Computer-controlled Cutting

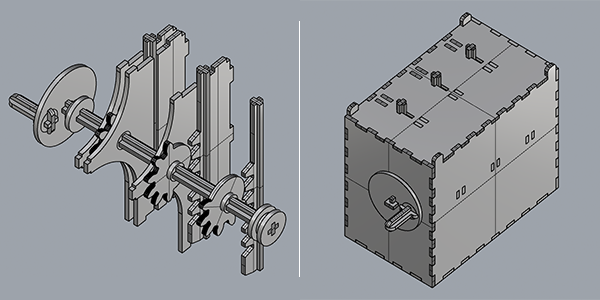

The first idea was a machine that creates sounds thanks to mechanical movement.

To download the cutting file click [here]

The first idea was a machine that creates sounds thanks to mechanical movement.

To download the cutting file click [here]

I started from the design of the rack and pinion. I made a 3D model with Rhino 3D, starting a 2D file generate from a online gear [InvoluteSpurGearBuilder]. Then i designed the supports for the mechanical components. To speed up design part, i used a online box-generator [http://makeabox.io/]

I considered 0.2mm of kerf when i exported my 3D model in 2D drawing.

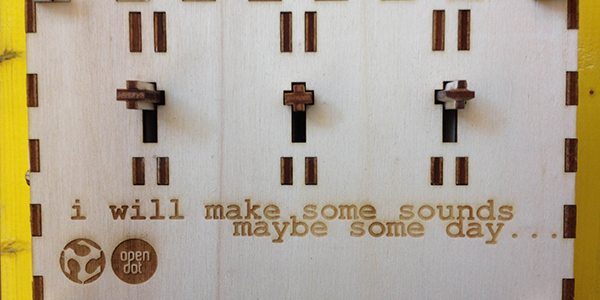

I cutted everything with a [Spirit GLS machine], using the print driver from Rhino.

Material: Playwood 4mm

Engraving settings: Speed 100%, Power 70%, PPI 1000.

Cut Setting: Speed 3.8%, Power 100%, PPI 1000.

At the end i used the vinyl cutter

[GX-24_Roland] to add the instructions to use this machine.

Our vynil cutter has a proprietary software [cut studio]. It's works very well with .AI files.

This why i used [illustrator] (the second version is now free) to make the cutting file.

Problems encountered: find the appropriate size of the gears.

Future: To generate different sound i want to add the top part of the machine with xylophone's metal bars.

During this week i also tried to make a parametric model with Grasshopper.

It was the first time for me, so I made a model where it is possible modify a simple joint between two rectangles.

It been very hard at the beginning, because the software interface and its commands was completely new for me.

Fortunately i found "Region union/substraction" command, that it been very usefull to get the final result.

Download the [Grasshopper file] here.