR4_PIN, LOW); //LOW or HIGH

pinMode(STEP1_PIN, OUTPUT);

pinMode(STEP2_PIN, OUTPUT);

pinMode(STEP3_PIN, OUTPUT);

pinMode(STEP4_PIN, OUTPUT);

digitalWrite(STEP1_PIN, LOW);

digitalWrite(STEP2_PIN, LOW);

digitalWrite(STEP3_PIN, LOW);

digitalWrite(STEP4_PIN, LOW);

pinMode(MS_PIN, OUTPUT);

digitalWrite(MS_PIN, LOW); //no microstepping

x = 0;

done = false;

forwards = "FRONT";

backwards = "BACK";

down = "down";

up = "up";

left = "left";

right = "right";

pumpx = 0;

}

void setDirX(String dir)

{

if (dir == "FRONT") {

digitalWrite(DIR2_PIN, 0); //LOW or HIGH

digitalWrite(DIR3_PIN, 0); //LOW or HIGH

} else {

digitalWrite(DIR2_PIN, 1); //LOW or HIGH

digitalWrite(DIR3_PIN, 1); //LOW or HIGH

}

}

void moveX(String dir, int n) //maximum 6000 back and forth from front or back position

{

while (x < n) {

digitalWrite(EN2_PIN, LOW); //activate motor

digitalWrite(EN3_PIN, LOW); //activate motor

setDirX(dir);

digitalWrite(STEP2_PIN, HIGH);

digitalWrite(STEP3_PIN, HIGH);

delay(2);

digitalWrite(STEP2_PIN, LOW);

digitalWrite(STEP3_PIN, LOW);

delay(2);

digitalWrite(EN2_PIN, HIGH); //deactivate motor

digitalWrite(EN3_PIN, HIGH); //deactivate motor

x++;

}

x = 0;

}

void setDirY(String dir)

{

if (dir == "left") {

digitalWrite(DIR1_PIN, 0); //LOW or HIGH

} else {

digitalWrite(DIR1_PIN, 1); //LOW or HIGH

}

}

void moveY(String dir, int n)

{

while (x < n) {

digitalWrite(EN1_PIN, LOW); //activate motor

setDirY(dir);

digitalWrite(STEP1_PIN, HIGH);

delay(2);

digitalWrite(STEP1_PIN, LOW);

delay(2);

digitalWrite(EN1_PIN, HIGH); //deactivate motor

x++;

}

x = 0;

}

void setDirPump(String dir)

{

if (dir == "down") {

digitalWrite(DIR4_PIN, 1);

} else {

digitalWrite(DIR4_PIN, 0);

}

}

void resetPump(){

while (pumpx > 0) {

digitalWrite(EN4_PIN, LOW); //activate motor

setDirPump(up);

digitalWrite(STEP4_PIN, HIGH);

delay(2);

digitalWrite(STEP4_PIN, LOW);

delay(2);

digitalWrite(EN4_PIN, HIGH); //deactivate motor

pumpx--;

}

}

void pumpIt(String dir, int n) //maximum 3000 units up or down

{

if(pumpx == n){

resetPump();

}

while (pumpx < n) {

digitalWrite(EN4_PIN, LOW); //activate motor

setDirPump(dir);

digitalWrite(STEP4_PIN, HIGH);

delay(2);

digitalWrite(STEP4_PIN, LOW);

delay(2);

digitalWrite(EN4_PIN, HIGH); //deactivate motor

pumpx++;

}

}

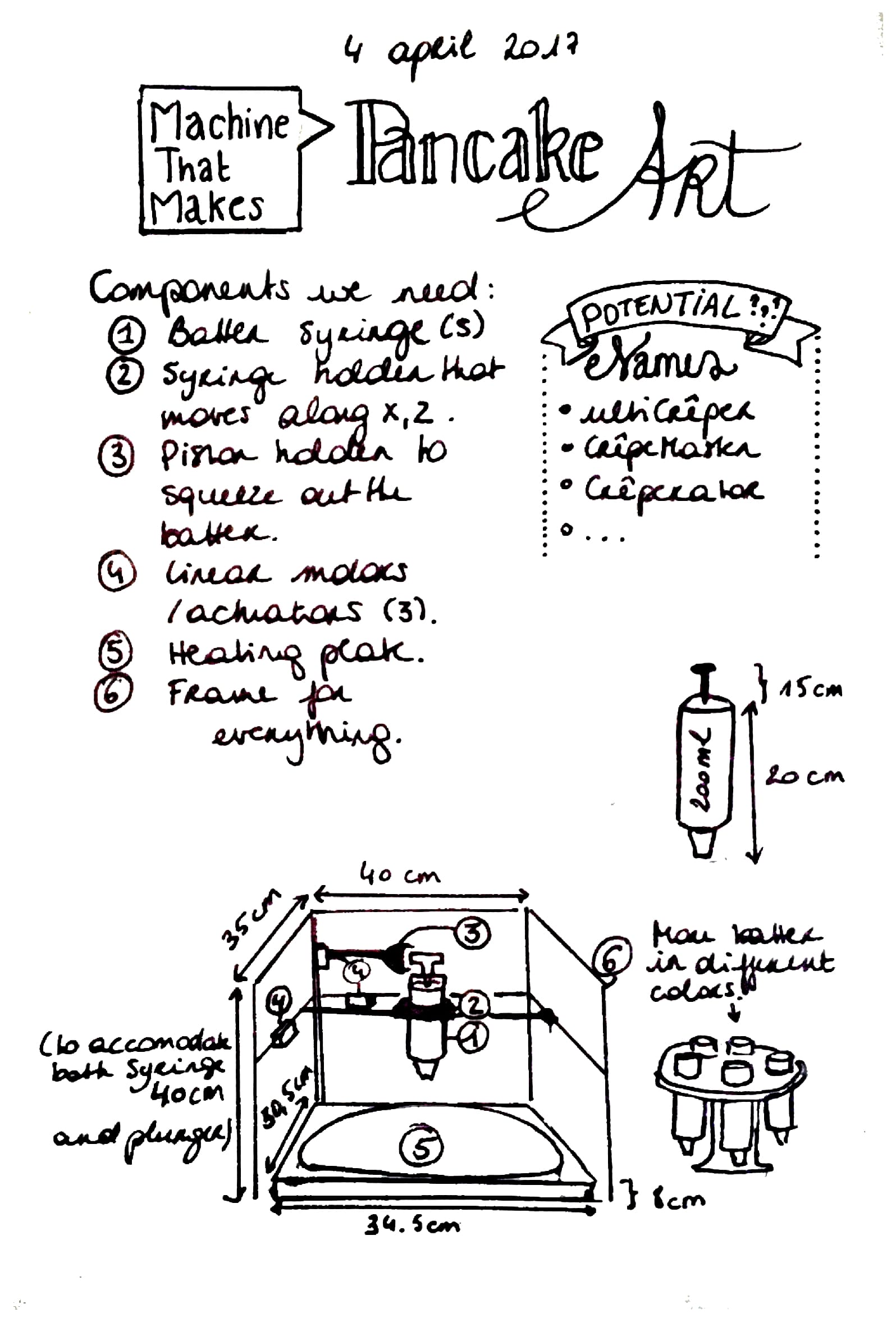

void drawPat(int a) { //One Unit is 4000 by 4.5cm distance to the plate edge

moveX(forwards, a);

moveY(right, a - 500);

moveX(backwards, a - 500);

moveY(left, a - 1000);

pumpIt(down,1000);

a = a - 500;

while (a >= 1000) {

moveX(forwards, a - 500);

moveY(right, a - 500);

moveX(backwards, a - 500);

moveY(left, a - 1000);

a = a - 500;

}

}

void loop()

{

while(!done){

drawPat(4000);

done = true;

}

}