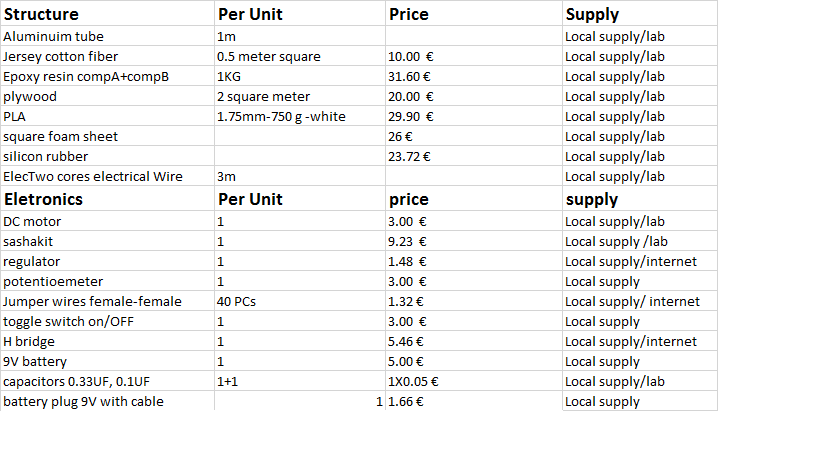

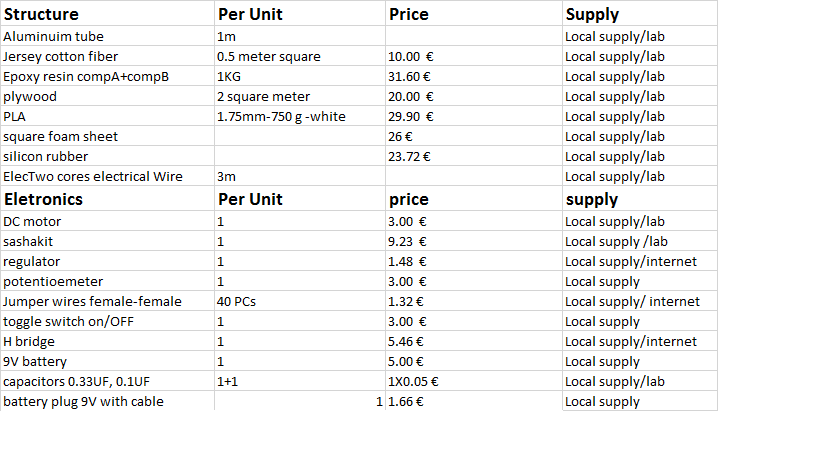

some prices on the table are approximate, almost of the components I used were found in opendot fablab and some prices may not be conform.

the olive shaker/harvester tool is around 2000mm, work similarly to traditional way used in farms by shaking olive's tree branches, motor motion in this machine is vibration. improvement and upgradings of the machine will be mentined after employing the model at hand.

here is links of some models that use power circuit that is not applied in this model and exist in the market.

https://www.alibaba.com/product-detail/Best-quality-agricultural-machinery-olive-cutting_60541645701.html https://www.alibaba.com/product-detail/Olive-Harvesting-Machine-Low-Price-olive_60059146100.html?spm=a2700.7724857.29.92.4nlKTe https://www.alibaba.com/product-detail/electric-olive-shaker-for-harvesting-nuts_708228594.html http://www.pellenc.com/agri/produits/olivion-shaker-rake/?lang=en http://www.agriexpo.online/fr/prod/lisam-srl/product-175454-20709.html http://www.evvvai.com/fr/peignes-electrique/4753-giulivo-plus-lamb-shaker-electric-to-battery-collection-olive-foxes.html https://www.kidonakis.com/en/items.php?catid=70 the tool is made with two main parts.

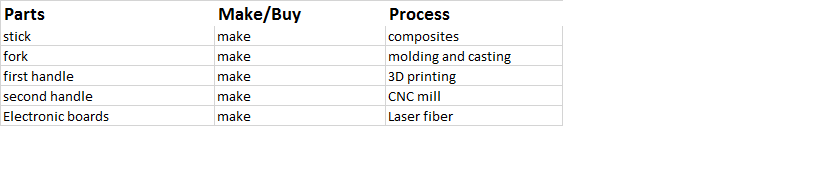

structural (the stick in cotton fiber and epoxy resin, fork in epoxy resin, first handle to house electronics in PLA, second handle in plywood to house secondary battery.

electronic circuit part developped using sashakit board and arduino IDE, dc vibrating motor, h-bridge to drive the motor, potentiometer to increase speed, toggle on/off switch, 9V battery, 5v voltage regulator.

some prices on the table are approximate, almost of the components I used were found in opendot fablab and some prices may not be conform.

sick, I need to sketch and model the stick, mill foam on shopbot, composites with cotton fiber and epoxy resin.

fork, I need to sketch model the fork, model the positive and negative molds, mill positive and negative foam molds on shopbot, prepare rubber silicon positive and negative molds, cast two mirroring fork parts.

first handle, I need to sketch and model body and base of first handle, and 3D print.

second handle, I need to sketch and mill on shopbot.

electronics circuit design, electronics production, and programming.

testing to requirtements.

tool design, specially the fork I made many designs draft before finding the final one. the stick design and material and process sere changed.

I started working on final project and use project parts to answer weekly assignement.

one week for stick design, model, and composites.

one week for fork design and model, molds modelling, preparing silicon molds result, casting two parts.

one week for modelling First handle, and second handle.

one week for electronics design, production, and programming tests

two days for finishing tasks, assembly, and test the final model.

testing the functionality to the design requirements.

ON/OFF toggle switch to start and stop the tool

map potentiometer to motor speed, choose threshold value of potentiometer in which DC motor can start working without noise.

visual motor speed.

if its tested on olive tree, it will be help to better evaluate the motor speed, battery autonomy. suggest improvement on fork design. adding features to tool, refine the design.