Realization

We work as geo-delocalized team splitted on 2 continents... :-) Few hours of TZ difference. So communication by skype / slack.

My role is design / milling test and Phonesavanh, as the main consumer of this board, (she will use this board in prototyping of main project) will do soldering and real application of board in real project.

To make traces we get the pinout of real Arduino, and pinout of Atmega168 - then we placed traces to deliver to good pins (we used the component that have dimentions of a shield, that permit us to align all traces and pins)

So here we are. Below is the schematic and board

One of the main challange is to avoid the dual side boards. I used 0 Ohm resistance to bypass the traces. We have 6 of them! Probably in next version we can reduce number of leds. As well we can pass to chip with integrated USB communication to simplify connections in the future.

Added maximal GND surface.

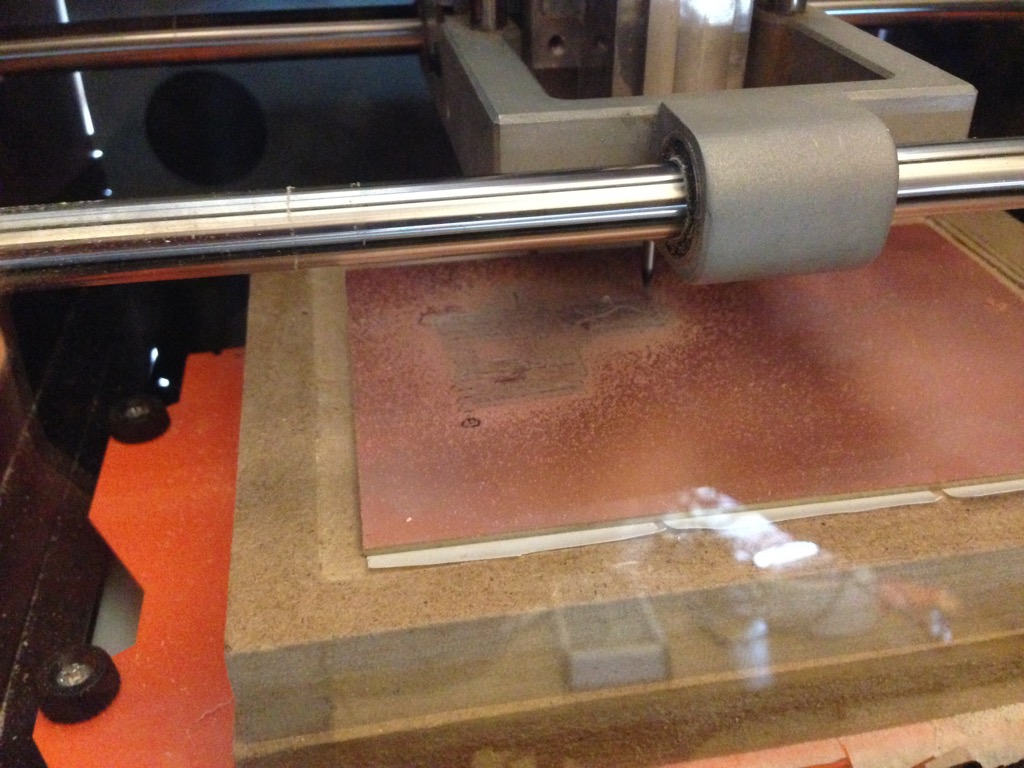

Preparation for milling

Let pass to mlling! Standard chip case does not permit to mill it simply by using the 1/64" mill. Traces betwee pins of ATMEGA chip will not be milled. There are 3 different ways to resolve it:

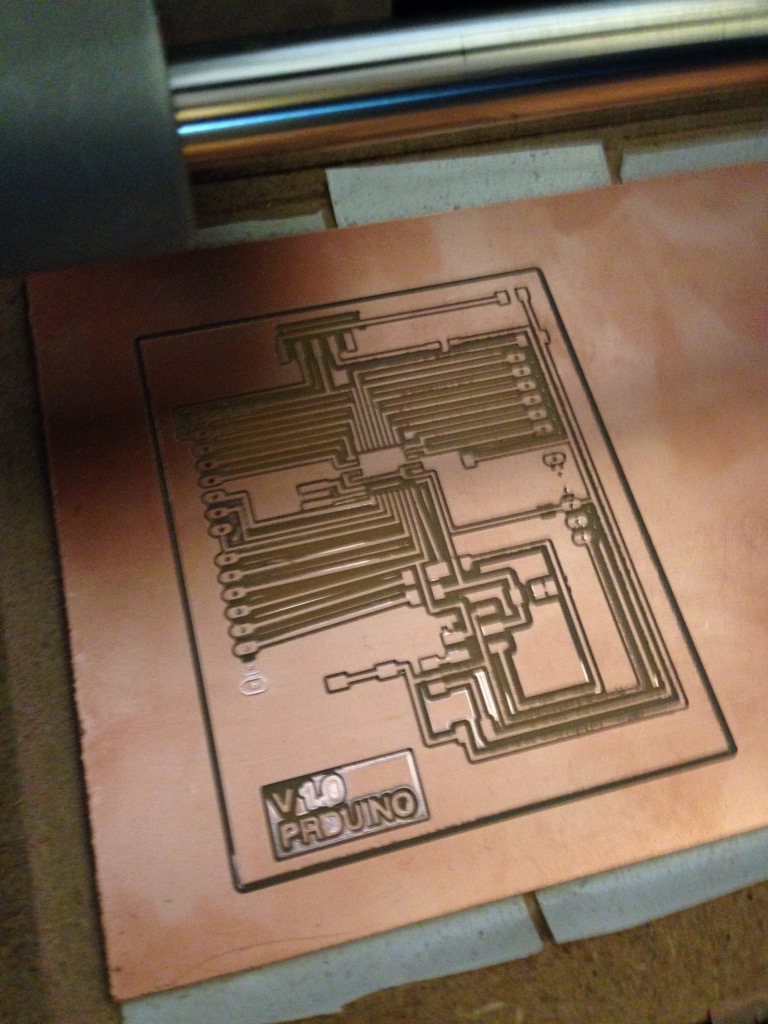

Milling

Now milling by Rolland SRM-20.

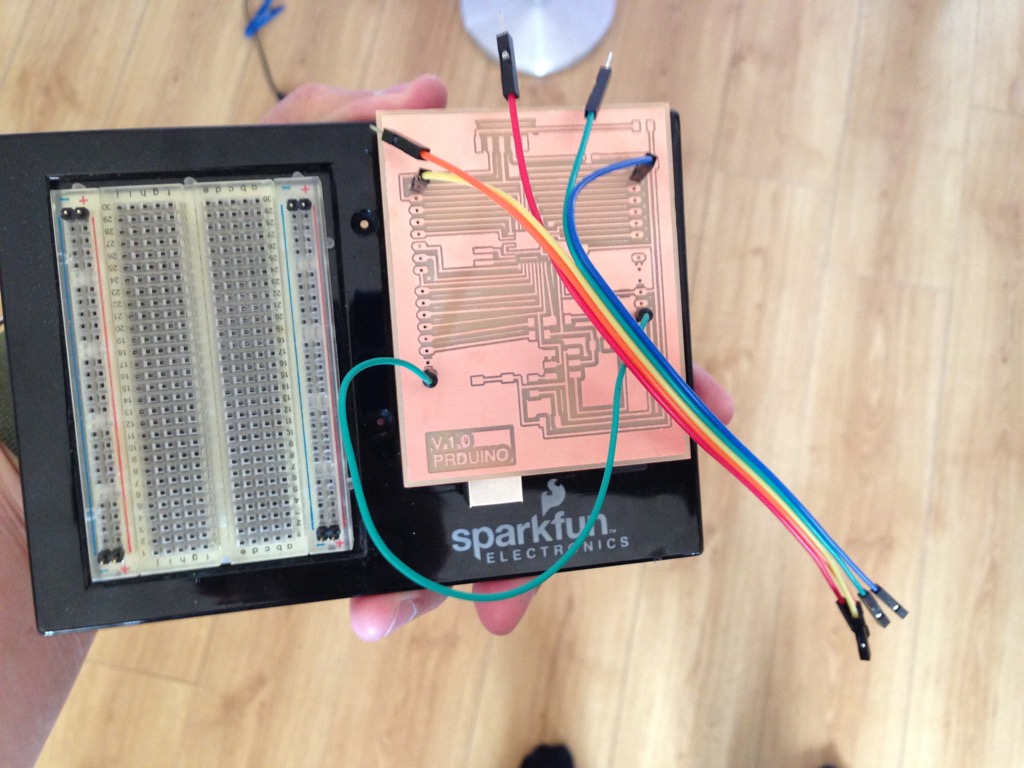

Visual control

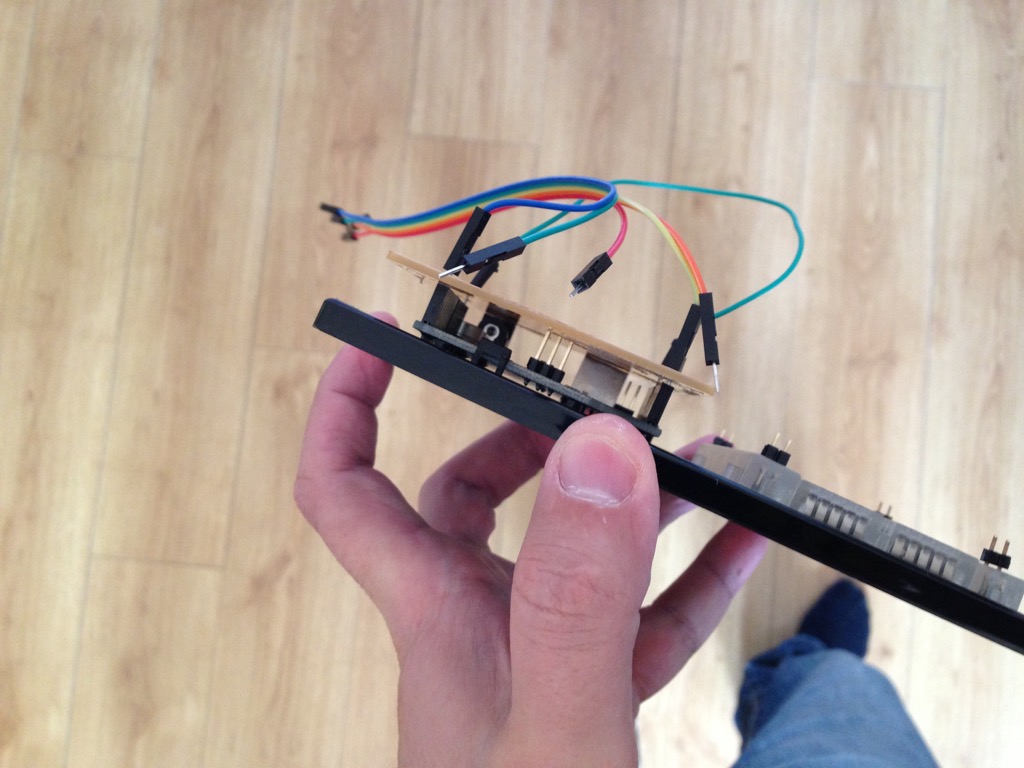

One of the goal is compatibility with Arduino UNO, so pins need to be on same physical places. Let check this out.

I used 4 pins that I put to extream holes and put the new board on the Arduino UNO board as a shield. And it match!

Now we pass to soldreing / programming and applying to real project prototyping!

Team work is awesome!